Prep Tables

Atosa USA SSTW-2424 NSF Rated 430 Stainless Steel Work Table - 24 Inches x 24 Inches

AtosaAtosa USA SSTW-2424 NSF Rated 430 Stainless Steel Work Table - 24 Inches x 24 Inches 18 Gauge Stainless Steel Top reinforced with a welded channel...

View full detailsAtosa USA SSTW-2430 NSF Rated 430 Stainless Steel Work Table - 24 Inches x 30 Inches

AtosaAtosa USA SSTW-2430 NSF Rated 430 Stainless Steel Work Table - 24 Inches x 30 Inches 18 Gauge Stainless Steel Top reinforced with a welded chanel ...

View full detailsAtosa USA SSTW-2436 NSF Rated 430 Stainless Steel Work Table - 24 Inches x 36 Inches

AtosaAtosa USA SSTW-2436 NSF Rated 430 Stainless Steel Work Table - 24 Inches x 36 Inches The function of preparing vegetables involves preparing usuall...

View full detailsAtosa USA SSTW-2448 NSF Rated 430 Stainless Steel Work Table - 24 Inches x 48 Inches

AtosaAtosa USA SSTW-2448 NSF Rated 430 Stainless Steel Work Table - 24 Inches x 48 Inches 18 Gauge Stainless Steel Top reinforced with a welded channel...

View full detailsAtosa USA SSTW-2460 NSF Rated 430 Stainless Steel Work Table - 24 Inches x 60 Inches

AtosaAtosa USA SSTW-2460 NSF Rated 430 Stainless Steel Work Table - 24 Inches x 60 Inches 18 Gauge Stainless Steel Top reinforced with a welded chanel ...

View full detailsAtosa USA SSTW-2472 NSF Rated 430 Stainless Steel Work Table - 24 Inches x 72 Inches

AtosaAtosa USA SSTW-2472 NSF Rated 430 Stainless Steel Work Table - 24 Inches x 72 Inches 18 Gauge Stainless Steel Top reinforced with a welded chanel ...

View full detailsAtosa USA SSTW-3030 NSF Rated 430 Stainless Steel Work Table - 30 Inches x 30 Inches

AtosaAtosa USA SSTW-3030 NSF Rated 430 Stainless Steel Work Table - 30 Inches x 30 Inches 18 Gauge Stainless Steel Top reinforced with a welded chanel ...

View full detailsAtosa USA SSTW-3036 NSF Rated 430 Stainless Steel Work Table - 30 Inches x 36 Inches

AtosaAtosa USA SSTW-3036 NSF Rated 430 Stainless Steel Work Table - 30 Inches x 36 Inches 18 Gauge Stainless Steel Top reinforced with a welded channel...

View full detailsAtosa USA SSTW-3048 NSF Rated 430 Stainless Steel Work Table - 30 Inches x 48 Inches

AtosaAtosa USA SSTW-3048 NSF Rated 430 Stainless Steel Work Table - 30 Inches x 48 Inches 18 Gauge Stainless Steel Top reinforced with a welded channel...

View full detailsAtosa USA SSTW-3060 NSF Rated 430 Stainless Steel Work Table - 30 Inches x 60 Inches

AtosaAtosa USA SSTW-3060 NSF Rated 430 Stainless Steel Work Table - 30 Inches x 60 Inches 18 Gauge Stainless Steel Top reinforced with a welded channel...

View full detailsAtosa USA SSTW-3072 NSF Rated 430 Stainless Steel Work Table - 30 Inches x 72 Inches

AtosaAtosa USA SSTW-3072 NSF Rated 430 Stainless Steel Work Table - 30 Inches x 72 Inches 18 Gauge Stainless Steel Top reinforced with a welded channel...

View full detailsAtosa USA SSTW-3084 NSF Rated 430 Stainless Steel Work Table - 30 Inches x 84 Inches

AtosaAtosa USA SSTW-3084 NSF Rated 430 Stainless Steel Work Table - 30 Inches x 84 Inches 18 Gauge Stainless Steel Top reinforced with a welded chanel ...

View full detailsAtosa USA SSTW-3096 NSF Rated 430 Stainless Steel Work Table - 30 Inches x 96 Inches

AtosaAtosa USA SSTW-3096 NSF Rated 430 Stainless Steel Work Table - 30 Inches x 96 Inches 18 Gauge Stainless Steel Top reinforced with a welded channel...

View full details

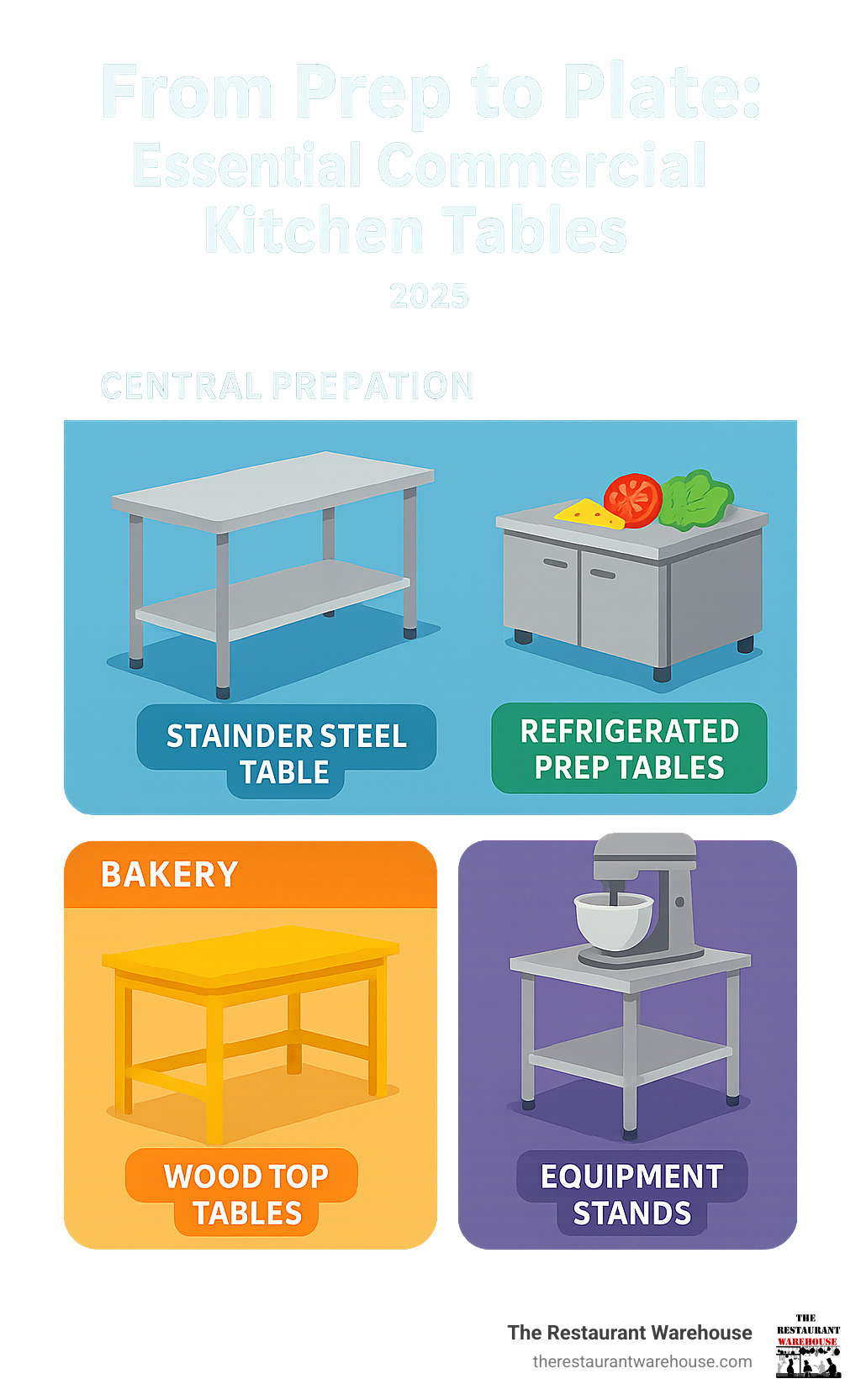

From Prep to Plate: Essential Commercial Kitchen Tables

Why Commercial Kitchen Tables Are the Foundation of Efficient Food Service

A commercial kitchen table is the undisputed backbone of any professional food service operation. It is far more than a simple surface; it is the primary stage where culinary creativity, precision, and safety converge. In the high-pressure environments of restaurants, busy cafes, large-scale institutional kitchens, and compact food trucks, these tables provide a durable, hygienic, and stable workspace for high-volume food preparation. Imagine a kitchen trying to function without them: prep work would be relegated to unstable, hard-to-clean surfaces, leading to inefficiency, safety hazards, and a breakdown in sanitation. The right work table is the foundational investment that ensures smooth operational flow and prevents the costly bottlenecks that can cripple a service.

Essential Commercial Kitchen Table Types:

- Stainless Steel Tables - The versatile industry standard, these tables are the workhorses for all general prep work, from chopping vegetables to portioning proteins. Their non-porous surface is critical for food safety.

- Wood Top Tables - Often called baker's tables, these are ideal for bakeries and pastry departments. The wood surface is naturally less sticky for dough and provides an excellent, firm surface for kneading and rolling.

- Refrigerated Prep Tables - These specialized units integrate cold storage directly into the workstation, keeping ingredients fresh and within arm's reach for assembling sandwiches, salads, and pizzas.

- Equipment Stands - Built with heavy-gauge steel, these sturdy stands are designed to safely support heavy countertop kitchen equipment like mixers, slicers, and grinders, saving valuable counter space.

- Filler Tables - These narrow tables are designed to maximize every inch of usable space, fitting between larger pieces of equipment to create small, useful surfaces in compact kitchens.

Engineered to meet stringent NSF (National Sanitation Foundation) standards, these tables are typically constructed from robust materials like 16- or 18-gauge stainless steel. Their primary function is to optimize kitchen workflow by creating clearly defined, designated prep stations. This separation is crucial for reducing the risk of cross-contamination between different food types and withstanding the daily rigors of aggressive cleaning and sanitization. The inherent durability and ease of cleaning are not just conveniences—they are essential pillars of food safety and operational efficiency. Selecting the right table based on its material, size, gauge, and specific features is a strategic investment in years of reliable, safe, and productive service.

The Unsung Hero: Core Benefits of a Commercial Work Table

In any professional kitchen, the commercial kitchen table is an unsung hero. While gleaming ranges and high-tech mixers often capture the spotlight, these reliable workhorses are the silent partners essential for every successful food operation. They are carefully engineered from corrosion-resistant materials that meet strict public health and sanitation standards, providing the literal foundation for a safe, efficient, and smooth-running kitchen. A high-quality table does more than just fill a space; it actively optimizes that space, significantly reduces cleaning time, and is a cornerstone of food safety compliance. Many are NSF certified and incorporate practical, thoughtful features like undershelves for accessible storage and integrated backsplashes to contain messes, which in turn helps prevent cross-contamination and boosts overall team efficiency. Learn why stainless steel options Steel the Show in Your Kitchen with Commercial Stainless Steel Tables.

Maximizing Durability and Longevity

Commercial kitchens are demanding, high-impact environments, making durability the most critical feature of any piece of equipment. A quality commercial kitchen table is specifically built with heavy-duty construction to withstand the rigors of high-volume use. It must be capable of supporting heavy equipment without buckling, enduring constant impacts from pots and pans, and resisting damage from aggressive cleaning chemicals. The secret lies in the use of commercial-grade materials. Most professional tables are crafted from 16-gauge or 18-gauge stainless steel—a crucial detail where the lower the gauge number, the thicker, stronger, and more dent-resistant the steel. This industrial-strength material is not just tough; it's built to last for decades. To further improve this longevity, many tables also feature galvanized or fully stainless steel legs and frames, providing extra protection against the inevitable corrosion that occurs in humid, steamy kitchen environments. Investing in a well-built table is a form of investment protection. It represents a higher upfront cost compared to a residential table but pays dividends by saving you from the frequent replacements, repairs, and potential safety liabilities associated with lesser-quality options, ensuring reliable service for years to come.

Enhancing Kitchen Workflow and Efficiency

Commercial work tables are the key to changing a potentially chaotic kitchen into a model of efficiency. Strategic placement of these tables creates designated workstations, a fundamental principle of professional kitchen design that boosts both productivity and safety. Instead of staff members crowding a single area to perform different tasks, you can establish separate, dedicated tables for vegetable prep, raw meat and poultry fabrication, and pastry work. This systematic organization dramatically reduces cross-contamination risks—a critical component of food safety—and improves the overall flow of movement during busy service periods. This streamlined prep process not only keeps ingredients and tools organized but also ensures operations run smoothly, even under pressure. The benefits are especially pronounced in optimized layouts for specialized operations like ghost kitchens and food trucks, where every square inch of space is at a premium. By creating dedicated work areas, you empower your team to achieve quick turnaround times without ever sacrificing the quality or safety of the final product. For more setup insights, see our Prep Table Kitchen Guide.

Upholding Food Safety and Sanitation

In the food service industry, food safety is paramount, and the very design of a commercial kitchen table is crucial to upholding it. Professional tables feature easy to clean surfaces made from non-porous materials like stainless steel. Unlike wood or laminate, a non-porous surface does not have microscopic holes or cracks where liquids, food particles, and bacteria can penetrate and take hold, making it fundamentally more hygienic. The presence of an NSF certification mark on a table provides an immediate guarantee that it meets strict public health standards for design, construction, and material safety for food service use. This mark is a clear signal to health inspectors that you are serious about health code compliance, and more importantly, it protects your customers from the risk of foodborne illness. The smooth, often seamless surfaces of these tables also lead to a significant reduction in cleaning time. Staff can quickly and effectively wipe down and sanitize the table between tasks, allowing them to focus more of their valuable time on food preparation. Learn the best cleaning practices in our guide on how to Clean Stainless Steel Equipment.

A Table for Every Task: Types of Commercial Work Tables

Professional kitchens are complex environments that require specialized work surfaces for a wide variety of different tasks. The modern commercial kitchen table market has evolved to meet this demand, offering a perfect match for nearly every culinary challenge, from the delicate work of plating a dessert to the heavy-duty job of butchering a primal cut. Using the right type of table for the right task is a strategic decision that creates highly efficient workstations, dramatically improves food safety protocols, and streamlines the entire kitchen operation from prep to service.

The main categories of work tables include the ubiquitous stainless steel tables for general prep, classic wood top tables for baking and dough work, and advanced refrigerated and specialty prep tables that integrate temperature control directly into the workspace. Understanding the specific strengths and applications of these options is the first step in designing and building a more effective, productive, and safer kitchen. For a complete overview of your options, consult our Restaurant Prep Table Guide.

Stainless Steel Work Tables: The Industry Standard

Stainless steel commercial kitchen table units are the undisputed industry standard, and for a multitude of good reasons. Their primary advantage is their best versatility. A single stainless steel table can safely and effectively handle both raw meat preparation and fresh vegetable prep with proper cleaning procedures in between, a flexibility that is invaluable in any kitchen. Their legendary durability and inherent corrosion resistance ensure they can withstand the harsh kitchen environment and maintain a clean, professional appearance even after years of heavy use. They are available in a vast array of configurations to suit any kitchen layout or specific need. Open base tables are a popular choice, offering maximum flexibility for storing large rolling ingredient bins, mobile carts, or even small undercounter appliances underneath. This design also makes daily floor cleaning significantly easier. In contrast, enclosed base tables provide hidden cabinet storage, often with sliding or hinged doors, which is perfect for keeping the workspace organized and protecting spare tools, containers, and other supplies from dust and spills. Both styles deliver the reliable, hygienic performance that stainless steel is known for. Explore all the available options in our comprehensive Stainless Steel Tables Guide.

Wood Top & Baker's Tables: The Bakery Essential

In the worlds of baking and pastry, wood top commercial kitchen table units, often referred to as baker's tables, are considered irreplaceable. Their signature butcher block tops, typically made from dense hardwoods like maple, provide a naturally non-stick surface for flour and dough. This unique property makes tasks like kneading dough, shaping loaves, and rolling out delicate pie crusts easier, faster, and more consistent. These tables are specifically designed for the unique demands of bakeries and cafes. Many models feature raised edges, known as risers, on the sides and back to help contain ingredients like flour and sugar, significantly reducing mess and waste. Furthermore, the wood surface tends to maintain a more neutral temperature compared to the cold conductivity of steel, which is much better for working with temperature-sensitive, butter-based doughs like puff pastry or croissants. While these tables do require more diligent maintenance, including regular oiling and specific cleaning protocols to ensure they remain sanitary and in good condition, the superior quality of the baked goods they help produce makes the effort entirely worthwhile. For more on different work surfaces, see our Table with Stainless Steel Top Guide.

Refrigerated and Specialty Prep Tables

Refrigerated and other specialty tables represent the peak of targeted kitchen efficiency. These are not just tables but highly engineered systems designed to keep perishable ingredients at optimal, food-safe temperatures directly at the point of use, drastically speeding up assembly and production workflows.

Sandwich prep stations are a prime example, featuring integrated cooling in the base and a refrigerated top rail that holds an array of food pans. This setup keeps deli meats, cheeses, vegetables, and condiments fresh, organized, and immediately accessible for rapid, assembly-line-style production. Pizza prep tables apply the same core principle, with refrigerated compartments for cheese, sauce, and various toppings, combined with a wide, often marble or refrigerated steel, workspace for assembling pies. Beyond refrigeration, other specialty tables solve unique operational challenges. Heavy-duty equipment stands provide a stable, dedicated footprint for heavy machinery like floor mixers and large slicers. Filler tables are narrow units designed to use awkward gaps between other pieces of equipment, turning wasted space into a valuable work or storage area. Finally, portable work tables equipped with casters offer unparalleled flexibility, which is ideal for catering operations, dynamic kitchens that require frequent reconfiguration, and compact food trucks. These specialized tables are purpose-built solutions for real-world operational challenges. Learn how Sandwich Prep Tables and Pizza Prep Tables can streamline your specific workflow.

Choosing the Perfect Commercial Kitchen Table for Your Needs

Choosing the right commercial kitchen table is a critical decision that involves a careful assessment of your operational needs and matching them with the right features and specifications. The process should begin with a thorough evaluation of your kitchen layout and the precise available space. Measure the area carefully, considering not just the table's footprint but also the clearance needed around it for staff movement and other equipment, ensuring the new table improves workflow rather than creating a dangerous bottleneck. Next, clearly define the primary tasks the table will be used for. Will it be for heavy butchering, light assembly, or delicate pastry work? The answer will guide your material choice, such as stainless steel versus wood, and the specific features you'll need. While your budget is always a practical consideration, it's crucial to view this purchase as a long-term investment in your business's infrastructure. A high-quality, durable table will outlast cheaper alternatives many times over, saving significant money and hassle in the long run. Finally, getting the size and configuration right is essential to provide ample workspace for your staff without cramping your kitchen's overall flow. For more in-depth guidance, see our Commercial Kitchen Stainless Steel Guide.

Key Features of a High-Quality Commercial Kitchen Table

Certain key features and specifications distinguish high-quality commercial kitchen tables from inferior ones. The steel gauge of the tabletop is arguably the most important factor in determining its durability. It's a counterintuitive measurement: the lower the gauge number, the thicker and stronger the steel.

| Gauge | Durability | Common Use | Cost |

|---|---|---|---|

| 18-Gauge | Good for light to medium duty | General prep, assembly stations, dry storage, holding lighter equipment. A solid, economical choice for many applications. | More economical |

| 16-Gauge | Very good for medium to heavy duty | High-volume prep, light butchering, supporting medium-weight equipment. The most common choice for general-purpose commercial kitchens. | Mid-range |

| 14-Gauge | Excellent for heavy duty | Butcher shops for heavy fabrication, bakeries for intensive kneading, supporting very heavy equipment, and withstanding extreme high-volume use. | Higher cost |

The steel grade also plays a critical role. 304 stainless steel contains a higher percentage of chromium and nickel, offering superior corrosion resistance. It's the best choice for tabletops and environments with high moisture or direct contact with acidic foods. 430 stainless steel is a more budget-friendly alternative that is perfectly suitable for drier conditions and is often used for table legs, bracing, and undershelves. For leg material, stainless steel offers the maximum corrosion resistance from top to bottom, while galvanized legs provide a great balance of durability and value for most situations. Adjustable feet, typically plastic or metal bullet feet, are an essential feature for leveling the table and eliminating dangerous wobbles on uneven kitchen floors. Finally, rounded edges (bullnose edges) are a key safety feature, preventing the painful cuts, bruises, and snags on chef coats that are common with sharp, squared corners in a kitchen.

Common Sizes and Configurations for a Commercial Kitchen Table

The commercial kitchen table is available in a vast range of sizes and configurations to fit any space. Standard dimensions for depth are typically 24 or 30 inches, while lengths vary widely. Common sizes include 24x48 inches for compact areas or filler spaces, the versatile 30x60 inches for general use, and the generous 30x72 inches for ample workspace. For kitchens that require maximum continuous prep area, large tables up to 30x96 inches are available. For more on these larger tables, see our 72x30 Stainless Steel Table Guide and 30x96 Stainless Steel Tables guide. Key configurations significantly impact functionality. Undershelves for storage are a nearly standard feature, perfect for keeping frequently used pots, pans, and ingredient bins accessible and off the floor. Backsplashes for cleanliness are raised lips at the back of the table that prevent water, food particles, and cleaning solutions from splashing onto walls, making sanitation easier. The choice between an open base versus an enclosed cabinet depends entirely on your storage needs; open bases offer flexibility and easier floor cleaning, while enclosed cabinets provide secure, hidden storage for sensitive items. Finally, portable tables with casters offer outstanding mobility, allowing you to reconfigure your kitchen space on the fly for cleaning, special events, or changing menu needs.

Must-Have Accessories and Add-Ons

A well-chosen commercial kitchen table becomes exponentially more valuable with the addition of the right accessories. These add-ons can transform a simple work surface into a highly organized, ergonomic, and efficient workstation that is customized to your specific operational needs.

Casters for mobility are invaluable for any kitchen that values flexibility. Equipping a table with a set of heavy-duty, locking casters allows it to be moved easily for thorough cleaning underneath or for rearranging the kitchen layout. Drawers for utensil storage are a game-changer for organization, keeping essential tools like knives, peelers, and whisks organized, sanitary, and within immediate reach, which improves daily efficiency. Overshelves for extra space are one of the most popular add-ons, providing convenient single or double-tiered overhead storage for spices, small containers, or frequently used small equipment without consuming any valuable counter space. Pot racks, whether attached to the table as an overshelf or mounted overhead, free up immense amounts of valuable cabinet and shelf space by providing a dedicated place for hanging pots and pans. Finally, some tables can be customized with sink attachments, creating integrated washing and prep stations that are especially useful in compact kitchens or for specific tasks like washing vegetables. When selecting accessories, always choose them based on the specific workflow challenges you need to solve. Our Kitchen Tools Utensils Guide offers more great organizational strategies.

The Critical Role of NSF Certification and Sanitation

In any commercial kitchen, adherence to strict food safety standards is non-negotiable. This is where third-party certification bodies like NSF International provide the gold standard for public health protection. An NSF certification mark on a commercial kitchen table signifies that it has undergone and passed a series of rigorous, independent tests for material safety, design, and construction hygiene. This certification provides a crucial guarantee that the table's materials are safe for direct food contact and that the overall design promotes easy and thorough cleaning, preventing it from becoming a potential breeding ground for harmful bacteria. NSF-certified tables are specifically designed with non-porous surfaces that are impervious to liquids, grease, and food particles, a feature that is absolutely crucial for preventing bacterial growth. This thoughtful design allows for ease of sanitization, saving valuable staff time while ensuring the highest levels of hygiene are maintained. During routine health inspections, the presence of the NSF mark on your equipment clearly demonstrates your commitment to food safety and can streamline the inspection process. Operators can verify a product's certification by checking the official NSF online listings or looking for the NSF mark on the product itself. For more details on what to look for, see our Stainless Steel Prep Table Guide.

Understanding Stainless Steel's Hygienic Advantages

Stainless steel is the universally recognized gold standard for food prep surfaces, primarily due to its exceptional hygienic properties. Its most important advantage is its remarkable corrosion resistance. Thanks to the chromium content in the alloy, stainless steel forms a passive, invisible layer of chromium oxide on its surface. This layer protects the underlying steel from rust, pitting, and corrosion when exposed to moisture, acidic foods (like tomatoes or citrus), and harsh cleaning chemicals. This means it won't harbor bacteria in microscopic pits or leach metallic substances into the food. This quality makes it completely non-reactive with food, ensuring that the taste, color, and safety of your ingredients remain pure and unaffected. Stainless steel also exhibits excellent durability against harsh cleaners, allowing your sanitation crew to use powerful, food-safe sanitizers as needed without worrying about damaging your long-term investment. The smooth, crevice-free design of a well-manufactured stainless steel table leaves no hiding places for food debris and contaminants, making it simple to wipe clean and ensuring that your sanitizing efforts are truly effective.

Designing for Cleanliness: Backsplashes and Edges

Beyond the material itself, thoughtful design features on a commercial kitchen table can greatly improve and support daily sanitation protocols. A backsplash is a simple but highly effective feature. This raised barrier, typically a few inches high along the back of the table, is excellent at preventing spills down walls, which can be difficult to clean and can attract pests. It also helps in containing ingredients on the work surface, reducing food waste and minimizing the time spent cleaning floors and surrounding areas. The design of the table's edge is also crucial for both safety and hygiene. Rounded "bullnose" or "marine" edges are vastly superior to sharp, squared-off corners. From a safety perspective, they prevent the painful bumps, bruises, and clothing snags that are common in a kitchen environment. From a cleaning perspective, these smooth, rounded edges are incredibly easy to wipe down, with no sharp 90-degree crevices that can trap food particles and bacteria. This continuous, uninterrupted surface ensures that every part of the table can be quickly and thoroughly sanitized. Together, these simple design elements help create a holistically sanitary environment and make it much easier for your team to maintain the highest standards of hygiene.

Frequently Asked Questions about Commercial Kitchen Tables

When selecting a commercial kitchen table, several important questions commonly arise regarding materials, capacity, and ergonomics. Getting clear answers to these questions is key to choosing the right table that will serve your kitchen well for years to come. Here are detailed answers to the most frequent ones.

What is the difference between 304 and 430 grade stainless steel?

The grade of stainless steel is a critical specification that directly affects its performance, longevity, and cost. The primary difference lies in their chemical composition. 304 grade stainless steel is the premium option, containing approximately 18% chromium and 8% nickel. The addition of nickel is key, as it significantly improves the steel's superior corrosion resistance. This makes 304 grade the ideal choice for tabletops, especially in wet environments near sinks or for direct contact with acidic foods and harsh cleaning chemicals. 430 grade stainless steel, on the other hand, contains a similar amount of chromium but has a negligible amount of nickel, making it a more economical choice. While it still offers good corrosion resistance, it's not as robust as 304 and performs best in drier conditions. It is perfectly suitable and commonly used for general-purpose use and dry storage, such as for table legs, bracing, and undershelves where direct food contact is minimal. A simple way to tell the difference is the "magnet test": 430 grade is magnetic, while 304 grade is generally non-magnetic.

How much weight can a typical commercial kitchen table hold?

Weight capacity varies significantly based on the table's gauge and overall construction. The steel gauge of the top is the biggest single factor; as a reminder, lower numbers mean thicker, stronger steel. Heavy-duty 14 or 16-gauge tables are true workhorses that can typically handle a uniformly distributed load of 600-800 lbs or more. This makes them ideal for supporting heavy countertop equipment like large planetary mixers or meat grinders. Standard 18-gauge tables are still very strong and suitable for most general applications, generally supporting around 400-500 lbs. This is more than sufficient for general food prep, assembly, and holding lighter equipment. However, other construction details like leg construction, the number of legs (tables over 72" usually have six), and the type of undershelf and bracing also affect the total capacity. Always check the manufacturer's official specifications for the exact weight limit of any table you are considering to avoid dangerous overloading.

What is the ideal height for a commercial work table?

The right height for a commercial kitchen table is crucial for staff ergonomics and preventing long-term fatigue and injury. The industry standard height is typically 34-36 inches from the floor to the work surface. This range has been established as a comfortable height for most people to perform standing prep work without hunching over or reaching up uncomfortably. This ergonomic design reduces physical strain on the back, neck, and shoulders during long shifts. However, for improved ergonomics, some tables offer adjustable legs that allow you to customize the height for staff comfort and specific tasks. This flexibility is a major benefit, allowing taller or shorter staff members to work comfortably and safely. Furthermore, certain tasks may be easier on a slightly different height surface; for example, tasks requiring significant downward pressure, like kneading dense dough, may be more comfortable on a slightly lower surface. Considering who will use the table and for what tasks is key to ensuring a comfortable and productive workspace.

Should I get a table with or without a backsplash?

This is a common question that depends entirely on where the table will be placed in your kitchen. A table with an integrated backsplash is designed to be placed against a wall. The backsplash prevents water, food debris, and cleaning solutions from splashing onto the wall, which keeps the wall cleaner, prevents moisture damage, and makes sanitation easier. If your table is intended for an island configuration, where staff will be working from all sides, then a flat top table without a backsplash is the correct choice. This allows for 360-degree access to the work surface, promoting collaborative work and flexible use of the space.

What's the difference between galvanized steel and stainless steel for legs and shelves?

While the tabletop is almost always stainless steel, the legs and undershelf are often made from either stainless or galvanized steel. Galvanized steel is carbon steel that has been coated with a protective layer of zinc to prevent rust. It is a strong and economical option, making it a very common choice for legs and undershelves. However, the zinc coating can be scratched or worn away over time, exposing the carbon steel underneath to rust, especially in a damp kitchen environment. Stainless steel legs and undershelves offer superior corrosion resistance for the entire life of the table and are the premium choice, especially for wet areas or kitchens where heavy-duty cleaning is frequent. Galvanized steel should never be used for a food-contact surface, but it is a safe and cost-effective choice for the support structure of a table.

Conclusion

The commercial kitchen table is far more than just a piece of furniture or a simple surface; it's the unsung hero and the foundational stage that supports every single dish your kitchen produces. From the initial prep work to the final plating, these sturdy, reliable surfaces are essential to a safe and efficient operation. Throughout this guide, we've explored how critical durability is for providing a reliable workhorse that can withstand the pressures of a professional kitchen, how strategic workflow optimization through designated workstations creates an efficient and organized environment, and how a table's material and design serve as your first and most important line of defense for food safety and sanitation.

Choosing the right table is a significant investment in your operation's long-term health and success. It requires careful consideration of your space, your menu, and your team's needs. Whether you require the immense strength of 14-gauge steel for a butchering station, the specialized surface of a wood top baker's table, or the flexibility of a portable table on casters, the perfect match for your unique challenges is out there. Making an informed choice based on factors like steel grade, configuration, and essential accessories will pay daily dividends.

At The Restaurant Warehouse, we understand that great food starts with great equipment. We are committed to providing commercial-grade quality at wholesale prices, ensuring that you never have to compromise on the safety or efficiency of your kitchen. Our wide selection means you can find the ideal table for your specific space and budget, from compact filler units to expansive 96-inch prep surfaces. Investing in the right table is an investment in faster prep times, higher staff morale, and unimpeachable food safety.

Ready to build a better, more efficient kitchen? Your perfect table is waiting. Let's build something amazing together. Whether you need a standard prep station or a specialized unit like the ones in our guide to find the perfect pizza prep table for your kitchen, we're here to help you lay the foundation for your culinary success.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment