Decoding Your Ice Machine Repair Cost

When your ice machine suddenly goes quiet, the first thing on your mind is usually, "How much is this going to cost me?" It’s a fair question. Knowing the potential expense helps you budget and figure out if a repair is even worth it.

While every ice machine hiccup is a little different, most problems fall into a few common categories, each with a somewhat predictable price range.

For most residential units, the average repair cost hovers somewhere between $70 and $400. The final bill really comes down to which specific part decided to call it quits. Commercial units, on the other hand, are a whole different ballgame—their complexity and the need for specialized technicians can drive costs up significantly.

Breaking Down Average Repair Costs

Minor fixes can be on the lower end, but more serious issues will obviously cost more. A simple water inlet valve, for example, might run you between $90 and $225. But if you’re looking at a busted motor, that cost can jump to anywhere from **$200 to $400. If you're weighing your options, it's helpful to explore the full cost breakdown to see how different repairs stack up.

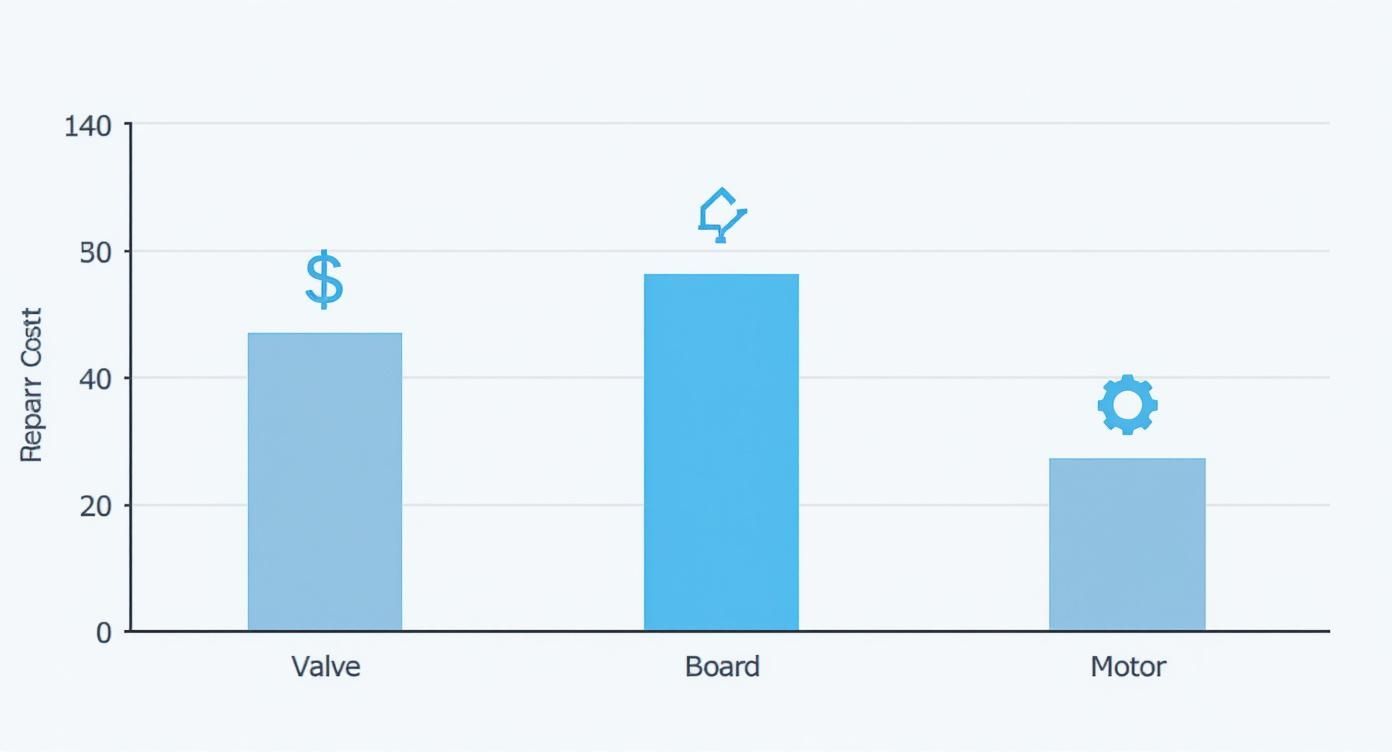

This infographic gives you a quick visual on the cost ranges for some of the most frequent ice machine failures, covering everything from valves to motors.

As you can see, a motor or control board replacement is a much bigger financial commitment than fixing a leaky valve.

Common Problems and Their Price Tags

To give you a clearer picture, let's look at what you can generally expect to pay for the most common failures in a residential setting. Think of this table as a quick reference guide to help you budget for a service call.

A faulty control board or a failed motor are often the priciest repairs. Their costs can sometimes approach half the price of a brand-new machine, making the repair-versus-replace decision much more critical.

Estimated Costs for Common Ice Machine Repairs

| Common Repair Issue | Average Cost Range (Residential) | What Typically Causes This |

|---|---|---|

| Water Inlet Valve Replacement | $90 – $225 | Mineral buildup from hard water or simple wear and tear over time. |

| Faulty Control Board | $150 – $300 | Power surges, moisture damage, or electronic component failure. |

| Broken Motor or Gears | $120 – $400 | Overworking, lack of lubrication, or natural aging of mechanical parts. |

| Ice Mold or Tray Replacement | $80 – $150 | Cracks from freezing/thawing cycles or mineral scale buildup. |

Keep in mind these are just estimates, but they give you a solid starting point for what to expect when you pick up the phone to call a technician.

Key Factors Driving Your Final Repair Bill

Ever get a repair quote and wonder why a seemingly simple fix on one ice machine costs twice as much as you expected? Your final repair bill isn't just some random number a technician pulls out of thin air; it’s a total calculated from a few key, interconnected factors. Once you understand what they are, you can read any quote with confidence and know exactly where your money is going.

Think of it like getting your car fixed. A tune-up on a standard family sedan is usually pretty straightforward and affordable. But if you’re repairing a high-performance luxury car? You're dealing with specialized parts and expert labor, which naturally drives the price way up. The exact same principle applies to ice machines.

The Type of Machine Matters Most

The single biggest variable influencing your bill is the kind of ice machine you own. It’s simple: a quick fix on a small, portable countertop unit is almost always going to be cheaper than tackling a problem in a high-capacity commercial beast.

Here’s a quick look at how different machine types stack up:

- Portable Ice Makers: These are the least expensive to repair. Their design is simple and parts are generally easy to find. That said, their low initial price often means it's more practical to just replace the whole unit rather than fix it.

- Freezer Add-On Units: You'll find these in many residential refrigerators. Repairs are usually moderately priced, but the real wild card is labor time—sometimes just getting to the unit inside the freezer can be a tricky process.

- Under-Counter and Commercial Models: These are the most complex machines, and as you'd guess, the most expensive to fix. They have intricate systems, are built to produce huge volumes of ice, and absolutely require a technician with specialized knowledge. If you think you have a problem, running through some initial troubleshooting tips for commercial ice machines can help you narrow down the issue before you even make the call.

Brand Complexity and Parts Availability

Just like with cars, some ice machine brands are more complex or use proprietary parts that are tougher to get your hands on. A technician working on a common, mass-market brand can probably find a replacement part quickly and at a decent price.

But if you own a high-end or less common brand, things can get complicated. The tech might have to special-order a component directly from the manufacturer, leading to higher part costs and longer wait times. A part's availability can easily turn a $150 repair into a $300+ headache.

The rule of thumb is simple: the more specialized the machine and its components, the more you can expect to pay for both the parts and the expertise needed to install them correctly.

This trend is playing out across the entire industry. The global ice maker market is growing fast—valued at around $3.02 billion in 2024 and projected to hit $3.82 billion by 2032. This growth means more advanced, integrated models are hitting the market, and their complex, costly components are naturally pushing repair expenses up for everyone.

Your Local Labor Rates

Finally, a factor that has nothing to do with your machine: where you live. Labor rates for skilled technicians can vary wildly from one region to another. A service call in a major city with a high cost of living is going to be more expensive than the same job in a small town.

Most technicians charge a flat diagnostic fee to show up and identify the problem, plus an hourly rate for the actual repair work. Because of this, local economic factors have a direct and significant impact on the labor portion of your final bill.

Residential vs. Commercial Repair Cost Differences

Trying to compare the repair costs for a home ice machine versus a commercial one is like comparing the upkeep on a family sedan to a commercial delivery truck. Sure, they both have engines and get you from point A to point B, but the truck’s parts are bigger, built tougher, and are a whole lot more expensive to fix. The same exact logic applies when your business’s ice machine goes down.

The gap starts with the machine’s design and purpose. A residential ice maker is built for convenience, kicking out a modest amount of ice using fairly simple parts. A commercial unit, on the other hand, is an absolute workhorse. It's engineered with heavy-duty compressors, complex control boards, and beefy water systems designed to run constantly and churn out huge volumes of ice.

Why Commercial Repairs Cost More

This fundamental difference in construction and capability has a direct impact on the final repair bill. A few key factors are responsible for the higher price tag that businesses face:

- Component Costs: Parts for commercial machines are industrial-grade, plain and simple. They’re built to take a beating, which makes them way more expensive than their residential cousins. A new compressor for a restaurant's ice machine can easily run several hundred dollars more than one for a standard home unit.

- Specialized Expertise: You can't just call any handyman to fix a commercial ice machine. Servicing these units requires a technician with specific training in complex refrigeration cycles and advanced electronics, and that specialized labor comes at a higher rate.

- Urgency and Downtime: For a business, a broken ice machine isn't just an annoyance—it's a critical failure. It can shut down drink service, affect food prep, and lead to lost revenue. That urgency often means paying a premium for priority or after-hours service, bumping up the total cost.

You see a similar pattern in other commercial services. For example, when you look at understanding commercial air duct cleaning costs, the scale of the job, the complexity of the system, and the specialized equipment needed are what drive the price up, just like with ice machines.

Let's put the repair costs into perspective by looking at the key differences side-by-side.

Comparing Home and Business Ice Machine Repairs

The table below breaks down the major distinctions between repairing a residential ice machine and its commercial counterpart. It highlights how factors like part costs, technician skill, and the impact of downtime create two very different scenarios for owners.

| Factor | Residential Ice Machines | Commercial Ice Machines |

|---|---|---|

| Average Repair Cost | Lower, typically $150 - $400 | Higher, often $400 - $1,500+ |

| Component Costs | Relatively inexpensive, mass-produced parts | Industrial-grade, durable, and significantly more expensive parts |

| Technician Skill Level | General appliance repair technician often sufficient | Requires a certified technician with specialized refrigeration knowledge |

| Complexity of Systems | Simple mechanics, fewer electronic components | Complex refrigeration cycles, advanced control boards, and water systems |

| Impact of Downtime | Inconvenience for the household | Direct financial loss, operational disruption, potential health code issues |

| Urgency of Repair | Low to moderate, can often wait a few days | High to critical, often requires same-day or emergency service |

As you can see, everything from the price of a single part to the urgency of the situation is amplified in a commercial setting, leading to a much higher overall repair expense.

The True Cost of Commercial Ownership

For any business owner, the sticker price of a new ice machine is just the tip of the iceberg. The real expenses pile up over the machine’s lifespan through maintenance and repairs.

In fact, while a new commercial unit might set you back between $5,000 and $10,000, the lifetime costs of repairs and upkeep can account for a staggering 80% of the total ownership expense. Data from 2021 showed the average commercial repair cost was around $708.44, with some fixes soaring as high as $2,000. You can dive into more details on the true cost of ice machine ownership to get a better handle on budgeting.

This brings up a critical point for any business owner: proactive maintenance isn't just a good idea; it's a core financial strategy. Investing in regular service is how you prevent the eye-watering emergency repair bills that can cripple both your workflow and your budget.

Deciding Between Repairing and Replacing Your Unit

When your ice machine suddenly gives up, you're hit with a classic dilemma that can really impact your budget: do you pay for a repair, or is it time to bite the bullet and buy a new one? Making the right call here is crucial. The last thing you want is to sink good money into a machine that's already on its last legs.

A fantastic rule of thumb to start with is the 50% Rule. It's a simple, practical guideline that works for all kinds of appliances. Here's how it works: if the repair quote is more than 50% of what it would cost to buy a brand-new, comparable machine, replacement is almost always the smarter financial move.

Let's say you get a $400 repair estimate for a residential ice maker that you could replace for $600. You’re already way over that 50% mark. In that case, putting that $400 toward a new, more efficient unit with a fresh warranty just makes more sense.

Look Beyond the Initial Cost

While the 50% Rule is a great starting point, the numbers don't tell the whole story. Several other factors play a huge role in figuring out whether a repair is a wise investment or just slapping a bandage on a much bigger problem.

Before you give a technician the green light, take a step back and think about the machine's history and overall health.

-

The Age of Your Machine: Most ice machines have a lifespan of about 5 to 10 years, depending on the model and how well you've maintained it. If your unit is already getting up there in age, a major repair might just be buying you a little extra time before the next part fails.

-

Frequency of Past Repairs: Is this the first time your machine has acted up, or do you and the repair tech know each other by name? A machine that needs constant attention is a money pit, plain and simple. Those recurring breakdowns are a clear sign that it's time to start looking for a replacement.

Weighing Efficiency and Future Value

Another key piece of the puzzle is energy efficiency. Technology gets better every year, and a new ice machine is almost guaranteed to be more energy-efficient than a model that’s several years old. Your old, patched-up unit might keep running, but it could be quietly costing you more on your monthly utility bills.

The money saved on energy costs with a new, ENERGY STAR-rated model can sometimes offset a significant portion of the purchase price over time. You're not just buying a new appliance; you're investing in lower long-term operating expenses.

Ultimately, the decision boils down to value. Are you paying to bring a reliable machine back to its former glory, or are you just delaying the inevitable? By combining the 50% Rule with an honest look at your machine’s age, repair history, and efficiency, you can make a confident choice.

If you decide that replacement is the best path forward, exploring a quality commercial ice machine from a trusted supplier is the next step to ensure you get a durable, efficient unit that meets your needs.

How to Lower Your Ice Machine Repair Costs

The single best way to manage a high ice machine repair cost is to stop problems before they even have a chance to start. Seriously. Think of your ice machine like you would your car; small, regular tune-ups are always going to be way cheaper than a complete engine overhaul down the road.

This isn't just about dodging a single repair bill. It's about shifting your mindset from reacting to expensive breakdowns to actively preventing them. So many of the most common failures—I'm talking clogged water lines, overworked compressors, you name it—are the direct result of neglecting basic upkeep. A little bit of time now saves a whole lot of headache later.

Embrace Proactive DIY Maintenance

You absolutely do not need to be a certified technician to handle the essential tasks that keep your ice machine humming along. A simple, consistent routine can prevent up to 70% of common equipment failures. These small actions make a massive difference.

Here are a few high-impact tasks anyone on your team can handle:

- Routine Cleaning: Regularly wipe down the inside and outside of the machine. This simple step prevents the buildup of mold and slime, which not only keeps your ice sanitary but also stops internal parts from getting all gummed up.

- Change the Water Filter: A clogged filter is a classic problem. It restricts water flow, forcing the machine to work harder and spit out small, poor-quality ice. Sticking to the manufacturer’s schedule (usually every six months) is one of the easiest ways to protect your investment.

- Keep Condenser Coils Clean: Think of the coils as the machine's radiator. If they're caked in dust and grease, the unit can't cool itself effectively. A quick brushing every few months is all it takes to help prevent the compressor from overheating—a notoriously expensive repair.

For a more detailed walkthrough, our guide on Atosa ice machine maintenance provides step-by-step instructions that you can apply to many different models.

Investing in prevention is always more affordable than reacting to a crisis. An hour of cleaning every month can easily save you from a $500+ emergency service call.

Simple Troubleshooting Before You Call

Sometimes, what looks like a major disaster has a surprisingly simple fix. Before you pick up the phone and commit to a diagnostic fee, run through a quick troubleshooting checklist. You might just solve the problem yourself.

If your machine suddenly stops working, check these common culprits first:

- Check the Power Supply: Is the machine plugged in all the way? Did a circuit breaker get tripped? It sounds almost too obvious, but you'd be surprised how often this is the issue.

- Inspect the Water Line: Make sure the water supply valve is fully open and the line isn’t kinked or frozen somewhere. No water in, no ice out.

- Confirm the Room Temperature: Is the area around the machine too hot or too cold? Ice machines are designed to operate within a specific temperature range, and extreme conditions can really mess with their performance.

By running through these simple checks, you can often pinpoint and fix the issue without ever having to worry about an ice machine repair cost. It’s this proactive mindset that truly helps you get the most out of your equipment.

Finding a Qualified Repair Professional

Choosing the right technician is single-handedly the most important decision you'll make when it comes to managing your ice machine repair cost. Hiring someone who's not up to the task can lead to wrong diagnoses, multiple return visits, and even more damage. Before you know it, a manageable expense has snowballed into a major financial headache.

Think of it like hiring a mechanic for a specialized European car—you wouldn’t trust just any generalist with it, and the same logic absolutely applies here. Your goal is to find a pro with proven, specific expertise.

Look for technicians who are factory-trained for your particular ice machine brand. These folks understand its unique quirks and, just as importantly, have access to the right parts. Also, make sure they hold the proper certifications for handling refrigerants. This isn't just a sign of competence; it's a legal requirement.

When you're searching for a reputable company, it’s smart to be aware of the common red flags. These tips for avoiding service scams can help you make sure you're hiring a trustworthy provider.

Questions to Ask Before You Hire

Before you commit to anything, arm yourself with a few key questions to vet any potential technician. How they answer will tell you a lot about their professionalism and how they structure their pricing.

A transparent technician will have no problem giving you straight answers about their fees, warranties, and process. If you get vague responses or feel pressured to commit on the spot, those are serious red flags.

Come to the conversation prepared with this checklist:

- What is your diagnostic fee? Most professionals charge a flat fee just to come out and figure out what’s wrong. You need to know this cost upfront.

- Do you offer a warranty? Ask about the warranty on both the parts they install and the labor they perform. A 90-day warranty is a solid industry standard to look for.

- Can you provide a written estimate? Never, ever move forward with a repair based on a verbal quote alone. A written estimate locks in the price and protects you from surprises later.

- Is this fee applied to the final repair cost? Many great companies will waive or credit the diagnostic fee if you decide to go ahead with their recommended repair. It's a great question to ask.

Got Questions About Ice Machine Repair? We've Got Answers

Even after breaking down the costs, you probably still have a few questions floating around. That's perfectly normal. Let's tackle some of the most common things people ask about ice machine repairs to make sure you have all the information you need.

How Long Does a Typical Ice Machine Repair Take?

For most common fixes in a home setting, like swapping out a water inlet valve or a bad thermostat, a good technician can usually get it done in about one to two hours. They can typically figure out the problem and replace the part in a single visit.

Of course, more serious jobs—like replacing a compressor—are a different story and will take quite a bit longer. When it comes to commercial ice machines, technicians know that time is money, so they work as fast as possible to get you back up and running. Still, the repair time will always come down to how complex the problem is and whether they need to special-order a part.

Is It Worth Fixing a Cheap Portable Ice Maker?

Honestly, in almost every case, the answer is no. Pouring money into repairing a cheap portable ice maker just doesn't make financial sense. These little countertop units usually cost between $100 and $200 brand new.

Once the repair bill starts creeping up toward the cost of a new machine, you're much better off just buying a replacement. You get a fresh-out-of-the-box appliance with a full warranty, which is a much smarter way to spend your money.

For these smaller, portable models, replacing them is almost always the more practical and economical path to take.

Why Is My Ice Machine Making Small or Hollow Cubes?

Small or hollow ice cubes are a classic sign that your machine is having trouble with its water supply. Before you start bracing for a big repair bill, there are a few simple things you can check yourself.

More often than not, the culprit is one of these:

- A clogged water filter that's slowing down the flow.

- Low water pressure coming into the machine.

- A water line that's gotten kinked or has frozen up.

Start by replacing the water filter and making sure the supply line is straight and clear. If those simple fixes don't do the trick, the problem is likely a failing water inlet valve, and that’s a job for a professional technician.

For all your commercial kitchen needs, from durable ice machines to essential cooking equipment, trust The Restaurant Warehouse to deliver quality products at competitive prices. Equip your business for success by visiting us at https://therestaurantwarehouse.com.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment