What is a Braising Pan? A Beginner's Guide to Tender, Flavorful Dishes

Let's get straight to the point. A commercial braising pan is a heavy-duty, hybrid piece of cookware designed to do two things exceptionally well: sear food at high heat and then simmer it slowly at low heat. Think of it as a culinary chameleon, blending the wide, flat surface of a frying pan with the depth and tight-fitting lid of a stockpot.

The Anatomy of a Perfect Braise

To really get what a braising pan is all about, you have to look at how it’s built. Every single feature is there to master the two-step dance of braising—a technique that turns inexpensive, tough cuts of meat into premium, fall-off-the-bone dishes. For any professional kitchen, this method is a cornerstone for maximizing both flavor and profitability.

The magic starts with its wide, flat base. This gives you a massive surface area, which is absolutely essential for searing. That’s the first step, where you hit the meat and vegetables with high heat to create a deep brown crust. This browning, known as the Maillard reaction, is what builds the complex, savory flavors that form the foundation of any great braised dish. Without that big surface, you'd end up overcrowding the pan, which just steams the food instead of searing it.

From Searing to Simmering

Once you’ve got that perfect sear, the pan’s other design elements take over. Its sides are relatively low and straight—just tall enough to hold your braising liquid but short enough to allow for easy evaporation when you want to reduce a sauce. This is a key difference from a Dutch oven, which has taller sides that can trap too much steam.

Finally, that tight-fitting lid is crucial for stage two. After adding your liquid, whether it's stock, wine, or broth, the lid traps all the heat and moisture inside. This creates a gentle, consistent simmer that works to break down the tough connective tissues in the meat, leaving you with an incredibly succulent texture.

A braising pan is the secret weapon for creating deep, rich flavors and incredibly succulent textures that define comfort food classics. It’s built for one purpose: turning humble ingredients into spectacular, high-margin menu items through a controlled, flavorful cooking process.

In short, a braising pan is a specialist's tool that excels where other cookware just can't keep up. It’s designed to handle every single step of the braising process in one vessel, from the initial, aggressive sear to the final, gentle simmer.

The Culinary History of Braising

The story of the braising pan is more than just a piece of cookware; it’s a journey that winds through ancient history, classic French kitchens, and the industrial age. It all started, surprisingly, not in France, but in China. As far back as the 5th century BCE, innovators there had already mastered cast iron, creating super-durable pots that could handle the intense, direct heat of an open flame.

These ancient pots were the very first ancestors of the braising pans we use today. Their ability to get searingly hot and then hold that temperature for hours was revolutionary. That same principle—superior heat retention—is exactly what makes a modern cast iron braising pan so perfect for getting a deep, flavorful sear before settling into a long, slow simmer.

The French Connection and Rise of Cast Iron

Let’s jump forward to 18th-century France. This is where chefs were perfecting the cooking method that would eventually give the pan its name: braising. The two-step process of searing meat and then slow-cooking it in liquid became a pillar of classic French cuisine, loved for its power to transform tough, budget-friendly cuts into something truly extraordinary.

At the same time, a different kind of revolution was brewing. In 1707, an Englishman named Abraham Darby patented a new sand-casting method that made producing cast iron cookware much cheaper and easier. This kicked off a massive boom. By 1860, U.S. foundries alone were churning out over 100,000 tons of cast iron goods every year, turning these tough pans into a kitchen staple. You can discover more about the resurgence of cast iron cookware and its impact on culinary history.

The braising pan represents the convergence of ancient material science from China and refined culinary techniques from France, democratized by industrial-age manufacturing.

From Open Hearths to Modern Kitchens

As kitchens evolved, so did the pans. The move away from open hearths to gas and electric stoves in the 19th and 20th centuries brought changes to the design. Handles got shorter and more practical for sliding into an oven, and the materials themselves were refined to heat more evenly on controlled cooktops.

This long journey led to the debut of the modern commercial braising pan right here in the United States in 1961. This new design was built specifically for high-volume foodservice, bringing a whole new level of efficiency to professional kitchens. It was tough enough to withstand the daily grind, capable of searing dozens of portions at once before simmering them to tender perfection. This cemented the braising pan’s place not just as cookware, but as a truly indispensable tool for chefs everywhere.

Braising Pan vs. Dutch Oven and Other Cookware

In a professional kitchen, every single piece of cookware has a job to do. While a few pans might look similar hanging on a pot rack, those subtle differences in design can lead to wildly different results on the plate. Getting a handle on these nuances is the secret to efficiency and quality, especially when you’re sizing up a braising pan against its closest relatives.

A Tale of Two Cousins: Braising Pan vs. Dutch Oven

Think of a braising pan and a Dutch oven as cousins who took different career paths. They both come from the same heavy-duty, slow-cooking family and sport tight-fitting lids. But that's where their stories diverge, and it all comes down to shape.

A Dutch oven has tall, straight sides, making it the undisputed champ for things like deep-frying, boiling a big batch of pasta, or simmering soups and stocks. Its depth is designed to completely submerge ingredients in liquid, which is exactly what you want for those tasks. You can find more on specialized pots in our guide on choosing the right stock pot.

A braising pan, however, is built differently on purpose. It has a much wider base and lower, gently sloped sides. This design gives you a huge surface area for getting a perfect, even sear on your proteins right from the start. Once you add liquid, those lower sides allow steam and moisture to escape more easily, which is crucial for reducing a sauce down to a rich, concentrated glaze. Trying to do that in a deep Dutch oven? It's a slow, inefficient process that just doesn't produce the same results.

Cookware Showdown: Braising Pan vs. The Competition

To really see where the braising pan shines, it helps to put it head-to-head with other common pieces of cookware. Each one is a specialist in its own right, but for the classic two-step braise, the differences become crystal clear.

| Cookware Type | Key Design Feature | Best For | Less Ideal For |

|---|---|---|---|

| Braising Pan | Wide base, low sloped sides, tight lid | Searing then slow-simmering in liquid; sauce reduction. | Deep frying, boiling large volumes of liquid. |

| Dutch Oven | Deep pot, tall straight sides, heavy lid | Soups, stews, boiling pasta, deep frying. | Achieving a wide, even sear; efficient sauce reduction. |

| Sauté Pan | Wide base, very low flared sides, no lid | Fast, high-heat cooking like searing and sautéing. | Slow cooking, braising, holding significant liquid. |

| Tilt Skillet | Massive, versatile, mechanical tilt function | Braising hundreds of portions, griddling, frying at scale. | Small-batch cooking; standard restaurant service. |

As you can see, while other pans can handle parts of the job, only the braising pan is perfectly engineered for the entire braising process from start to finish.

The right pan isn't just a container; it's a tool engineered for a specific culinary task. A braising pan is the master of the two-step sear-and-simmer, offering a balance of surface area and depth that other cookware can't match for this specific technique.

Expanding the Cookware Comparison

The differences get even sharper when you look at other kitchen staples. A sauté pan shares that wide, flat bottom that’s great for searing, but its low, flared sides and lack of a lid mean it’s built for speed. It’s perfect for flash-in-the-pan cooking but completely unequipped to hold liquid and trap steam for the long, slow simmer that defines a braise.

At the complete opposite end of the spectrum is the mighty tilt skillet. This is the industrial-scale giant of the kitchen, capable of braising, griddling, and simmering massive quantities at once. While it performs similar functions, its sheer size and utility hookups make it a fixture in huge operations like hospitals or university cafeterias. For most independent restaurants, it’s simply overkill.

Making the Right Choice for Your Kitchen

The pan you choose has a direct impact on your final dish. For those signature braised recipes where the rich, velvety sauce is just as important as the tender protein, the braising pan is the hands-down winner. Its design gives you total control over sauce reduction, which is where all that deep, complex flavor develops.

A Dutch oven is a versatile workhorse, absolutely, but it's a generalist, not a braising specialist. Mastering the art of braising means understanding your tools, and that goes beyond just the pan itself. Thinking about using the right pan for your stove is another small detail that can make a big difference in your results, proving once again that in the kitchen, the right tool always matters.

Mastering Commercial Braising Techniques

Knowing what a braising pan is designed for is one thing, but truly mastering the technique is where the magic happens. Braising is a combination cooking method that can turn humble, tougher cuts of meat into absolute showstoppers, making it a powerful tool for smart menu engineering in any commercial kitchen. Think of it as a two-act play: a quick blast of dry heat, followed by a long, slow simmer in moist heat.

The whole process kicks off with the sear. This step is about so much more than just adding color; it’s where you build a deep, rich foundation of flavor through the Maillard reaction. A properly heated braising pan gives you that wide surface area you need to get a great crust on proteins and vegetables without overcrowding the pan—a rookie mistake that just steams the food instead.

The Art of the Slow Simmer

Once your ingredients are beautifully browned, it’s time for the next critical step: deglazing. This is where you add a cool liquid—like wine, stock, or even just water—to the hot pan. As that liquid sizzles, it lifts all those caramelized brown bits, known as the fond, from the bottom of the pan. This simple move infuses your braising liquid with an incredible depth of flavor. This is where your sauce truly begins.

After deglazing, you’ll add the rest of your braising liquid. Here’s a pro tip: the liquid should only come about halfway up the sides of your main ingredient.

The goal is to gently simmer, not boil. You want the top part of the meat to roast in the steamy, enclosed environment created by the lid, while the bottom half tenderizes down in the liquid. This dual-action cooking is what creates that signature fall-off-the-bone texture.

A good braising pan is an essential tool for perfecting techniques that create incredibly tender results, especially for dishes like these fantastic slow-cooked shin beef recipes.

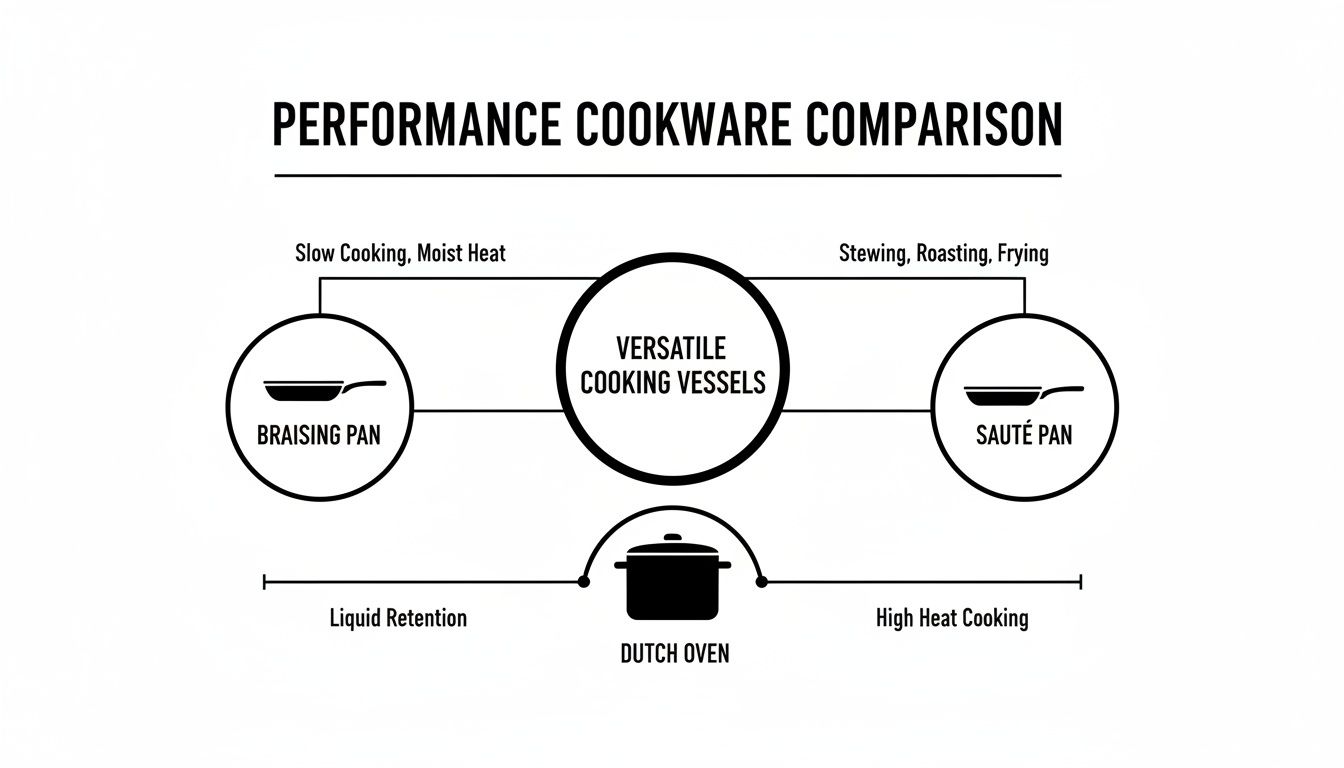

This diagram helps visualize how a braising pan compares to other common pieces of cookware, highlighting why its design is so perfect for this two-stage cooking process.

As you can see, the braising pan's lower sides and wide base make it ideal for both searing and a controlled simmer, unlike the deeper Dutch oven or a sauté pan that lacks a lid.

From Simmer to Sauce

The final act of braising happens after the protein is perfectly tender and you've set it aside to rest. That liquid left in the pan? It’s pure, flavor-packed gold. This is where the low sides of the braising pan become your best friend once again. You can pop the pan right back on the heat to rapidly reduce the liquid, concentrating all those amazing flavors into a rich, velvety sauce to finish the dish.

Mastering this entire process empowers a kitchen team to:

- Maximize Flavor: Turn less expensive cuts of meat into premium, deeply flavorful dishes that command a higher price point.

- Improve Efficiency: Most of the cooking time is completely hands-off, freeing up your cooks for other prep and service tasks.

- Ensure Consistency: Create perfectly tender and juicy results every single time, from the first plate of service to the last.

How to Choose the Right Commercial Braising Pan

Picking the right commercial braising pan is a bigger deal than you might think. This isn't just another pot—it's a critical investment that has a real impact on your kitchen's efficiency, the quality of your menu, and your bottom line. You're choosing a workhorse that needs to fit your kitchen's unique rhythm.

The whole decision really boils down to three key things: the material the pan is made of, its size and capacity, and the brand's reputation for holding up to the daily grind. Get these right, and you’ve got a piece of gear that will pay for itself over and over. Each material brings something different to the table, from insane durability to incredible heat control, and the best choice always comes back to your menu and your kitchen's flow.

Selecting the Best Pan Material

The material of your braising pan is everything. It determines how it heats up, what kind of upkeep it needs, and how long it's going to last. In the commercial world, three main options dominate the scene, each with its own set of pros and cons.

- Stainless Steel: This is the undisputed champion of durability and low-maintenance cooking. It's totally non-reactive, so you can throw in acidic ingredients like tomatoes or wine without a second thought. While it doesn't hold heat quite as tenaciously as cast iron, its ability to shrug off dents, scratches, and corrosion makes it a go-to for high-volume kitchens.

- Cast Iron: Famous for its incredible heat retention and perfectly even cooking. Once a cast iron braiser gets hot, it stays hot, giving you the ideal surface for a deep, consistent sear. The trade-off? It demands regular seasoning to keep its surface non-stick and to fend off rust, and it can react with acidic foods, which can sometimes impart a metallic taste.

- Enameled Cast Iron: Here you get the best of both worlds. It gives you the superior heat retention of cast iron but comes with a non-reactive, easy-to-clean enamel coating. This versatility does come at a higher price, but it completely eliminates the need for seasoning and can handle any ingredient you can think of.

In the world of professional cooking, the braising pan stands out for transforming humble ingredients into gourmet stars. Today, in major markets like Europe and North America, stainless steel braising pans dominate 65% of sales, lasting 20+ years with proper care and retaining 95% heat efficiency. Learn more about the rise of braising in modern cuisine on stahlkitchens.com.

Sizing Up Your Needs

Once you've settled on a material, capacity is your next big call. And let's be clear: this isn't about getting the biggest pan you can afford. It’s about matching the pan's volume to your actual production needs. A pan that's too big is a pain to store and wastes energy to heat up, while one that's too small will have you cooking in batches and wasting precious time.

Take a hard look at your menu and your typical service volume. A small bistro that runs a single braised special might do great with a 12-quart pan—it’s versatile enough for daily service without being a beast to handle. On the other hand, a high-volume catering operation pumping out hundreds of portions of braised short ribs will absolutely need a 20-quart pan, or even larger, just to keep up.

At the end of the day, having the right equipment is fundamental to a successful kitchen. For a wider look at outfitting your space, take a peek at our commercial kitchen equipment guide for more insights.

Care and Maintenance for a Lifetime of Performance

A quality braising pan is a serious investment in your kitchen’s future. Treat it right, and it will be a reliable workhorse churning out incredible dishes for decades to come. Good maintenance isn't just about scrubbing it clean; it's about protecting the cooking surface and the pan's overall structure.

Of course, not all pans are created equal, and each material needs a slightly different approach. The trick is to understand what your specific pan needs to prevent common headaches like rust, stubborn stains, or chipping before they even start. Following these simple, material-specific tips will keep your pan in peak condition and protect that investment.

Cast Iron Care and Seasoning

For a raw cast iron braising pan, seasoning is everything. This simple process creates a natural, non-stick surface that also shields the iron from rust. Keep harsh soaps and metal scrubbers far away—they're the enemy here and will strip that beautiful seasoning right off, forcing you to start from scratch.

When it's time to clean, just scrub the warm pan with a stiff brush and hot water. If you have some stubborn, stuck-on bits, a paste made from coarse salt and a little water works wonders. After cleaning, these next steps are crucial:

- Dry It Completely: Immediately towel-dry the pan or, even better, place it over low heat for a few minutes to evaporate every last drop of moisture.

- Apply a Thin Layer of Oil: While the pan is still warm, wipe a very thin coat of cooking oil over the entire surface, inside and out.

- Store Properly: Find a dry spot to store it where it won't be exposed to any humidity that could lead to rust.

Stainless Steel and Enameled Cast Iron

Stainless steel is loved for its durability, but it can sometimes develop pesky stains or those bluish heat tints. To get rid of them without scratching up the surface, never reach for steel wool. Instead, you can simmer a solution of water and white vinegar in the pan, or use a good stainless steel cleaner with a soft cloth.

Enameled cast iron, on the other hand, needs a gentle touch to keep its coating from chipping.

A classic mistake is hitting an enameled pan with thermal shock—plunging a sizzling hot pan into cold water. Always let your braising pan cool down quite a bit before washing to prevent the enamel from cracking.

For any burnt-on food, let the pan soak with warm, soapy water before going at it with a non-abrasive sponge. Sticking to these best practices will ensure your equipment serves your kitchen well for years. For even more tips on equipment upkeep, check out our comprehensive guide on cleaning restaurant equipment.

Got Questions About Braising Pans? We’ve Got Answers.

Alright, let's wrap things up by tackling some of the most common questions that pop up when chefs and operators are thinking about adding a new braising pan to their kitchen. Getting these final details sorted will help you feel confident you're making the right choice.

Can I Use a Braising Pan on an Induction Cooktop?

Yes, you absolutely can, provided it's the right kind. Most commercial braising pans made today are designed to work with induction, especially if they're made from magnetic stainless steel or any type of cast iron. The key is to always double-check the manufacturer's specs before you buy to make sure it’s a perfect match for your kitchen's cooktops.

What’s the Best Size for a Small Restaurant?

For most smaller to mid-sized restaurants, a braising pan somewhere in the 12 to 15-quart range hits the sweet spot. A pan this size gives you enough capacity to handle batch cooking for a busy service without being so huge and heavy that it becomes a pain to handle, clean, and store.

The braising pan connects ancient hearths to modern kitchens, with roots in Bronze Age metalworking from 3000 B.C. Legion Industries later pioneered the modern commercial insulated braising pan in 1961, cutting preheat times to under 10 minutes. Discover more about the long evolution of cookware on booniehicks.com.

And if you're weighing your options, a high-quality enameled cast iron braiser is often worth the extra investment. Yes, the upfront cost is higher, but you get that incredible, even heat you expect from cast iron, plus you can skip the seasoning and it won’t react to acidic ingredients like tomatoes or wine. It's a true kitchen workhorse.

Ready to find the perfect braising pan to take your menu to the next level? Head over to The Restaurant Warehouse. We've got a fantastic selection of commercial-grade cookware designed for serious performance and durability. Equip your kitchen today.

About The Author

Sean Kearney

Sean Kearney is the Founder of The Restaurant Warehouse, with 15 years of experience in the restaurant equipment industry and more than 30 years in ecommerce, beginning with Amazon.com. As an equipment distributor and supplier, Sean helps restaurant owners make confident purchasing decisions through clear pricing, practical guidance, and a more transparent online buying experience.

Connect with Sean on LinkedIn, Instagram, YouTube, or Facebook.

Leave a comment