A Practical Guide to Grease Trap Sizing

Figuring out the right grease trap size isn't a guessing game. It's a specific calculation that comes down to your kitchen's unique wastewater flow and the equipment you’re running. Get it right, and you prevent messy, expensive plumbing emergencies. Get it wrong, and you could shut down your whole operation during a Saturday night dinner rush.

Think of this as a critical business decision, not just another plumbing task.

Why Nailing Your Grease Trap Size Is So Important

Your grease trap is the unsung hero of your kitchen's plumbing. Its entire job is to catch all the fats, oils, and grease (FOG) before they can get into the sewer lines, cool off, and harden into the kind of stubborn clogs that give restaurant owners nightmares.

When your trap is sized correctly, this all happens quietly in the background. But a miscalculation in either direction creates some serious risks for your business, both operationally and financially.

The Problem with Undersized and Oversized Traps

An undersized trap is the most common mistake, and it creates problems almost immediately. It gets overwhelmed by the sheer volume of wastewater, which means it doesn't have enough time to let the FOG separate properly. That grease just flows right into your pipes, leading to backups that can flood your kitchen, create nasty odors, and land you some hefty non-compliance fines from the health inspector.

On the flip side, an oversized unit has its own set of issues. If a trap is too big for your kitchen's actual output, the wastewater sits around for way too long. It becomes stagnant and septic, producing a corrosive hydrogen sulfide gas that smells awful and can literally eat away at the trap's materials, causing it to fail way sooner than it should.

Key Sizing Factors and Their Business Impact

Understanding the "why" behind each sizing factor helps clarify how critical this calculation is. Getting it wrong doesn't just cause a plumbing issue; it has a direct impact on your daily operations, budget, and reputation.

| Sizing Factor | Why It's Important | Consequence of Miscalculation |

|---|---|---|

| Wastewater Flow Rate | This is the total volume of water your kitchen produces. It dictates the base capacity needed to handle your peak output. | Undersizing: Leads to immediate system overload, grease pass-through, and frequent, costly backups. |

| Fixture Units | Sinks, dishwashers, and floor drains all contribute to the flow. Each one needs to be accounted for. | Oversizing: Causes wastewater to go septic, creating foul odors and corrosive gases that damage the trap. |

| Retention Time | The amount of time wastewater needs to sit in the trap for grease to separate and float to the top. | Undersizing: Insufficient retention means grease doesn't separate, defeating the trap's purpose entirely. |

| Local Regulations | Your local municipality sets the specific codes and formulas you must follow. | Ignoring Codes: Results in failed inspections, fines, and potentially being forced to rip out and replace the unit. |

Ultimately, getting the size right is about protecting your investment and ensuring your kitchen can run without a hitch.

The Real-World Impact of Getting It Wrong

The stakes are a lot higher than many restaurant operators realize. The fact is, over 70% of urban wastewater problems are linked directly to grease blockages. This shows just how vital a correctly sized unit is, not only for your business but for the public infrastructure, too. If you want to dig deeper, you can explore more data on the importance of grease management to see the bigger picture.

A correctly sized grease trap is a direct investment in your operational stability. It’s your best defense against unexpected downtime, emergency plumbing bills, and health code violations that can tarnish your reputation and hit your bottom line hard.

The goal here is simple: match the trap’s capacity precisely to your kitchen’s peak FOG output. This ensures you get efficient separation without overwhelming the system or letting waste turn septic. It's all about finding that perfect balance that keeps your kitchen running smoothly, cleanly, and in full compliance with the law.

Calculating Your Kitchen's Flow Rate

Getting your grease trap sizing right starts with a crucial number: your kitchen's wastewater flow rate. This isn't a figure you can just eyeball. It needs a proper calculation based on your sinks and equipment to figure out your peak flow, measured in Gallons Per Minute (GPM). This ensures your trap can keep up when the kitchen is running at full tilt.

There are two main ways the industry tackles this calculation. One method is based on the physical dimensions of your sinks, and the other uses a standardized fixture rating system. We’ll walk through both so you can figure out the best approach for your kitchen.

The Sink Dimension Method For GPM

The most direct way to calculate your flow rate is by looking at the biggest source of wastewater: your sinks. This method is refreshingly straightforward and just requires a tape measure. The basic idea is to find the total volume of your sinks and then figure out how fast all that water can drain out.

First things first, you need the total capacity of your sinks in cubic inches. Grab your tape measure and get the length, width, and depth (in inches) for every sink compartment that drains into the grease trap.

Multiply those three numbers for each compartment to get its individual volume. If you have a standard NSF-approved 3-compartment sink, you'll do this three times and then add the results together.

-

Here's a quick example:

- Sink Dimensions: 24 inches (Length) x 24 inches (Width) x 14 inches (Depth)

- Volume per Compartment: 24 x 24 x 14 = 8,064 cubic inches

- Total for a 3-Compartment Sink: 8,064 x 3 = 24,192 cubic inches

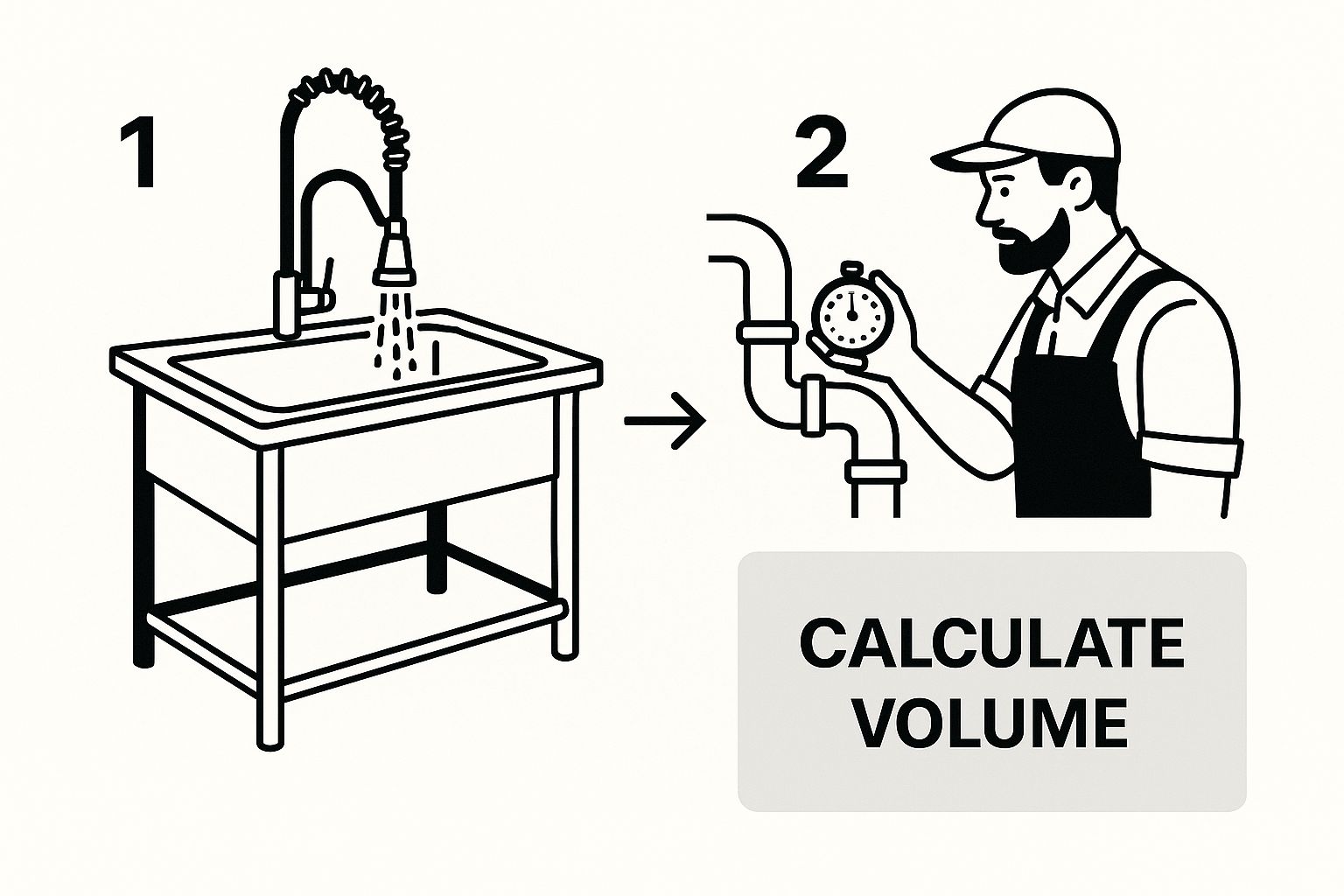

This visual breaks down how measuring your sinks and pipes is the foundation for getting the right grease trap size.

It really just highlights that getting these measurements right is the first step to an accurate flow rate calculation.

Turning Cubic Inches into Gallons

Once you have the total volume in cubic inches, you need to convert it into a unit that makes more sense—gallons. The magic number here is 231 cubic inches, which is exactly one US gallon.

The formula is simple:

Total Volume (Cubic Inches) / 231 = Sink Capacity (Gallons)

Let's use our three-compartment sink example:

- 24,192 cubic inches / 231 = 104.7 gallons

That number is how much water the sink would hold if you filled every compartment to the very top. But let's be realistic, that rarely happens during a busy shift. So, we adjust. It's standard practice to assume sinks are filled to about 75% capacity during normal use.

- Adjusted Capacity: 104.7 gallons x 0.75 = 78.5 gallons

This gives us a much more practical estimate of the wastewater you're actually dealing with during a typical dishwashing cycle.

Don't Forget Drainage Time

The last piece of the puzzle is figuring out how quickly that water empties. This drainage time is what ultimately determines your Gallons Per Minute (GPM).

Most plumbing codes set a standard for this.

- One-Minute Drainage: If your local code assumes a one-minute drain time (a common and conservative standard), your GPM is simply the adjusted capacity. In our case, that’s 78.5 GPM.

- Two-Minute Drainage: If the code specifies a two-minute period, you just divide that capacity by two. For our example, that would be 78.5 / 2 = 39.25 GPM.

A one-minute drain time prepares your system for a worst-case scenario where multiple sinks are dumped at once. Always, always check your local plumbing code’s requirements on this—it’s one of those things that’s usually non-negotiable.

The Drainage Fixture Unit (DFU) Method

There's another way to do this, often used in more complex kitchens: the Drainage Fixture Unit (DFU) method. This system is a bit more abstract. It assigns a standard value (a DFU) to every piece of equipment that sends water down the drain. It’s a way to standardize the load from different sources beyond just sinks.

Instead of measuring, you just add up the DFU values for everything connected to the trap. Here are some typical DFU values you'd see:

- Three-Compartment Sink: 3 DFUs

- Single Compartment Prep Sink: 2 DFUs

- Commercial Dishwasher: 4 DFUs

- Floor Drain: 1 DFU

So, if you had a kitchen with two three-compartment sinks (3 DFU each), a prep sink (2 DFU), and a floor drain (1 DFU), you’d have a total of 9 DFUs.

From there, you consult a DFU-to-GPM conversion chart from your local plumbing authority or the Uniform Plumbing Code (UPC). These charts directly translate your total DFU value into the required GPM flow rate for your grease trap.

Pro Tip: The DFU method really shines when you have lots of different fixtures. It does a better job of accounting for the varied discharge from things like dishwashers and floor drains than the sink-dimension method can on its own.

So, Which Method Should You Use?

Choosing between the two often comes down to what your local regulators want to see and how complex your kitchen setup is.

| Method | Best For | Key Advantage | Potential Downside |

|---|---|---|---|

| Sink Dimension | Simpler kitchens with just a few sinks | Direct and easy to calculate with a tape measure. | Might not accurately capture the load from dishwashers or floor drains. |

| DFU Method | Complex kitchens with varied equipment | Standardizes the load from multiple fixture types for a more holistic view. | Requires an official DFU-to-GPM conversion chart from your local authority. |

For most small-to-medium restaurants, the sink dimension method is perfectly fine and widely accepted. But if you’re planning a large operation or a new build, your architect or plumber will almost certainly be using the DFU method to ensure you’re fully up to code.

Your first step, before you even pick up a calculator, should be to check the guidelines from your local health and plumbing departments. They get the final say.

How to Navigate Local Plumbing Codes

Getting your grease trap sizing calculations right is a fantastic start, but those numbers mean very little until the local health and plumbing authorities give you the green light. Let’s be clear: compliance isn't just a suggestion, it's the final and most important step in this process. While national standards like the Uniform Plumbing Code (UPC) give us a solid framework to start from, your local municipality holds all the cards—and their rules are almost always stricter.

This is a classic stumbling block for a lot of restaurant owners. Assuming that regulations are the same everywhere is a quick way to end up with failed inspections and unexpected, expensive rework. Your local jurisdiction has its own specific set of requirements, and you absolutely have to play by their book.

Finding and Understanding Your Local Requirements

Your first move should be to track down the specific codes for your city or county. Most municipalities publish their plumbing and wastewater ordinances online, so start there. A quick search for terms like "[Your City] grease trap requirements" or "[Your County] FOG ordinance" usually does the trick.

If you come up empty online, it’s time to pick up the phone and go straight to the source. Get in touch with the building department, public works, or the city engineering office. Ask to speak with a plumbing plan checker or a pretreatment coordinator—these are the folks who review and approve installations day in and day out.

Pro Tip: Don't just ask, "What size grease trap do I need?" Show them you've done your homework. Ask pointed questions like, "What's the required grease retention time for a restaurant like mine?" or "Do you require a specific formula for calculating GPM?" This signals that you're serious and helps them give you the exact information you need.

Common Local Code Variations to Watch For

Every jurisdiction is a little different, but over the years, I've seen some common themes pop up in local regulations. Keep a sharp eye out for these specific mandates, because they will directly impact your grease trap sizing and installation plans.

- Mandatory Retention Times: Many codes dictate a minimum amount of time that wastewater has to sit in the interceptor to let the FOG separate properly. A common rule is a 30-minute retention time, which can dramatically increase the required size of your unit compared to what a standard GPM calculation might suggest.

- Specific Sizing Formulas: Don't be surprised if your city completely rejects the sink dimension or DFU methods. They may enforce their own unique formula, sometimes based on the number of seats in your restaurant or the total square footage of your kitchen.

- Dishwasher Rules: This is a big one. Pay close attention to regulations about high-temperature dishwashers. Some areas require a separate, smaller grease trap just for the dishwasher line to help cool the water before it hits the main interceptor.

- Indoor vs. Outdoor Interceptor Mandates: You'll often find strict rules about where an interceptor can be installed. Larger, high-volume kitchens might be required to install a large-capacity outdoor interceptor, while a smaller café might get the okay for an indoor unit.

Understanding Common Code Requirements

To give you a better idea of what to expect, here’s a look at the kind of regulations you'll likely encounter. Think of this as a decoder ring for understanding what your local authorities are focused on.

| Regulatory Focus | Common National Guideline | Likely Local Variation | Why It Matters for Compliance |

|---|---|---|---|

| Sizing Method | Formulas based on fixture dimensions or drain fixture units (DFUs). | Mandating a unique formula (e.g., based on seating capacity or kitchen area). | The local formula is the only one that matters. Using a standard one could lead to an immediate rejection. |

| Retention Time | Often not explicitly defined in basic GPM calculations. | A specified minimum time, like 25 or 30 minutes, is frequently required. | This significantly increases the required tank volume, making your interceptor much larger than you might expect. |

| Dishwasher Hookup | May allow direct connection to the main interceptor. | Requiring a separate, dedicated trap or a "solids interceptor" for the dishwasher line. | This adds another piece of equipment and complexity to your plumbing plan, impacting space and cost. |

| Unit Placement | General guidelines for accessibility and maintenance. | Strict rules on indoor vs. outdoor placement, often based on kitchen size or GPM. | Your building layout must accommodate their rules, potentially requiring costly outdoor installation and excavation. |

Navigating these regulations can feel like a full-time job, especially when you're also juggling everything else that comes with running a restaurant.

For more complex projects like a new build-out or a major renovation, bringing in a professional is a smart move. When you need precise calculations and a design that’s guaranteed to be compliant, working with an expert MEP consultant in Dubai can be invaluable for making sure every detail meets local standards. This kind of expertise is just as vital as understanding other critical systems, like the one we detail in our guide to commercial kitchen ventilation requirements.

The Real-World Consequences of Getting It Wrong

Let's be blunt: trying to cut corners or ignore these local rules is simply not an option. The fallout can range from a minor inconvenience to a financial nightmare for your business.

The most immediate problem is a failed inspection. This grinds your project to a halt until you rip out the wrong unit and install a compliant one, leading to frustrating and expensive construction delays.

If you’re already up and running, you could be slapped with steep fines that add up daily until the problem is fixed. In the most severe cases, the city can shut your business down entirely until you're fully compliant with their wastewater regulations. Getting it right the first time will save you an incredible amount of time, money, and stress.

Grease Trap vs. Grease Interceptor: What’s the Difference?

In the world of kitchen plumbing, you’ll often hear the terms "grease trap" and "grease interceptor" thrown around like they’re the same thing. They’re not. While both are designed to capture fats, oils, and grease (FOG), they are fundamentally different tools for different jobs.

Getting this choice right is crucial. The wrong system can lead to constant maintenance headaches, failed inspections, and a plumbing nightmare that just can't keep up with your kitchen's output. The right one, however, will integrate seamlessly into your workflow, quietly doing its job.

What Is a Grease Trap?

Think of a grease trap as a compact, point-of-use device. These are the smaller units you typically see installed indoors, tucked directly under a three-compartment sink or near a specific prep station. Their job is to handle lower volumes of wastewater right at the source.

The official term for these units is hydromechanical grease interceptors (HGIs). They work by using a system of internal baffles that slow down the flow of hot, greasy water. This slowdown gives the lighter FOG a chance to cool, solidify, and float to the surface, while the cleaner water exits from the bottom of the unit.

- Capacity: They are typically rated for flow rates under 100 Gallons Per Minute (GPM).

- Location: Almost always found indoors, fitting neatly under a sink or in a nearby utility closet.

- Maintenance: Because they’re smaller, they fill up faster. This means more frequent cleaning is necessary—sometimes weekly or bi-weekly, depending on how much FOG your kitchen produces.

If you want to get into the nitty-gritty of how these units work, check out our detailed guide on grease traps for kitchens.

What Is a Grease Interceptor?

A grease interceptor, on the other hand, is the heavy-hitter. This is a much larger, higher-capacity system designed to manage the entire wastewater stream from a large commercial operation. They're officially known as gravity grease interceptors (GGIs) because they rely on a massive tank and the simple force of gravity to separate FOG over a longer period.

These systems are huge, often holding 750 gallons or more, and are almost always buried outside the building. They function a lot like a small septic tank, collecting wastewater from every floor drain, sink, and dishwasher in the kitchen. This gives the grease and oil plenty of time to naturally separate from the water.

Because of their immense size, grease interceptors don't need to be cleaned out as often, usually requiring a professional pumping service every one to three months. The trade-off is a much more complex and expensive installation process that involves excavation and major plumbing work.

Deciding Which System Your Kitchen Needs

So, which one is right for you? It’s not about which is "better," but which is the correct tool for the job. Your choice will come down to your kitchen's scale, layout, and how much FOG you're producing.

A small deli, coffee shop, or café with a single three-compartment sink is a perfect candidate for an indoor grease trap. The installation is far simpler and cheaper, and the unit can be easily accessed for its more frequent cleaning schedule. The lower flow rate is exactly what these smaller units are built for.

Conversely, a high-volume hotel kitchen, a busy restaurant, or a university dining hall is pushing out a massive amount of FOG-laden water from multiple sinks, high-temp dishwashers, and floor drains. For that kind of operation, a large outdoor grease interceptor is the only real solution. It’s the only system that can handle that sheer volume and provide enough retention time for the grease to separate effectively.

Here’s a quick breakdown to help you decide:

| Factor | Grease Trap (Indoor HGI) | Grease Interceptor (Outdoor GGI) |

|---|---|---|

| Kitchen Volume | Best for low-to-medium volume kitchens (cafés, delis). | Essential for high-volume operations (hotels, large restaurants). |

| Available Space | Requires minimal indoor space, often under a sink. | Needs significant outdoor space for underground installation. |

| Installation Cost | Relatively low, involving basic plumbing connections. | High, requiring excavation, heavy equipment, and extensive plumbing. |

| Maintenance | Frequent cleaning (weekly/monthly) is required. | Less frequent pumping (quarterly) but requires a professional service. |

Ultimately, your decision will be heavily guided by your calculated flow rate and, most importantly, your local plumbing codes. Many health departments have specific rules that dictate when a large-capacity interceptor becomes mandatory, often based on factors like seating capacity or the total number of fixtures in your kitchen. Always check with your local authorities first.

Common Sizing Mistakes You Must Avoid

Getting your grease trap sizing right feels like a huge win, but one small oversight can unravel all your careful math. I’ve been in and around commercial kitchens for years, and I see the same few mistakes trip up even the most conscientious managers. Sidestepping these common pitfalls is the real secret to making sure your system works from day one and doesn't become a recurring, expensive headache.

Think of this as your field guide to getting it right the first time. These aren't just hypotheticals; they're real-world blunders that can shut a kitchen down cold.

Only Planning for Average Flow

This one is the classic mistake: sizing a grease trap based on a slow Tuesday lunch rush. Your system doesn't run on averages. It has to survive your absolute busiest, most chaotic moments. A trap that hums along just fine most of the week can be completely overwhelmed by a sold-out Saturday night service.

When every sink is draining, the dishwasher is churning, and the floor drains are catching spills, you hit peak flow. That sudden surge of wastewater is the true test of your system. If your trap can’t handle that maximum load, it will fail precisely when you can least afford for it to.

Real-World Example: I worked with a new bistro that calculated its GPM based on typical daytime use. During their grand opening weekend, the kitchen was slammed. Draining all three sink compartments while the high-temp dishwasher cycled sent a tidal wave of greasy water into their undersized trap. It backed up immediately and flooded the kitchen floor. They had to close for two days for an emergency replacement and cleanup.

Always, always base your grease trap sizing on the maximum potential flow your kitchen can produce at one time.

Forgetting to Account for Every Fixture

It’s so easy to focus on the big three-compartment sink and just forget about the other drains. But here's the deal: every single fixture that handles fats, oils, or grease (FOG) has to be part of your calculation. This is non-negotiable, but it’s a step that gets missed more often than you'd think.

Here are the usual suspects people forget:

- Prep Sinks: Even a sink used for rinsing vegetables can introduce oils and solids into the drain line.

- Woks or Tilt Skillets: These pieces of cooking equipment often have direct drains that carry a heavy grease load.

- Floor Drains: Every spill and wash-down in the cook line area sends greasy water right into those drains.

- High-Temperature Dishwashers: These are major FOG factories and often have their own specific plumbing code requirements.

Forgetting a single prep sink can throw your entire calculation off, leaving you with a system that's constantly struggling and prone to clogs. Do a thorough walk-through and inventory every single water source in your kitchen.

Ignoring Future Growth and Menu Changes

The kitchen you run today might not be the kitchen you’re running in two years. A common strategic mistake is sizing your grease trap with zero breathing room for growth. This kind of shortsighted thinking can be incredibly expensive down the line.

Are you planning to add another high-volume fryer next year? What if you expand your catering business, doubling your dishwashing needs? A new, more powerful dishwasher or an expansion of your dining room will dramatically increase your wastewater output.

A grease trap is a long-term piece of infrastructure. Installing a unit that just barely meets your current needs leaves you boxed in. When your business grows—and you want it to grow!—you'll be forced into a costly and disruptive replacement project. It’s far smarter and more cost-effective to plan for your future now.

Look at your five-year business plan. If expansion is even a possibility, it’s wise to select a grease trap that can handle a 20-25% increase in flow rate beyond your current peak calculations. That bit of foresight provides a crucial buffer, ensuring your plumbing can grow with your business instead of holding it back.

Got Questions About Grease Trap Sizing? We've Got Answers

Even after you've run the numbers, some practical questions always pop up. It's totally normal. Kitchen managers and restaurant owners often wrestle with the same uncertainties when it's time to make the final call on a grease trap.

Let's cut through the confusion. Here are some straight answers to the questions we hear all the time out in the field.

How Does Trap Size Affect My Cleaning Schedule?

The size of your grease trap is directly tied to how often you'll be calling the pump truck. The golden rule in the industry is the "one-quarter rule," which says a trap needs to be cleaned out once the fats, oils, grease, and solids take up 25% of its total space.

A correctly sized unit will probably hit that 25% mark every one to three months, which is manageable. But an undersized trap? That thing will get overwhelmed fast, sometimes needing to be pumped out every single week. This doesn't just blow up your maintenance budget; it seriously increases the risk of a sudden, messy backup. And always, always check your local codes—some places require a fixed cleaning schedule no matter what the 25% rule says.

Shouldn't I Just Buy a Bigger Trap to Clean It Less Often?

It sounds logical, right? A bigger tank should mean fewer cleanouts. In reality, an oversized grease trap can create more headaches than it solves. For a trap to work right, it needs a steady, consistent flow of wastewater moving through it.

If your trap is too big for your kitchen's actual output, the wastewater just sits there. It becomes stagnant. This leads to anaerobic decomposition, which creates hydrogen sulfide gas. Not only does this gas produce a powerful, rotten-egg smell that can seep into your kitchen, but it's also corrosive and can physically eat away at the trap's material, causing it to fail way sooner than it should.

The best approach is always to size the trap accurately for your kitchen's real-world flow rate. It ensures better performance and a longer life for your equipment. Oversizing is a common but expensive mistake that can compromise your entire system.

Does My Commercial Dishwasher Really Need a Grease Trap?

Yes, one hundred percent. Your commercial dishwasher is a major source of FOG and absolutely must be connected to your grease management system. The combination of hot water and powerful detergents in a dishwasher emulsifies grease, breaking it down into tiny droplets that mix with the water.

This greasy, soapy water flows easily out of the dishwasher, but as it cools down in your plumbing, that grease will harden back up into a stubborn, concrete-like blockage. It's also critical that the high-temperature water from the dishwasher (typically over 140°F) doesn't flow directly into the trap. Water that's too hot keeps the FOG in a liquid state, allowing it to pass straight through the trap and into the city sewer lines, which can lead to hefty fines.

This is a huge focus for municipalities these days, and it's driving the market to expand. The global grease trap market, valued at around USD 1.20 billion, is projected to hit nearly USD 1.48 billion by 2031, largely because of stricter regulations on grease discharge. You can discover more insights about this growing market and how it's tied to the rising number of commercial kitchens.

At The Restaurant Warehouse, we know that the right equipment is the foundation of a successful kitchen. From figuring out the initial sizing to getting the final installation right, our team is here to help you find the perfect, compliant grease trap for your restaurant. Equip your kitchen for success and explore our extensive catalog of commercial-grade solutions at https://therestaurantwarehouse.com.

About The Author

Sean Kearney

Sean Kearney is the Founder of The Restaurant Warehouse, with 15 years of experience in the restaurant equipment industry and more than 30 years in ecommerce, beginning with Amazon.com. As an equipment distributor and supplier, Sean helps restaurant owners make confident purchasing decisions through clear pricing, practical guidance, and a more transparent online buying experience.

Connect with Sean on LinkedIn, Instagram, YouTube, or Facebook.

Leave a comment