Fridge Not Getting Cold? A Practical Diagnostic Guide

When you open your commercial fridge and get hit with a wave of lukewarm air, it’s a gut-wrenching moment for any restaurant operator. Your mind immediately goes to inventory loss and the potential for a massive, expensive repair. But before you panic, take a breath. More often than not, the cause is something surprisingly simple, like a blocked air vent or dirty condenser coils.

You’d be surprised how many “emergency” calls could have been solved in five minutes. Before assuming the worst, a few quick checks can often get you back up and running, saving your food and your wallet.

Your First Steps in Diagnosing a Warm Fridge

That lukewarm air is a universal sign of trouble, especially when food safety is on the line. But jumping straight to calling a technician can be a costly mistake. Instead, a methodical approach will quickly tell you if you're dealing with a minor hiccup or a major mechanical failure. This is all about ruling out the easy stuff first.

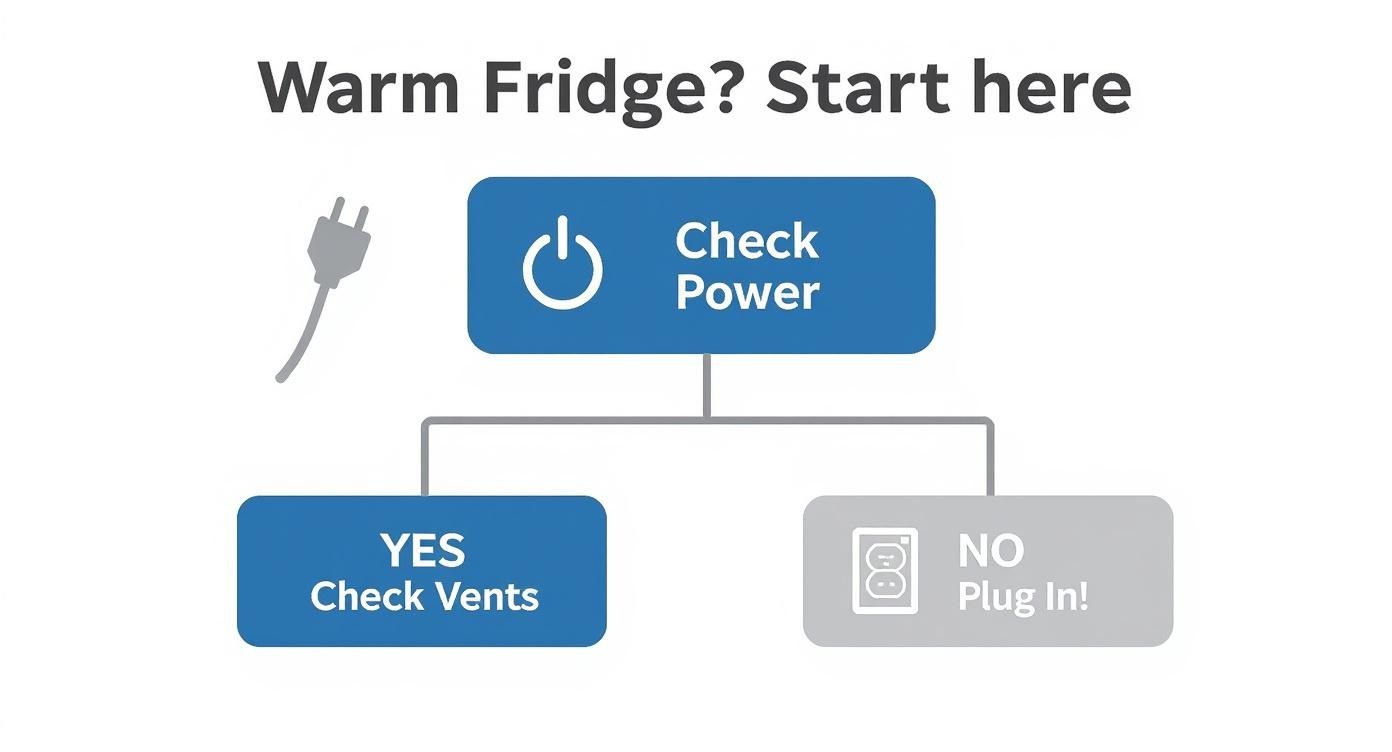

You don't need to be a refrigeration expert for this part—just have a keen eye and a few minutes to spare. It’s amazing how often an overstuffed shelf or a door that isn't sealing right is the real culprit. This simple decision tree infographic can walk you through the initial checks.

As the graphic shows, the absolute first step is just confirming the unit has power. You'd laugh at how many times I've seen a plug simply knocked out of the wall.

Just How Common Are Refrigerator Failures?

Discovering your fridge isn't getting cold can feel like a rare disaster, but the data shows it’s more common than you might think. Studies from places like Consumer Reports reveal that refrigerators are actually one of the least reliable major appliances out there.

An estimated 33% of all refrigerators will need a repair within their first five years. While many of those issues are with icemakers, a significant 13% of owners report complete cooling failures.

This is critical information for any restaurant operator. Knowing that cooling issues are a known vulnerability helps shift your mindset from "if" a problem will happen to "when," making routine maintenance feel a lot more important.

A warm refrigerator isn’t just an inconvenience; it's a critical failure that directly impacts your bottom line through spoiled inventory and potential downtime. Mastering these initial diagnostic steps is the first line of defense.

To help you troubleshoot methodically, I've put together a quick checklist.

Quick Diagnostic Checklist for a Warm Fridge

When your fridge starts to warm up, run through this table to quickly identify the most common problems. It breaks down the likely cause, what you'll probably see, and whether you can tackle it yourself.

| Potential Cause | Common Symptoms | DIY Fix Difficulty |

|---|---|---|

| Blocked Air Vents | Fridge is cool in some spots, warm in others. | Easy |

| Dirty Condenser Coils | Unit runs constantly but doesn't get cold. | Easy |

| Bad Door Gasket | Condensation or frost buildup around the door. | Easy to Moderate |

| Incorrect Thermostat | Temperature is consistently too high. | Easy |

| Fan Motor Failure | You don't hear the fan running at all. | Difficult (Call a Pro) |

| Low Refrigerant | Fridge isn't cooling and you see oily residue. | Difficult (Call a Pro) |

By starting with the "Easy" fixes, you can often solve the problem in minutes without a service call.

To get started, focus your attention on these four key areas first:

- Power and Settings: Is the unit plugged in securely? Has someone accidentally bumped the thermostat? Make sure it's set below 40°F.

- Air Circulation: Cold air needs to move. Check that food containers aren't crammed up against the internal vents, blocking airflow. This is a huge one.

- Door Gaskets: Take a look at the rubber seals around the door. Are there any cracks, gaps, or gunk preventing a tight seal? Warm air seeping in will kill your cooling efficiency.

- Condenser Coils: These are usually on the back or bottom of the unit. If they're caked in dust and grime, the fridge can't release heat properly and will struggle to cool.

By methodically checking these four areas, you can knock out the most frequent causes of a warm fridge and often fix the problem yourself.

Easy Fixes to Try Before You Panic

That sinking feeling when you realize your commercial fridge is running warm is a familiar nightmare for any operator. It’s easy to jump straight to worst-case scenarios and start pricing out new compressors. But before you panic, take a deep breath.

More often than you'd think, the problem is something simple—a fix you can handle yourself in under five minutes with zero tools.

Let’s start with the absolute basics. Is the unit plugged in all the way? It sounds almost too obvious, but cords get bumped loose during nightly cleaning all the time. Next, find the temperature dial. A staff member could have easily knocked it to a warmer setting by accident. Always make sure it’s set to 40°F or lower to keep your inventory safe.

Inspecting the Door Gaskets

A bad door seal is a classic energy vampire and a very common reason for a fridge to struggle. If warm kitchen air is constantly seeping inside, the compressor has to work overtime just to keep up, and eventually, it's going to lose the battle.

Run your hand along the edge of the door gasket. Do you feel any cool air escaping? Look closely at the rubber seal for any visible cracks, tears, or grimy buildup that could be preventing a tight fit. Sometimes, a simple wipe-down with warm, soapy water is all it takes to restore the seal.

Pro Tip: Try the dollar bill test. Close the refrigerator door on a dollar bill. If you can pull it out with little to no resistance, your gasket isn't sealing properly, and you're definitely losing cold air.

In a busy commercial kitchen, doors are opened hundreds of times a day, so worn-out gaskets are a common wear-and-tear issue. If you spot a tear, replacing it is a straightforward repair that can make a world of difference in your unit's performance. You can learn more in our guide on how to find the right Atosa door gasket for your model.

Avoiding Overcrowding and Blocked Vents

Cold air needs room to breathe. If your refrigerator is packed to the gills, you're almost certainly creating warm spots and blocking airflow. Honestly, this is one of the most frequent culprits behind a fridge not cooling evenly.

Take a moment to find the air vents inside your unit—they're usually located on the back or side walls. Now, take a critical look at how your items are stored.

Common Airflow Blockers to Look For:

- Large Boxes: Pushing a big pizza box or a case of produce right up against the back wall can block a critical vent, cutting off cold air to an entire section.

- Stacked High: Stacking food containers all the way to the ceiling will stop the natural circulation of cold air from top to bottom.

- Cramped Shelves: When every last square inch is filled, air simply has nowhere to go. Always try to leave small gaps between items to let the air move.

Simply rearranging a few shelves to create clear channels for air to circulate can instantly improve your refrigerator’s cooling power. It's a quick organizational fix that costs nothing but can solve a major temperature headache.

Time to Check the Coils and Fans for Airflow

So, you've checked the obvious stuff like the door seal and made sure the vents aren't blocked, but your fridge is still warm. Now it’s time to roll up your sleeves and look at the real heart of your refrigerator's cooling system: the condenser coils and fans. These parts work together to pull heat out of the unit. When they're dirty or broken, your fridge basically can’t breathe, and that’s when the temperatures start creeping up.

Think of the condenser coils like the radiator in your car. Their whole job is to get rid of the heat that the cooling system has worked so hard to remove from inside the cabinet. The problem is, over time, they become total magnets for all the dust, grease, and grime floating around your kitchen.

All that gunk builds up and acts like a thick, insulating blanket. It traps the heat right where you don't want it, forcing the compressor to run harder and longer than it was ever meant to. Eventually, it just can't keep up. You'll notice your fridge isn't getting cold enough, even though you can hear it running constantly.

Finding and Cleaning the Condenser Coils

First things first: unplug the refrigerator. Always. Safety is non-negotiable here. The coils are usually in one of two places:

- On the back of the unit: A lot of older models have a big, black grid of coils mounted right on the back. These are super easy to get to.

- Underneath the unit: Most modern commercial refrigerators tuck the coils away at the bottom, hidden behind a front or back kick plate. You’ll need to pop that panel off to access them.

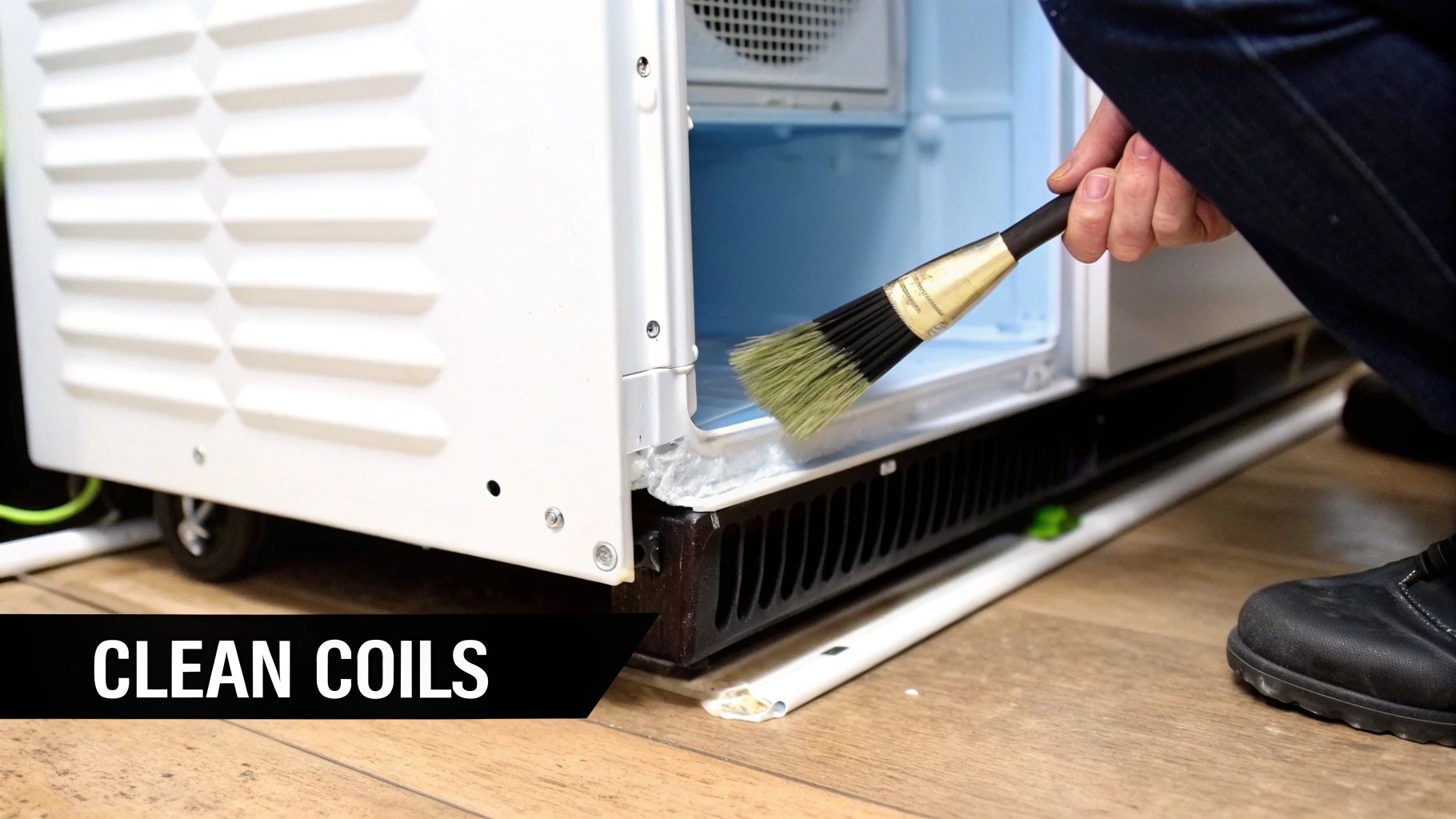

Once you’ve found the coils, you'll need a long, flexible coil brush and a vacuum. Gently brush the dust and caked-on grime off the coils, working your way from top to bottom. Then, use your vacuum's hose attachment to suck up all the debris you’ve loosened. Really pay attention to the little cooling fins—dust loves to get packed in there. For a more detailed walkthrough, check out our guide on cleaning the condenser on Atosa refrigerators.

A quick coil cleaning every three to six months can make a huge difference in efficiency and prevent one of the most common reasons for cooling failure. It's a five-minute job that can save you a thousand-dollar repair bill down the road.

Checking the Condenser and Evaporator Fans

Your refrigerator relies on two critical fans to keep the air moving. If either one gives out, you're going to have a problem.

The condenser fan lives down by the compressor and coils. Its job is to blow air across the coils to help them cool down. When the compressor is running, you should see this fan spinning. If it's not moving, take a peek to see if anything is jamming the blades—sometimes a stray piece of plastic or a wire can get in the way.

The evaporator fan is inside the freezer compartment, usually tucked behind a panel on the back wall. This is the fan that pushes all that cold air from the freezer into the main refrigerator area. If you're not feeling any air coming out of the vents inside your fridge, this fan could be the culprit. Another dead giveaway is a grinding or squealing noise, which usually means the motor is on its last legs.

When you think about the global refrigeration market hitting over $100 billion by 2025, and a serious failure rate of 13%, the scale of the problem becomes clear. That's a staggering number of potential failures leading to massive food waste. This is exactly why keeping up with simple maintenance on parts like coils and fans is so incredibly important for your bottom line.

Diagnosing Deeper Mechanical Problems

So, you've cleaned the coils and made sure the fans are spinning, but your fridge is still acting like a lukewarm cooler. At this point, it's time to roll up your sleeves and investigate the core mechanical and electrical parts. This is where things get a bit more technical, but with a careful approach, you can usually pinpoint exactly what's gone wrong.

The three main suspects we're looking at now are the defrost system, the start relay, and the temperature control thermostat. Each one plays a critical role in the cooling cycle, and when one of them fails, the whole system can grind to a halt, leaving you with warming temperatures and valuable inventory at risk. Let's break down how to figure out which one is causing your headache.

The Defrost System Has Failed

Your refrigerator's evaporator coils are designed to get frosty, but a built-in defrost system is supposed to melt that frost away on a regular schedule to keep the air flowing. When this system fails, the coils get completely encased in a solid block of ice, choking off the flow of cold air.

A classic sign of this problem is a thick sheet of ice forming on the back wall of the freezer compartment while the refrigerator section feels warm.

The defrost system itself has a few key parts that could be the culprit:

- The defrost heater: This element is what warms up to melt the ice off the coils.

- The defrost timer: This part tells the system when it's time to switch from cooling to defrosting.

- The defrost terminator: This sensor detects when all the ice has melted and signals the heater to shut off.

If you suspect a defrost issue, that thick, uniform ice buildup is the most telling sign. A quick visual inspection behind the freezer panel will confirm it.

Checking the Temperature Control and Start Relay

The temperature control thermostat is the brain of the operation, sensing the internal temperature and telling the compressor when to turn on and off. If this part is faulty, it may never send the signal for the compressor to start, leaving your fridge warm even if every other part is working perfectly.

You can often hear a faint "click" when you turn the temperature dial from its warmest setting to its coldest. If you hear that click and the compressor kicks on, your thermostat is likely doing its job.

The start relay, on the other hand, is a small device attached directly to the compressor. Its only job is to provide the jolt of electricity needed to get the compressor motor running. If you can hear the compressor hum for a moment and then click off without ever fully starting, a bad start relay is an extremely common cause.

If your refrigerator is completely silent but the interior light is on, the problem often points to either the temperature control thermostat or the compressor's start relay. These components act as the "on" switch for the entire cooling system.

Properly configuring your temperature controller is crucial for efficient operation. For those using specific models, our comprehensive guide to configuring your Dixell controller for Atosa refrigerators can provide detailed, step-by-step instructions.

The Reality of Refrigerator Reliability

While you're diagnosing these issues, it's worth remembering that not all refrigerators are created equal. Industry data shows an overall repair rate of around 12.5%, but some brands are notoriously more prone to cooling failures than others.

Repair professionals often cite certain models as being particularly susceptible to compressor failures—a primary reason for a fridge not getting cold. This highlights a crucial reality: even with advanced technology, certain units are just more likely to face these costly breakdowns. You can find more insights about the most reliable refrigerator brands and avoid a problematic purchase in the future.

It’s one thing to handle a bit of DIY maintenance, but a smart operator knows their limits. You can absolutely tackle many of the common fridge hiccups yourself, but some problems are clear signals to step back and bring in a professional.

Trying to wrestle with a major mechanical failure or a sealed system issue without the right training and tools? That’s a recipe for turning a repairable problem into a catastrophic one. Trust me, that’s a bill you don’t want to see.

The trick is learning to spot the red flags that point to a much deeper issue. If you've gone through all the basic checks and your fridge is still acting like a lukewarm cooler, it’s time to look for these serious warning signs.

Serious Symptoms You Should Never Ignore

Some issues are immediate stop signs. If you see, hear, or smell any of the following, unplug the unit and grab your phone. These problems usually involve the sealed refrigerant system or high-voltage parts, which are flat-out dangerous for anyone who isn’t certified.

Here are the definitive signs that you need a pro, no questions asked:

- A Hot Compressor That Isn't Running: The compressor is the heart of your whole refrigeration system. If it feels scorching hot but you don’t hear that familiar hum of it kicking on, you could be looking at a seized motor or a busted start relay.

- Strange Chemical Smells: A faint, chemical-like odor is often the tell-tale sign of a refrigerant leak. Refrigerant is hazardous stuff, and only certified technicians can handle it safely and legally.

- Oily Residue: Finding a greasy, oily film on the floor under your unit or on components near the compressor is another classic symptom of a refrigerant leak.

Crucial Takeaway: Any problem related to the sealed system—which includes the compressor, evaporator coils, condenser coils, and the refrigerant lines connecting them all—is strictly a job for a licensed technician. These are complex repairs that require specialized recovery equipment, and they are not safe to attempt on your own.

Finding a Trustworthy Technician

Once you’ve made the call to bring in help, the next challenge is finding someone reliable and honest. Not all repair services are created equal, and asking a few key questions upfront can save you a world of frustration.

Start by searching for companies that specialize in commercial refrigeration. They get the urgency of a restaurant environment. When you call, have the make and model of your unit handy, along with a clear description of what’s going on.

Before you agree to anything, make sure you ask these critical questions:

- Do you charge a flat diagnostic fee to come out?

- Is that diagnostic fee applied to the final repair bill if I move forward?

- Will you provide a detailed, itemized quote before you start any work?

- Do you offer a warranty on your parts and labor?

A reputable tech will be transparent about their pricing and stand behind their work. That’s the kind of peace of mind you need when your equipment—and your inventory—is on the line.

Common Questions About a Fridge Not Getting Cold

Even after checking all the usual suspects, you might still be scratching your head about what’s going on with your specific unit. When a commercial fridge stops getting cold, every scenario feels like an emergency, so let's tackle a couple of the most common questions we hear from operators in the trenches.

One of the most frequent puzzles is when the freezer is working perfectly, but the refrigerator side is warm. Since most units share a single cooling system, this almost always points to an airflow problem between the two compartments.

Why Is My Freezer Working but Not the Fridge

When the freezer is frosty but the fridge is warming up, it's a classic sign that cold air isn't making the journey from one section to the other. The whole cooling process starts in the freezer, and a fan is supposed to push that chilled air over into the refrigerator compartment.

A few things can put a stop to this:

- A Faulty Evaporator Fan: This is the fan responsible for moving the cold air. If its motor has burned out, no cold air is ever going to reach your fridge. Simple as that.

- Blocked Air Damper: The damper is a small vent that opens and closes to control airflow. It can get stuck shut or blocked by a buildup of ice.

- Frosted-Over Coils: If the defrost system fails, the evaporator coils inside the freezer can turn into a solid block of ice, physically blocking any air from passing through.

If you can hear the fan running in the freezer but don’t feel any air coming through the vents in the fridge, the pathway is almost certainly blocked. This is a tell-tale sign of an airflow issue, not a total cooling system failure.

Do I Really Need to Clean My Coils

Yes. Absolutely. We can't stress this enough.

Dirty condenser coils are one of the top reasons a fridge has to work way harder than it should, which eventually leads to a breakdown. Think of it like trying to run a marathon while wearing a heavy winter coat—the system is just going to overheat and get exhausted.

A regular cleaning every 3-6 months is non-negotiable in a commercial kitchen where grease, flour, and dust are everywhere. It’s a simple, preventative task that has a direct impact on your unit’s health and efficiency, helping you avoid that dreaded "fridge not getting cold" emergency. A clean system runs cooler, uses less energy, and lasts a whole lot longer.

At The Restaurant Warehouse, we provide the durable, reliable commercial refrigeration you need to keep your inventory safe and your kitchen running smoothly. Explore our selection of top-tier equipment and find the perfect fit for your operation at https://therestaurantwarehouse.com.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment