Unlocking Efficiency: The Ultimate 2-Door Sandwich Prep Table Roundup

Why 2-Door Sandwich Prep Tables Are Essential for Modern Kitchens

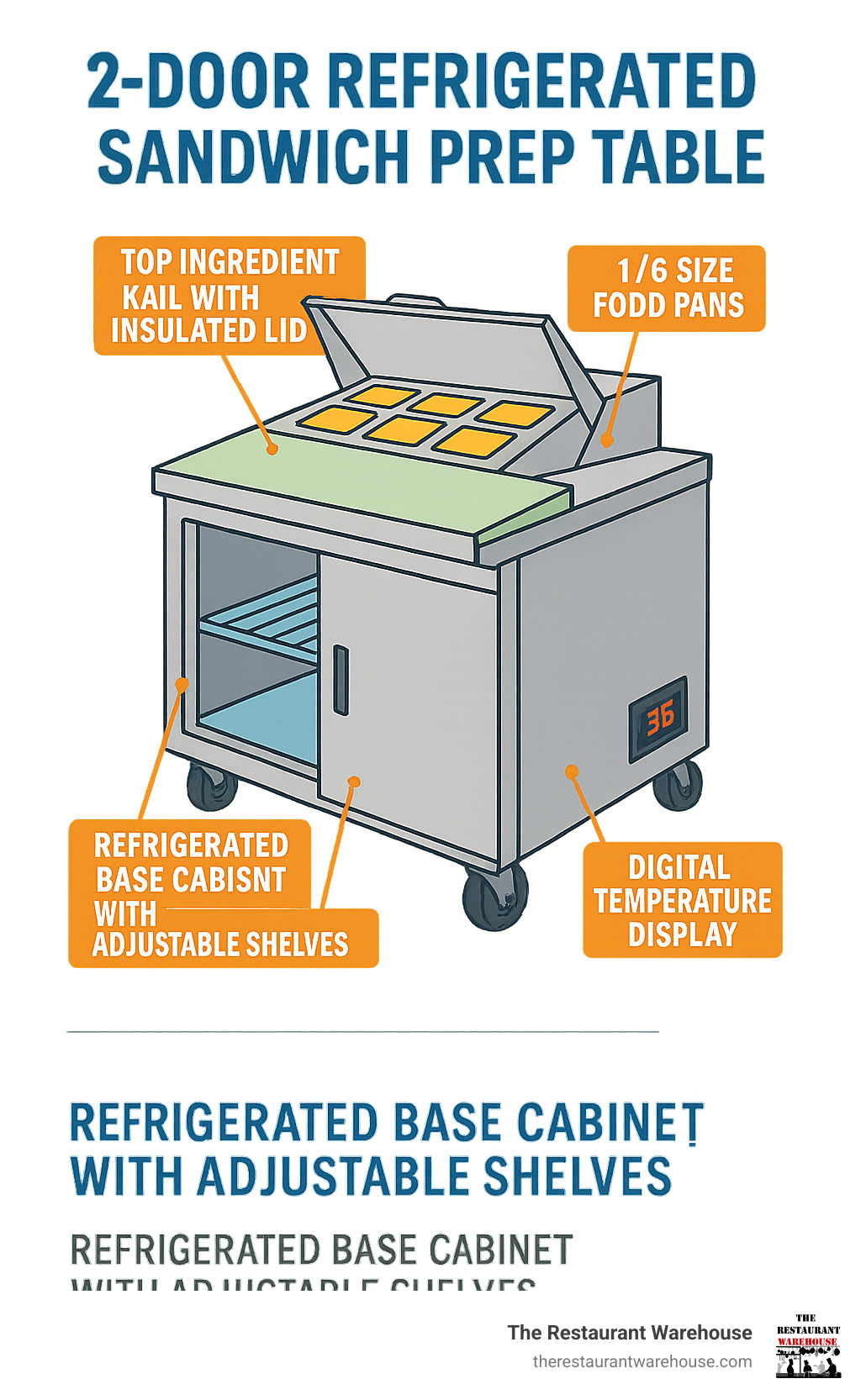

A 2 door refrigerated sandwich prep table is a cornerstone of efficiency in any modern commercial kitchen, from busy urban delis and cafes to high-volume ghost kitchens and catering operations. It is a versatile and indispensable workstation that masterfully combines refrigerated storage, a dedicated cutting and assembly surface, and immediate access to organized ingredients into a single, compact unit. The primary function of this equipment is to hold perishable ingredients at precise, food-safe temperatures, typically between 33°F and 41°F, while ensuring they are within arm's reach during the busiest service periods. This integration eliminates wasted steps, streamlines the production line, and empowers staff to work faster and smarter.

Key benefits of 2-door prep tables:

- Optimized Capacity: These units typically offer between 12 and 15.5 cubic feet of refrigerated base storage, complemented by a top rail that can hold anywhere from 12 to 24 standard food pans. This dual-capacity design allows for bulk backup storage below and immediate-use ingredients above.

- Precision Temperature Control: Equipped with digital thermostats and easy-to-read displays, these tables allow chefs to precisely set and monitor the internal temperature, ensuring compliance with food safety regulations and maintaining the peak freshness of ingredients.

- Durable Construction: Built to withstand the rigors of a commercial environment, these tables feature a heavy-duty stainless steel exterior for longevity and ease of cleaning, paired with a high-density polyethylene cutting board that provides a safe and durable prep surface.

- Improved Mobility: Most models are fitted with 4-inch casters, two of which are locking. This feature provides crucial mobility for deep cleaning behind and under the unit, as well as flexibility for reconfiguring the kitchen layout as needed.

- Superior Energy Efficiency: Modern prep tables increasingly use advanced, eco-friendly R290 refrigerant systems. This not only reduces the kitchen's environmental footprint but also leads to significant savings on energy bills over the life of the unit.

These units fundamentally streamline the food preparation process by creating a self-contained ecosystem where everything a cook needs is readily accessible. The refrigerated base cabinet acts as a mini walk-in, storing backup containers of sliced meats, cheeses, and vegetables, while the top rail holds an array of pans for the immediate assembly of sandwiches, salads, or burritos. As one coffee shop owner noted: "This has been one of the best purchases for my bakery. It saves our chef a lot of time and it is so convenient when working in a fast pace kitchen environment."

Beyond the clear advantages in speed, a well-specified 2-door table significantly supports better kitchen ergonomics. The standardized working height, generous cutting board depth, and optimal reach distance to the top pans are all designed to keep a cook's movements within their primary reach zone. This thoughtful design minimizes the need for excessive bending, stretching, and twisting, reducing the risk of repetitive strain injuries during long and demanding shifts. Features like self-closing doors and smooth-gliding drawer-style pan rails further reduce unnecessary motion and physical effort.

Consistency is another key benefit that cannot be overstated. By establishing a fixed layout of pans in the top rail, every station can be set up to mirror the same ingredient sequence. This standardization is invaluable for reducing training time for new staff and minimizing errors during high-pressure service. Managers can codify recipes and create station maps, ensuring that a guest receives the exact same high-quality sandwich or salad regardless of who is on the line or what shift it is.

From a food safety perspective, the integrated, insulated lid that covers the pan rail is a critical feature. It plays a vital role in maintaining stable product temperatures, especially between rushes. When staff close the lid during prep lulls, cold air is trapped directly over the ingredients, protecting them from ambient kitchen heat and helping them retain their quality, texture, and safety for longer periods.

A 2-door format strikes an ideal balance between a manageable footprint and substantial capacity. It offers ample refrigerated base storage for a wide range of ingredients without overwhelming the floor plan of smaller kitchens. The two-door cabinet can be strategically organized, perhaps dedicating one side to proteins and the other to produce, to further streamline restocking and inventory management.

These tables are true workhorses, capable of serving multiple dayparts with ease. They can be stocked for breakfast sandwiches and burritos in the morning, transition to salads and wraps for the lunch rush, and be reconfigured for cold appetizers or dessert prep in the evening. The organized cold rail makes it simple and fast to change over the mise en place, maximizing the unit's utility throughout the entire day.

When evaluating the return on investment (ROI), look beyond the initial purchase price. Consider how this single piece of equipment eliminates countless extra footsteps to and from distant reach-in coolers, reduces the open-door time on other refrigeration units (saving energy), and cuts down on food waste by keeping ingredients properly stored and visible. These operational savings, combined with faster ticket times and reduced spoilage, compound over time to deliver a powerful financial return.

These tables bring organization, precise temperature control, and a comfortable, ergonomic prep surface together into one cohesive system. They serve as the backbone of efficient sandwich, salad, and deli lines, empowering culinary teams to perform at their best. Choosing the right combination of pan capacity, base storage, and lid style is a critical decision that ensures your team can move with speed and precision without ever sacrificing food safety or product quality.

Why Your Kitchen Needs a 2-Door Refrigerated Prep Table

During the chaos of a lunch rush, a 2 door refrigerated sandwich prep table becomes the calm, organized heart of the entire operation. These units are expert problem-solvers, creating a central hub for all cold food prep. Instead of having staff constantly moving between separate refrigerators, storage racks, and cutting stations—a process filled with inefficiency and potential for error—they can work from a single, optimized location that contains everything they need.

This centralized approach dramatically improves efficiency. With every necessary ingredient perfectly chilled and within immediate reach, your team can assemble food items significantly faster. This directly translates to quicker service, higher table turnover, and increased customer satisfaction. Furthermore, food safety standards are far easier to maintain when ingredients are consistently kept in the critical temperature range of 33°F to 41°F, well away from the temperature danger zone where harmful bacteria can multiply. This unwavering temperature control is fundamental to protecting both your customers and your hard-earned reputation.

Superior organization is another transformative benefit. With every ingredient housed in its own designated pan, the frantic searching through cluttered walk-in coolers becomes a thing of the past. This high level of visibility not only speeds up service but also helps to reduce food waste, as ingredients are less likely to be lost, over-ordered, or forgotten until they spoil. The direct result of this efficiency and organization is consistent product quality, which is the bedrock of building customer trust and loyalty. For more on developing a comprehensive refrigeration strategy, our guide on Freshness on Demand: Top Commercial Prep Fridge Options offers valuable insights.

Boosting Kitchen Efficiency and Speed

A 2 door refrigerated sandwich prep table acts as the mission control for your food preparation line, creating a centralized workstation that methodically eliminates wasted motion. By drastically reducing the need for staff to move between disparate storage areas and prep stations, you not only speed up production but also minimize kitchen traffic, which in turn reduces the risk of collisions and other accidents. This creates a safer and less chaotic work environment.

Quick ingredient access is a complete game-changer for throughput. With every topping, sauce, and protein neatly organized in the top pans, a cook can assemble multiple orders in sequence without ever taking more than a step or two. This highly streamlined process leads directly to faster order fulfillment and shorter ticket times, a critical metric for any food service business. The all-in-one solution of a refrigerator, a dedicated prep surface, and an organized ingredient rail consolidates multiple pieces of equipment into one efficient system, saving valuable floor space and optimizing your kitchen's workflow. For more on optimizing your kitchen's layout for maximum efficiency, see our Prep Table Kitchen Guide.

Enhancing Food Safety and Quality

Protecting your customers and your business's reputation begins and ends with an unwavering commitment to food safety. A 2 door refrigerated sandwich prep table is a frontline tool in this effort, providing consistent temperature control that is essential for success. These units are engineered to maintain the crucial 33°F to 41°F temperature range, which inhibits the growth of dangerous bacteria and ensures your ingredients are held safely for hours.

Many high-quality prep tables are NSF certified, which means they have been tested and certified to meet strict public health and safety standards. This certification provides peace of mind that the equipment is designed for safe food handling, with materials that are easy to clean and sanitize. The organized pan system is also a key feature in helping to prevent cross-contamination. By keeping raw and ready-to-eat ingredients physically separated in their own containers, you minimize the risk of foodborne illness. Furthermore, the insulated lids not only maintain stable temperatures but also act as a physical barrier, protecting ingredients from airborne contaminants during service.

These tables are specifically designed to keep food out of the notorious food safety "danger zone" (40°F to 140°F), the temperature range where bacteria can multiply at an astonishing rate. The powerful refrigeration system works continuously to circulate cold air, ensuring that even with the lid open during a rush, the ingredients remain at safe holding temperatures.

Practical KPIs and Throughput Gains

Astute operators measure the impact of a new prep table by tracking key performance indicators (KPIs) such as average ticket time, orders completed per labor hour, and the food waste percentage. Consolidating all prep tasks at a single 2-door station can easily shave precious seconds off each and every order. A seemingly small 15-second reduction per order, when multiplied across 200 tickets in a lunch rush, saves a total of 50 minutes of valuable line time. This recovered time can be used for restocking, cleaning, or preparing for the next service, boosting overall productivity.

A centralized and standardized station also greatly simplifies staff cross-training. With clear pan layouts, intuitive organization, and labeled containers, it becomes much easier for new team members or staff from other stations to step in and provide support during peak periods, ensuring service remains smooth and uninterrupted.

Layout and Line Design Considerations

- Ergonomic Placement: Position the table so that the cook faces the pass or service window, minimizing the need to turn around and improving communication with front-of-house staff.

- Lid Clearance: Ensure there is enough overhead space for the lid to open fully without striking shelves, cabinets, or other equipment.

- Ventilation is Key: Always provide at least 3-4 inches of clearance around the condenser coils (usually at the back or side) for proper airflow. Restricted airflow forces the compressor to work harder, increasing energy consumption and risking equipment failure.

- Workflow Adjacency: Position trash, recycling, and compost bins within a single step of the workstation to facilitate quick and easy disposal of scraps without disrupting the workflow.

- Logical Flow: Arrange the ingredient pans from left to right (or right to left) in the exact order they are used in your most popular recipes. This creates muscle memory and dramatically reduces assembly time and errors.

Food Quality Over a Full Daypart

Maintaining ingredient integrity throughout a long service is crucial. Best practices include prepping ingredients in smaller, more frequent batches and keeping particularly high-risk items (like dairy or mayonnaise-based sauces) in deeper, covered pans to shield them from temperature fluctuations. Use time-stamped labels on all pans and practice a strict First-In, First-Out (FIFO) rotation system, using ingredients from the refrigerated base to restock the top rail. During slow periods, make it a habit to close the lid, wipe down the cutting board, and verify the temperature of the ingredients with a calibrated probe thermometer. These simple habits are essential for preserving the optimal texture, flavor, and safety of your food from the first order of the day to the last.

Choosing the Perfect 2 Door Refrigerated Sandwich Prep Table: Key Features

Selecting the right 2 door refrigerated sandwich prep table is a critical decision that requires a careful consideration of key features that will directly impact your daily operations, efficiency, and bottom line. Making an informed choice ensures you invest in a unit that not only meets your current needs but can also adapt to your kitchen's future growth. For a broader perspective on selecting the right equipment, our Restaurant Prep Table Guide offers valuable and comprehensive insights.

Understanding the Capacity of a 2 door refrigerated sandwich prep table

Capacity is arguably the most critical factor for a 2 door refrigerated sandwich prep table, as it dictates both your bulk storage volume and your immediate ingredient accessibility. This is a two-part equation: the cubic feet of the refrigerated base and the number of food pans the top rail can accommodate.

Two-door models typically offer a refrigerated base capacity ranging from 12 to 15.5 cubic feet. This space is invaluable for storing backup supplies, marinating proteins, or holding pre-prepped items. The refrigerated base usually includes adjustable, heavy-duty shelving, allowing you to customize the space to fit various container sizes, from large tubs of sauce to full-size hotel pans.

The top rail pan capacity determines how many different ingredients you can have ready for immediate use. This capacity is measured in terms of standard 1/6 size food pans. A standard-top unit might hold 12 to 18 pans, while a mega-top design can hold 24 or more. When choosing, map out your menu. Count every single topping, protein, cheese, and sauce you offer. A diverse menu with build-your-own options will require a higher pan capacity to avoid constant restocking during a rush. For more on sizing your unit correctly, explore our detailed guide on All You Need to Know About 48 Inch Sandwich Prep Table.

Construction and Durability: What to Look for in a 2 door refrigerated sandwich prep table

The construction quality of a 2 door refrigerated sandwich prep table directly determines its longevity and ability to withstand the demanding conditions of a commercial kitchen. Prioritizing units built with robust, high-quality materials is a wise long-term investment.

Stainless steel is the undisputed industry standard for both its durability and its hygienic properties. Look for units with a resilient stainless steel exterior (often 430 grade for cost-effectiveness and durability) and a corrosion-resistant interior, such as 304 grade stainless steel or high-quality aluminum. A 304 stainless steel interior is particularly beneficial as it offers superior resistance to rust and corrosion from acidic ingredients like tomatoes, citrus, and vinegar-based dressings.

The cutting board is another critical component. It is typically made from high-density, non-porous polyethylene, which is durable, resists knife scarring, and is easy to clean. The depth of the cutting board is an important consideration, with options varying between 10 and 11.75 inches. A deeper board provides more workspace for assembling large or complex items. A cutting board that is easily removable is a significant advantage, as it allows for thorough cleaning and sanitizing away from the main unit.

Finally, consider mobility. Most quality units come standard on 4-inch casters, which are essential for rolling the table out for cleaning floors and walls behind it. Ensure that at least two of the casters are locking to provide stability and prevent the unit from moving during vigorous prep work. For more on the importance of materials, see our Stainless Steel Prep Table Guide.

Temperature, Refrigeration, and Energy Efficiency

A powerful and reliable refrigeration system is the heart of any 2 door refrigerated sandwich prep table. Modern units are equipped with advanced features designed for optimal performance, food safety, and energy conservation.

Most tables feature digital temperature controls and a clear LED display, allowing for precise monitoring and adjustment to maintain the critical 33°F to 41°F temperature range. Some advanced models even include self-diagnostic systems that can alert operators to potential issues before they become critical failures.

A key advancement in refrigeration technology is the widespread adoption of eco-friendly R290 hydrocarbon refrigerant. R290 has zero ozone depletion potential (ODP) and a very low global warming potential (GWP), making it a much more environmentally responsible choice than older refrigerants like R-134a. Crucially, R290 is also highly energy-efficient, absorbing heat more effectively and leading to lower electricity consumption and tangible cost savings on your utility bills.

Energy efficiency is further improved by features like high-density, foamed-in-place polyurethane insulation that minimizes temperature loss, and self-closing doors that prevent cold air from escaping. An integrated condensate evaporator is another valuable feature, as it automatically evaporates excess condensation, eliminating the need for a separate floor drain and simplifying installation.

Pan, Lid, and Board Details That Matter

- Pan Compatibility: Ensure the top rail is designed to accept standard pan sizes (1/6, 1/3, 1/2-size pans) to give you flexibility in your setup. Some rails can accommodate pans up to 6 inches deep for high-volume ingredients.

- Lid Design: Insulated, hinged lids are standard and provide the best temperature retention. A well-designed lid should have a sturdy handle and a tight seal to keep cold air in and contaminants out.

- Cutting Board Depth: A deeper cutting board provides more than just prep space; it's valuable plating real estate. Consider if you need extra room for wrapping large sandwiches, boxing salads, or adding side items.

Ambient Conditions and Placement

The performance of your prep table is highly dependent on its environment. Always consider the ambient heat load of your kitchen—a unit placed next to a hot cookline will have to work much harder than one in a cooler area. Check the manufacturer's specifications for the maximum ambient temperature the unit is rated for. Ensure you provide adequate clearance for ventilation, typically 3-4 inches on the sides and back, to allow the condenser to breathe. The unit must be placed on a level floor for the doors to seal properly and the refrigeration system to function correctly. Finally, verify that you have a dedicated 115V electrical circuit available for the unit to prevent power issues.

Types of 2-Door Prep Tables and Their Applications

When you begin shopping for a 2 door refrigerated sandwich prep table, you will quickly find several variations, each designed to meet specific kitchen needs and operational demands. Understanding the key differences between these types is crucial for choosing a unit that will seamlessly integrate into your workflow and maximize your productivity. Our comprehensive guide on how to Choose Sandwich Prep Station can help you expertly match your operational needs with the right piece of equipment.

Standard Top vs. Mega Top: Which is Right for You?

The most significant choice you'll make is between a standard top and a mega top model of a 2 door refrigerated sandwich prep table. This decision hinges entirely on your menu's complexity and volume.

Standard top units are the reliable workhorses for kitchens with a more focused or streamlined menu. They typically feature two rows of 1/6 size food pans in the top rail. A standard 48-inch unit, for example, might hold 12 pans, making it an ideal and efficient choice for classic sandwich shops, small cafes, or pizzerias with a set list of toppings. They provide ample capacity for core ingredients without taking up unnecessary space or energy.

Mega top models, on the other hand, are specifically designed for high-volume operations and menus that prize variety and customization. They feature a deeper top section that can accommodate three rows of pans, significantly increasing the on-hand ingredient capacity to 24 pans or more. This makes them perfect for build-your-own salad bars, delis with an extensive list of meats and cheeses, or burrito and bowl concepts that require a wide array of toppings. Some mega-top models can also hold deeper 6-inch pans, further boosting capacity for popular ingredients.

For simpler operations, a standard top is often more cost-effective and provides all the necessary functionality without the potential for unused capacity. However, if your brand is built on customization and a vast selection of fresh ingredients, a mega top is an essential investment.

Common Sizes and Configurations (48" vs. 60")

Beyond the top style, the overall width of the unit is a critical consideration, with 48-inch and 60-inch models being the most common choices in the 2-door category.

48-inch models represent a perfect balance of functionality and a compact footprint. They are ideally suited for medium-volume kitchens, cafes, smaller delis, and ghost kitchens where space is often at a premium. A typical 48-inch unit provides around 12 cu. ft. of refrigerated storage in the base and can hold between 12 to 18 pans in a standard top, or more in a mega-top configuration. This size provides a generous prep surface for one or two cooks to work comfortably. For a closer look at this popular size, see our detailed guide on 48 Inch Sandwich Prep Refrigerators.

60-inch models are built for higher-volume applications, large restaurants, busy catering operations, and institutional kitchens. They offer a more expansive prep surface, allowing multiple staff members to work side-by-side without getting in each other's way. Their refrigerated base capacity is also larger, typically ranging from 14.3 to 15.5 cu. ft. or more, providing crucial extra storage for busy services. The top rail on a 60-inch unit can hold 16 pans or more, easily accommodating even the most complex menus.

The choice between a 48-inch and a 60-inch model ultimately depends on your expected sales volume, the physical space available in your kitchen, and the complexity of your menu.

Additional Variations and Use Cases

Beyond the primary types, several other variations can influence your decision:

- Doors vs. Drawers: While most base cabinets have swing doors, some models offer refrigerated drawers instead. Drawers can provide better organization and easier access to full pans of backup ingredients, while doors are better suited for storing bulkier, irregularly shaped items.

- Compressor Location: The location of the compressor—either side-mounted or rear-mounted—affects placement and maintenance. Rear-mounted units are more common and have a smaller side-to-side footprint, while side-mounted units can be easier to service and may perform better in high-temperature environments as they don't draw air from the hot area behind the unit.

- Cutting Board Depth: Some models emphasize deeper cutting boards (12 inches or more), which are specifically designed for operations that assemble large-format items like oversized subs, calzones, or large pizzas.

Practical Scenarios:

- In a compact urban cafe, a 48-inch standard-top unit paired with a dedicated hand sink can create a highly efficient and code-compliant workstation for a one or two-person team.

- For a high-volume deli with rotating seasonal specials, a 60-inch mega-top with three pan rows allows them to offer their full standard menu plus limited-time ingredients without having to swap pans mid-service.

To make the best choice, map your entire menu to a potential pan layout. Use clear labels and diagrams to ensure the station remains consistent and intuitive for all staff members across every shift.

Maintenance, Cost, and Warranty Considerations

Investing in a 2 door refrigerated sandwich prep table involves looking far beyond the upfront price tag. The true, long-term value of your investment is determined by its ongoing maintenance needs, its total cost of ownership over several years, and the comprehensiveness of its warranty coverage. Proactive planning in these areas will ensure your equipment runs efficiently for years to come. For detailed, practical advice on upkeep, consult our Sandwich Prep Table Maintenance guide.

Essential Maintenance for Longevity

Proper, consistent maintenance is the absolute key to the longevity and peak performance of your 2 door refrigerated sandwich prep table. A schedule of regular care not only extends the life of the unit but also prevents inefficient operation and costly emergency breakdowns.

Essential Maintenance Schedule:

- Daily: At the end of each day, remove and thoroughly clean the cutting board. Wipe down all stainless steel surfaces, both interior and exterior, with a food-safe cleaner. Pay special attention to cleaning the door gaskets, as built-up grime can prevent a proper seal.

- Weekly: Carefully clean the condenser coils. These coils are responsible for releasing heat from the system, and when they become clogged with dust and grease, the compressor is forced to work much harder, consuming more energy and risking burnout. Use a stiff brush or vacuum to gently remove buildup. Also, check the temperature accuracy with a calibrated external thermometer to ensure the digital display is correct.

- Monthly: Perform a deeper clean. Remove all food pans and shelving. Sanitize the entire top rail and the interior of the cabinet. Inspect the door gaskets for any cracks, tears, or loss of flexibility; a poor seal is a major source of energy waste. Check that the casters roll smoothly and that the locking mechanisms engage securely.

- General Care: Always ensure the unit has a stable 115V power source from a dedicated circuit. Maintain adequate airflow around the condenser at all times. Train staff to avoid propping doors open for extended periods.

Following these steps diligently will significantly extend your prep table's useful life and maintain its energy efficiency.

Deep-Cleaning and Troubleshooting

Beyond routine tasks, a proactive approach to troubleshooting can save you from major headaches and downtime.

Common Issues & Solutions:

- Rail Not Staying Cold: This is a common complaint. First, ensure the lid is closing fully and creating a good seal. Check that food pans are not overfilled, which can obstruct airflow. The most likely culprit is dirty condenser coils, so clean them thoroughly.

- Water Pooling in Cabinet: Inspect the door seals for any gaps that could be letting in moist ambient air. Also, check the condensate drain line to ensure it is not clogged and that the evaporator pan is positioned correctly.

- Excessive Noise or Vibration: This often points to dirty condenser coils or a blocked fan. Clean the coils and ensure there is proper clearance around the unit. Also, check that the table is perfectly level, as an unlevel unit can cause the compressor to vibrate.

- Unit is Freezing Food: The thermostat may be set too low or may be malfunctioning. Adjust the setting and verify the internal temperature with a separate thermometer. If the problem persists, the thermostat may need to be recalibrated or replaced.

Keeping spare wear-and-tear parts on hand, such as a set of door gaskets, can minimize downtime when a component fails.

Understanding Price Range and Warranty

The initial cost of a 2 door refrigerated sandwich prep table can vary significantly based on several key factors.

Factors Influencing Cost:

- Size and Capacity: Larger 60-inch units and mega-top models will naturally cost more than smaller 48-inch, standard-top units.

- Materials & Brand Reputation: Units constructed with higher-grade 304 stainless steel throughout and from more established brands often carry a higher price but may offer greater durability and reliability.

- Refrigeration System: Models featuring modern, energy-efficient R290 refrigerant systems may have a slightly higher upfront cost but will save you money on energy bills over time.

- Features & Certifications: Premium features like digital self-diagnostics, drawers instead of doors, and certifications like ENERGY STAR will all affect the final price.

Typical Price Range: New commercial units can range from approximately $1,500 for entry-level models to well over $4,000 for premium, feature-rich units. Many robust, reliable models from reputable manufacturers fall within the $2,500 to $4,000 range.

Warranty Information: Review the warranty carefully, as it is a good indicator of the manufacturer's confidence in their product. Most commercial units come with a multi-part warranty:

- Parts and Labor: This typically covers all components and the labor to replace them for a period of 1 to 2 years.

- Compressor: The compressor, being the most vital and expensive component, usually carries a separate, longer warranty, often for 5 years or more.

A strong warranty significantly reduces the total cost of ownership by protecting you from expensive, unexpected repair bills.

Total Cost of Ownership

The smartest buyers evaluate equipment based on its Total Cost of Ownership (TCO), not just its purchase price. Energy consumption is a major component of TCO. Look for energy-saving features like efficient compressors, thick polyurethane insulation, self-closing doors, and R290 refrigerant. Simple habits compound these savings: keeping the lid closed when not in use, cleaning coils regularly, and minimizing door openings. If local utility companies offer rebates for purchasing ENERGY STAR certified refrigeration, be sure to factor those savings into your payback period calculation. The monthly energy savings, combined with labor efficiencies and reduced food spoilage, can dramatically shorten the ROI timeline on a high-quality unit.

Conclusion

The 2 door refrigerated sandwich prep table is far more than just another piece of commercial equipment; it is a fundamental upgrade to your kitchen's entire operational ecosystem. These units are true efficiency powerhouses, expertly combining organization, stringent food safety, and a streamlined workflow into a single, compact, and indispensable solution. By centralizing all cold preparation tasks, they methodically eliminate wasted motion, reduce staff stress and physical strain, and dramatically speed up service, directly impacting your bottom line.

The food safety benefits provided by these tables are critical and cannot be overstated. The ability to consistently maintain the crucial 33°F to 41°F temperature range is your first line of defense in protecting your customers from foodborne illness and safeguarding your business's hard-won reputation. This precise temperature control ensures ingredients stay fresher for longer, which in turn reduces costly food waste. This level of reliability and consistency builds the customer trust that is absolutely vital for long-term success in the competitive food service industry.

Choosing the right unit is a strategic decision that involves carefully matching its features to your specific operational needs. As we've explored, you must consider capacity (both the cubic feet of the base and the pan count of the top rail), the durability of its construction (prioritizing stainless steel), and its configuration (standard vs. mega-top, 48-inch vs. 60-inch, doors vs. drawers). Furthermore, embracing modern features like eco-friendly R290 refrigerants and ENERGY STAR ratings can offer significant long-term savings on operating costs. When backed by a solid warranty (typically 1-2 years parts and labor, plus 5+ years on the compressor), these tables represent a reliable, durable, and intelligent long-term investment.

At The Restaurant Warehouse, we are deeply committed to providing the highest quality commercial equipment at true wholesale prices. Our mission is to help you build a more efficient, productive, and profitable kitchen by eliminating the unnecessary markups common in the industry, making professional-grade equipment accessible to every business, from independent startups to established chains.

A 2 door refrigerated sandwich prep table is a strategic investment in your kitchen's future success. The powerful combined benefits of improved efficiency, unwavering food safety, and superior organization create tangible value that pays dividends every single day. When you are ready to lift your food preparation capabilities and streamline your entire operation, Explore our complete guide to sandwich prep tables to find the perfect option for your business.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment