The Dough Whisperer's Handbook: Everything You Need to Know About Industrial Mixers

Introduction: The Heartbeat of High-Volume Baking

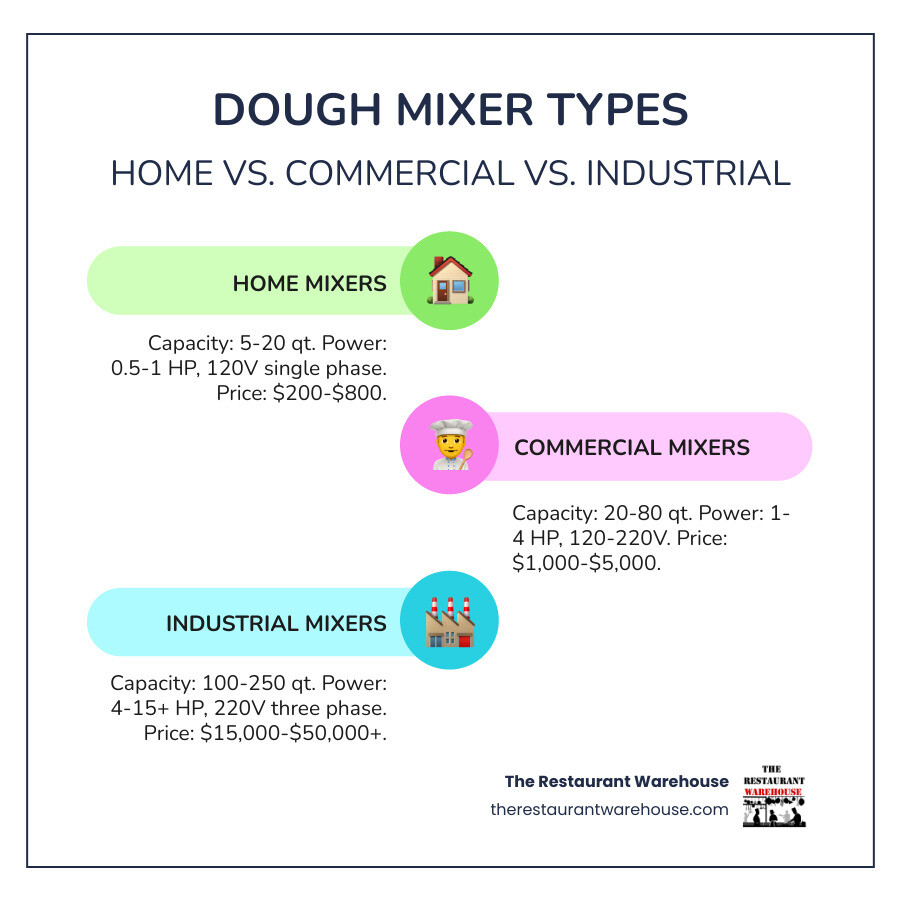

Industrial dough mixers are powerful, large-capacity machines designed to handle batch sizes ranging from hundreds to thousands of pounds of dough. Unlike home or small commercial mixers, these workhorses operate with multi-horsepower motors, specialized mixing actions, and robust construction to maintain consistent quality across massive production volumes.

Key characteristics of industrial dough mixers:

- Capacity: Handle 800 lbs to 4,000+ lbs of dough per batch

- Power: Range from 4 HP to 15+ HP motors, requiring 220V, 3-phase electrical connections

- Types: Spiral mixers, planetary mixers, sigma arm mixers, and continuous mixers

- Applications: Artisan breads, pizza dough, bagels, crackers, biscuits, pastries, and specialty snacks

- Construction: Heavy-duty stainless steel bowls, cast iron frames, and sanitary designs

The difference between mixing 20 pounds of dough by hand and processing 2,000 pounds per hour isn't just about scale—it's about precision, consistency, and the ability to meet demand without sacrificing quality. Industrial dough mixers replicate the rolling and kneading motions that traditionally could only be produced by hand, but they do it with engineering that keeps dough cooler, prevents overdevelopment, and delivers uniform results batch after batch.

For restaurant owners, commissaries, wholesale bakeries, and CPG snack producers navigating the equipment landscape, understanding industrial dough mixers can feel overwhelming. The technical specifications alone—bowl RPM, agitator horsepower, absorption ratios, 3-phase electrical requirements—read like a foreign language. Add in the massive price tags (often $15,000 to $50,000+), and it's easy to see why many operators struggle with this decision.

Choosing the wrong mixer can bottleneck your entire operation, while choosing the right one can transform your production capacity and product quality almost overnight. Your mixer affects everything from dough development and proofing schedules to labor planning and maintenance budgets.

I'm Sean Kearney from The Restaurant Warehouse, and I've spent years helping bakeries and foodservice operations find the right equipment at prices that don't require a second mortgage. Whether you're scaling up from a small commercial mixer or launching a high-volume operation, understanding industrial dough mixers is essential to making a smart investment.

CTA: Want personalized guidance on matching mixer capacity to your menu and volume? Contact The Restaurant Warehouse today to review your production goals with an equipment specialist.

Decoding the Machinery: Types of Industrial Dough Mixers

When we talk about industrial dough mixers, we're not just discussing a single machine. The market offers a diverse range, each engineered for specific dough types, production volumes, and desired mixing actions.

Spiral Mixers

Spiral mixers are arguably the most popular type of industrial dough mixer for bakeries specializing in bread, pizza, and other yeast-leavened products. Their design features a stationary agitator (the "spiral hook") that remains fixed while the mixing bowl rotates around it.

Key benefits:

- Low-friction heat: Less friction is generated, keeping dough cooler and preventing premature yeast activation

- Pizza dough: Excel at developing strong gluten structures without overworking

- Bagel dough: Perfect for dense, stiff dough requirements

- High-hydration doughs: Handle wet, sticky doughs like ciabatta or sourdough efficiently

- Reduced mixing times: Achieve desired consistency faster while maintaining cooler temperatures

Models like the American Eagle AE-200K and AE-250K can handle up to 396 lbs of dough, showcasing the sheer power of these machines.

Planetary Mixers

Planetary mixers are the versatile workhorses of the industrial dough mixer family. The agitator rotates on its axis while also orbiting the inside of the stationary bowl, much like planets orbiting the sun.

Key benefits:

- Versatility: With dough hooks, wire whips, and flat beaters, they handle almost any mixing task

- Multiple attachments: A single machine performs various functions

- Batters and frostings: Exceptional at aerating ingredients and creating smooth consistencies

- Medium-consistency doughs: Handle many types of bread and pastry dough effectively

Hobart's Legacy+ series, with models ranging from 30-quart to 140-quart floor mixers, exemplifies the robust capabilities of industrial planetary mixers.

Double Arm & Fork Mixers

These specialized industrial dough mixers are designed for the most delicate doughs, particularly those requiring minimal oxidation.

Key benefits:

- Gentle kneading: Mimic the natural motion of human hands, lifting and stretching dough

- Artisan breads: Perfect for highly hydrated, delicate doughs

- Low oxidation: Minimize air incorporation, preventing over-oxidation

- Specialty doughs: Ideal for panettone, pandoro, and other delicate sweet breads

Horizontal Mixers

Horizontal mixers, particularly "Sigma arm" mixers, are designed for the toughest, stiffest doughs. Their agitators resemble large Z-shaped blades that rotate horizontally within a trough-shaped bowl.

Key benefits:

- Highest capacity: Handle extremely large batches up to 4,000 lbs

- Stiff doughs: Ideal for low-hydration doughs requiring intense mixing

- Crackers and biscuits: Perfect for hard-tack crackers and low-moisture products

- Specialty snacks: Built for cookies, energy bars, pretzels, and granola

To summarize the main decision points:

- Choose spiral if your core business is bread and pizza with temperature control priority

- Choose planetary if you need one machine for dough plus various batters and fillings

- Choose double arm or fork if you're artisan-focused where dough structure comes before throughput

- Choose horizontal/sigma if you're producing very stiff doughs or high volumes at industrial scale

Key Factors When Choosing an Industrial Dough Mixer

Selecting the right industrial dough mixer impacts your product quality, operational efficiency, and bottom line. Here are the crucial factors to consider:

Capacity and Batch Size

- Flour capacity vs. dough capacity: Dough capacity is typically 1.5 to 1.6 times the flour capacity. For example, an AE-200K handles 165 lbs of flour and 264 lbs of dough.

- Bowl volume: Ranges from 13 quarts for smaller units to 250-quart bowls or larger

- Production needs: Estimate your peak hourly or daily dough production

- Batch sizes: Consider whether you need 800 lbs per batch or up to 4,000 lbs

Map one full production day by listing every dough type and required weight, grouping similar doughs, and calculating batch cycles at different capacities.

Power and Performance

- Horsepower: Industrial mixers range from 2 HP to 15+ HP

- Voltage: Most require 208V, 220V, or 200-240V

- Phase: Three-phase power (3-Phase) is standard for industrial mixers, providing more efficient and consistent power

- Motor types: Some feature dual motors or direct drive systems for improved efficiency

Remember to budget for any electrical upgrades needed for higher voltage or 3-phase power.

Dough Consistency and Absorption Ratio

Different doughs have vastly different mixing requirements:

- Stiff vs. soft doughs: Match mixer type to your dough consistency

- Mixer suitability: Spiral mixers excel with high-hydration doughs, while sigma arm mixers handle stiff, low-hydration doughs

The U.S. Department of Agriculture (USDA) provides guidance on ingredient handling and temperature control. Learn more from the USDA Food Safety and Inspection Service.

Construction and Durability

- Stainless steel bowls: Essential for hygiene and durability

- Cast iron frames: Provide stability and absorb vibrations

- Sanitary design: Modern mixers feature toolless changeovers and easy-clean designs

Consider ingress protection, accessibility for cleaning, and spare parts availability when evaluating construction quality.

CTA: Need help turning your recipes and production targets into a clear mixer spec sheet? Book a strategy call with The Restaurant Warehouse team for a custom recommendation.

Maximizing Uptime: Safety, Maintenance, and Modern Technology

In a high-volume operation, downtime is costly. Ensuring your industrial dough mixer runs safely, efficiently, and consistently requires attention to its safety features, proper maintenance, and leveraging modern technology.

Essential Safety Features

Safety is paramount in any industrial setting. Industrial dough mixers are powerful machines with moving parts that can pose significant risks if not properly guarded.

- Bowl guards: These physical barriers prevent operators from coming into contact with the mixing agitator while the machine is running. They are often made of stainless steel or durable plastic.

- Safety interlocks: These mechanisms ensure the mixer cannot operate unless the bowl guard is fully closed and locked. For instance, the AE-4065 mixer's safety guard must be completely down for operation. Many mixers also include an opening in the front guard for adding ingredients during mixing, allowing for continuous operation while maintaining safety.

- Emergency stop buttons: Prominently located, these buttons allow for an immediate shutdown of the machine in case of an emergency, preventing injury or damage.

- Programmable Logic Controllers (PLCs): Modern industrial mixers are often equipped with PLCs, which are specialized industrial computers that control and monitor the mixer's operations and safety systems. They can be programmed to ensure sequences of operation are followed correctly and to trigger safety shutdowns if conditions are not met.

- Certifications: Always look for certifications like ETL, NSF/ANSI 8, CSA, and CE Standards. These indicate that the mixer meets rigorous safety and sanitation standards. For example, the Omcan MX-IT-0025 states its electrical system and safety devices conform to European Regulations. Understanding these standards is key to ensuring a safe working environment. You can learn more about food equipment safety standards from authoritative sources like NSF International.

Beyond hardware, reinforce safety through training and SOPs. Lockout/tagout procedures, mandatory guard usage, and routine inspection checklists dramatically reduce both injuries and unplanned outages.

Maintenance and Cleaning for Your Industrial Dough Mixer

Proper maintenance and cleaning not only extend the life of your industrial dough mixer but also ensure food safety and consistent product quality.

- Daily cleaning procedures: After each use, the bowl, agitator, and exterior surfaces should be thoroughly cleaned. For mixers with removable bowls, this is simpler, allowing for comprehensive washing. However, some mixers, like the Eurodib LM30T, have fixed bowls and non-removable hooks, which users report can make cleaning more challenging, especially with sticky doughs. A hygienic design, such as AMF mixers engineered for maximum strength and cleanability, is crucial. Features like Peerless's EZ Kleangate facilitate toolless changeovers, significantly reducing cleaning time.

- Lubrication schedules: Moving parts, gears, and bearings require regular lubrication according to the manufacturer's guidelines to prevent wear and tear.

- Removable vs. fixed bowls: While fixed bowls offer stability, removable bowls (often on independent wheels for easy transport, as seen in MF Italy's IBT series) can greatly simplify cleaning and dough transfer. Consider your operational flow when deciding.

- Inspections: Regular visual inspections for wear, loose parts, or damage can prevent minor issues from becoming major, costly repairs.

Create a written preventive maintenance plan that includes:

- Daily operator checks (noises, vibration, leaks)

- Weekly cleaning and fastener checks

- Monthly lubrication and belt/chain inspections (where applicable)

- Annual professional service or in-depth teardown

Logging maintenance tasks not only extends equipment life but can also support warranty claims and third-party audits.

The Role of Automation and Technology

Modern industrial dough mixers are far more than just motors and bowls; they are sophisticated pieces of equipment that leverage technology to improve efficiency, consistency, and control.

- Programmable timers: Most industrial mixers feature built-in timers, often with dual settings for different mixing stages. These timers can automatically switch speeds (e.g., the AE-4065 has dual 30-minute timers with automatic speed switching) or stop the mixer when a cycle is complete, ensuring consistent mixing times for every batch.

- Variable Frequency Drives (VFDs): VFDs allow for precise control over motor speed, enabling operators to fine-tune the mixing action for different dough types and desired consistencies. They also contribute to energy efficiency by only drawing the power needed for the task.

- 'Mix by Energy' concept: Advanced systems, like those from AMF Mixers, use intuitive data technology to apply a "Mix by Energy" concept. This involves monitoring the energy consumed during mixing to ensure consistent dough development, regardless of slight variations in ingredients or ambient conditions. This kind of data integration allows for unparalleled consistency in dough quality.

- Data integration: Some modern mixers are "Industry 4.0 compliant," meaning they can be integrated into a larger smart factory system. This allows for remote monitoring, diagnostics, and even remote assistance, as highlighted by MF Italy's IBT Industrial series. This connectivity provides valuable data for process optimization and predictive maintenance.

When evaluating automation features, ask vendors to demonstrate:

- How recipes are stored, edited, and protected from unauthorized changes

- What data points are captured (e.g., energy usage, run time, fault codes)

- How alerts are delivered to your team (HMI, email, SMS, SCADA)

- Whether remote diagnostics are included and how software updates are handled

Even if you’re not ready for full digital integration today, choosing a mixer platform that can grow with you—rather than limit you—can prevent costly replacements later.

Ready to find the perfect mixer for your operation? Explore our extensive restaurant equipment supply guide for all your needs.

Frequently Asked Questions about Industrial Dough Mixers

We understand that investing in an industrial dough mixer brings a lot of questions. Here are some of the most common inquiries we receive, along with our expert answers.

How do I calculate the right mixer capacity for my bakery?

Calculating the correct capacity for your industrial dough mixer involves more than just looking at the bowl size. It requires a thoughtful assessment of your current and future production needs.

- Determine your peak dough production: Calculate the maximum amount of finished dough (in pounds or kilograms) you need to produce during your busiest hour or shift.

- Consider flour vs. dough capacity: Mixer specifications often list both flour capacity and dough capacity. Dough capacity is typically about 1.5 to 1.6 times the flour capacity. For example, if a mixer states a 165 lbs flour capacity, its dough capacity might be around 264 lbs. Always use the dough capacity as your primary metric when matching it to your production needs.

- Factor in absorption ratio: The absorption ratio (the amount of water relative to flour) affects the density and volume of your dough. Stiffer doughs (lower absorption) take up less space but require more power. Softer, higher-hydration doughs take up more volume. Some manufacturers, like Hobart, even offer a "mixer capacity and absorption ratio calculator" to help you determine the right size for your specific recipes.

- Batch size optimization: How many batches do you want to run per hour? A mixer with a 200 kg (440 lbs) dough capacity like the MF Italy IBT E 200 might be perfect for a certain output, but if you need to double that, you might consider the 300 kg (660 lbs) IBT E 300 or multiple smaller mixers.

- Future growth: Always consider your business's growth trajectory. Investing in a slightly larger mixer than your immediate needs might save you from needing an upgrade sooner than expected.

What's the difference between a 1-phase and 3-phase motor for a mixer?

This is a crucial technical detail, especially for industrial dough mixers, as it impacts power, efficiency, and installation.

- 1-Phase Power: This is the standard electrical service found in most homes and smaller commercial buildings. It consists of two hot wires and a neutral, providing power in a single wave. While suitable for smaller commercial mixers (e.g., 120V or 220V 1-phase), it's generally less efficient and provides less consistent power for motors under heavy, continuous loads.

-

3-Phase Power: This is the workhorse of industrial and heavy commercial applications. It consists of three alternating currents that are out of phase with each other, providing a constant, smooth power delivery.

- Motor efficiency: 3-phase motors are inherently more efficient and powerful than 1-phase motors of the same size. They run cooler, last longer, and are better suited for the continuous, heavy-duty demands of an industrial dough mixer.

- Consistent performance: The smooth power delivery of 3-phase electricity results in more consistent motor speed and torque, which translates directly to more uniform dough mixing.

- Cost implications: Installing 3-phase power, if you don't already have it, can be a significant upfront electrical expense. However, the operational benefits and longevity of 3-phase mixers often outweigh this initial cost for high-volume bakeries.

- Most true industrial dough mixers (e.g., AE-200K, AE-250K, Omcan MX-CN-0040) require 3-phase power (208V, 220V, or 240V, 60Hz, 3Ph). Always verify your facility's electrical capabilities before purchasing.

How does a spiral mixer prevent dough from overheating?

Spiral mixers are renowned for their ability to keep dough cool, which is vital for developing complex flavors and textures, especially in artisan breads.

- Stationary agitator: Unlike planetary mixers where the agitator moves throughout the bowl, in a spiral mixer, the spiral-shaped agitator stays largely in one place.

- Rotating bowl: The bowl itself rotates, bringing the dough to the agitator. This motion gently folds and stretches the dough rather than aggressively beating it.

- Gentle friction: This "gentle friction" mixing action generates significantly less heat compared to the more vigorous mixing of planetary or horizontal mixers. Less heat means less chance of prematurely activating yeast or over-developing the gluten, which can lead to a tough, dense product.

- Reduced oxidation: The slower, gentler action also minimizes the incorporation of air (oxidation) into the dough, helping to preserve the natural flavors and colors of the ingredients.

- Ideal for delicate doughs: This combination of gentle action and low heat generation makes spiral mixers the preferred choice for delicate, long-fermentation doughs like sourdough, ciabatta, and Neapolitan pizza dough, where maintaining a cool dough temperature throughout the mixing process is crucial for optimal results. As American Eagle states, they "duplicate the rolling and kneading motions that traditionally could only be produced by hand," keeping the dough cooler and preventing it from becoming overdeveloped.

How many mixers should I buy for a new facility?

There’s no single answer, but you can use these guidelines:

- One large mixer might be enough if you run a simple menu with one or two base doughs and have flexible production windows.

- Two medium mixers often make sense when you have multiple dough types, need redundancy for maintenance, or run different formulas at the same time.

- A mixed fleet (for example, one industrial spiral plus one planetary) is ideal when you need both high-volume dough output and versatility for fillings, glazes, and batters.

Think not only about maximum output, but also about what happens if one mixer is down for service. A bit of built-in redundancy is often cheaper than emergency outsourcing or lost production days.

How can I future‑proof my mixer purchase?

To avoid outgrowing your mixer too quickly:

- Choose a capacity that covers current needs plus a reasonable growth buffer (often 20–30%).

- Opt for controls and connectivity (timers, VFDs, PLCs) that can integrate with future production software.

- Verify that your vendor stocks parts and offers support for the full expected life of the mixer.

- Standardize on platforms where possible so operators can move easily between machines.

Building these criteria into your RFP or quote request helps you compare not only price, but long-term value across different models.

If you’re ready to turn these FAQs into a concrete equipment plan, reach out to The Restaurant Warehouse and we’ll help you translate your answers into specific mixer recommendations and quotes.

Conclusion: Kneading the Way to Success

Choosing the right industrial dough mixer is a cornerstone decision for any high-volume bakery or food service operation. It's an investment that directly impacts your efficiency, product consistency, and overall productivity. From the gentle touch of a spiral mixer perfect for artisan breads to the sheer power of a horizontal mixer tackling the stiffest cracker doughs, understanding the nuances of each type is key.

We've explored the diverse types of mixers, the critical factors influencing your choice—capacity, power, dough type, and construction—and the importance of safety, maintenance, and modern technology in maximizing your uptime.

As you move toward a final decision, keep these practical steps in mind:

- Clarify your menu and dough types (hydration levels, fermentation style, and desired crumb structure)

- Quantify production targets in pounds or kilograms per shift and per day

- Match mixer type (spiral, planetary, double arm, horizontal) to your primary dough style

- Right-size capacity based on peak production, desired batch frequency, and future growth

- Evaluate infrastructure (power, space, sanitation workflows, and data connectivity)

- Plan for safety and maintenance with clear SOPs, training, and preventive service schedules

At The Restaurant Warehouse, we pride ourselves on helping businesses like yours steer these complex decisions, offering premium equipment at wholesale pricing without the heavy retail markup. We believe that top-tier quality shouldn't come with an exorbitant price tag.

CTA: Ready to move from research to action? Contact us now to discuss your dough mixer project and get recommendations custom to your recipes, volume, and budget.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment