Tidy Up Your Commercial Kitchen: 6 Ways to Maximize Space and Efficiency

Why Commercial Kitchen Organization is the Foundation of Restaurant Success

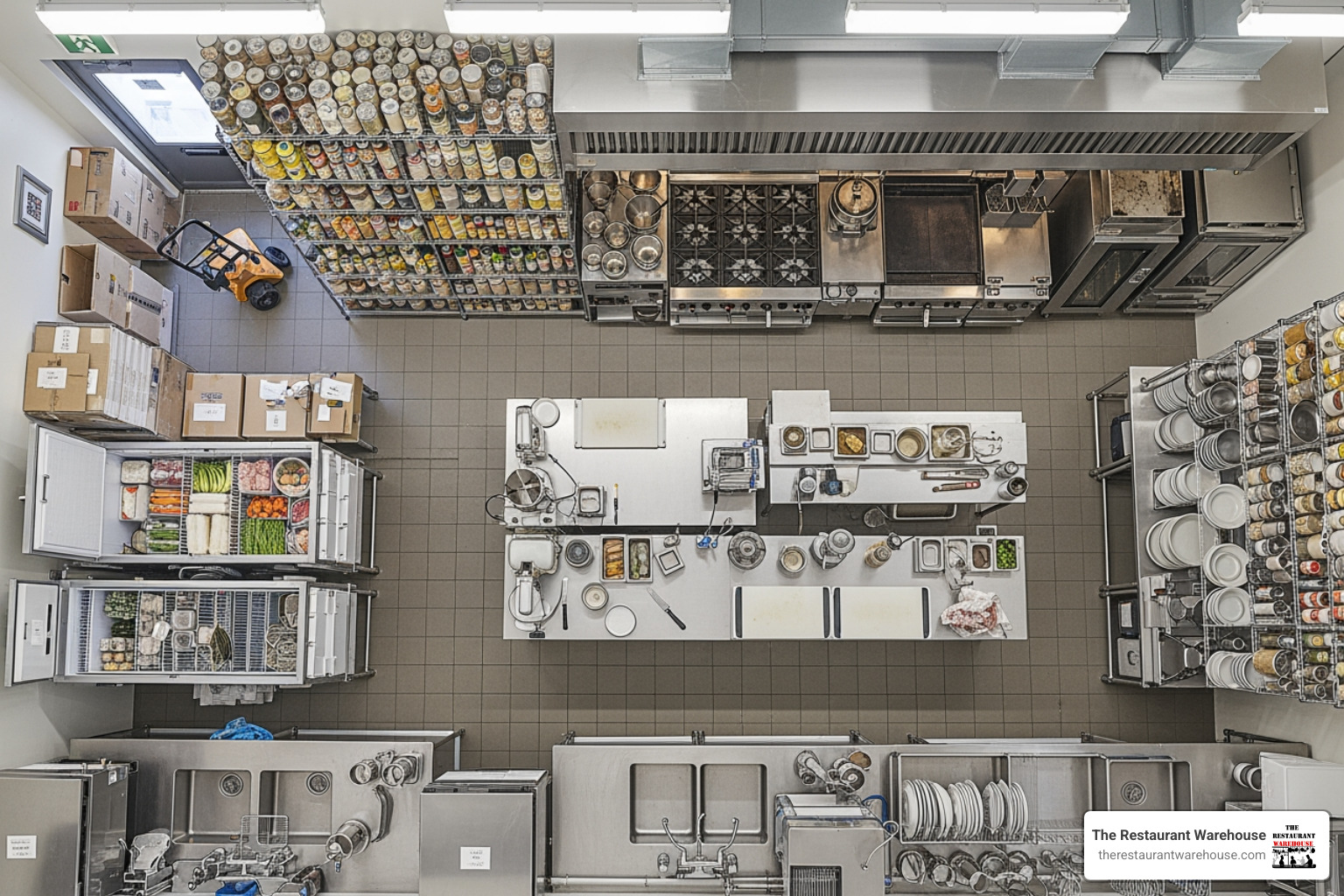

Commercial kitchen organization is the strategic system of arranging supplies, ingredients, and workflows to maximize efficiency, safety, and profitability. A disorganized kitchen during a dinner rush leads to chaos, with staff hunting for misplaced ingredients and losing precious minutes. Orders back up, and frustration mounts. In contrast, a well-organized kitchen, where every tool has a home and every ingredient is logically stored, allows the team to move like a well-oiled machine.

Effective organization delivers tangible benefits:

- Increased Speed: Staff locate ingredients and utensils instantly, reducing prep and service times.

- Reduced Waste: Proper storage and FIFO rotation prevent spoilage. Poor practices can cause up to 35% of a restaurant's food waste.

- Improved Safety: Clear zones and designated storage minimize accidents and cross-contamination.

- Lower Costs: Less waste, fewer accidents, and faster service directly boost your bottom line.

- Improved Morale: A clean, logical workspace reduces stress and increases staff retention.

The good news is that you don't need a massive budget or a complete kitchen redesign to achieve this. This guide provides six actionable ways to maximize space and efficiency in your commercial kitchen. These practical, budget-friendly methods will help you reduce waste, speed up service, and create a safer, more profitable workspace.

If you want custom recommendations for your specific operation, book a strategy call with our team and get a customized organization roadmap for your restaurant.

Throughout this article, you'll also find links to additional resources, including best practices from neutral authorities like the U.S. Food & Drug Administration (FDA) that can help you align your organization systems with current food safety guidance.

Way 1: Master "Mise en Place" for a Flawless Workflow

The French term "mise en place" translates to "everything in its place," and it's the heartbeat of a professional kitchen. This philosophy is the bedrock of efficient commercial kitchen organization. Before the first order arrives, a carefully executed mise en place sets the stage for a seamless service by ensuring every ingredient is prepped, portioned, and organized, and every utensil is within easy reach.

This approach reduces unnecessary movement and mental clutter, which dramatically increases speed and consistency. It also fosters a calmer, more productive work environment. Mise en place is more than pre-cut vegetables; it is a mindset that treats organization as a non-negotiable part of cooking.

The Anatomy of a Perfect Prep Station

A well-organized prep station is a masterclass in ergonomics. The core principle is simple: everything you need should be within arm's reach to minimize wasted movement. Arrange utensils and ingredients based on their frequency of use, with the most common items closest to the cook.

For example, a station for peeling shrimp should have three containers: one for unprocessed shrimp, one for the peeled product, and a third for waste. This simple system streamlines the process and keeps the workspace tidy. Similarly, essential cooking utensils like tongs and spatulas should always be kept directly next to the cooking area, not tucked away in a drawer.

Consider creating prep maps for each station:

- A diagram showing where each ingredient, smallware, and tool lives

- Color-coding for different food categories (for example, red for raw proteins, green for produce)

- Labels on shelves and containers that match the map

Standard Operating Procedures for Mise en Place

To make mise en place reliable across shifts:

- Create written prep lists for each daypart with specific quantities and par levels.

- Assign responsibility for each list to a specific role.

- Include timing expectations, such as when prep must be completed relative to opening.

- Add quality checkpoints, such as portion size and storage requirements.

By treating mise en place as a trainable skill, you ensure that your kitchen runs smoothly regardless of who is on the schedule.

Way 2: Design Smart Kitchen Zones for Peak Efficiency

Effective commercial kitchen organization extends beyond individual workstations to the entire layout. Kitchen zoning is a fundamental concept for creating an efficient workflow. Instead of a single, sprawling space, your kitchen should be a series of interconnected stations, each with a specific purpose. This logical flow minimizes unnecessary movement, reduces cross-traffic, and helps prevent accidents.

Think of it as an assembly line, where ingredients move seamlessly from delivery to the customer's plate. By categorizing the kitchen into distinct zones, you empower staff to focus on their tasks and eliminate clutter. A poorly organized kitchen can lead to delays and unhappy diners, as staff constantly battle an inefficient layout. Designing smart kitchen zones is a critical step in changing your kitchen into a model of productivity.

Key Zones and Their Purpose

To implement effective zoning, identify several core areas designed for a specific stage of the culinary process:

- Receiving Area: This is where all incoming deliveries are processed. It should be near the delivery entrance and have space for sorting items before they are moved to storage. Keep basic tools here such as scales, thermometers, and clipboards for logging deliveries.

- Storage Areas: This includes both dry and cold storage. Dry storage is for non-perishable goods and requires sturdy shelving in a cool, dry environment. Cold storage includes refrigerated and frozen spaces, where organization is paramount for food safety and inventory control.

- Food Preparation (Prep) Area: Featuring sanitary work surfaces, this is where ingredients are washed, cut, and portioned. Separate prep stations are crucial to avoid cross-contamination between different food types, especially raw meat and ready-to-eat items.

- Hot Food Production Zone: The heart of the kitchen, this zone includes various stations for different cooking methods. It's designed for rapid, high-volume production during service. The sequence of stations should mirror the flow of your menu—for example, salad and cold appetizers near the pass, then hot stations.

- Washing/Sanitizing Station: This area is dedicated to cleaning and sanitizing all dishes, utensils, and cookware. Its location should minimize the traffic of dirty items through clean areas and should include clearly marked zones for dirty, washing, rinsing, sanitizing, and drying.

- Service Area (Pass): The final stop before food reaches the customer, where dishes are plated, garnished, and checked for quality. It acts as a bridge between the kitchen and the dining room. Keep ticket rails, heat-safe surfaces, and finishing tools here.

Matching Zones to Your Menu and Service Style

Zones should support how you actually serve guests:

- Fast casual: Emphasize speed and volume. Position prep close to the hot food production zone, and make sure grab-and-go and expo areas are easy to reach from multiple sides.

- Full-service dining: Focus on communication and plating quality. Give the pass enough space for garnishing, sauces, and final checks.

- Catering or banquet operations: You may need flexible zones that can switch from bulk prep to plating lines for events.

Walk through a typical service in your mind (or literally walk it with your team) and note any points where staff cross paths, double back, or wait for space. These friction points signal that zones need to be adjusted.

Traffic Flow and Safety Considerations

Good zoning isn't just about speed; it's also about safety and compliance with food safety guidelines, such as those from the FDA Food Code. Consider the following:

- Keep raw and ready-to-eat pathways separate as much as possible.

- Ensure handwashing sinks are easy to access from all zones.

- Design clear walking aisles and mark them with floor tape if space is tight.

- Avoid creating choke points where hot plates, bussing tubs, and line cooks collide.

Regularly review incident logs (such as slips, burns, or near misses) and identify whether zoning adjustments could reduce those risks.

Documenting Your Zoning Plan

Once you have an effective layout:

- Sketch a simple floor plan and label each zone.

- Post it in the back of house so new staff understand the flow.

- Incorporate the zoning logic into onboarding and daily lineups.

As your menu or service model changes, revisit the plan to make sure your layout still supports how you operate today, not just how you operated when you opened.

If you're unsure where to start, contact us for a kitchen organization review. Our team can walk through your current layout (virtually or on-site, depending on your area) and recommend zoning improvements that match your concept and budget.

Way 3: Implement Bulletproof Storage and Inventory Protocols

Your kitchen's storage areas are the financial core of your restaurant. How you store ingredients directly impacts profitability, as poor storage practices can cause up to 35% of food waste. Strong storage and inventory protocols are also essential for health code compliance and preventing spoilage, which protects your customers and your reputation.

The "First-In, First-Out" (FIFO) Rule for Commercial Kitchen Organization

FIFO, or "First In, First Out," is a cornerstone of commercial kitchen organization. This principle dictates that the oldest inventory is used first, ensuring products are consumed before they expire. This simple practice dramatically minimizes waste and maintains product freshness.

To implement FIFO:

- Always place new items behind existing stock.

- Date all products upon receipt with both the arrival date and a clear "use-by" date.

- Use shelf labels that indicate product name, par level, and storage guidelines.

- Train staff to pull from the front and restock from the back every time.

Building a Practical Inventory System

A strong inventory system doesn't have to be complicated or expensive. Focus on consistency:

- Create a master inventory sheet organized by storage area.

- Assign each item a specific location, and label shelves so staff always return items to the same spot.

- Set par levels based on your sales volume and delivery schedule.

- Schedule regular counts—at minimum weekly for high-cost items and monthly for everything else.

Safe Storage Practices to Prevent Cross-Contamination

Specific storage practices are vital for preventing cross-contamination. In refrigerated storage, follow a strict top-to-bottom hierarchy:

- Top Shelves: Ready-to-eat foods like prepared salads and cooked items.

- Middle Shelves: Washed produce, fruits, and vegetables.

- Bottom Shelves: Raw meats, poultry, and seafood.

Adhere to the "6-inch rule": store all food and supplies at least six inches off the floor to prevent contamination and allow for easy cleaning. Use airtight containers to protect food from dust and pests. Finally, always store chemicals and cleaning supplies in a designated area completely separate from food.

For temperature control, follow authoritative guidance on safe food temperatures, such as the charts provided by FoodSafety.gov. Regularly calibrate thermometers and log temperatures for your cold storage environments.

Way 4: Go Vertical and Mobile to Maximize Your Space

In any foodservice operation, every square inch of kitchen space is precious. Smart commercial kitchen organization leverages vertical space and mobile solutions to turn limitations into advantages. Building upwards by utilizing wall space is a highly effective strategy for storing less-frequently used items, which frees up valuable counter and floor space for active operations.

The beauty of vertical and mobile solutions lies in their flexibility. They allow you to customize storage to fit awkward spaces and reconfigure layouts as your needs evolve.

Essential Vertical and Mobile Storage Solutions

To truly optimize space and workflow, rely on a combination of versatile storage solutions:

- Wall-Mounted Shelving: These are a game-changer for getting items off countertops. Durable wall shelves are ideal for storing frequently used ingredients or small supplies in labeled, stackable containers.

- Adjustable Wire Shelving: A staple in most kitchens, these units are inexpensive, easy to assemble, and highly customizable. They are perfect for pantries, dry storage, and walk-in coolers, providing modular and adaptable shelving.

- Mobile Carts: Mobility is a huge asset in a busy kitchen. Rolling carts can serve as flexible prep space, temporary storage, or a way to transport items between stations. Assign carts to specific tasks (e.g., banquet plating, dessert service) and label them accordingly.

- Magnetic Knife Holders: These simple tools are brilliant for safe knife storage. Mounted on a wall, they keep blades protected and easily accessible, while freeing up drawer and counter space.

- Pegboards: For smaller, frequently used utensils like whisks or measuring cups, a pegboard is an excellent way to keep them visible and within arm's reach. Outline each tool's shape on the board so staff know exactly where to return it.

- Overhead Racks: In smaller kitchens, hanging pots and pans above the cooking area not only saves cabinet space but also makes them incredibly easy for staff to grab.

Planning Vertical Storage Safely

When adding vertical solutions, prioritize safety and compliance:

- Ensure all wall-mounted units are properly anchored and rated for the weight they will hold.

- Keep heavy items at waist to shoulder height; reserve higher shelves for light, infrequently used items.

- Maintain clearance from fire suppression systems, walkways, and doors.

- Avoid placing storage above open food prep areas where items could fall or shed dust.

Making Mobile Solutions Work for You

Mobile carts and racks can dramatically increase flexibility, but only if they are organized:

- Assign each cart a primary function and label it clearly (e.g., "Salad Prep Cart," "Banquet Cart").

- Store all related tools and supplies on the same cart so it can operate as a self-contained mini station when needed.

- Create designated parking spots for carts when not in use so they don't clog aisles.

These small details keep your vertical and mobile storage from becoming clutter on wheels and instead turn them into powerful organization tools that expand your usable space.

Way 5: Standardize with Containers and Labeling

Consistency is a cornerstone of efficient commercial kitchen organization. This is most evident in the choice of storage containers and the meticulous practice of labeling. When every ingredient has a designated, clearly marked home, you dramatically reduce errors, speed up inventory checks, and ensure your team can locate anything at a glance. This standardization builds a system that fosters speed and predictability, which is vital for maintaining consistency and controlling food costs.

The Power of Uniform Containers and Clear Labels

The secret weapon of many professional kitchens is the use of uniform, stackable containers, often with interchangeable lids. This seemingly small detail has a profound impact:

- Stackable Containers: Versatile and cost-effective, these containers neatly stack, making pantry and refrigerator organization a breeze.

- Large Food Storage Bins: For larger quantities, robust, clear containers are indispensable for storing bulk items like flour, sugar, or grains.

- Squeeze Bottles: For liquids like oils, vinegars, and sauces, transferring them into squeeze bottles offers precision and speed.

Labeling Standards That Withstand Busy Service

Labeling is non-negotiable. Every container must be clearly labeled with:

- Item name

- Date prepared or received

- Use-by date

- Preparer's initials (for accountability)

While masking tape and a marker are common, many operations benefit from a dedicated labeling device or printed labels for legibility and consistency. Whatever method you use, make sure labels are water-resistant enough to survive refrigeration and handling, and easy to remove during dishwashing.

Color-Coding for Faster Organization

Color-coding can add a visual layer to your organization system:

- Use different colored tape or labels for raw proteins, produce, dairy, and ready-to-eat items.

- Match colors on containers with colors on shelves or storage zones.

- Use colored cutting boards that correspond to ingredients.

If you want help choosing the right mix of containers and labels for your concept, reach out to our team for recommendations based on your menu, volume, and storage constraints.

Way 6: Conduct Regular Audits and Cleaning

Even the most perfectly organized kitchen will succumb to clutter without consistent maintenance. Regular audits and cleaning are not just about hygiene; they are a critical component of continuous improvement in commercial kitchen organization. This ongoing commitment prevents the buildup of dirt and disorganization, ensuring your kitchen remains a safe, efficient, and pleasant place to work.

Deep cleaning is paramount, as bacteria can thrive on dirty surfaces. Beyond health risks, grime and grease buildup can negatively affect the odor and taste of your food. Regular maintenance also protects your investments and ensures optimal performance from your kitchen's infrastructure. Establishing a clear plan and checklist, along with assigning responsibilities, fosters accountability and ensures high standards are consistently met.

Creating a System for Ongoing Commercial Kitchen Organization

Maintaining a high level of organization requires a systematic approach. Here’s how to establish a robust system for ongoing success:

- Daily Tasks: At the end of each shift, wipe down all prep surfaces, wash utensils, empty trash bins, and reset workstations. A daily "gut check" of refrigerators to wipe down shelves and assess contents is also a best practice.

- Weekly Tasks: Perform more thorough cleaning and organizational checks. Deep clean larger fixtures, sanitize storage shelves, check inventory levels, and rotate stock according to FIFO. Address any areas where clutter is starting to accumulate.

- Monthly Tasks: Conduct comprehensive inventory audits and perform deep cleaning of hard-to-reach areas. Review cleaning schedules and protocols to ensure they remain effective.

- Assigning Responsibilities: Every task must have a clear owner. Create a cleaning schedule that delineates responsibilities so nothing falls through the cracks.

- Staff Training: Train your team on all cleaning and organizing procedures. Post signage detailing protocols in key areas and regularly monitor adherence to maintain high standards.

- Decluttering Sessions: Periodically, hold focused decluttering sessions to remove broken items, expired products, or anything no longer needed. If it doesn't serve a purpose, it doesn't belong in an organized kitchen.

Internal Audits and Mock Inspections

Beyond day-to-day cleaning, build a culture of internal review:

- Conduct mock health inspections where a manager walks through the kitchen using a checklist similar to what a local inspector might use.

- Schedule organization audits every quarter, where you evaluate whether zones, storage locations, and labeling are still working or need to be updated.

- Involve team members from different roles—prep, line, dish, and management—so you capture different perspectives.

Document findings, assign corrective actions, and set deadlines. Over time, this turns organization into an ongoing process rather than a one-time project.

Engaging Staff in Continuous Improvement

Your team works in the space every day, so they are often the best source of ideas:

- Encourage staff to submit suggestions for improving storage, labeling, or workflow.

- Recognize and reward ideas that lead to measurable improvements (such as faster ticket times or fewer stockouts).

- Include quick organization discussions in pre-shift meetings so improvements become part of the culture.

When staff feel ownership over the system, they are more likely to maintain it, and your organization standards will be more resilient when you experience turnover or busy seasons.

Frequently Asked Questions about Commercial Kitchen Organization

How can I apply these principles to a smaller kitchen or food truck?

Even compact spaces benefit immensely from strategic commercial kitchen organization. For smaller kitchens and food trucks, the principles are the same, but execution is even more critical. The focus is on maximizing every available inch.

- Go Vertical: Use wall shelving, magnetic holders, and pegboards to get items off precious counter space.

- Multi-use Tools: Invest in utensils and supplies that serve multiple functions to reduce the total number of items needed.

- Under-Counter Storage: Make the most of under-counter refrigerated spaces, which are excellent space-saving solutions.

- Meticulous Mise en Place: In a tight space, "everything in its place" is amplified. Perfect organization is essential to avoid chaos during service.

- Mobile Solutions: Mobile carts can be invaluable, acting as flexible prep stations or temporary storage that can be moved as needed.

What is the single most impactful organizational change I can make?

Without a doubt, the most impactful change is implementing the First-In, First-Out (FIFO) system. While other changes contribute to efficiency, FIFO directly tackles food cost, waste, and food safety—three of the biggest challenges in any restaurant. By consistently rotating stock so older items are used first, you virtually eliminate spoilage, maintain product quality, and significantly reduce food costs.

How does kitchen organization affect staff morale and retention?

Commercial kitchen organization plays a significant role in staff morale. A chaotic kitchen is a constant source of stress and frustration, leading to burnout and dissatisfaction. Conversely, a well-organized kitchen creates a safer, more professional, and respectful environment. When workflows are logical, staff can perform their duties efficiently and confidently. This reduces stress and makes the job more enjoyable. An organized kitchen shows you value your team's time and effort, fostering pride and professionalism that leads to higher job satisfaction and better staff retention.

Conclusion

Mastering commercial kitchen organization is a strategic investment that directly impacts your restaurant's speed, safety, and profitability. We've explored six actionable ways to achieve this: mastering "mise en place," designing smart kitchen zones, implementing FIFO and strong storage protocols, leveraging vertical and mobile solutions, standardizing containers and labeling, and committing to regular audits and cleaning.

When implemented consistently, these strategies create a kitchen that operates like a well-oiled machine. The result is faster service, reduced food waste, a safer environment, and a healthier bottom line. A well-organized kitchen also fosters higher staff morale and contributes to the impeccable service that keeps customers coming back.

Remember that organization is not a one-time project; it is an ongoing discipline. Start with one or two of the strategies in this guide, implement them fully, and then layer on additional improvements over time. Small, consistent changes can transform your back-of-house from a source of stress into a powerful competitive advantage.

If you’re ready to take the next step and want expert eyes on your layout, storage, and systems, book a strategy call with The Restaurant Warehouse team. We can help you prioritize changes, avoid common pitfalls, and build an organization plan that fits your concept, space, and budget.

By treating organization as a core part of your business strategy—not just a housekeeping task—you’ll position your restaurant to deliver faster, safer, more consistent service every day.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment