Choosing Pizza Prep Stations A Practical Guide

A pizza prep station is the central hub of any serious pizzeria. It’s a specialized, all-in-one workstation that cleverly combines refrigeration, a tough work surface, and an organized topping rail into a single, seamless unit. This isn't just about convenience; it's about making the entire pizza assembly process faster, more efficient, and safer by keeping every essential ingredient perfectly chilled and right at your fingertips.

The Heartbeat of Your Pizzeria

Picture your pizzeria during the Friday night rush. It’s controlled chaos, right? Now, think about a Formula 1 pit stop—a whirlwind of precise activity where every team member knows their job and every tool is perfectly placed for maximum speed. That’s exactly what a pizza prep station brings to your kitchen. It’s the culinary equivalent of that pit crew's workstation, bringing order and rhythm to the chaos.

This is so much more than a simple table. It’s an engineered piece of equipment designed to be the central nervous system of your pizza production line. Without one, your team is scrambling between the walk-in cooler, a separate prep table, and scattered bins of toppings. Every trip wastes precious seconds that add up on every single order.

To really get what makes these stations so effective, it's helpful to see how they transform the day-to-day grind.

How a Pizza Prep Station Transforms Your Kitchen

| Benefit | Impact on Kitchen Operations | Real-World Example |

|---|---|---|

| Speed & Efficiency | Dramatically cuts down on the time it takes to assemble a pizza by keeping all ingredients within arm's reach. | During a dinner rush, a pizzaiolo can build ten pizzas in the time it would take to build seven without a dedicated station, simply by eliminating trips to the walk-in. |

| Food Safety | Maintains a consistent, food-safe temperature for all toppings, reducing the risk of spoilage and foodborne illness. | Cheese, pepperoni, and fresh vegetables stay below 40°F in the refrigerated rail, even in a hot kitchen, ensuring they are always safe to serve. |

| Consistency | Ensures every pizza is made with the same fresh, properly stored ingredients, leading to a more consistent final product. | Portion control becomes easier and more accurate when all toppings are organized in front of the cook, meaning every "supreme" pizza has the same amount of toppings. |

| Reduced Labor Costs | By making the assembly process more efficient, one person can do the work of two, or the whole team can produce more in less time. | A single well-trained cook at a prep station can handle a ticket line that might otherwise require an extra person just to fetch ingredients. |

A dedicated pizza prep station isn't just a piece of equipment; it's a system that fundamentally changes your workflow for the better.

Core Components Working in Harmony

A professional pizza prep station is more than just the sum of its parts. Each component is designed to work together, creating a seamless workflow that ensures every pizza is made quickly, consistently, and safely. This integration is what separates a purpose-built station from a clumsy, makeshift setup.

Let's break down the three fundamental elements that make it all work:

- Refrigerated Cabinet: The base of the unit is all about cold storage. This is where you keep your dough balls, backup sauces, and bulk cheese. It eliminates those constant trips to the walk-in, keeping your pizzaiolo focused on assembly.

- Durable Work Surface: This is where the magic happens. Typically made of stainless steel or cool marble, this large, deep countertop is designed to be spacious enough for stretching even the largest doughs without ingredients spilling everywhere.

- Refrigerated Topping Rail: This is the most iconic feature. It's a series of chilled pans holding every single topping—from pepperoni and mushrooms to onions and peppers—at a food-safe temperature, directly in front of the cook.

The real value of a pizza prep station lies in its ability to consolidate motion. By bringing every necessary ingredient into a single, ergonomic zone, it can dramatically reduce labor costs and increase ticket times, turning a chaotic process into a streamlined assembly line.

More Than Just Equipment—It's an Investment

Investing in proper pizza prep stations isn't just about making life easier; it's a strategic business decision that pays off. The global demand proves this, with the commercial pizza prep table market valued at around USD 1.5 billion in 2023 and projected to hit USD 2.3 billion by 2032.

This growth shows that modern pizzerias get it: efficiency directly impacts profitability. For many places, pairing a perfectly made pizza with the right beverage is a key part of the customer experience. A well-organized station ensures you deliver on both speed and quality, which are absolutely crucial for success. For some great ideas, check out our guide on creating a classic pizza and beer pairing.

Ultimately, these stations are non-negotiable assets for any serious pizzeria aiming for consistency, speed, and growth.

The Anatomy of a High-Performance Prep Station

Alright, now that we’ve covered the basics, let’s get into the good stuff—the features that separate a workhorse prep station from a metal box that just gets in the way. It’s a lot like buying a car. Sure, they all have engines, but the real driving experience comes down to the details under the hood, the suspension, and the layout of the dashboard. For a pizza station, it's the work surface, the refrigeration system, and the design of the ingredient rail that determine how your kitchen flows during a chaotic dinner rush.

Getting a handle on these details helps you judge a unit by how it will actually perform in your kitchen, not just by its price tag. The right combination of features can transform your prep line into a powerhouse of efficiency. The wrong ones? They create frustrating bottlenecks that slow down every single order.

The Foundation: Your Work Surface

Your team will spend most of their time right here, making the work surface one of the most critical parts of the whole setup. This is the stage for your pizza artistry, and the material you choose directly impacts how you handle dough, how easy cleanup is, and how long the station will last. You've generally got three options, each with its own pros and cons.

- Stainless Steel: This is the undisputed champion of the commercial kitchen. Stainless steel is a workhorse, valued for its incredible durability and how easy it is to sanitize. It's non-porous, which means no lingering flavors or bacteria, and it can take a real beating day after day.

- Marble: Often the top pick for artisan pizzerias, marble has a natural ability to stay cool. This is a huge advantage when you're working with delicate doughs, as it helps prevent them from sticking or getting overworked. The trade-off is that it needs a bit more TLC to prevent stains and chips.

- Polyethylene: This high-density plastic is a tough, budget-friendly alternative. It’s gentler on your knives and a breeze to clean. Often, you'll see it as a removable cutting board that sits right on top of the station, which makes deep cleaning incredibly simple.

Choosing the right surface really comes down to balancing your dough-making style with your kitchen's cleaning routine. High-volume shops usually lean toward the ruggedness of stainless steel, while craft pizzerias might spring for the unique thermal properties of marble.

Keeping Your Cool: Refrigeration Systems

The refrigeration system is the heart and soul of your prep station. It’s what keeps all those toppings and ingredients at a safe, consistent temperature. The tech powering your cooler directly affects ingredient freshness, food safety, and even your monthly energy bill. This is a big deal, especially when you consider the broader market for prep refrigerators is already valued at over USD 9 billion and is projected to hit nearly USD 14.5 billion by 2035. That growth is all about the demand for energy-efficient units that cut down on running costs. You can dig deeper into the numbers in this comprehensive industry report.

There are two main types of cooling systems you'll encounter:

- Forced-Air Systems: These use fans to actively push cold air all around the ingredient rail and storage cabinets. This approach guarantees a consistent temperature everywhere and is great for quickly cooling down fresh ingredients you've just loaded in. The only catch is that the constant airflow can sometimes dry out delicate toppings like fresh veggies if they aren't covered properly.

- Cold-Wall Systems: This design works by running refrigerant lines right through the unit's walls to chill the interior. It's a gentler way to cool and helps maintain higher humidity, which is fantastic for preserving the texture of fresh produce. The downside? It can be a little slower to recover its temperature after the lid has been open for a while.

Your menu should guide your choice here. If you're working with a lot of fresh, delicate vegetables, a cold-wall system might be your best bet. But if your top priority is rapid temperature recovery during high-volume rushes, a forced-air system is probably the smarter pick.

The Topping Rail: Your Assembly Superhighway

The ingredient rail is mission control for your pizza-making process. The way it's configured—and the pans it holds—can either become a major bottleneck or an assembly superhighway. You want a layout that feels intuitive, letting your team move quickly and accurately from sauce to cheese to toppings without a second thought.

Take a look at how this setup gives you a deep cutting board with plenty of space for large doughs, while the raised rail keeps every ingredient perfectly chilled and right at your fingertips. That kind of ergonomic design is what minimizes wasted movement and maximizes output. A well-designed rail, combined with the right work surface and cooling system, creates a workstation that empowers your team to crush it, even on the busiest nights.

Finding the Right Size Pizza Prep Station for Your Volume

Choosing the right size for your pizza prep station isn't just about what fits in your kitchen; it’s about matching your equipment's capacity to your pizzeria's peak performance. A station that's too small acts like a bottleneck, creating a frustrating logjam that slows down your entire production line. On the flip side, an oversized unit is just a waste of capital and precious kitchen real estate, sucking up energy and space you could use for something else.

The goal is to find that sweet spot where your team has everything they need during the busiest hours without being overwhelmed or underutilized. This requires looking at your actual numbers, not just guessing. Once you understand your real-world production volume, you can pick a station that empowers your team and supports your growth.

Calculating Your Peak Hour Pizza Output

Before you even glance at a single model, you need to know your numbers. Your "peak hour" is the busiest 60-minute window of your week, usually on a Friday or Saturday night. That number is your North Star for sizing your equipment.

Here’s a simple way to figure it out:

- Track Your Orders: For a few weeks, log how many pizzas you sell hour-by-hour during your busiest shifts.

- Identify the Peak: Find the single hour where you consistently sell the most pizzas.

- Add a Buffer: Take that peak hour number and add 20-25% to it. This gives you a cushion for future growth or those unexpectedly slammed nights.

That final number is your target. For instance, if your busiest hour averages 40 pizzas, your target production capacity should be right around 50 pizzas per hour. This ensures your new pizza prep station won't be holding you back the moment your business starts to grow.

Matching Station Size to Production Volume

Pizza prep stations are measured by their length in inches, and that length directly ties to how many topping pans they can hold and how much workspace is available. A larger unit allows multiple pizzaiolos to work side-by-side without bumping elbows—a critical factor for any high-volume kitchen.

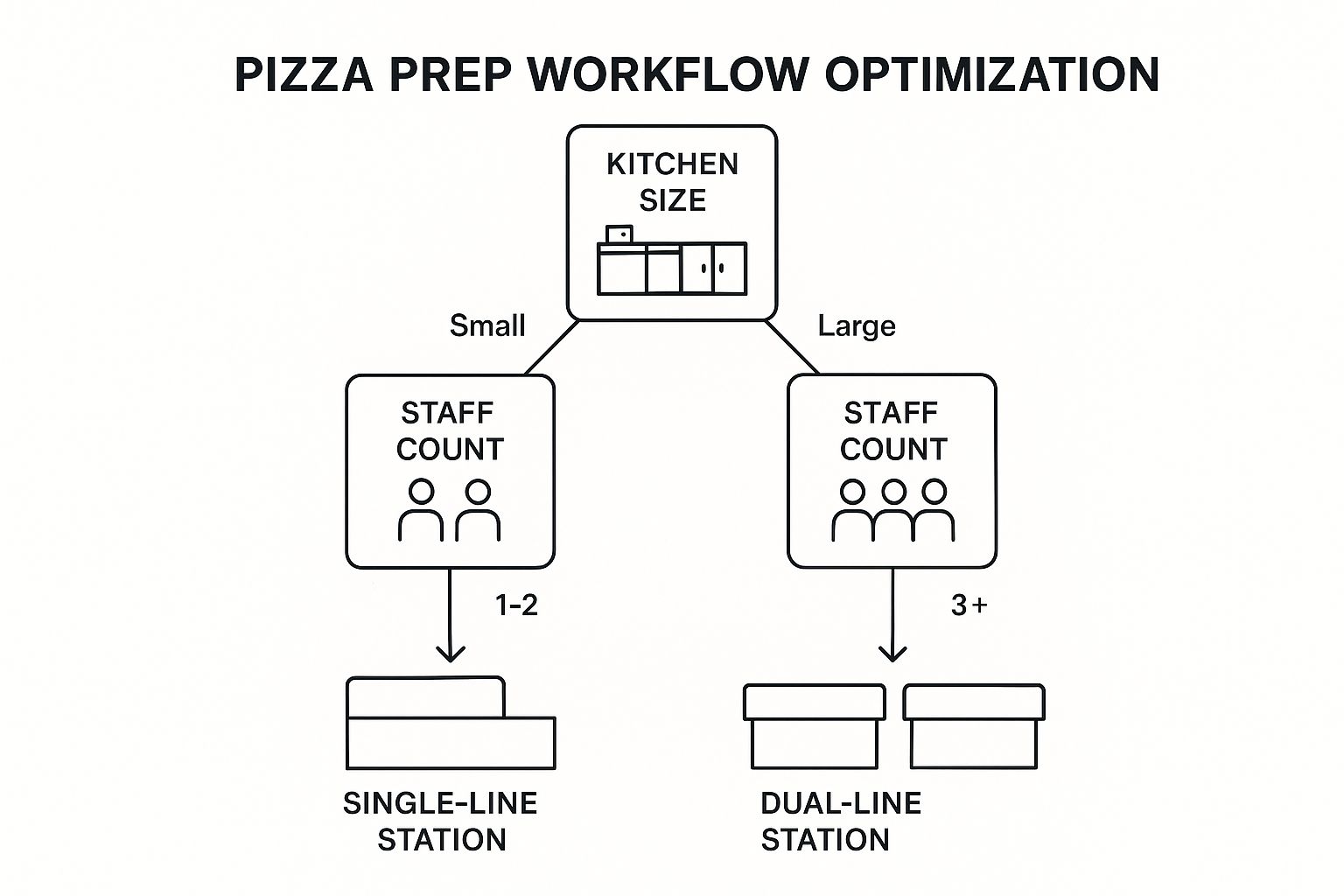

This visual guide can help you map out the best workflow for your kitchen and staff size.

As the infographic shows, a growing kitchen and a bigger team naturally demand more advanced, multi-line prep stations to keep the workflow moving smoothly.

To make this even easier, we've put together a sizing guide to help you match table dimensions with your output.

Pizza Prep Station Sizing Guide

| Table Size (Inches) | Typical Pan Capacity | Ideal for (Pizzas per Hour) | Best For |

|---|---|---|---|

| 48" - 60" | 6-8 pans | 20-30 | Food trucks, cafes, or small pizzerias with a single operator. |

| 67" - 93" | 9-12 pans | 30-60 | The sweet spot for most independent pizzerias, supporting two cooks. |

| 100"+ | 12+ pans | 60+ | High-volume chains or massive operations with 3+ staff members. |

Ultimately, picking the right size comes down to being honest about your current volume and realistic about your growth. This table should point you in the right direction.

Standard Top vs Mega Top Stations

Beyond sheer length, you'll run into another key distinction: standard top versus "mega top" models. This choice directly impacts your topping capacity and can make or break your workflow during a rush.

A mega top pizza prep station is designed with an extra row of topping pans, typically increasing capacity by 30-50% compared to a standard model of the same length.

A standard top is perfectly fine for pizzerias with a focused menu of 10-15 toppings. But if your menu is extensive or you offer build-your-own options with dozens of ingredients, a mega top becomes a total game-changer. It means your team isn't constantly having to run to the walk-in to restock the topping rail, saving critical seconds on every single order.

Making the wrong choice here can create serious workflow problems, potentially driving up labor costs by as much as 25% from all that wasted movement.

Integrating Your Prep Station into Your Kitchen Workflow

You can buy the best pizza prep station on the market, but if you just drop it into a poorly planned kitchen, you’re setting yourself up for failure. The real magic happens when you stop seeing it as a standalone piece of equipment and start thinking of it as the heart of your entire pizza-making ecosystem. Strategic placement is everything—it creates a seamless flow from dough to oven that can shave precious seconds off every single order.

This is all about the science of motion, or maybe more accurately, the lack of it. Every extra step a cook takes to grab cheese or reach for a tool is wasted time, and that lost time multiplies like crazy during a dinner rush. Smart placement cuts down on those movements, reduces staff fatigue, and prevents the kind of kitchen chaos that can absolutely sink a busy Friday night.

Designing Your Pizza Production Line

How you lay out your kitchen will dictate how well your prep station actually functions. There are a couple of common approaches that offer different ergonomic benefits, and the right one for you really depends on your space and your team.

The Linear Assembly Line is hands-down the most popular layout. In this setup, the workflow moves in a straight, logical line:

- Dough Storage: It all starts at one end, usually in a refrigerated drawer or a nearby proofer.

- Pizza Prep Station: This is the central hub where dough gets stretched, sauced, and topped.

- Oven: Positioned right after the prep station for a quick, effortless transfer.

This configuration is incredibly efficient for high-volume shops because it creates a clear path with no backtracking. Once your ingredients are prepped, the next step is often the oven itself. For those utilizing wood-fired models, understanding how to maximize performance is crucial, starting with choosing the right firewood for your pizza oven.

The Central Island layout, on the other hand, places the prep station right in the middle of the kitchen. Other key areas like dough prep and the oven are arranged around it. This works beautifully in larger, more open kitchens, allowing multiple staff members to access the station from different sides and promoting better communication.

A well-integrated prep station should feel like a cockpit for your pizzaiolo. Every control, ingredient, and tool should be within a pivot or a single step, transforming frantic running into fluid, focused movements. This optimization is crucial in a competitive market.

In the United States alone, the pizza industry generated an estimated $50.1 billion from over 74,000 businesses. Big chains have long embraced operational innovations like prep stations to gain an edge, and independent pizzerias—which make up a huge slice of the market—can achieve the same efficiencies with smart layout design. You can learn more about the latest pizza industry trends from this 2025 report.

Overlooking the Practical Logistics

Beyond the workflow, there are a few practical details that often get forgotten until it’s way too late. Ignoring these can lead to equipment failure, safety hazards, or costly renovations down the line.

- Ventilation is Vital: Your station's condenser needs to breathe. If you shove it too close to a wall or another heat-producing appliance, you force the compressor to work overtime. This will shorten its lifespan and drive up your energy bills. Always leave at least 3-4 inches of clearance around the back and sides.

- Plan Your Power: Pizza prep stations are serious machines that need a dedicated electrical circuit. Make sure you have the correct voltage and outlet type installed nearby before the unit arrives. Trust me, you want to avoid last-minute delays and surprise electrician fees.

- Leave Room for Maintenance: Your team needs space to clean around and under the station. Even more importantly, a technician will eventually need to access the mechanical parts for service. Plan for enough clearance to make these essential tasks easy, not impossible.

Extending the Life of Your Pizza Prep Station

Your pizza prep station is a huge investment, and it’s the absolute workhorse of your production line. Keeping it in top shape isn't just about passing a health inspection; it's a core business strategy that protects your investment. With a bit of proactive care, you can add years to its life, sidestep those soul-crushing emergency repair calls, and make sure it stays a reliable asset instead of a recurring headache.

Think of it like owning a high-performance car. You wouldn't just ignore the check engine light or skip oil changes. Your prep station needs that same level of consistent attention to keep running at peak performance. This means going beyond a simple wipe-down at the end of the night and actually putting a solid maintenance plan in place.

The Foundation of Durability

The material your station is made from is a massive factor in how long it will last. Most commercial units are built with stainless steel, but not all stainless steel is created equal. You’ll usually see two grades pop up: 304 and 430.

-

Type 430 Stainless Steel: This is the more common and affordable option. It’s plenty durable for a lot of kitchen tasks, but it doesn't hold up as well against corrosion, especially from salt and acidic ingredients like tomato sauce.

-

Type 304 Stainless Steel: This is the premium stuff. It’s got more nickel and chromium, which gives it far superior resistance to rust and corrosion. Spending a little extra for a 304-grade exterior can easily save you thousands in the long run by preventing pitting and wear.

Investing in the higher-grade steel is one of the easiest first steps to ensure your pizza prep stations can handle the tough environment of a commercial kitchen.

Creating a Practical Maintenance Schedule

A consistent cleaning and maintenance schedule is your absolute best defense against your equipment dying an early death. It doesn’t need to be complicated, but it does need to be consistent. The trick is to break it down into daily, weekly, and monthly tasks so it becomes a manageable routine for your team.

A great starting point is to establish clear protocols. You can find excellent guidance in resources that explain how to properly clean restaurant equipment to meet health and safety standards.

Here’s a simple but effective schedule to get you started:

Daily Tasks:

- Wipe down all exterior and interior surfaces with a food-safe sanitizer.

- Clean the cutting board thoroughly, getting rid of all food debris.

- Empty and sanitize every ingredient pan from the topping rail.

- Check and log the internal temperatures to make sure they're in the safe zone (33°F-41°F).

Weekly Tasks:

- Pull out the door gaskets and clean them with warm, soapy water to remove grease and food buildup. This is crucial for a tight seal.

- Check and clean the drain lines to prevent clogs and funky odors.

"Neglecting condenser coils is the number one cause of premature refrigeration failure. A monthly cleaning takes 15 minutes but can prevent a repair bill that costs thousands."

Monthly Tasks:

- Clean the Condenser Coils: This is non-negotiable. Grab a stiff brush and a vacuum to clear out all the dust, flour, and grease that’s built up on the coils. Clogged coils make the compressor work way too hard, which drives up your energy bill and leads to burnout.

- Check Gaskets for Damage: Give the door gaskets a good look-over for any rips or tears that could break the seal. A bad seal lets cold air pour out, forcing your unit to work harder.

- Calibrate Thermometers: Use a separate, trusted thermometer to make sure your unit's built-in display is giving you an accurate reading. An off-kilter thermostat can lead to serious food safety issues. This kind of proactive approach helps you catch tiny problems before they turn into full-blown disasters.

Comparing Top Brands and Making a Confident Choice

Alright, you’ve figured out the features you need and the perfect size for your kitchen. Now comes the final step: navigating the sea of brands. Choosing a pizza prep station can feel a lot like picking out a new truck. Some are built like tanks for rugged, long-term durability, others are known for efficiency, and some offer the best all-around value for a new owner. The key is to match the brand's reputation with what your pizzeria actually needs to thrive.

Leading names like True, Avantco, and Turbo Air each have their own loyal following, and for good reason. Instead of getting bogged down in marketing hype, let's focus on what these brands are genuinely known for out in the real world.

What Top Brands Are Known For

- True Manufacturing: If you're looking for reliability, True is often considered the industry standard. Their units are built like absolute tanks with high-quality components. Think of it as a long-term investment that’s known for rock-solid performance and holding its value over the years.

- Avantco: This brand is all about delivering exceptional value. Avantco pizza prep tables are a go-to choice for new pizzerias or anyone working with a tighter budget. They offer dependable performance without that premium price tag, making them a smart, practical choice.

- Turbo Air: Known for smart innovation and energy efficiency. Turbo Air often designs its units with clever features like self-cleaning condensers and high-efficiency refrigeration systems, which can lead to lower utility bills and operating costs down the road.

This is just a quick overview, of course. For a more detailed breakdown, digging into a guide on the best pizza prep stations and their specific models can give you some fantastic insights.

Your Final Buyer's Checklist

Making a choice you feel great about means cutting through the noise and zeroing in on what truly matters for your operation. Before you pull the trigger, run through this quick checklist. It boils down all the key takeaways from this guide into a few actionable points.

Your prep station is so much more than a piece of metal; it’s the engine of your entire production line. Your final decision should be a balanced equation of the initial price, its long-term reliability, and how well the unit supports your unique kitchen workflow.

Use these final questions to guide your purchase:

- Warranty and Service: What does the warranty actually cover (parts, labor, the compressor), and for how long? Are there certified service techs for that brand in your area? A great warranty doesn't mean much if you can't get a repair done quickly.

- Long-Term Cost of Ownership: Look past the sticker price. Does the unit have energy-saving features that will cut your utility bills over time? Think about the potential cost of repairs and replacement parts for that specific brand.

- User Reviews and Reputation: What are other pizzeria owners saying? Hunt for reviews that talk about how the unit holds up during a chaotic dinner rush and its durability after a few years of heavy use.

- Alignment with Your Workflow: Does the layout of the topping rail, the depth of the cutting board, and the cabinet space feel right for how your team works? The perfect unit should feel like a natural extension of your process, not something you have to work around.

Answering these questions will give you the confidence to make a purchase that perfectly aligns with both your operational needs and your financial goals.

Got Questions About Pizza Prep Stations? We've Got Answers

Stepping up to a new piece of equipment always brings a few questions to mind. When that equipment is the absolute workhorse of your pizza line, getting straightforward, practical answers is crucial for keeping your kitchen humming, your food safe, and your investment protected.

We've pulled together some of the most common questions we hear from pizzeria owners about their pizza prep stations. These are the quick, no-fluff answers you need to get the most out of your unit.

What’s the Right Temperature for the Topping Rail?

You absolutely have to keep that refrigerated topping rail in the food-safe zone, which is between 33°F and 41°F (that’s 0.5°C to 5°C). This temperature range is non-negotiable for preventing nasty bacteria from growing on perishable toppings like meats, cheeses, and prepped veggies.

It's a really good habit to double-check this temperature every day with a separate thermometer, just because the built-in display can sometimes be a degree or two off. Also, resist the urge to overfill the ingredient pans; piling them high can block the cold airflow and create warm spots where your toppings can spoil.

Think of the 33°F to 41°F range as a hard and fast rule. Drifting outside this zone, even for a few minutes during a crazy rush, can put the safety and quality of every single pizza you make at risk.

Can I Just Use a Sandwich Prep Table for Making Pizza?

Look, you technically can, but it's a terrible idea for any real pizza operation. The whole game is in the design of the workspace. A dedicated pizza prep station is built with an extra-deep cutting board—we're talking 19 inches or more—specifically to give you room to work with large pizza doughs.

A sandwich prep table, on the other hand, has a much skinnier board. Trying to make pizzas on one is a recipe for a cramped, messy disaster where toppings are spilling everywhere and your whole workflow just grinds to a halt. If you're serious about making pizza efficiently and at volume, a purpose-built pizza prep station is the only way to go.

How Often Do I Need to Clean the Condenser Coils?

You should be cleaning those condenser coils every 90 days at the absolute bare minimum. But in a real pizzeria kitchen, with all that airborne flour and grease, doing it every 30 to 60 days is a much smarter move.

Here’s why this is so important:

- Efficiency: Clogged coils make the compressor work way harder to keep things cool, which means your energy bills will be noticeably higher.

- Longevity: That extra strain is the number one reason compressors fail early, and that’s an expensive, kitchen-stopping repair you don't want.

- Performance: A clean unit gets back to its set temperature much faster after the doors have been opened, keeping your ingredients safer.

A few minutes with a stiff brush and a vacuum can save you from some major headaches and costly repairs down the road, keeping your station running like a champ for years.

Ready to build the perfect pizza-making workflow? The Restaurant Warehouse offers a wide selection of high-performance pizza prep stations and flexible financing options to fit any budget. Equip your kitchen for success and explore our catalog.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment