Steam Your Way to Success with These Commercial Vegetable Steamers

Why Commercial Vegetable Steamers Are Essential for Modern Restaurants

A commercial vegetable steamer is a secret weapon for professional kitchens, changing how they cook vegetables, seafood, and proteins while preserving nutrients and flavor.

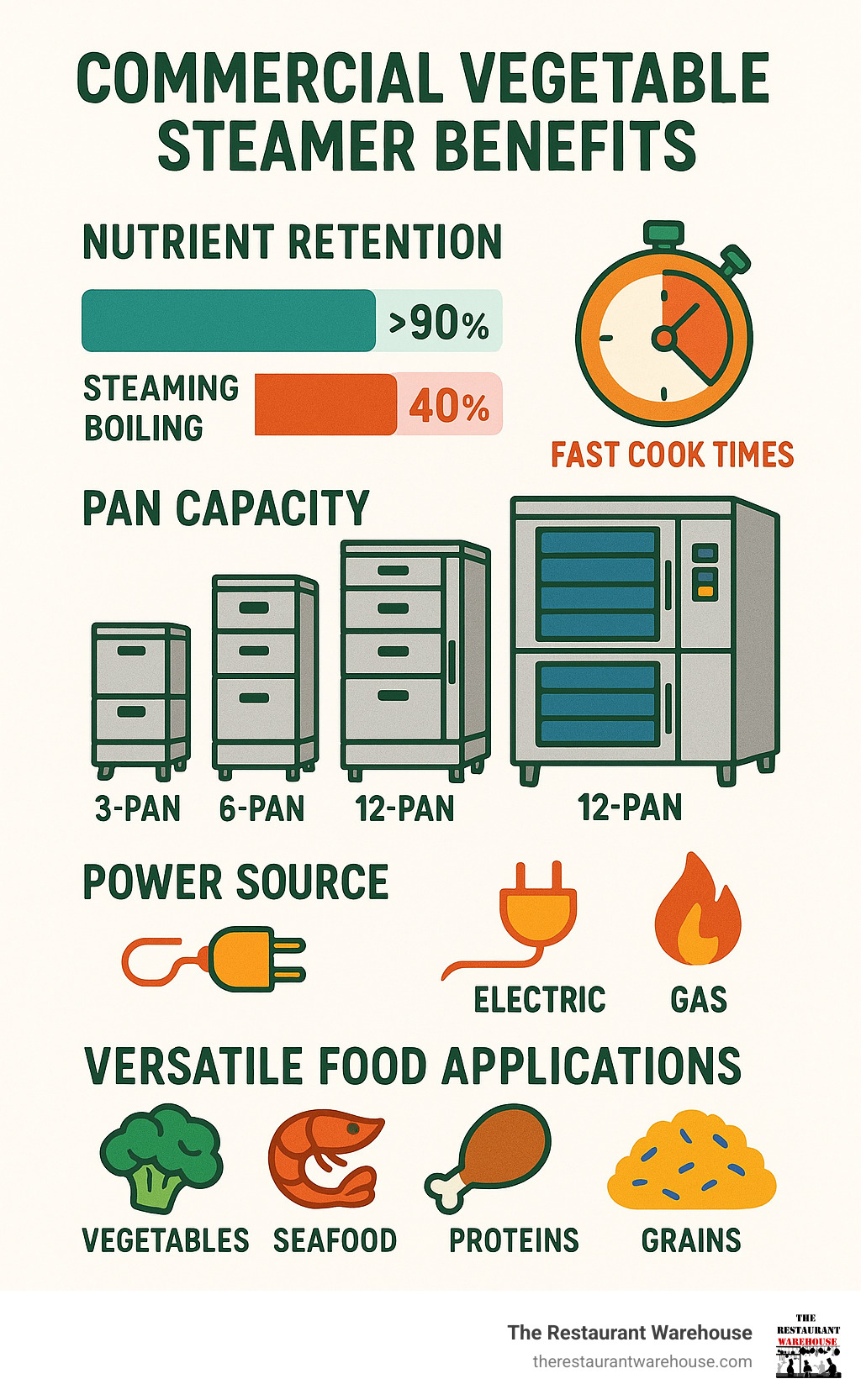

Top Commercial Vegetable Steamer Benefits:

- Nutrient retention: Steam cooking preserves over 90% of vitamins vs. boiling

- Speed: Steam vegetables in minutes, not traditional cooking times

- Consistency: Even heat distribution for uniform results every time

- Versatility: Cook vegetables, seafood, dumplings, rice, and more

- Capacity: Models range from 3-pan countertop units to 12-pan floor steamers

- Power options: Electric (3.5-31.1 kW) or gas (32,000-200,000 BTU)

For budget-conscious owners, steamers offer incredible value by reducing food waste, speeding up service, and creating healthier menu options. Key decision factors include your kitchen's volume, available space, and utility connections. Countertop models suit smaller operations, while high-volume kitchens benefit from floor models with auto-fill water connections.

Research shows steaming retains food's original texture, color, and nutritional value, unlike boiling. This leads to better-looking plates and healthier food that can command premium prices.

Modern steamers feature automatic water refill, timed drains, programmable controls, and even IoT compatibility for remote monitoring.

Commercial vegetable steamer basics:

What is a Commercial Steamer and Why Does Your Kitchen Need One?

During a dinner rush, a commercial vegetable steamer is your kitchen's best friend, helping staff turn out perfectly cooked, vibrant vegetables. A commercial vegetable steamer is a powerhouse that uses pressurized steam for fast, even cooking. Built from heavy-duty stainless steel, these units are designed for the demands of high-volume kitchens, unlike flimsy home models.

These steamers generate steam via a boiler or direct water injection, creating a gentle, efficient cooking environment. The result is food that cooks rapidly while retaining its nutrients. Commercial steamers excel at batch cooking with incredible consistency. This precision, essential for professional kitchens, ensures every dish meets customer expectations.

Steam cooking is a simple, healthier cooking method. With no oil or butter, it preserves the natural integrity of food while delivering the speed and efficiency busy kitchens need. For restaurant owners looking to upgrade, a quality steamer is a key item for your Restaurant Kitchen Equipment Checklist. It's an investment in increased efficiency and better food quality.

The Core Benefits of Steam Cooking

Steam cooking is a game-changer for professional kitchens, and the results speak for themselves.

- Nutrient retention is where steam cooking shines. Boiling leaches water-soluble vitamins like C and B. Steam cooking retains over 90% of these nutrients in the food, which health-conscious customers appreciate.

- The improved flavor is remarkable. Since food doesn't touch water, natural flavors stay concentrated and intense.

- Vibrant color is another huge win. Steam cooking preserves the natural pigments that make vegetables visually appealing on the plate.

- Improved texture sets steamed vegetables apart from mushy, boiled ones. They maintain a perfect firmness—tender with a pleasant bite.

- Speed and efficiency make steamers lifesavers during busy service. Most vegetables steam in just 3-8 minutes, leading to faster ticket times and better table turnover.

- Consistency is what every kitchen manager dreams about. A commercial steamer delivers identical results every time, regardless of the operator, maintaining quality standards across shifts.

- Versatility is an underrated benefit. These steamers are incredible for cooking seafood, reheating items, preparing rice, steaming dumplings, and cooking delicate proteins like fish fillets.

How to Choose the Perfect Commercial Vegetable Steamer for Your Kitchen

Selecting the right commercial vegetable steamer doesn't have to be overwhelming. It's about matching the unit to your kitchen's volume, space, and budget. Don't buy on price alone. A cheap unit that can't handle a dinner rush costs more in the long run, while an oversized model wastes energy and space.

Start by assessing your current needs and growth plans. Count how many steamed items you serve during your busiest service, then add about 20% for growth. Also, consider your kitchen's physical space and utility connections. Match your steamer to your actual workflow with help from our Buy Commercial Kitchen Equipment guide.

Types of Commercial Steamers: Finding Your Fit

Commercial steamers are either boiler steamers or boilerless steamers. Understanding the difference is key.

| Feature | Boiler Steamers | Boilerless/Connectionless Steamers |

|---|---|---|

| Water Usage | Higher - continuous boiler operation | Lower - only heats water as needed |

| Installation | Complex - requires water line, drain, electrical | Simple - plug-and-play operation |

| Maintenance | Regular boiler cleaning and deliming | Minimal - no boiler to maintain |

| Steam Recovery | Faster between loads | Slower initial steam generation |

| Ideal Use Case | High-volume operations with continuous use | Smaller operations or intermittent use |

| Energy Efficiency | Better for constant operation | More efficient for occasional use |

- Boiler steamers are workhorses for busy kitchens, keeping steam ready on demand. They require professional installation with water and drain lines.

- Boilerless steamers heat water on demand, making them more energy-efficient for lighter, intermittent use. They are easier to install, with some models just plugging into a standard outlet.

- Countertop models typically hold 3-5 pans and are great for restaurants that steam vegetables as sides or for specific menu items.

- Floor models have 6-12 pan capacity to handle large batches for banquets, cafeterias, or high-volume restaurants. They require dedicated floor space and utility connections.

- Electric steamers offer precision and convenience, with power ranging from 3.5 kW to over 30 kW.

- Gas steamers heat up faster and often cost less to operate, with ratings from 32,000 to 200,000 BTU. They require proper ventilation and gas connections.

- Convection steamers use fans to circulate steam for faster, more even cooking, ideal for mixed loads.

Key Features to Look for in a Commercial Vegetable Steamer

Focus on features that improve your daily operations.

- Pan capacity: Steamers use standard 12\" x 20\" hotel pans. A 3-pan unit suits smaller operations; busy kitchens may need 8-12 pans.

- Power source: Choose gas or electric based on utility costs. Gas heats faster, while electric offers precise control.

- BTU and kW ratings: Higher ratings mean faster steam generation and quicker recovery between loads.

- Controls: Manual controls are simple and durable. Programmable controls offer consistency and can store recipes.

- Stainless steel construction: Look for durable 18/8 stainless steel for longevity and easy cleaning.

- Insulation: Good insulation saves energy and keeps the kitchen cooler. Polyurethane foam is highly effective.

- Auto-fill features: These systems automatically maintain water levels, preventing dry burning and ensuring consistent steam.

- Smart drain systems: Technology like PowerFlush automatically flushes the generator, reducing mineral buildup and maintenance.

For top-tier safety and quality, consider NSF Rated Equipment.

Sizing Your Steamer: Matching Capacity to Your Output

Getting the size right is crucial. Too small creates bottlenecks; too large wastes energy and space.

- Menu Analysis: List all steamed items and estimate peak service volumes. Include items partially steamed during prep.

- Peak Hour Volume: Calculate portions needed during your busiest hour, factoring in different cooking times to determine batch turnover.

- Kitchen Footprint: Ensure adequate clearance for loading, unloading, and pan storage. A floor model typically needs 3 feet of clearance.

- Available Space: Consider floor space and overhead clearance for ventilation. Steamers produce significant moisture that your hood system must handle.

- Pan Size Standards: The standard 12\" x 20\" pan size allows you to use existing hotel pans and find replacements easily.

- Future Growth: It's often more cost-effective to buy a slightly larger steamer now than to replace a smaller one in a few years.

Our Restaurant Equipment Guide offers more insights on sizing equipment.

Installation, Maintenance, and Safety Best Practices

Proper installation, maintenance, and safety are key to maximizing the life and performance of your commercial vegetable steamer. A well-maintained unit can last for years, while neglect leads to premature failure. Safety is about protecting your team from preventable injuries like steam burns.

Most issues are preventable with the right knowledge and consistent practices. Our Clean Restaurant Equipment guide covers the broader picture of equipment care.

Installation Requirements and Considerations

Proper initial installation saves countless headaches. These units require specific infrastructure.

- Utility Connections: Ensure proper utility connections. Electric units need dedicated high-voltage circuits (e.g., 208V three-phase), while gas models require correctly sized lines and regulators. Inadequate utilities cause performance issues.

- Voltage and Phase: Verify your kitchen's electrical capacity before buying. Single-phase power limits you to smaller units (under 7 kW), while three-phase is needed for larger models.

- Water Filtration: A water filtration system is essential insurance against hard water, which destroys steam generators. A reverse osmosis system removes minerals, reducing service calls and extending equipment life.

- Drainage Needs: Steamers require a proper drain connection (typically 1.5\" NPT) and adequate floor drainage to handle condensation.

- Ventilation and Hood Space: Steamers release significant heat and moisture that your hood system must capture. Refer to our Commercial Kitchen Hood Guide for specific requirements.

Essential Maintenance for Your Commercial Vegetable Steamer

A little daily attention prevents major repairs.

- Daily Cleaning: Drain the cooking compartment and wipe all surfaces. Clean all removable parts, paying close attention to door gaskets to prevent steam leaks.

- Weekly Deliming: Use a commercial descaler or 5% lemon juice solution weekly (or more often with hard water) to keep the generator efficient. Follow instructions, soak, and flush thoroughly.

- Gasket Inspection: Check gaskets monthly for cracks or hardening and replace them at the first sign of damage to prevent energy waste.

- Float Valve Checks: Clean and check float valves to ensure the auto-fill system works properly, preventing overfilling or dry burning.

- Tank Draining: Drain the tank twice weekly to prevent mineral buildup and bacterial growth, especially if the unit is not used daily.

- Cleaning Solutions: Natural cleaners like lemon juice or white vinegar effectively remove mineral deposits. Always rinse thoroughly.

Critical Safety Precautions

Safety around steam is essential, as steam burns are severe.

- Handling Hot Surfaces: Always assume all surfaces are hot during and after operation.

- Use Insulated Gloves: Non-negotiable for handling pans or opening the door. Use heavy-duty gloves designed for steam equipment.

- Proper Door Opening: Stand to the side, never in front, when opening the door. Open it slowly to let steam escape gradually.

- Electrical Safety: Ensure all connections are grounded and protected by circuit breakers. Never use a steamer with damaged cords. Install GFCIs where required.

- Prevent Dry Burning: Never operate a steamer without adequate water. Auto-fill systems help, but manual-fill units require constant attention.

For comprehensive safety information, visit Product Safety Warnings.

More Than Just Vegetables: Open uping Your Steamer's Versatility

Your commercial vegetable steamer is one of the most versatile tools in the kitchen, capable of handling far more than just vegetables.

- Seafood: Delicate seafood like fish, shrimp, and mussels cooks perfectly, retaining moisture and texture. Steamed salmon retains its rich oils and buttery texture.

- Proteins: Chicken breasts cook evenly and stay incredibly moist. Hard-boiled eggs are easier to peel when steamed—a favorite prep cook trick.

- Grains: Grains like rice and quinoa cook to fluffy perfection, freeing up valuable stovetop space. No more checking and stirring.

- Dumplings and Dim Sum: The moist environment creates the perfect tender-yet-firm texture for these traditional steamed items.

- Pasta: Reheating pre-cooked pasta is effortless. The pasta is refreshed without becoming mushy, a valuable technique for banquet operations.

- Retherming: Steamers are ideal for bringing refrigerated or frozen pre-cooked meals to a safe serving temperature, a capability heavily relied upon in healthcare and school foodservice.

The gentle nature of steam cooking makes it nearly impossible to overcook most items, making steamers perfect for less experienced cooks while delivering restaurant-quality results.

For more information on keeping food at proper temperatures after cooking, check out our Best Food Warmer guide.

Frequently Asked Questions about Commercial Steamers

Here are answers to the most common questions about running a commercial vegetable steamer.

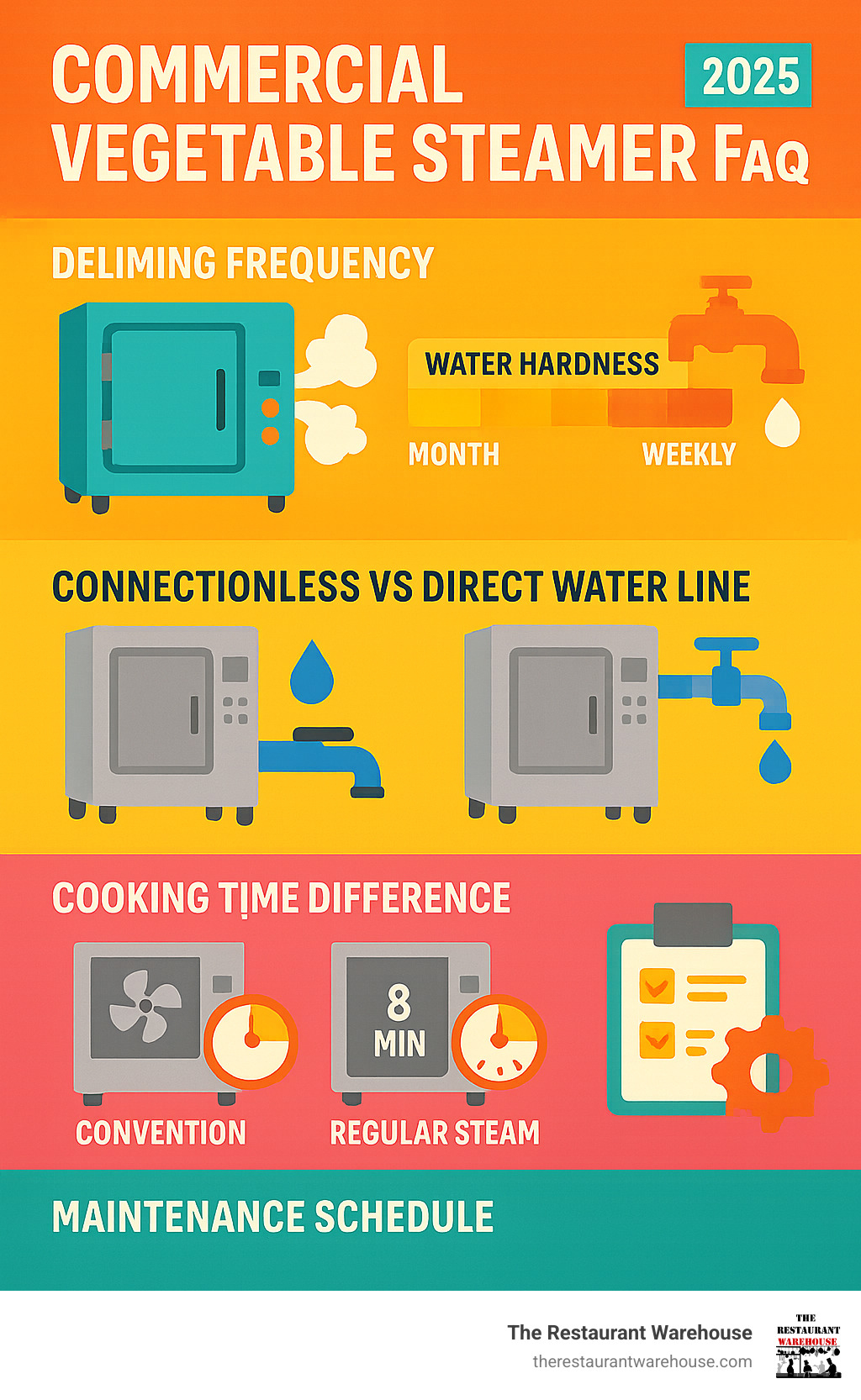

How often do I need to delime my commercial steamer?

Deliming frequency depends on your water hardness and usage frequency. With very hard water, delime weekly; with soft water, monthly may suffice. A general guideline from manufacturer recommendations is every 100 operating hours. Watch for signs of scale buildup like longer heating times or weak steam output, and establish a regular schedule based on your kitchen's conditions.

Can I use a commercial steamer without a direct water line?

Yes. Boilerless steamers or connectionless models have manual-fill reservoirs and don't require a direct water line. This offers portability benefits, making them ideal for caterers, food trucks, or locations where plumbing modifications are impractical.

What's the difference between a convection steamer and a regular steamer?

A convection steamer uses a fan for forced air circulation. This moving steam results in faster cooking times and more even heat distribution, eliminating hot spots and ensuring consistent results across all pans. The convection fan technology adds some complexity, but the improved cooking results are often worth the slightly higher initial cost.

Conclusion

Investing in the right commercial vegetable steamer is a strategic move to improve your kitchen's consistency, quality, and efficiency. Success comes from matching the steamer to your specific needs, menu, and volume. A properly sized unit becomes an invaluable part of your team, delivering perfect results every time.

Boosting kitchen efficiency goes beyond just cooking faster. Steamers free up your stovetop, reduce the skill level needed for consistent results, and eliminate the guesswork that leads to waste. Improving food quality is where steamers truly shine. The vibrant colors, retained nutrients, and perfect textures create dishes that look as good as they taste. Offering genuinely nutritious options is a significant competitive advantage.

At The Restaurant Warehouse, we know the right equipment is crucial. We cut out the middleman and retail overhead, offering honest wholesale pricing on quality equipment so you can invest wisely. Our affordable equipment options don't mean compromising on quality. Whether you need a compact countertop unit or a powerhouse floor model, we have solutions that fit real-world budgets.

The investment you make today in a quality steamer will pay dividends for years. Better food quality leads to happier customers, faster service means higher table turnover, and healthier menu options can command premium prices. It's not just about the equipment—it's about building a more successful operation.

Ready to see what steam cooking can do for your kitchen? Explore our complete Commercial Kitchen Equipment Guide and find how the right equipment choices can transform your operation from good to exceptional.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment