Kitchen Muscle: Top Heavy Duty Equipment Picks for Serious Chefs

The Backbone of Commercial Kitchens

Heavy duty kitchen equipment forms the foundation of any successful commercial kitchen operation. For restaurant owners looking to equip their kitchens properly, here's what you need to know:

- Definition: Commercial-grade appliances designed for continuous operation, high-volume production, and extended durability

- Key characteristics: Stainless steel construction, 3+ horsepower motors, 30,000-150,000 BTU outputs

- Essential types: Ranges, ovens, refrigeration, food processors, dishwashers

- Price range: $1,500-$20,000+ depending on equipment type and capacity

When the difference between profit and loss comes down to operational efficiency, investing in the right heavy-duty kitchen equipment becomes critical. Unlike residential or light-duty appliances, commercial-grade equipment is engineered to withstand the punishing demands of high-volume food production day after day, year after year.

"Proper commercial kitchen equipment is essential to a restaurant's success," notes industry experts, and with good reason. Heavy-duty equipment features robust construction (typically AISI 304 stainless steel), powerful motors (often 1.5+ HP), and specialized safety features designed specifically for professional environments.

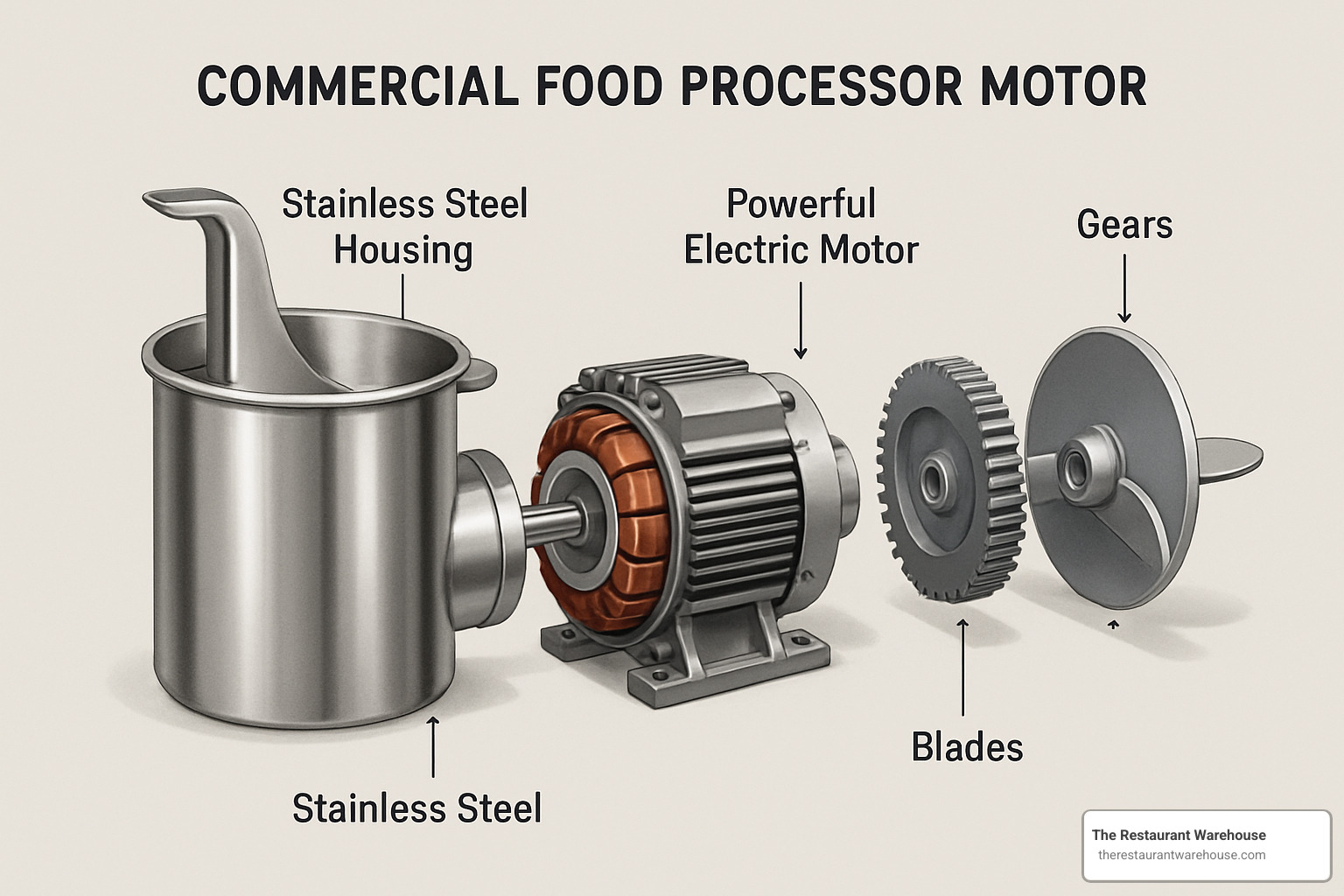

The distinction between standard and heavy-duty equipment isn't just marketing—it's measured in tangible metrics like duty cycles, motor power, and construction materials. Commercial food processors should have at least 700 Watts of power, while professional bowl cutters can perform up to 5,000 cuts per minute. Commercial ranges can deliver up to 362,000 BTU with 10 burners, providing the muscle needed for high-volume cooking.

For budget-conscious restaurant owners, understanding these specifications helps make informed investments that balance upfront costs with long-term operational savings. The right equipment not only increases kitchen efficiency but also improves food quality and consistency—essential factors for customer satisfaction and repeat business.

What Qualifies as Heavy Duty Kitchen Equipment?

When you walk into a professional kitchen, you'll quickly notice the difference between the equipment there and what you might have at home. Heavy duty kitchen equipment isn't just bigger—it's built differently from the ground up.

Think of it as the difference between a family sedan and a commercial truck. Both will get you places, but only one is designed to haul heavy loads day in and day out without breaking a sweat.

True commercial-grade equipment stands out through its robust construction—primarily AISI 304 stainless steel that shrugs off the constant humidity and acidic environments of busy kitchens. These workhorses are engineered for continuous duty cycles, happily running for 8+ hours straight when your Saturday night service just won't quit.

The heart of these machines—their motors—typically pack 3-horsepower or greater, maintaining consistent performance even when pushed to their limits. For gas equipment, you'll find impressive 30,000-150,000 BTU burners that heat rapidly and recover quickly between cooking tasks.

Safety and sanitation aren't afterthoughts either. Look for NSF and ETL certification marks that guarantee food safety compliance, along with thoughtful safety features like interlocks, thermal protection, and emergency shutoffs that protect your staff during hectic service periods.

Many modern units also carry ENERGY STAR® ratings, helping you balance operational costs while reducing your environmental footprint—something we at The Restaurant Warehouse always point out to cost-conscious owners.

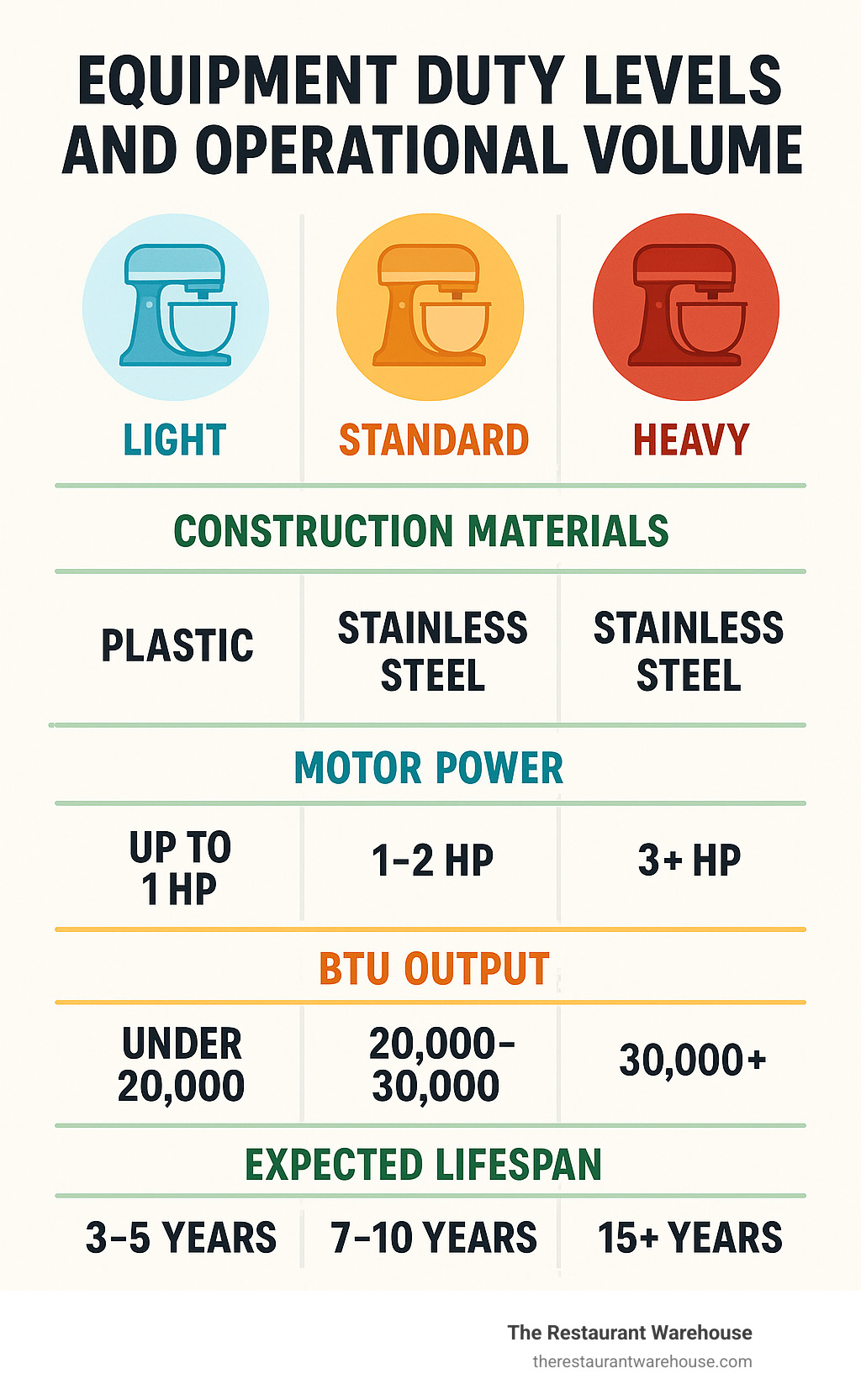

Heavy vs. Standard: Key Differences

The true value of investing in heavy duty equipment becomes crystal clear when you compare it side-by-side with standard options:

While standard equipment might get by with motors in the 0.5-1 HP range, heavy duty kitchen equipment muscles through with 1.5-3+ HP powerplants. The difference shows in thickness too—standard plates might be 1/2" or less, while heavy duty gear boasts robust 3/4"-1" construction that distributes heat more evenly and resists warping.

Perhaps most telling is the duty cycle. Standard equipment needs breaks, designed for intermittent use of 4-6 hours. Heavy duty? It keeps churning through 8+ hour shifts without complaint. This translates directly to longer periods between repairs—typically 3-5+ years compared to 1-2 years for standard options.

The investment math makes sense too. While standard equipment might pay for itself in 1-2 years, heavy duty options deliver value over a 5-10+ year timeline. They're built entirely from stainless steel rather than mixed materials, and typically carry warranties of 1-3+ years instead of the standard 90 days to 1 year.

As one of our chef customers memorably put it: "I'd rather cry once at the purchase price than cry every day with broken equipment during service." For busy restaurants serving 150+ covers daily, that wisdom is worth its weight in gold—or should we say, stainless steel.

Heavy Duty Kitchen Equipment Categories You Can't Skip

When outfitting a commercial kitchen, certain categories of heavy duty kitchen equipment are absolutely essential for serious operations. These aren't just nice-to-have items – they're the workhorses that will power your kitchen through busy services and help deliver consistent quality to your customers.

Cooking Powerhouses (heavy duty kitchen equipment)

The heart of any commercial kitchen is its cooking line. Think of these pieces as your kitchen's engine – they need to run reliably hour after hour, service after service.

Those impressive 36"–60" gas ranges with outputs reaching a whopping 362,000 BTU truly form the backbone of most professional kitchens. What makes them special? It's those reversible grates that give you flexibility, multi-zone controls for precision, and those sturdy oven compartments built to withstand constant use. At The Restaurant Warehouse, we're particularly proud of our commercial ranges with all-stainless construction and 3/4" thick griddle plates that distribute heat beautifully.

Your charbroilers need to keep up too. The best commercial units deliver up to 140,000 BTU, making them perfect for non-stop, high-volume grilling. Look for models with adjustable grates and independent heat zones – your cooks will thank you when they can perfectly control temperatures across the cooking surface.

Don't overlook a quality griddle – those heavy-duty countertop gas models reaching 150,000 BTU allow for efficient cooking across large surfaces. I always recommend looking for 1" thick plates for the best heat retention and recovery during those hectic lunch rushes.

And combi ovens? They're the Swiss Army knives of commercial kitchens, combining convection, steam, and combination cooking modes. The premium models even feature self-cleaning functions (a real time-saver), programmable recipes, and precise humidity controls that can make even a novice cook look like a pro.

Prep Workhorses (heavy duty kitchen equipment)

The battle for kitchen efficiency is often won or lost during prep time. That's where these heavy duty kitchen equipment items earn their keep by slashing labor costs and improving consistency.

A proper commercial food processor should have at least 700 Watts of power to handle whatever tough ingredients you throw at it. Our selection includes continuous-feed options that process up to 33 pounds of ingredients at once – imagine how much time that saves compared to hand-cutting!

Have you ever seen a high-efficiency bowl cutter in action? It's mesmerizing – performing up to 5,000 cuts per minute and dramatically reducing prep time. The dual-speed models give you versatility for different ingredients and textures.

Blixers (those clever combination blender/mixers) provide incredible versatility for both liquid and solid ingredients. The best ones feature sealed S-blade systems that keep things safe while making pouring a breeze.

And let's talk about power mixers – those commercial immersion blenders with 1.5+ HP motors make quick work of soups, sauces, and purees. Look for models with thermal overload protection if you'll be using them continuously.

As Vulcan Equipment research has shown, quality food prep equipment pays for itself through labor savings and consistent food quality. Just imagine the hundreds of labor hours your kitchen could save annually with the right tools!

Cold Storage & Holding

Temperature control isn't just about food safety – it's about maintaining quality too. Your refrigeration solutions need commercial-grade reliability.

Heavy duty kitchen equipment like reach-in refrigeration units maintain precise temperatures between 33°–38°F thanks to powerful compressors and digital Dixell controllers. The features that really matter? Insulated doors that maintain temperature, adjustable shelving for flexibility, and self-closing features that prevent costly cold air loss.

Blast chillers are specialized units that rapidly cool hot foods to safe temperatures, extending shelf life and maintaining quality. The professional models can chill food from 160°F to 37°F in under 90 minutes – a game-changer for food safety and inventory management.

For kitchens where space is at a premium, undercounter refrigeration provides accessible cold storage while maximizing workspace. Our models feature durable stainless steel construction and environmentally friendly refrigerants.

Need help choosing? Check out our comprehensive guide to commercial refrigeration to find the perfect unit for your specific needs.

Cleaning & Sanitation Giants

Even the best kitchen equipment won't perform if it's not properly cleaned. That's where these sanitation workhorses come in.

High-temperature dishwashers sanitize through 180°F+ rinse cycles, processing more than 150 racks per hour. The best models include automatic deliming features and low-water consumption designs that save on utility bills while keeping everything sparkling clean.

Those triple-basin sinks might seem basic, but NSF-certified washing stations with separate compartments for washing, rinsing, and sanitizing are essential for proper sanitation. Look for 16-gauge stainless steel construction that stands up to years of heavy use.

For tackling those tough cleaning jobs, power washers delivering 1,500+ PSI make quick work of stubborn grease and soil on floors, walls, and equipment exteriors.

Proper sanitation equipment doesn't just keep health inspectors happy – it extends the life of your other kitchen investments by keeping them clean and well-maintained. Think of it as protection for your bigger equipment investments.

Features That Matter Most

When shopping for heavy duty kitchen equipment, certain features truly separate the professional-grade workhorses from their lighter counterparts. Understanding these key elements will help you make smart investments that serve your kitchen for years to come.

Durability tops the list for any serious kitchen investment. Look for AISI 304 stainless steel construction, which offers exceptional resistance to corrosion, especially important in steamy, humid kitchen environments. This restaurant-grade stainless can take years of punishment from cleaning chemicals, temperature swings, and daily abuse without showing its age.

The horsepower behind your equipment makes a world of difference during busy service. Commercial-grade motors typically start at 1.5 HP and go up from there. A professional food processor with a robust 3¼ horsepower motor will power through prep tasks all day without breaking a sweat, while lesser models might burn out mid-service.

When it comes to wattage and BTU output, bigger numbers generally mean better performance. Your commercial food processors should pack at least 700 Watts of power, while gas cooking equipment typically delivers between 30,000 to 150,000 BTU depending on what you're cooking. These aren't just impressive numbers—they translate directly to faster cooking times and quicker recovery during peak service.

Capacity matters tremendously in volume production. The best heavy duty kitchen equipment is designed to handle serious output. Commercial food processors that can process up to 33 pounds of ingredients at once save valuable prep time, while industrial refrigerators store hundreds of pounds of product at precisely controlled temperatures.

Don't overlook safety features when comparing equipment. The best commercial gear includes thermal overload protection that prevents motor burnout, emergency shutoffs for when things go wrong, and intuitive safety interlocks. For busy kitchens where spills happen, look for IP67-rated controls that can withstand the inevitable splashes during cleaning.

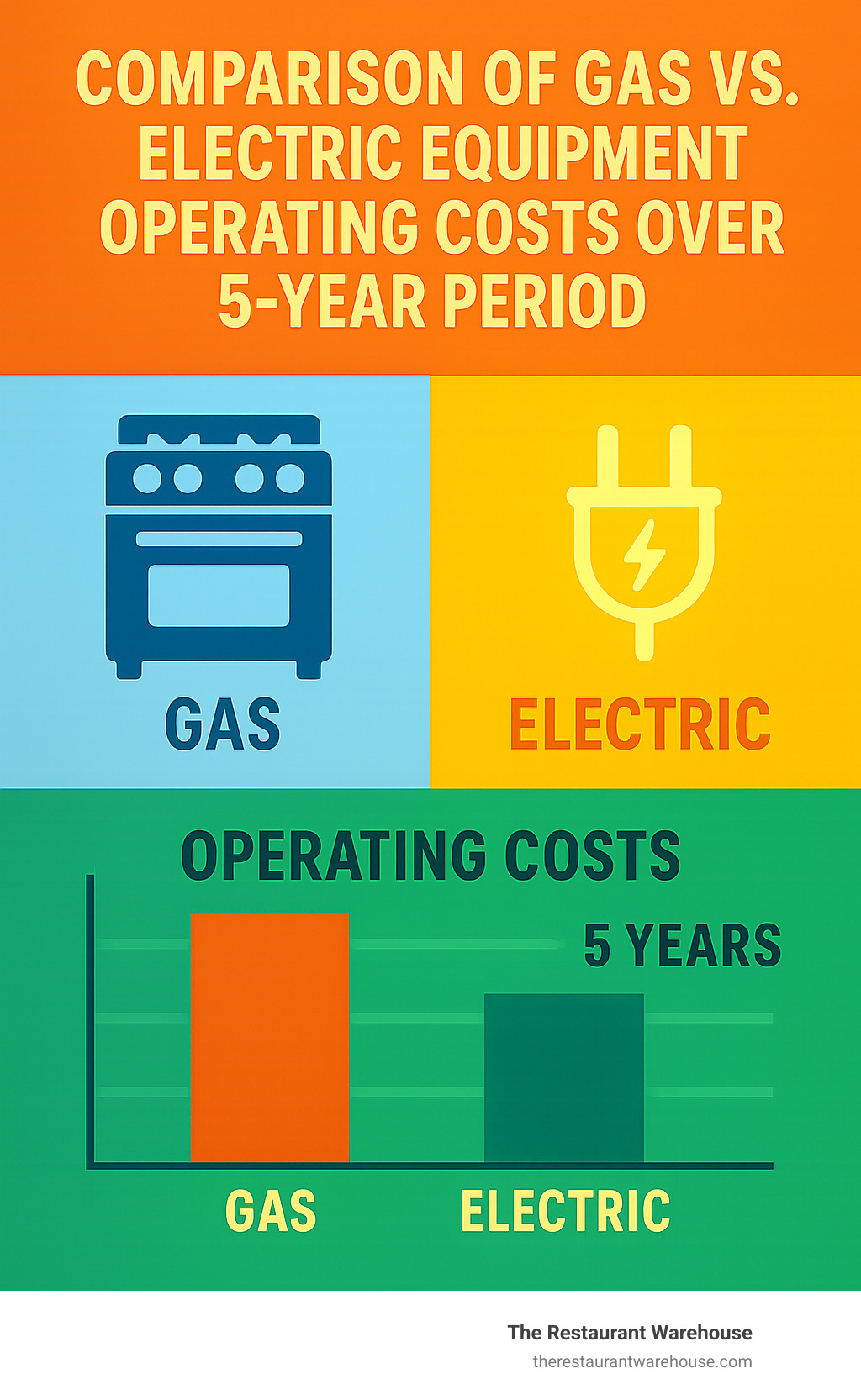

Smart kitchen operators also pay attention to energy efficiency. ENERGY STAR® certified equipment might cost slightly more upfront but can reduce consumption by up to 30%—savings that add up dramatically over the equipment's lifetime.

Smart & Sustainable Innovations

Today's heavy duty kitchen equipment isn't just powerful—it's smarter and more sustainable than ever before.

ENERGY STAR® certified equipment delivers the performance professional kitchens demand while significantly reducing utility bills. These high-efficiency burners and motors maintain cooking power while using up to 30% less energy than standard models—a difference you'll notice every month when the bills arrive.

IoT temperature monitoring has revolutionized food safety management. Connected refrigeration and cooking equipment provides real-time temperature data and sends alerts directly to your phone when something's amiss. Beyond convenience, these systems automatically document HACCP compliance, saving you paperwork headaches during inspections.

Many chefs are finding the advantages of induction technology in professional kitchens. Modern induction ranges and griddles deliver incredibly precise temperature control with up to 90% energy efficiency compared to traditional gas or electric. As a bonus, they generate far less ambient heat, making your kitchen a more comfortable place to work during those long summer shifts.

Heat recovery systems in advanced dishwashers capture what would otherwise be wasted heat from exhaust and use it to preheat incoming water. This clever design can reduce energy consumption by up to 25% while maintaining spotless results. Similarly, low-flow rinse arms maintain cleaning power while cutting water usage by as much as half—savings that add up quickly in high-volume operations.

According to research on green kitchen technologies, these sustainable innovations deliver meaningful environmental benefits and significant cost savings over the equipment's lifespan. At The Restaurant Warehouse, we've seen operators reduce their utility bills by thousands annually just by making smarter equipment choices.

The best part? Today's eco-friendly equipment performs as well or better than traditional models, proving you don't have to choose between sustainability and performance in your kitchen.

Expert Buying Guide & Financing Roadmap

Ready to invest in heavy duty kitchen equipment but feeling overwhelmed by the options? Don't worry—we've helped hundreds of restaurant owners make smart equipment decisions that align with their unique needs and budgets.

The key to smart equipment purchasing starts with understanding your operation inside and out. Begin with a thorough menu analysis—different cuisines demand specialized tools. If you're running a Chinese restaurant, you'll need those high-powered wok stations with 100,000+ BTU output. Pizza shops require stone deck ovens that maintain consistent temperatures for that perfect crust.

Next, be honest about your volume. We've seen too many restaurants struggle with undersized equipment during rush periods, creating frustrating bottlenecks that slow service and irritate customers. On the flip side, buying oversized units just wastes your hard-earned money and valuable kitchen space.

"The biggest mistake I see is restaurants not measuring their space properly," says one of our equipment specialists. Take time to create a scaled layout that accounts for ventilation requirements and workflow patterns. Your staff will thank you when they're not bumping into each other during busy service!

Don't forget about code compliance—local health departments, fire marshals, and building inspectors all have requirements your equipment must meet. This isn't just bureaucratic red tape; these regulations ensure your kitchen is safe for your team and customers.

When comparing equipment, look beyond the price tag to warranty terms. Those extra years of coverage from premium manufacturers can save you thousands in repair costs down the road. Quality heavy duty kitchen equipment also holds its value better, which matters when you're ready to upgrade or sell.

Match Equipment to Menu & Footprint

Your menu is the blueprint for your equipment needs. Every cuisine has its specialized tools that can make or break your kitchen's efficiency.

For Asian cuisine, invest in those high-BTU wok ranges with water-cooling systems that handle intense stir-frying without overheating. BBQ restaurants need commercial smokers with precise temperature control and proper wood chip systems for that authentic flavor. Bakeries thrive with convection ovens featuring steam injection capabilities for perfect breads and pastries.

Fast-casual concepts benefit enormously from rapid-cook combination ovens that can reduce cooking times by up to 80%—a game-changer when customers expect quality food in minutes. These specialized pieces aren't luxuries; they're essential tools that help deliver your menu consistently.

Kitchen footprint matters just as much as menu. A cramped kitchen with the wrong equipment layout creates unnecessary stress and inefficiency. We've seen dramatic productivity improvements when restaurants match their equipment configuration to their available space and workflow needs.

For more detailed guidance on selecting cooking equipment matched to your specific requirements, check out our commercial gas range guide. It breaks down exactly what features matter most for different cooking styles.

Pay Once or Lease?

The age-old question: should you buy your heavy duty kitchen equipment outright or lease it? Both approaches have their merits, and the right choice depends on your specific situation.

Buying equipment outright gives you full ownership with no ongoing payments. You'll also potentially benefit from tax advantages like depreciation. The downside? It requires a substantial upfront investment and places maintenance responsibility squarely on your shoulders.

Leasing, on the other hand, lets you get up and running with lower initial costs. Many leases include maintenance packages, removing that headache from your plate. Leasing also makes upgrading easier when newer technology becomes available. The trade-off is a higher total cost over time and being locked into contractual obligations.

Here's something many restaurant owners don't know about: Section 179 tax benefits. This handy tax code allows businesses to deduct the full purchase price of qualifying equipment bought or financed during the tax year—up to $1,080,000 for 2022. That's a significant potential savings worth discussing with your accountant.

Smart restaurant owners also map payment structures to their cash flow patterns. If your business is seasonal, look for financing options with customized payment schedules that align with your busy periods.

For a deeper dive into all your financing options, including detailed comparisons of lease types and qualification requirements, visit our restaurant equipment leasing guide. We've helped hundreds of restaurant owners find financing solutions that keep their kitchens running without breaking the bank.

Maintenance, Compliance & Safety

Keeping your heavy duty kitchen equipment in top condition isn't just about protecting your investment—it's about ensuring your kitchen runs smoothly day after day. Think of maintenance as preventive medicine for your kitchen's workhorses.

Your maintenance schedule should follow a natural rhythm that aligns with your operation's pace. Daily wipe-downs are your first line of defense—a quick but thorough cleaning of surfaces and removable parts after each shift keeps food particles from building up and causing problems later. Most food-contact components in modern equipment are dishwasher-safe, making end-of-day sanitization a breeze.

When the calendar flips to a new month, it's time for more thorough attention. Monthly deliming of water-using equipment prevents mineral buildup that can silently kill efficiency and drive up energy costs. This is also the perfect time to deep clean those hard-to-reach areas and check that temperature-critical units are still perfectly calibrated. Professional-grade descaling solutions are worth every penny here—they maintain heating efficiency without damaging delicate components.

The quarterly rhythm brings more substantial care requirements. Gasket replacements for any showing signs of wear, servicing ventilation components, and comprehensive safety inspections should all be on your checklist. Be sure to document these procedures—your friendly neighborhood health inspector will appreciate your diligence, and your future self will thank you when warranty questions arise.

Once a year, it's time to bring in the pros. Scheduling manufacturer-certified technicians for preventive maintenance pays dividends in equipment longevity. These trained eyes will adjust burners for optimal performance, service complex refrigeration systems, and provide safety certifications that keep you compliant with regulations.

Well-maintained heavy duty kitchen equipment doesn't just last longer—it operates more efficiently every day, reducing utility costs while maintaining consistent food quality that keeps customers coming back.

Preventive Care Checklist

Creating a simple maintenance routine can add years to your equipment's life and prevent those heart-stopping breakdowns during your busiest service times.

Your moving parts need love too—apply food-grade lubricant monthly to mixer gears, slicer rails, and other mechanical components to prevent metal-on-metal wear. Temperature control calibration should happen quarterly using certified thermometers; even small deviations can affect food quality and safety.

Weekly electrical component inspections are non-negotiable safety measures—damaged cords, plugs, or connections can create fire hazards or equipment failures at the worst possible moment. Document everything in your maintenance logs, which serve double duty for warranty validation and health inspections.

Perhaps most importantly, invest time in staff training. Even the best equipment can be damaged by improper use. When everyone understands proper operation and daily cleaning procedures, your maintenance needs decrease dramatically. As one chef told me, "I'd rather spend an hour training my team than a day waiting for repairs."

Staying Audit-Ready

The alphabet soup of regulations (HACCP, OSHA, NSF, UL) doesn't have to give you heartburn if you stay ahead of compliance requirements.

Your HACCP records should include temperature logs for refrigeration and cooking equipment that demonstrate your commitment to food safety. These simple documents can be the difference between sailing through an inspection and facing citations or closures.

Sanitation documentation showing regular cleaning schedules and proper chemical usage isn't just paperwork—it's protection for your business and customers. Similarly, scheduling required fire suppression inspections every six months ensures your emergency systems will work when needed most.

Don't overlook OSHA compliance requirements for proper safety guards, emergency procedures, and employee training. These measures protect both your team and your business from preventable accidents and liabilities.

At The Restaurant Warehouse, we understand that compliance can feel overwhelming. That's why we help our customers develop streamlined systems that satisfy regulatory requirements without creating mountains of paperwork. After all, you got into the restaurant business to create amazing food experiences, not to become a full-time record keeper.

Frequently Asked Questions About Heavy Duty Kitchen Equipment

What's the typical lifespan of a heavy-duty range?

When customers ask me about longevity, I always tell them that a well-maintained heavy duty kitchen equipment range can be your faithful kitchen companion for 10-15 years. Think of it as a relationship that needs care to flourish!

The lifespan really comes down to four key factors. First, construction quality makes an enormous difference—those fully stainless steel models with reinforced frames simply stand up better to daily abuse. Second, how well you treat it matters—regular cleaning and professional service visits are like health check-ups for your equipment. Third, consider your usage patterns—a range working double shifts daily will naturally age faster than one used for single-service operations. Finally, your kitchen environment plays a role—kitchens heavy with grease and high humidity can accelerate wear on even the best components.

While many of our Restaurant Warehouse customers proudly tell us stories of their equipment lasting 15+ years, I generally recommend budgeting for replacement after 8-10 years. It's always better to be pleasantly surprised by extra years of service than caught off-guard by an unexpected failure during your busiest service!

How do I size ventilation hoods correctly?

Ventilation hood sizing is both an art and a science—and getting it wrong can lead to uncomfortable working conditions, code violations, or even fire hazards.

Your hood should extend beyond your equipment footprint by 6-12 inches on all exposed sides—think of it as creating a "capture zone" for heat and smoke. The equipment underneath matters tremendously; grease-producing workhorses like fryers and griddles need more powerful ventilation than gentler equipment. Your ceiling height also affects the equation, as higher ceilings often require increased CFM (cubic feet per minute) ratings to effectively capture rising heat.

Local codes can be quite specific about ventilation requirements, so always check with authorities before finalizing your design. As a general rule, you'll need Type I hoods with fire suppression systems over cooking equipment, while Type II hoods usually suffice for dishwashing stations and some baking operations.

When in doubt, it's better to go slightly oversized than undersized. A properly sized hood should quietly and efficiently capture all heat and effluent rising from below, keeping your kitchen comfortable and your staff happy.

Can I use heavy duty gear in a high-end home kitchen?

Yes, you absolutely can—and many serious home chefs do—but there are some important realities to consider before taking the plunge.

Heavy duty kitchen equipment often has different utility requirements than your standard home appliances. Many commercial units need 220V power connections, higher gas pressure inputs, or water volumes that might exceed typical residential specifications. Your kitchen might need significant electrical or plumbing upgrades to accommodate these beasts.

Ventilation becomes critically important too. Professional equipment generates substantially more heat and cooking effluent than residential models, potentially requiring commercial-grade ventilation systems that might be challenging to retrofit into a home setting.

Space constraints are another consideration—commercial equipment typically has larger footprints and might not play nicely with standard residential kitchen dimensions. And be aware that some manufacturers explicitly void warranties when their commercial equipment is installed in residential settings.

For most serious home chefs, I recommend looking at what we call "bridge" equipment—commercial-grade units specifically designed for residential use. These give you much of the performance of true heavy duty kitchen equipment while working within the practical constraints of a home kitchen. At The Restaurant Warehouse, we're always happy to help you steer these options to find the perfect balance for your culinary ambitions.

Conclusion

Choosing the right heavy duty kitchen equipment isn't just a purchase—it's an investment in your restaurant's future. When you select equipment that truly matches your operation's needs, you're building a foundation for success that will support your business for years to come.

Throughout my years working with restaurant owners, I've seen how quality equipment transforms kitchens from chaotic to efficient. The right tools don't just make cooking easier—they improve food consistency, speed up service, and ultimately improve your customers' experience.

Think of your kitchen equipment as team members that never call in sick. They show up every day, ready to perform at peak capacity, as long as you treat them right. That's why looking beyond the price tag to consider the total value over time is so important. A range that costs 20% more but lasts twice as long is actually the better deal in the long run.

Heavy duty kitchen equipment that's properly sized for your operation creates a ripple effect of benefits:

- Your staff works more efficiently with reliable tools

- Food quality remains consistent during rush periods

- Energy bills stay lower with modern, efficient appliances

- Maintenance costs decrease with quality construction

- Your kitchen can handle growth without immediate upgrades

At The Restaurant Warehouse, we've built our business on helping restaurants find that sweet spot where quality and value meet. We've eliminated the traditional markups and overhead that drive up equipment prices, allowing you to invest in better-quality gear without blowing your budget.

Whether you're opening your first restaurant or upgrading your fifth location, our comprehensive commercial kitchen equipment guide walks you through the entire process of outfitting a kitchen that works as hard as you do.

The true measure of value isn't what you pay on day one—it's what that equipment delivers over thousands of service hours. By choosing the right heavy duty kitchen equipment from the start, you're setting your kitchen up for years of reliable performance, consistent food quality, and the operational efficiency that separates thriving restaurants from struggling ones.

Your kitchen is the heart of your restaurant. Make sure it beats strong with equipment built to last.

About The Author

Sean Kearney

Sean Kearney is the Founder of The Restaurant Warehouse, with 15 years of experience in the restaurant equipment industry and more than 30 years in ecommerce, beginning with Amazon.com. As an equipment distributor and supplier, Sean helps restaurant owners make confident purchasing decisions through clear pricing, practical guidance, and a more transparent online buying experience.

Connect with Sean on LinkedIn, Instagram, YouTube, or Facebook.

Leave a comment