From Deli to Dough: Unpacking the Versatility of Prep Coolers

Why Commercial Sandwich Coolers Are Essential for Your Kitchen

A sandwich cooler, also known as a sandwich prep table, is a specialized commercial refrigeration unit that combines ingredient storage with a convenient prep workspace. These all-in-one stations keep ingredients at safe temperatures while providing easy access for rapid food assembly, solving a major challenge in foodservice operations. In a high-pressure kitchen environment, every second counts. The constant movement between a walk-in cooler, a separate refrigerator, and a cutting board creates bottlenecks, increases the risk of cross-contamination, and leads to staff fatigue. This disjointed process not only slows down service but also drives up labor costs and can compromise food quality as ingredients spend more time in the temperature danger zone.

A sandwich cooler consolidates this entire process into a single, highly efficient workstation. It is purpose-built to keep meats, cheeses, vegetables, and sauces at precise, food-safe temperatures right at the point of assembly, changing a chaotic workflow into a streamlined production line.

Key features of sandwich coolers:

- Optimal Temperature Range: These units are engineered to maintain a consistent temperature between 38°F and 40°F. This is crucial for food safety, as it stays safely below the FDA's 41°F threshold for cold holding, inhibiting bacterial growth and keeping ingredients at peak freshness.

- Dual Storage System: A sandwich cooler features two distinct temperature-controlled zones. The refrigerated base cabinet is perfect for storing bulk backups and less-frequently used items, while the top-mounted rail holds pans of your most-used ingredients for immediate access.

- Integrated Workspace: A built-in cutting board, typically running the full length of the unit, provides a dedicated surface for prep and assembly. This eliminates the need for a separate prep table, saving valuable kitchen space and reducing unnecessary movement.

- Effortless Ingredient Access: The top-loading pans are covered by insulated lids that trap cold air, maintain temperature consistency, and protect ingredients from airborne contaminants. When service is flowing, staff can quickly access everything they need in one place.

- Durable Stainless Steel Construction: Built to withstand the rigors of a commercial kitchen, these units are almost universally made from stainless steel. This material is not only durable and corrosion-resistant but also non-porous and easy to sanitize, which is essential for passing health inspections.

Kitchens that adopt sandwich prep tables consistently report significant improvements across the board, including faster ticket times, a measurable reduction in food waste, and improved food safety compliance. The precise temperature control and instant ingredient access create a seamless workflow that traditional, separated refrigeration and prep areas simply cannot match. The result is a more productive, safer, and more profitable operation.

Beyond pure efficiency, modern sandwich coolers are designed with labor ergonomics in mind. The traditional kitchen dance of twisting and turning between reach-in refrigerators and cutting surfaces is a leading cause of staff fatigue and repetitive strain injuries. With a prep table, everything is positioned within a natural working arc, allowing employees to work comfortably and efficiently for longer periods. This ergonomic design not only reduces physical strain but also helps maintain consistent portioning and quality throughout a long and busy shift.

Ingredient integrity is paramount, and this is where a sandwich cooler truly shines. The tightly controlled 38-40°F temperature range is the sweet spot for preserving the quality of delicate ingredients. It keeps produce crisp, proteins fresh, and sauces safe, all while staying well under the FDA's 41°F threshold for cold holding. By centralizing all your ingredients, you can standardize pan sizes, streamline your restocking procedures, and flawlessly implement a First-In, First-Out (FIFO) rotation system to minimize spoilage and maximize profits.

The Heart of an Efficient Kitchen: Core Benefits of a Prep Cooler

A sandwich cooler is the engine of an efficient kitchen, changing potential chaos into a model of smooth, streamlined operation. By consolidating refrigeration, prep space, and ingredient organization into a single ergonomic workstation, it delivers a powerful trifecta of benefits: faster ticket times, significantly reduced food waste, and dramatically improved workflow efficiency. These units are not just equipment; they are a strategic investment in productivity and quality.

Want to dive deeper into commercial refrigeration options? Check out our comprehensive guides:

- Commercial Refrigerators Guide

- Choosing the Right Commercial Refrigeration System for Your Restaurant

Boosting Food Safety and Quality

Food safety is non-negotiable in any foodservice establishment. Sandwich coolers are engineered to be your first line of defense, maintaining ingredients within the critical temperature range of 38°F to 40°F. This narrow window is ideal for safe cold holding, creating a protective barrier against the growth of harmful bacteria, which accelerates rapidly above 41°F. The system's powerful, forced-air refrigeration ensures that this temperature is consistent throughout the cabinet and pan rail, eliminating dangerous hot spots. Furthermore, the insulated lids that cover the top-mounted food pans are essential. They not only maintain consistent temperatures, even when the ambient kitchen temperature rises during a busy service, but also shield ingredients from cross-contamination from splashes or airborne particles, ensuring every dish served is both fresh and safe.

Maximizing Speed and Workflow

The ergonomic design of a sandwich cooler is purpose-built for speed and efficiency. Consider the workflow without one: a cook grabs bread, walks to a reach-in for meat and cheese, moves to another cooler for vegetables, and finally assembles the sandwich on a separate prep counter. This process is filled with wasted motion. With a sandwich cooler, the entire sequence is optimized. Staff can grab ingredients from the refrigerated rail, prep them on the integrated cutting board, and assemble the final order without taking more than a single step. The easy-access ingredient pans keep your most-used items visible and within arm's reach, preventing delays and eliminating the need to search for items mid-order. This streamlined workflow directly translates to increased output and reduced ticket times, especially during peak hours when every second is critical to customer satisfaction.

Ensuring Consistency and Cost Control

Beyond speed, a sandwich cooler promotes consistency, a hallmark of a professional kitchen. When ingredients are neatly organized in standardized pans, it becomes much easier for staff to follow recipes and use correct portion sizes. This leads to a more consistent final product for your customers and provides powerful cost control for your business. By preventing over-portioning, you reduce food costs, and by keeping ingredients perfectly chilled and organized, you minimize spoilage. This level of organization also simplifies inventory management and makes it easier to implement a strict First-In, First-Out (FIFO) system, further cutting down on waste. The prep table helps you deliver a uniform, high-quality product every time while protecting your bottom line.

For more insights on choosing equipment that maximizes efficiency, see our guide on the Best Commercial Refrigerators.

A Tour of the Types: Finding Your Perfect Fit

Sandwich coolers come in a variety of configurations, each designed to solve specific kitchen challenges and cater to different operational needs. The main types include standard top, mega top, and cut-top units, along with a crucial choice between doors or drawers for the base cabinet. Choosing the right one is a strategic decision that requires a careful assessment of your menu's complexity, your daily customer volume, and the physical constraints of your kitchen space.

What works for a high-volume, build-your-own deli might be excessive and inefficient for a small café with a curated menu. Understanding the nuanced differences between these models is the key to finding your perfect fit and maximizing your return on investment. For a comprehensive look at all available options, check out our complete selection: Sandwich Prep Tables.

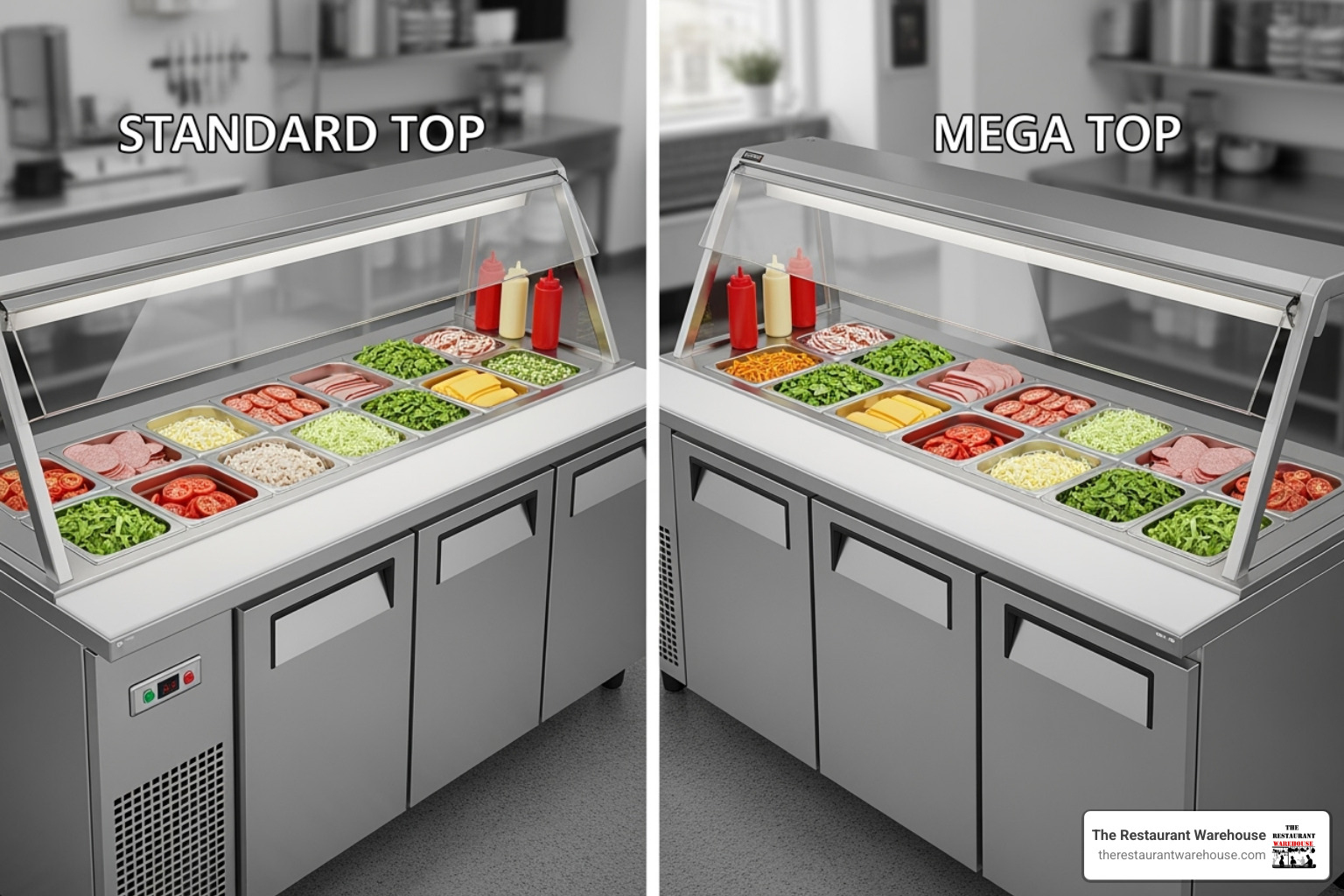

Standard Top vs. Mega Top: Choosing the Right Sandwich Cooler

This is the most fundamental choice you'll make, and it represents a direct trade-off between prep workspace and ingredient variety.

- Standard top units are the versatile workhorses of the industry. They feature a single row of food pans (typically 1/6 or 1/9 size) positioned at the back of the unit. This design maximizes the depth of the cutting board, providing a generous and uncluttered area for assembly. Standard tops are ideal for operations that need more physical room for complex assembly—like rolling large wraps or plating elaborate salads—and that rely on a limited number of core ingredients.

- Mega top units are built for maximum capacity and variety. They feature an additional row of deeper food pans, often doubling or even tripling your on-hand ingredient capacity compared to a standard top. While this significantly reduces the depth of the cutting board, it's the perfect solution for busy delis, sub shops, or custom-order concepts where a vast array of toppings, sauces, and proteins is essential for meeting customer expectations and ensuring fast service. With a mega top, there's no more running to the walk-in for a niche ingredient mid-order.

Our detailed guides on specific prep table models provide in-depth information on these reliable and popular units.

Doors vs. Drawers: Access and Organization

Your choice between doors and drawers for the refrigerated base cabinet will fundamentally shape your kitchen's restocking and organization workflow.

- Cabinet door models offer maximum storage flexibility. The spacious interior, typically equipped with adjustable shelving, excels at storing bulk items. They are ideal for large containers of pre-prepped ingredients, backup pans, large bottles of dressing, or bulk bags of produce. The wide-opening doors make restocking from large containers simple and efficient.

- Refrigerated drawer models are designed for the hyper-organized, high-speed kitchen. Each pull-out drawer is configured to hold specific food pan sizes, effectively creating a refrigerated filing system for your ingredients. This allows for incredibly quick access to backup pans, encourages precise portion control, and is significantly more energy-efficient. Opening a single, smaller drawer releases far less cold air than opening a full-size door, reducing compressor run times and lowering your utility bills.

For more insights into refrigerated storage solutions, our Undercounter Refrigerator Freezer Guide covers additional options.

Additional Selection Variables That Matter

- Unit width and section count: Prep tables come in standard widths, including 27, 36, 48, 60, and 72 inches, with even larger models available. Wider units are divided into sections, each with its own door or set of drawers. A 48-inch unit typically has two sections, while 60- and 72-inch models can have two or three. This allows multiple staff members to work side-by-side without getting in each other's way. If you anticipate two assemblers sharing the station during peak hours, a 60- or 72-inch model with a mega top is an excellent choice, as it can give each person their own dedicated cluster of pans.

- Compressor location and airflow: The location of the compressor and its airflow pattern are critical for proper installation and performance. Rear-breathing units are common but require several inches of clearance from the wall for ventilation. Front-breathing or side-breathing models are more versatile, allowing them to be installed flush against a wall or next to other equipment, making them ideal for tight kitchen layouts. Always match your selection to your line layout to ensure the condenser has access to cool, clean intake air and that hot discharge air can escape without being trapped.

- Pan rail depth and compatibility: Before purchasing, verify which pan sizes the top rail supports (e.g., 1/6, 1/9, 1/3, 1/2) and how many pans it can hold. Ensure the total capacity is sufficient to get you through your busiest production windows without constant refilling. The depth of the pans supported is also important; deeper pans hold more product but may not be suitable for all ingredients.

- Lids and night covers: Most units ship with hinged, insulated lids that help maintain temperature during service and should be kept closed when not in use. For after-hours, a solid night cover is a valuable accessory. It helps the unit retain cold air more effectively, reduces energy consumption, and prevents frost buildup overnight, ensuring the unit is ready for service the next day.

Not Just for Sandwiches: Pizza Prep Tables

It's worth noting the sandwich cooler's close cousin: the pizza prep table. While they share the same core benefits of consolidated, refrigerated prep, pizza tables have key modifications for their specific task:

- Deeper cutting board: Pizza making requires a significantly larger workspace to stretch dough, apply sauce, and arrange toppings. Pizza prep tables feature an extra-deep cutting board to accommodate this.

- Different pan configuration: They typically use fewer, larger pans (like 1/3-size pans) to hold bulkier ingredients like shredded mozzarella, pepperoni, and sliced mushrooms.

- Raised rail design: The ingredient rail on a pizza table is often raised higher than the cutting board. This creates a physical barrier that prevents flour, cornmeal, and other debris from the dough-making surface from contaminating the cold ingredients.

These units are highly versatile; a pizza prep table can work wonderfully for large salads or wraps, while a sandwich cooler can certainly suit a small pizzeria with a limited menu. The key is to carefully match the equipment's features to your specific menu and workflow needs. For pizza-focused operations, these guides offer deeper insights:

Real-World Fit Scenarios

- Small Café with 8-10 Core Items: A compact 27- or 36-inch standard top unit is perfect. It provides enough pan capacity for a curated menu while leaving ample cutting board space for careful assembly and plating.

- High-Volume, Build-Your-Own Deli: A 60- or 72-inch mega top is essential. It maximizes ingredient variety to meet customer demand and allows two or even three assemblers to work simultaneously during the lunch rush.

- Catering Commissary: A unit with drawer bases is ideal here. It speeds up swapping empty pans for full ones and helps maintain strict portion control for large-batch production. A standard top provides a large, clean work surface for packing and wrapping finished products.

- Ghost Kitchen/Virtual Brand: A 48-inch mega top with a front-breathing compressor offers a great balance of capacity and footprint flexibility, allowing it to be placed in tight, non-traditional kitchen spaces.

Key Features to Look For in a Sandwich Cooler

When you're ready to invest in a sandwich cooler, focusing on a few key features will simplify your decision-making process and ensure you select the right unit for your needs. Not all prep tables are created equal, and understanding the nuances of their construction, cooling systems, and certifications will guarantee you get a reliable, efficient, and long-lasting piece of equipment.

| Feature | Description | Ideal Use Case |

|---|---|---|

| Size & Capacity | Width (27"-72"), number of doors/drawers, cubic foot capacity of the base, and pan capacity of the top rail (e.g., 8, 12, 18, 24 1/6-size pans). | Matched to menu complexity, sales volume, and available kitchen space. |

| Top Style | Standard Top (single pan row, large cutting board), Mega Top (double/triple pan row, maximum ingredient capacity), Cut Top (extra-deep cutting board). | Café/Wraps (Standard), High-Volume Deli (Mega), Pizza/Specialty (Cut). |

| Base Style | Doors (flexible bulk storage with adjustable shelves) or Drawers (organized pan storage, energy-efficient, quick access). | Bulk storage needs (Doors), High-speed, organized workflow (Drawers). |

| Material | Exterior/Interior: 304 or 430-grade stainless steel. Cutting Board: NSF-approved high-density polyethylene. | All commercial kitchens for durability, hygiene, and longevity. |

| Cooling System | Forced-air circulation, eco-friendly R290 refrigerant, digital temperature control with display, high-efficiency ECM fan motors. | All commercial kitchens requiring consistent, reliable, and efficient cooling. |

| Energy Efficiency | ENERGY STAR certified, low amperage draw, high-quality gaskets, insulated lids. | Any operation looking to reduce long-term operating costs and environmental impact. |

| Certifications | NSF (sanitation and material safety), ETL/UL (electrical safety), DOE 2012+ compliant (energy efficiency). | All commercial kitchens in North America for regulatory compliance and safety. |

Focusing on quality construction, a reliable and efficient cooling system, and smart sizing will ensure you get a unit that becomes a cornerstone of your kitchen's productivity. For comprehensive guidance, our Commercial Refrigerators Buyers Guide covers all essential considerations.

Sizing Up Your Space: From Compact to Colossal

Choosing the right size sandwich cooler is the most critical first step. Before you even look at models, measure your available space carefully. Don't forget to account for clearance for door swings and the required ventilation space around the compressor (check the spec sheet!). Use painter's tape on the floor to map out the unit's footprint to visualize its impact on your workflow. Width options typically range from compact 27-inch models, perfect for small cafes or adding a secondary prep station, to massive 72-inch or even 93-inch units for the busiest kitchens. The 48-inch and 60-inch models are often the most popular all-rounders, offering a great balance of capacity and footprint.

Beyond physical dimensions, analyze the pan capacity. This number dictates how many different ingredients you can keep chilled and ready on the line. Also, look for thoughtful design features like ADA height options (34-inch countertop height) for improved staff comfort and accessibility. Our size-specific guides can help you find the perfect fit:

Material World: Durability and Cleanliness

Commercial kitchen equipment must be built to last and be easy to clean. Stainless steel construction is the industry standard and is non-negotiable for both the exterior and interior. However, not all stainless steel is the same. Look for units using higher-grade 304 stainless steel for interior surfaces and the top, as it has superior corrosion resistance, especially against salts and acids found in food. The exterior is often made of durable and magnetic 430 stainless steel. This robust construction resists rust, dents, and harsh cleaning chemicals, while its non-porous surface is easy to sanitize and prevents the absorption of odors.

The cutting board should be made of NSF-approved, high-density polyethylene. Unlike wood, this material is non-porous, meaning it won't absorb liquids, bacteria, or odors. It's also knife-friendly, preventing excessive dulling of your cutlery, and is typically removable for easy deep cleaning and sanitizing. Investing in quality materials upfront translates directly to fewer maintenance headaches, better food safety compliance, and a longer service life for your equipment.

The Chill Factor: Cooling Systems and Energy Efficiency

A modern, efficient refrigeration system is the heart of a great sandwich cooler. The industry standard is forced-air refrigeration, which uses fans to actively circulate cold air throughout the cabinet and pan rail. This ensures even temperature distribution, rapid recovery after door openings, and the elimination of hot spots. Contrast this with older, less effective 'cold wall' systems. Look for units using R290 refrigerant. This is a natural, non-toxic hydrocarbon that is exceptionally efficient and has a very low Global Warming Potential (GWP), making it the environmentally responsible choice that also lowers your electricity bill.

Energy efficiency is a feature that pays you back every month. ENERGY STAR certified units have met strict EPA guidelines for lower power consumption, often using 15-20% less energy than standard models. Key features contributing to this include efficient ECM fan motors, high-quality insulation, and precise digital temperature controls that prevent the compressor from overworking. Compliance with standards like DOE 2012 is another strong indicator of quality engineering and energy-conscious design.

Build Details That Separate Great from Good

- Gaskets and Hardware: Look for heavy-duty, easily removable snap-in door gaskets. A perfect seal is crucial for efficiency, and when gaskets inevitably wear out, snap-in designs make replacement a simple, tool-free task. Robust, full-length door handles and self-closing hinges are built to withstand the repetitive stress of a busy service.

- Rails and Lids: Well-designed, insulated lids are essential for maintaining pan temperature. They should be easy to lift and hold their position. Some premium units feature removable rail inserts, allowing the entire pan well to be taken out for deep cleaning.

- Drainage and Defrost: An effective condensate management system is key. Look for automatic defrost cycles and a self-contained hot gas condensate system that evaporates moisture, eliminating the need for a separate drain line and preventing puddles on the floor.

- Serviceability: In the event of a problem, easy serviceability is a lifesaver. Features like a slide-out condenser unit, front-access panels, clear wiring diagrams, and the use of common, non-proprietary service parts can significantly lower downtime and future repair costs.

Installation and Site Prep Essentials

- Provide the manufacturer's recommended clearance around the condenser intake and discharge (typically 2-4 inches).

- Place the unit away from heat sources like fryers, griddles, and direct sunlight, as this will force the compressor to work harder.

- Use a dedicated, properly rated electrical circuit to avoid voltage drops and ensure safe operation.

- Level the unit upon installation so that doors close and seal correctly and condensation drains properly.

- Allow the cooler to sit upright for at least 24 hours after delivery before powering it on. This allows the compressor oil and refrigerant to settle, preventing catastrophic damage on startup.

Spec Sheets and Verification

Before you click 'buy', download and carefully review the manufacturer's specification sheet. Verify all critical details: exact dimensions, clearance requirements, voltage and amperage, pan capacities, and included certifications. Ensure that any accessories you need—such as extra pans, specific lids, night covers, or casters—are available and compatible with your chosen model.

Long-Term Value: Maintenance, Customization, and Support

The true value of a sandwich cooler is measured not just by its purchase price, but by its performance and longevity over years of service. To maximize this long-term value, a three-pronged approach is essential: diligent preventative maintenance, smart customization to fit your workflow, and understanding the support systems available to you. A well-maintained and properly configured unit will remain a productive asset for years. For comprehensive guidance, refer to our Sandwich Prep Table Maintenance guide.

Essential Maintenance for Your Sandwich Cooler

Consistent, proactive maintenance is the single most important factor in extending the life of your prep table and ensuring its performance. A simple, regular cleaning schedule can prevent the vast majority of common equipment failures.

- Daily Tasks: At the end of each day, wash and sanitize all food pans, lids, and the cutting board. Wipe down all stainless steel surfaces, both interior and exterior, with a food-safe cleaner. Check the digital temperature display to ensure it's holding in the 38°F-40°F range.

- Weekly Tasks: Perform a deeper clean. Remove the cutting board and scrub it thoroughly. Check and clear any debris from the interior drain lines to prevent clogs and backups. Inspect door and drawer gaskets for any signs of cracking, tearing, or brittleness that could cause air leaks.

- Monthly Tasks: This is the most critical maintenance task: clean the condenser coils. Unplug the unit, locate the coils (usually behind a front or rear grille), and use a stiff brush and a vacuum to remove all accumulated dust, grease, and debris. Clogged coils are the number one cause of compressor strain and premature failure.

- Quarterly/Annual Checks: It's wise to periodically check that the unit is still level, inspect fan motors for unusual noises, and calibrate the thermostat with a reliable, independent thermometer to ensure accuracy.

For more on commercial refrigeration maintenance, check our guide on Commercial Refrigeration best practices.

Customizing Your Workstation

Tailor your sandwich cooler to your exact operational needs with a range of available accessories. These add-ons can further boost efficiency and functionality:

- Overshelves: Add single or double-tiered shelving above the unit for convenient vertical storage of non-refrigerated items like bread, wrappers, spices, or utensils.

- Sneeze Guards: Essential for any customer-facing or buffet-style operation, these glass or acrylic shields protect food from contamination while keeping it visible.

- Caster Wheels: Swapping standard legs for heavy-duty casters (with locks) provides mobility, making it vastly easier to move the unit for deep cleaning behind and underneath it, or for reconfiguring your kitchen layout.

- Extra Pans and Lids: Having multiple sets of food pans allows for a seamless ingredient rotation system. Pre-filled pans can be stored in the base cabinet and swapped in instantly when a pan on the line runs empty.

- Night Covers: A solid or vinyl cover that fits over the entire pan rail area provides superior insulation overnight, reducing energy consumption and preventing temperature fluctuations.

Troubleshooting Common Issues

Even with perfect maintenance, issues can arise. Knowing how to diagnose common problems can save you time and a costly service call.

- Unit Not Cooling Properly: First, check the thermostat setting. Second, clean the condenser coil immediately. Third, inspect the door gaskets for a proper seal. If these steps don't work, it may be a more serious issue like a refrigerant leak or a failed compressor requiring a technician.

- Excessive Ice Buildup (in base or on coils): This is almost always caused by warm, moist air entering the unit. Check for a torn gasket, a door that isn't closing properly, or staff habits of leaving the door open for extended periods.

- Unit is Too Loud: Some noise is normal, but a sudden increase in volume or a new rattling/grinding sound is not. Ensure the unit is level. Check if a fan blade is obstructed or if the noise is coming directly from the compressor, which could indicate a pending failure.

Understanding Warranty and Support

Before you buy, understand the warranty. Most commercial prep tables come with a multi-part warranty, such as a 1- to 3-year warranty on parts and labor, and a separate, longer 5- or 7-year warranty on the compressor part itself. Know what is covered and for how long. Also, investigate the manufacturer's service network. Having access to certified technicians in your area who can provide warranty service is crucial for minimizing potential downtime.

Frequently Asked Questions about Sandwich Prep Tables

Navigating the options for a new sandwich prep table can bring up many questions. Here are answers to some of the most common queries to help clarify your decision-making process.

What is the ideal temperature for a sandwich prep table?

The ideal and safest temperature range for a sandwich cooler is between 38°F and 40°F (3.3°C to 4.4°C). This range is critical because it complies with the FDA Food Code requirement to keep cold-held foods at or below 41°F. Operating in this slightly cooler range provides a crucial safety buffer, significantly slowing bacterial growth and ensuring your ingredients—from deli meats to fresh produce—remain at their peak quality and safety.

How do I know what size sandwich prep table I need?

Choosing the right size is a three-part calculation:

- Physical Space: First, measure your available line space, making sure to account for the manufacturer's required clearance for ventilation (usually 2-4 inches on sides and back) and room for doors to swing open.

- Menu Complexity: A simple, curated menu might only require a compact 27-inch or 36-inch unit. A complex, build-your-own concept with dozens of toppings will necessitate a larger 60-inch or 72-inch mega top model to hold all the necessary ingredients.

- Daily Volume: High-volume operations need larger base cabinets and more pan capacity to minimize the frequency of restocking during busy shifts. A larger unit can also accommodate a second employee, doubling your output potential.

Can I use a sandwich prep table for other foods like salads or burritos?

Absolutely. The term "sandwich prep table" is something of a misnomer. These units are incredibly versatile and are perfectly suited for any made-to-order cold food assembly line. They are commonly used as salad stations, burrito and taco bars, poke bowl counters, and wrap stations. Any operation that involves assembling a final dish from multiple refrigerated ingredients will see a massive boost in efficiency and consistency from using a prep table.

What is the difference between a sandwich prep table and a salad prep table?

While the terms are often used interchangeably, there can be subtle differences. Salad prep tables sometimes feature a deeper cutting board and are often configured to hold larger, deeper food pans (like 1/3-size pans) to accommodate bulky leafy greens. However, the core technology and benefits are identical, and either type can typically be adapted for the other's purpose.

What ambient conditions are ideal for reliable operation?

Most commercial sandwich coolers are designed to operate effectively in an ambient kitchen environment of up to 80-85°F. However, for optimal performance and energy efficiency, it's best to place the unit away from heat-generating equipment like fryers, charbroilers, and direct sunlight. Ensuring the condenser has unobstructed airflow as per the manufacturer's specifications is the most critical factor for reliable operation in any kitchen.

Are doors or drawers better in the base?

Neither is definitively "better"—they just serve different workflows. Doors offer maximum flexibility for storing large, bulky, or oddly shaped items. Drawers provide superior organization, energy efficiency (less cold air loss per opening), and speed for kitchens that have a standardized pan-based backup system. The choice depends entirely on how you plan to organize your cold storage.

How often should I clean the condenser coils?

For most kitchens, a thorough cleaning of the condenser coils once a month is a solid rule of thumb. However, in environments with high levels of grease, flour, or dust in the air (like bakeries or kitchens with lots of fried items), you may need to increase the frequency to every two weeks. This single maintenance task is the most effective way to lower energy consumption and extend the life of your compressor.

What does NSF certification mean and why is it important?

NSF stands for the National Sanitation Foundation. An NSF certification on a piece of foodservice equipment means that it has been tested and certified to meet strict standards for public health protection. This includes ensuring the materials used are safe for contact with food, the unit is designed to be easily cleaned and sanitized (no hard-to-reach crevices), and it performs as advertised. Health inspectors look for the NSF mark, so it is a critical certification for regulatory compliance.

What maintenance items are most frequently overlooked?

- Cracked Door Gaskets: Small tears in gaskets leak cold air constantly, forcing the compressor to run non-stop.

- Dirty Condenser Coils: This is the most common and most damaging-when-neglected issue, leading to high energy bills and eventual compressor failure.

- Overfilled Pans: Piling ingredients high above the pan rim blocks the cold airflow from the rail, causing food to enter the temperature danger zone.

- Blocked Interior Drains: Forgetting to clear out small bits of food from the interior drain can lead to clogs, water backup, and unsanitary conditions.

Conclusion

A sandwich cooler is far more than just a piece of commercial refrigeration; it's a strategic centerpiece that fundamentally revolutionizes cold food preparation. By intelligently consolidating refrigerated storage and a dedicated prep surface into one ergonomic and efficient workstation, it systematically eliminates wasted motion, improves food safety protocols, and streamlines your entire kitchen workflow. This optimization translates directly into tangible business benefits: faster service, happier customers, reduced food waste, and a healthier bottom line.

The key benefits are clear and impactful. Consistent and precise temperature control between 38°F and 40°F acts as your primary defense for food safety, while the ergonomic design, complete with an integrated cutting board, boosts staff productivity and reduces fatigue. With a wide array of versatile options—from standard tops for focused menus to mega tops for maximum variety, and from flexible door bases to hyper-organized drawer models—there is a sandwich cooler perfectly suited to fit any operation's specific needs. Investing in a unit with quality stainless steel construction, an energy-efficient cooling system using R290 refrigerant, and proper certifications ensures long-term value and lower operating costs for years to come.

If you are planning to upgrade or purchase your first prep table, follow this simple roadmap for success:

- Analyze Your Menu: Map your ingredient list to the required number and size of pans.

- Measure Your Space: Carefully measure your kitchen line and verify all electrical and airflow requirements before ordering.

- Plan for Volume: Choose a unit width and base configuration (doors vs. drawers) that matches your current and projected sales volume and staffing plan.

- Establish Procedures: From day one, build Standard Operating Procedures (SOPs) for daily cleaning, proper loading (no overfilling pans), and regular temperature checks.

- Accessorize for Efficiency: Invest in accessories like overshelves or extra pan sets that remove friction from your daily service.

Investing in a quality sandwich cooler is a commitment to operational excellence that your staff will appreciate and your customers will notice through faster, more consistent service. At The Restaurant Warehouse, we make this critical investment accessible by providing high-quality commercial restaurant equipment at wholesale prices. We eliminate the high retail markups and overhead so you can equip your kitchen with the professional-grade tools it needs to succeed and thrive.

The right prep table is not an expense; it is an investment that pays dividends daily in efficiency, safety, and satisfaction. Let us help you find the perfect solution to transform your kitchen's workflow and lift your business.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment