Top Commercial Ice Machine Buying Guide | Find Your Perfect Model

A commercial ice machine is one of those pieces of equipment you don't think about until it stops working—usually during a critical dinner rush. It's an absolute workhorse for any foodservice or hospitality business, designed to pump out large quantities of ice, day in and day out. But here's the secret: choosing the right one is less about the machine itself and more about matching its capabilities to the real-world needs of your operation.

How to Choose a Commercial Ice Machine

Picking a commercial ice machine can feel like a high-stakes decision, and in many ways, it is. This is a strategic investment that directly impacts your daily success. Think of it like choosing a delivery vehicle for your business; a cozy café serving a few dozen iced lattes a day doesn't need the same semi-truck-sized capacity as a large hotel catering to hundreds of guests. The "best" machine is simply the one that fits your unique requirements like a glove.

This guide is here to simplify the process by focusing on the core factors that truly matter. We'll explore the essential decision points to help you find the perfect match for your establishment, whether you run a bustling bar, a healthcare facility, or a quick-service restaurant.

Understanding the Core Decision Factors

Making a smart choice comes down to balancing four key elements. Each one plays a distinct role in ensuring you have a reliable supply of high-quality ice without overspending on a unit that’s total overkill for your needs. Before you buy a commercial ice machine, it's vital to think through each of these aspects carefully.

Here are the key factors to evaluate:

- Ice Type: The shape and size of the ice, which affects everything from drink dilution and presentation to how much liquid a cup can hold.

- Production Capacity: The amount of ice the machine can produce in a 24-hour period. This must be enough to cover your busiest rush.

- Condenser Technology: The cooling system—air, water, or remote—which dictates energy use, noise level, and where you can install the machine.

- Storage and Footprint: The size of the storage bin and the physical space the machine will take up in your kitchen or service area.

The right commercial ice machine does more than just make ice; it supports operational efficiency, enhances product quality, and ensures you never run out during a critical rush. It’s a foundational tool for success.

A Growing and Essential Market

The demand for dependable ice production is only getting stronger, and the market trends reflect that. The global commercial ice machine market, currently valued at around USD 5.3 billion, shows steady growth driven by the hospitality, foodservice, and healthcare sectors. It’s projected to climb to roughly USD 7.4 billion by 2033, which just goes to show how essential this equipment continues to be.

To help you get started, the table below provides a quick snapshot of the different types of machines we'll be covering. Think of it as a roadmap for the more detailed information that follows.

Quick Guide to Ice Machine Types

This table summarizes the most common ice machine types and the business environments where they shine.

| Machine Type | Primary Use Case | Key Benefit |

|---|---|---|

| Modular Ice Machine | High-volume restaurants, hotels, bars | Customizable production and storage |

| Undercounter Ice Machine | Small cafes, office breakrooms, bars | Space-saving and convenient placement |

| Countertop Ice Dispenser | Healthcare facilities, self-serve stations | Sanitary dispensing and easy access |

| Ice/Water Dispenser | Lobbies, cafeterias, breakrooms | Provides both ice and water from one unit |

Understanding these basic categories is the first step toward finding a machine that fits seamlessly into your operations and keeps the ice flowing.

Finding the Right Ice Type for Your Business

Choosing a commercial ice machine isn't just about how much ice it can pump out; it's about the kind of ice it produces. Believe it or not, the shape, size, and even the texture of the ice you serve have a huge impact on drink quality, how your drinks look, and your operational costs. It’s the difference between a perfectly chilled cocktail that keeps its punch and a sad, watery soft drink that goes flat in minutes.

The best way to think about ice is as a key ingredient. Just like a great chef wouldn't use the wrong cut of meat or type of flour, you need to pick an ice that truly complements what you're serving. Get it right, and you elevate the entire customer experience. Get it wrong, and you can unintentionally drag down an otherwise fantastic product.

The Slow-Melting Power of Cube Ice

When you picture ice in a glass, you're almost certainly thinking of cube ice. It's the industry standard for a very good reason. Its solid shape and large surface area mean it melts nice and slow, delivering maximum cooling with minimum dilution. This makes it a non-negotiable for bars and restaurants where protecting the integrity of the beverage is everything.

You'll generally find cube ice in two main forms:

- Full Cube (or Dice Cube): This is the workhorse for high-end spirits and cocktails. Its classic, solid form looks fantastic in a glass and melts very slowly, chilling drinks without turning them into a watered-down mess. A fine whiskey on the rocks served with a single, crystal-clear full cube is a real statement of quality.

- Half Cube (or Half-Dice): Smaller and more versatile, the half-cube is the most popular choice for high-volume places like fast-food restaurants, convenience stores, and bustling bars. It packs tightly into glasses, displaces more liquid (making drinks look fuller), and is perfect for blended drinks since it breaks down easily.

For many businesses, keeping drinks from getting diluted is a top priority. It's why some high-end bars even explore options like chilling stones for drinks to manage this. This focus just underscores how critical it is to choose the right ice from your machine in the first place.

The Softer Side: Nugget and Flake Ice

Not every drink or situation calls for a hard, slow-melting cube. Sometimes, a softer, more chewable ice is the real star of the show. This is where nugget and flake ice machines come in, offering a completely different texture and a whole new set of uses.

Nugget ice, which you might know as "chewable ice" or "Sonic ice," is a massive customer favorite. It's made by compressing tiny flakes of ice together, creating a soft, porous pellet that soaks up the flavor of whatever beverage it's in.

This unique quality makes it the go-to for a bunch of different applications:

- Soft Drinks and Sodas: It cools drinks down fast and adds that fun, chewable texture that people absolutely love.

- Healthcare Facilities: For patients who need to stay hydrated, it's much easier to chew and swallow.

- Smoothie and Coffee Shops: Its soft texture is gentle on blender blades and helps create a perfectly smooth, consistent drink.

Flake ice, on the other hand, is made of small, soft, irregular-shaped ice chips. It has amazing packing and cooling properties, making it the top choice for displays where presentation and preservation are everything. You’ll see it being used in:

- Seafood Displays: It molds perfectly around fish and other seafood, keeping it fresh and looking great without bruising the delicate product.

- Produce Displays: It helps keep veggies crisp and hydrated in salad bars and grocery stores.

- Therapeutic Applications: Physical therapy clinics love it for ice packs because it conforms so well to the body.

Choosing Your Signature Ice

At the end of the day, the right ice type comes down to your business and what your customers expect. A high-end steakhouse will invest in a machine that makes crystal-clear gourmet or full-cube ice to elevate its cocktail program. In contrast, a quick-service drive-thru will build its entire beverage station around nugget ice to delight its soda-loving crowd.

By understanding the unique perks of each shape, you can confidently pick an ice type that doesn't just cool your drinks, but actually enhances your brand and keeps your customers coming back for more.

Figuring Out Your Daily Ice Production Needs

Choosing the right commercial ice machine is really a two-part puzzle. First, you need a machine that can churn out enough ice to get you through your absolute busiest day. Second, you need a bin that’s big enough to hold it all. Getting this balance right is the secret to a never-ending supply of fresh, clean ice.

I like to think of it like this: the ice machine (often called the "head" unit) is the factory, working tirelessly to make ice. The storage bin is its warehouse, holding onto the finished product until your staff or customers need it. A factory that makes more ice than the warehouse can hold is just creating waste, while a huge warehouse paired with a small factory will have a lot of empty, wasted space.

The goal is to match your production power to your real-world demand. This way, you can breeze through peak hours without having invested in a beast of a machine that’s overkill—and overly expensive—for your typical day.

Start with Industry Benchmarks

Before you start crunching numbers, it helps to have a solid starting point. Thankfully, the foodservice industry has some reliable rules of thumb for estimating how much ice a business typically goes through. These benchmarks give you a realistic baseline based on the type of operation you're running.

Here are a few common estimates to get you started:

- Restaurants: A good starting point is 1.5 pounds of ice per meal served. So, a restaurant that serves 200 guests on a busy night will need at least 300 pounds of ice.

- Bars and Cocktail Lounges: Here, drinks are the main event, so you’ll need more. Plan for about 3 pounds of ice per seat. A 50-seat bar should look for a machine that can produce 150 pounds daily just for serving drinks.

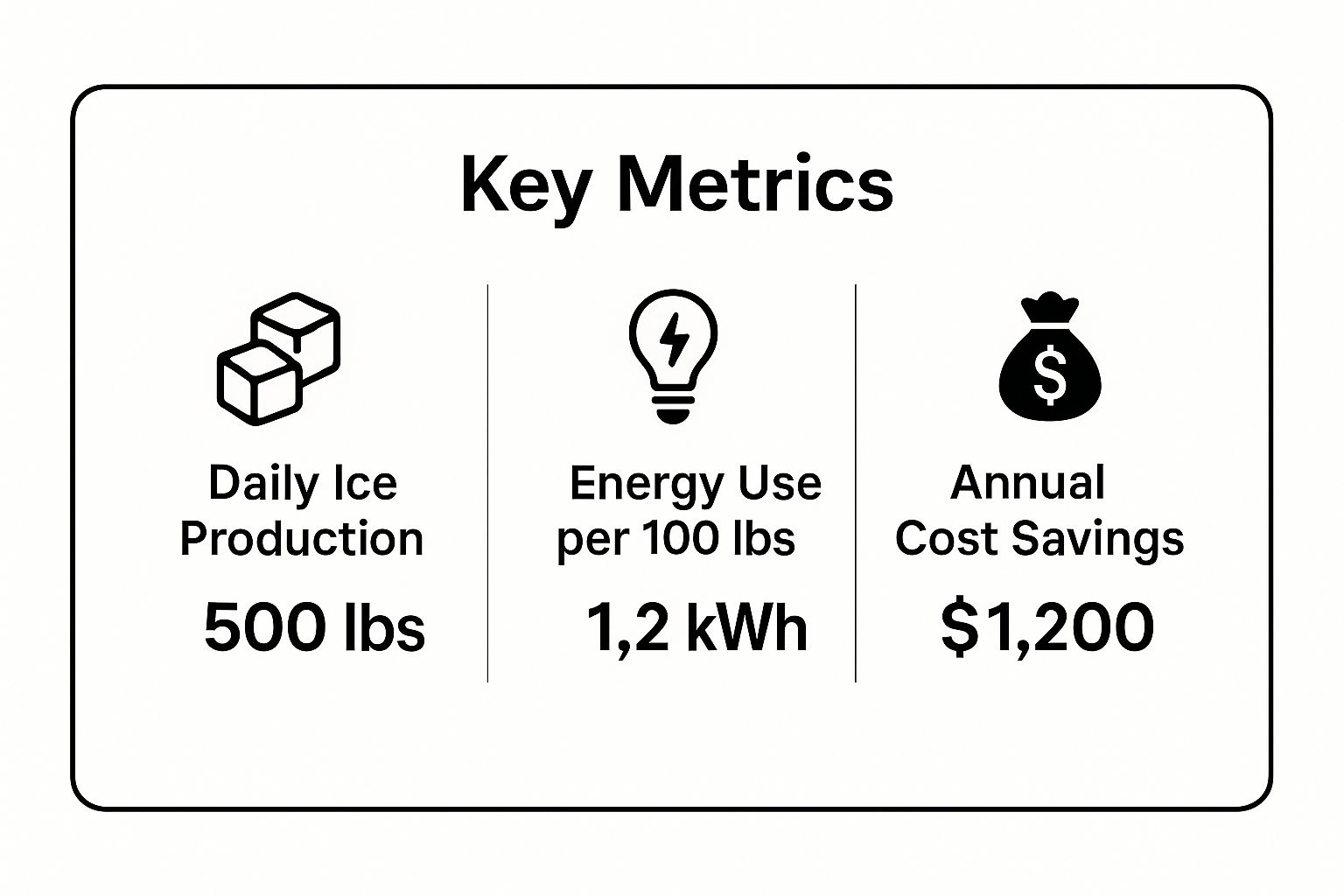

- Hotels: A solid estimate is 5 pounds of ice per room. A 100-room hotel will need a machine capable of pumping out 500 pounds of ice per day to keep guests happy.

- Healthcare Facilities: Plan for 10 pounds of ice per patient bed, which covers both drinking ice and therapeutic uses.

- Cafeterias & Self-Serve Stations: You can estimate about 1 pound of ice per person.

These figures are a fantastic foundation, but they are just a starting point. Now you need to adjust them to fit the unique realities of your business.

Refine Your Calculation for Real-World Use

Let's customize that baseline number. I want you to think about your busiest day of the entire year—maybe it’s a sweltering Saturday in August, a major holiday, or during a big local festival. That’s the number you need to plan for, not your quiet Tuesday average. Running out of ice during a peak service is a completely preventable disaster.

Consider these factors to fine-tune your estimate:

- Your Drink Menu: Do you serve a lot of fountain drinks? They use way more ice than bottled beverages. Blended or frozen cocktails are also serious ice consumers.

- Climate and Season: If your business is in a warmer climate, you’ll naturally go through more ice year-round. But every business should plan for at least a 20% bump in consumption during the hot summer months.

- Water Pitchers: If you offer table-side water service, you'll need a good amount of extra ice just to fill pitchers.

- Future Growth: Are you planning an expansion or expecting business to pick up? It’s far more cost-effective to buy a slightly larger machine now than to have to replace an undersized one in a year or two.

Key Takeaway: Always, always calculate for your peak demand, not your average day. Then, add a buffer of at least 20% to cover unexpected rushes, hot weather, and future growth. This simple step is the best insurance you can buy against running out of ice.

Putting It All Together: A Restaurant Example

Let's walk through a real-world calculation for a hypothetical 75-seat restaurant that also has a small bar area.

- Restaurant Seating (75 seats): 75 seats x 1.5 lbs of ice per guest = 112.5 lbs

- Bar Seating (10 seats): 10 seats x 3 lbs of ice per seat = 30 lbs

- Initial Total: 112.5 + 30 = 142.5 lbs

Now, let's add that crucial buffer for all the real-world variables.

- Safety Buffer (20%): 142.5 lbs x 0.20 = 28.5 lbs

- Final Daily Need: 142.5 lbs + 28.5 lbs = 171 lbs

Based on this math, the restaurant owner should be looking for a commercial ice machine that can produce somewhere between 180 and 250 pounds of ice every 24 hours. This capacity gives them plenty of cushion to handle a full house on a hot day without ever risking the dreaded sound of an empty ice bin.

Comparing Air, Water, and Remote Condensers

At the heart of every commercial ice machine is its condenser, the real engine that drives the entire ice-making process. I like to compare it to the radiator in your car. A car's engine generates a massive amount of heat, and the radiator’s whole job is to pull that heat away to keep things running smoothly. A condenser does the exact same thing for your ice machine.

As the machine works its magic turning water into ice, it generates a surprising amount of heat. The condenser’s critical role is to remove that heat from the refrigerant, allowing the cooling cycle to keep going. The type of condenser you choose is one of the most important technical decisions you'll make, as it directly impacts your machine's efficiency, where you can install it, and what you’ll pay in utility bills over the long haul.

As you can see, focusing on the right specs for your environment can lead to some serious cost reductions over the life of the machine.

Let's dive into the three main types of condensers so you can figure out which one makes the most sense for your business.

Condenser Technology Comparison

Choosing the right condenser isn't just a technical detail—it's a decision that affects your kitchen's environment, your monthly utility bills, and your initial budget. Each type has its own ideal setting and specific trade-offs.

To make it easier, I've broken down the key differences in this table. Think about your kitchen's temperature, ventilation, and how much you're willing to invest upfront versus what you'll pay over time.

| Condenser Type | Ideal Environment | Upfront Cost | Operating Cost | Key Consideration |

|---|---|---|---|---|

| Air-Cooled | Well-ventilated spaces with moderate temperatures (below 80°F). | Low | Moderate | Requires at least 6 inches of clearance for airflow and vents heat into the room. |

| Water-Cooled | Hot, poorly ventilated, or tight spaces where heat and noise are concerns. | Medium | High | Uses a lot of water, leading to higher utility bills. May be restricted in some areas. |

| Remote | High-volume kitchens, hotels, and venues where keeping heat and noise out is a priority. | High | Low | The quietest and most energy-efficient option, but installation is more complex and expensive. |

This table gives you a quick snapshot, but let's get into the specifics of what makes each of these tick.

The Popular and Practical: Air-Cooled Condensers

Air-cooled condensers are, by a long shot, the most common and budget-friendly option you'll find. They work exactly like you’d imagine—by pulling in the surrounding air, passing it over the condenser coils to soak up heat, and then pushing the now-hot air out. They are totally self-contained, which makes installation pretty straightforward and relatively inexpensive.

But, this simplicity comes with a few important trade-offs you need to be aware of:

- They Need to Breathe: These units absolutely must have good ventilation. You’ll need to ensure there’s enough clearance (usually at least six inches) all around the machine for proper airflow.

- They Make Heat: An air-cooled machine is going to vent warm air into the room. In a small, busy kitchen, this can easily raise the ambient temperature, making your staff uncomfortable and forcing your HVAC system to work overtime.

- Ambient Temperature is Everything: Their efficiency is directly tied to the temperature of the air they pull in. In a really hot kitchen (anything above 80°F), the machine has to work much harder to cool down, which means less ice production and more energy use.

Our Take: An air-cooled commercial ice machine is an excellent choice for businesses with well-ventilated spaces and moderate ambient temperatures. Its lower upfront cost and simple installation make it a very popular starting point for many restaurants and cafes.

The Quiet and Consistent: Water-Cooled Condensers

A water-cooled condenser takes a different approach, using water instead of air to cool the refrigerant. It connects right into your plumbing, circulating cool water through the system to absorb heat before sending the warmed water down the drain. This method offers some clear advantages over its air-cooled cousins.

Because they don’t rely on the air in the room, water-cooled machines aren't bothered by hot kitchen environments. Their performance stays consistent even on the most sweltering summer days. They also run much more quietly and don't dump hot air into your workspace, which can be a huge bonus for staff comfort in tight quarters.

The major drawback, however, is a big jump in your utility bills. These machines use a constant flow of water, which leads to significantly higher water and sewage costs. In areas with high water prices or usage restrictions, they might not be a practical or financially smart option.

The Powerful and Silent: Remote Condensers

For businesses where heat and noise are absolute deal-breakers, a remote condenser offers the best of both worlds. This system splits the ice machine into two parts. The ice-making head unit stays inside your facility, while the condenser—the part that actually generates all the heat and noise—is installed outside, usually on the roof.

Refrigerant lines run between the two components, carrying the heat completely out of your kitchen. This keeps your workspace cool and quiet, creating a much better environment for your staff. This setup is also incredibly efficient, as the outdoor condenser can use the cooler outside air to its advantage, especially at night or during cooler months.

The main thing to consider with a remote system is the higher upfront cost. The equipment itself is more expensive, and the installation is more complex, requiring a qualified technician to run the refrigerant lines. However, for large-scale operations like hotels, event venues, and busy restaurants, the long-term energy savings and improved working conditions often justify the initial investment. This sector is a key driver in the global commercial ice machine market, which was valued at USD 1.4 billion and is projected to grow. You can discover more about the growing ice machine market on businessresearchinsights.com.

Essential Cleaning and Maintenance Practices

Your commercial ice machine is a serious investment, and just like any high-performance equipment, it needs regular care to keep it running safely and efficiently. Letting maintenance slide isn't just a minor oversight; it can quickly lead to health code violations, foul-tasting ice, and expensive, premature breakdowns. A proactive cleaning schedule is your absolute best defense against these problems.

Think of your ice machine as a living environment. It's in constant contact with water, air, and organic materials—the perfect recipe for mold, slime, and bacteria to thrive if it's not cleaned. These contaminants are a serious health risk for your customers and force your machine to work much harder, which drives up energy bills and puts a strain on critical parts.

Your Actionable Maintenance Checklist

The key to keeping up with maintenance is to create a consistent, manageable routine. When you break the tasks down into daily, weekly, and semi-annual jobs, nothing gets overlooked. A fantastic way to keep everything organized is to incorporate a detailed kitchen equipment maintenance checklist into your regular duties.

Here’s a simple but effective schedule to get you started:

- Daily Tasks: At the end of each shift, give the exterior of the machine a good wipe-down. Check the ice scoop and its holder, making sure they’re clean and properly stored outside the ice bin. This simple step is huge for preventing hand-to-ice contamination.

- Weekly Tasks: Take a look at the air filter. A clogged filter is like trying to breathe through a dusty screen—it chokes the airflow, causing the condenser to overheat and run inefficiently. Clean or replace it as needed. You should also do a quick visual check inside the bin for any early signs of slime or mold.

- Semi-Annual Tasks: This is deep cleaning time. At least twice a year, you need to perform a full descaling and sanitization cycle using chemicals approved by the manufacturer. This two-part process is what removes mineral buildup (scale) and kills any microbial growth.

The Critical Role of Water Filtration

Honestly, the single best thing you can do to make maintenance easier is to install and maintain a quality water filter. Hard water is loaded with dissolved minerals like calcium and magnesium. As the water freezes, these minerals get left behind, forming a hard, crusty deposit inside your machine called scale.

Scale buildup is the silent killer of ice machines. It insulates evaporators, making it harder to produce ice, and can clog water lines and valves, leading to a complete system shutdown.

A good water filtration system tackles this problem at the source by removing those minerals before they ever get inside. This drastically cuts down on how often you need to descale, saving you time and money on cleaning chemicals. Plus, it makes for a better final product—filtered water produces clearer, harder, and better-tasting ice.

If you find your machine is struggling to make ice, scale is one of the most common culprits. For a deeper dive into fixing this, check out these helpful troubleshooting tips for a commercial ice machine not making ice in our other guides.

Why You Cannot Ignore Slime and Mold

Beyond minerals, the other major enemy is biological growth. Airborne yeast and bacteria love the dark, moist interior of an ice machine, and they can quickly form a pink or black slimy film. This isn't just gross to look at; it’s a serious health hazard that can contaminate your ice and get you flagged on a health inspection.

Regular sanitizing is the only way to fight it. While descaling gets rid of mineral deposits, sanitizing is what kills the bacteria, mold, and slime. These are two separate but equally vital steps that must be done together during your semi-annual service. This ensures your commercial ice machine is not only running well mechanically but is also completely food-safe.

Navigating Installation and Financial Options

You’ve done the hard work—you’ve picked the perfect ice type, figured out your daily production needs, and chosen the right condenser for your space. Now comes the final, practical step: bringing your commercial ice machine to life. This stage boils down to two things that are just as crucial as the machine itself: a proper installation and a smart financial plan.

Getting the installation right from the very beginning saves you from a world of future headaches, from frustrating leaks and electrical hiccups to a potentially voided warranty. At the same time, choosing the right way to pay ensures this critical investment fits comfortably within your budget, keeping your cash flow healthy for all the other things your business needs.

Getting Your Utilities in Order

A commercial ice machine is not like a toaster that you just plug into the wall. It's a serious piece of equipment that needs specific utility connections to run safely and effectively. Think of these as its essential lifelines.

Before your new machine even shows up on a truck, you need to have three key things ready to go:

- A Dedicated Water Line: Your machine needs a constant, reliable supply of cold water. This usually means having a dedicated water line installed with a shut-off valve close by, which makes maintenance much easier.

- A Proper Floor Drain: As the machine makes ice and runs its cleaning cycles, it has to get rid of excess water. The standard, most reliable solution is a gravity-fed floor drain located right near the unit.

- The Correct Electrical Hookup: These machines draw a lot of power. They almost always need their own dedicated circuit with the correct voltage and amperage to avoid tripping breakers and disrupting your entire kitchen.

The single biggest mistake you can make is assuming your current setup will work. Always consult with a licensed plumber and electrician before you finalize your purchase. They can check out your site and tell you exactly what’s needed, helping you avoid costly, last-minute surprises.

Exploring Your Financial Avenues

A brand-new commercial ice machine is a major purchase. While buying it outright is always an option, it’s definitely not the only one. Many businesses, especially new ones or those looking to preserve their capital, find that leasing or renting offers a more flexible and budget-friendly way forward.

For a deeper dive into the specifics of acquiring this equipment, our complete commercial ice machine guide offers some additional valuable perspectives.

Leasing Your Equipment

Leasing is a lot like a long-term rental, often with an option to buy the machine at the end of the term. You’ll make fixed monthly payments over a few years, which is a fantastic way to manage your cash flow because it turns a big one-time hit into a predictable monthly expense.

- Key Benefit: Lower upfront cost and predictable monthly payments.

- Consideration: You will likely pay more over the total term than if you bought it outright.

All-Inclusive Rental Programs

Rental or subscription programs are getting more and more popular. These deals often bundle the machine, preventive maintenance, repairs, and even water filter changes into a single monthly fee. This all-in-one approach gives you total peace of mind since you won’t get hit with unexpected repair bills.

- Key Benefit: No surprise repair costs and maintenance is included.

- Consideration: You don’t own the machine and are locked into the provider for service.

Ultimately, the best path for you depends on your business's cash flow, your long-term goals, and how hands-on you want to be with equipment maintenance. By thinking through both the physical installation needs and these financial options, you can make sure your new ice machine is a successful and stress-free investment right from day one.

Got a Few More Questions?

Even after digging into all the details, you might still have a few questions rattling around. That’s completely normal. Let’s tackle some of the most common things business owners ask when they’re picking out and running a commercial ice machine.

How Often Should I Clean My Ice Machine?

The manufacturer will always tell you to do a deep clean and full sanitization at least every six months. Think of this as the absolute bare minimum to keep your ice safe and your machine running smoothly.

But honestly, your environment is what really dictates the schedule. If your ice maker is in a hot kitchen with a lot of airborne yeast (like in a bakery or pizzeria) or if you know your building has hard water, you really should bump that up to every three months. Being proactive like this stops gross slime and damaging scale from building up before they turn into major headaches.

Can I Install a Commercial Ice Machine Myself?

I get why you'd ask, but unless you're a licensed plumber and a licensed electrician, this is a job for a professional. A proper installation is non-negotiable for a few critical reasons.

These machines are thirsty for very specific utilities:

- A dedicated water line to give it a constant supply.

- A correctly configured drain to handle the meltwater and runoff.

- Its own dedicated electrical circuit to handle the high power draw safely.

Trying to DIY this can lead to messy, damaging leaks, create a serious fire or electrical hazard, and will almost certainly void your manufacturer's warranty. Paying a professional for a few hours of work is a small price to protect your much bigger investment in the machine itself.

The most frequent mistake I see business owners make is underestimating how much ice they actually need. They plan for a quiet Tuesday afternoon instead of their busiest Saturday night in July. Always, always calculate for your peak demand and then add at least a 20% buffer. This ensures you never have to make that dreaded walk to tell a customer you're all out of ice.

Ready to find the perfect ice solution for your business? The Restaurant Warehouse has a massive selection of top-quality commercial ice machines and flexible financing to fit any budget. Explore our inventory and get equipped for success today.

Find Your Commercial Ice Machine Now at The Restaurant Warehouse

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment