Deep Frying Done Right – Top Commercial Deep Fryers Reviewed

The Kitchen Workhorse: Why Commercial Deep Fryers Matter

Commercial deep fryers are the workhorses of professional kitchens, capable of turning out large volumes of crispy, golden favorites that customers love. If you're looking to purchase a commercial deep fryer, here's what you need to know:

- Capacity Range: Commercial fryers hold between 10-90 pounds of oil

- Power Options: Electric (1,750W-24kW) or Gas (34,000-170,000 BTU)

- Price Range: $1,200-$15,000 depending on size and features

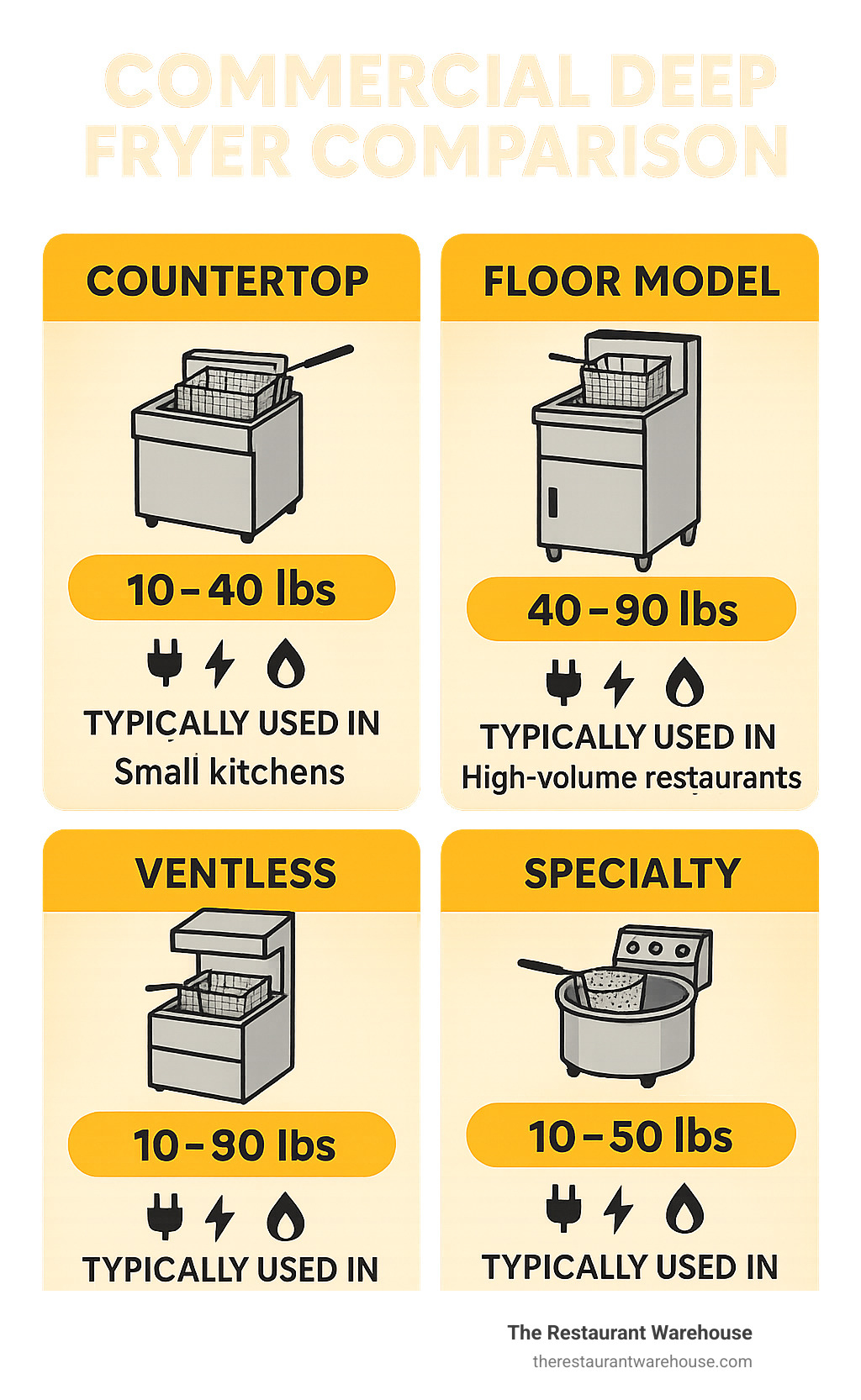

- Key Types: Countertop, floor model, ventless, and specialty fryers

As one kitchen equipment expert noted, "Deep fat fryers are almost a must if you want to satisfy the enormous demand for popular fried foods like French fries and fried chicken." This statement rings true for restaurant owners looking to maximize profits and menu versatility.

Commercial fryers differ significantly from residential models in their construction, capacity, and recovery time. While a home fryer might struggle with a few batches of fries, a commercial unit can produce up to 30 pounds of fried chicken per hour without breaking a sweat.

The right fryer can become one of the most profitable pieces of equipment in your kitchen. Fast heat recovery, durable stainless steel construction, and proper oil management systems make commercial fryers a smart investment for any food service operation looking to expand their menu with crowd-pleasing fried items.

Whether you're opening a new restaurant or upgrading your current equipment, choosing the right commercial deep fryer is crucial for operational efficiency and food quality. The best fryer for your business will depend on your menu, volume needs, available space, and utility connections.

Commercial Deep Fryers 101: What Sets Them Apart

Ever wondered what makes a true commercial deep fryer different from the one gathering dust in your home kitchen cabinet? It's like comparing a family sedan to a heavy-duty truck – they might look similar at first glance, but they're built for entirely different purposes.

Commercial deep fryers are the heavyweight champions of professional kitchens, designed to handle the relentless demands of restaurant service. While your home fryer might manage a few batches of mozzarella sticks for game day, a commercial unit can churn out basket after basket of perfectly crispy fries during a 12-hour shift without breaking a sweat.

The differences start with capacity – commercial models typically hold between 10-90 pounds of oil, compared to the measly 2-4 pounds in residential units. This extra capacity isn't just about cooking more food; it's about maintaining consistent temperatures when cold products hit the hot oil.

Power is another game-changer. Commercial electric fryers pack anywhere from 1,750 to a whopping 24,000 watts, while gas models deliver an impressive 34,000-170,000 BTU. All this muscle translates to recovery times measured in seconds rather than minutes – critical when you're serving hundreds of customers.

| Feature | Residential Deep Fryer | Commercial Deep Fryer |

|---|---|---|

| Oil Capacity | 2-4 pounds | 10-90 pounds |

| Construction | Lightweight aluminum/steel | Heavy-duty stainless steel |

| Power Output | 1,200-1,800 watts | 1,750-24,000 watts (electric) or 34,000-170,000 BTU (gas) |

| Recovery Time | Slow (minutes) | Fast (seconds) |

| Daily Usage | 1-2 hours | 8-16+ hours |

| Certifications | Basic UL | NSF, ETL, ENERGY STAR |

| Temperature Range | Up to 375°F | Up to 400°F |

| Safety Features | Basic | Advanced (auto shutoff, cool zones) |

| Price Range | $50-$300 | $1,200-$15,000 |

Those certifications aren't just fancy acronyms, either. NSF (National Sanitation Foundation) and ETL (Intertek Testing Services) listings ensure your equipment meets strict health and safety standards – something your local health inspector will definitely be checking. Many models also carry ENERGY STAR certification, which can save you significant money on utility bills over time.

Key Differences Between Residential and Commercial Deep Fryers

The heart of a commercial deep fryer is built for marathon cooking sessions. While you might fire up a home fryer once a week, restaurant models often run 12+ hours daily, seven days a week, for years on end. That's why they're constructed with heavy-duty stainless steel tanks and components that can withstand constant use and cleaning.

Temperature consistency is another crucial difference. When you drop frozen fries into a commercial fryer, it recovers to cooking temperature in about 60-90 seconds. A home unit might leave you waiting several minutes, resulting in soggy, oil-soaked food. This recovery time is what separates perfectly crispy restaurant fries from the disappointing ones you make at home.

Commercial fryers also reach higher temperatures (up to 400°F versus 375°F for residential models) and maintain them with precision thanks to commercial-grade thermostats. And while we're talking safety, professional units include features like automatic high-temperature shutoffs and cool zones that residential models simply don't have.

Main Types of Commercial Deep Fryers

The world of commercial deep fryers offers more variety than you might expect, with each type designed for specific cooking needs:

Open-pot fryers feature exposed heating elements that make cleaning a breeze – perfect for french fries and other lightly battered foods. Their simpler design often means lower maintenance costs over time.

Tube-type fryers contain heating tubes running through the oil, creating a "cool zone" at the bottom where food particles collect without burning. This design is ideal for heavily battered items like chicken, preventing that burnt taste that can ruin oil.

Flat-bottom fryers heat the entire oil volume evenly with no sediment zone, making them perfect for delicate items like funnel cakes and donuts that need to float while cooking.

Pressure fryers are the secret behind many famous fried chicken restaurants. They seal during cooking, creating pressure that reduces cooking time and oil absorption while locking in moisture.

Gas floor models are the workhorses of high-volume operations, with oil capacities of 40-90 pounds and powerful burners delivering up to 170,000 BTU of cooking power.

Electric countertop models offer convenience for smaller operations, with 10-30 pound oil capacities and the ability to plug into standard outlets – perfect for adding frying capability without major kitchen modifications.

Ventless fryers are game-changers for locations where traditional hood installation is impossible or prohibitively expensive. Their built-in filtration systems capture grease-laden vapors and odors, opening up frying possibilities in non-traditional spaces.

Specialty fryers are purpose-built for specific foods – like donut fryers with rotating product lifts, pressure chicken fryers, or flat-bottom designs for perfect funnel cakes and tempura.

Choosing the right type depends on your menu, volume, and kitchen constraints – but don't worry, we'll help you steer those waters in the following sections.

How to Choose the Right Commercial Deep Fryer for Your Operation

Finding your perfect commercial deep fryer doesn't have to feel like searching for a needle in a haystack. Let's break it down into bite-sized pieces that make sense for your kitchen.

First, take a good look at your menu. Are you mainly frying lightly breaded mozzarella sticks and french fries? An open-pot fryer will be your best friend. Serving lots of battered chicken or fish that tends to shed? A tube-style fryer creates a "cool zone" where those particles can settle without burning and tainting your oil.

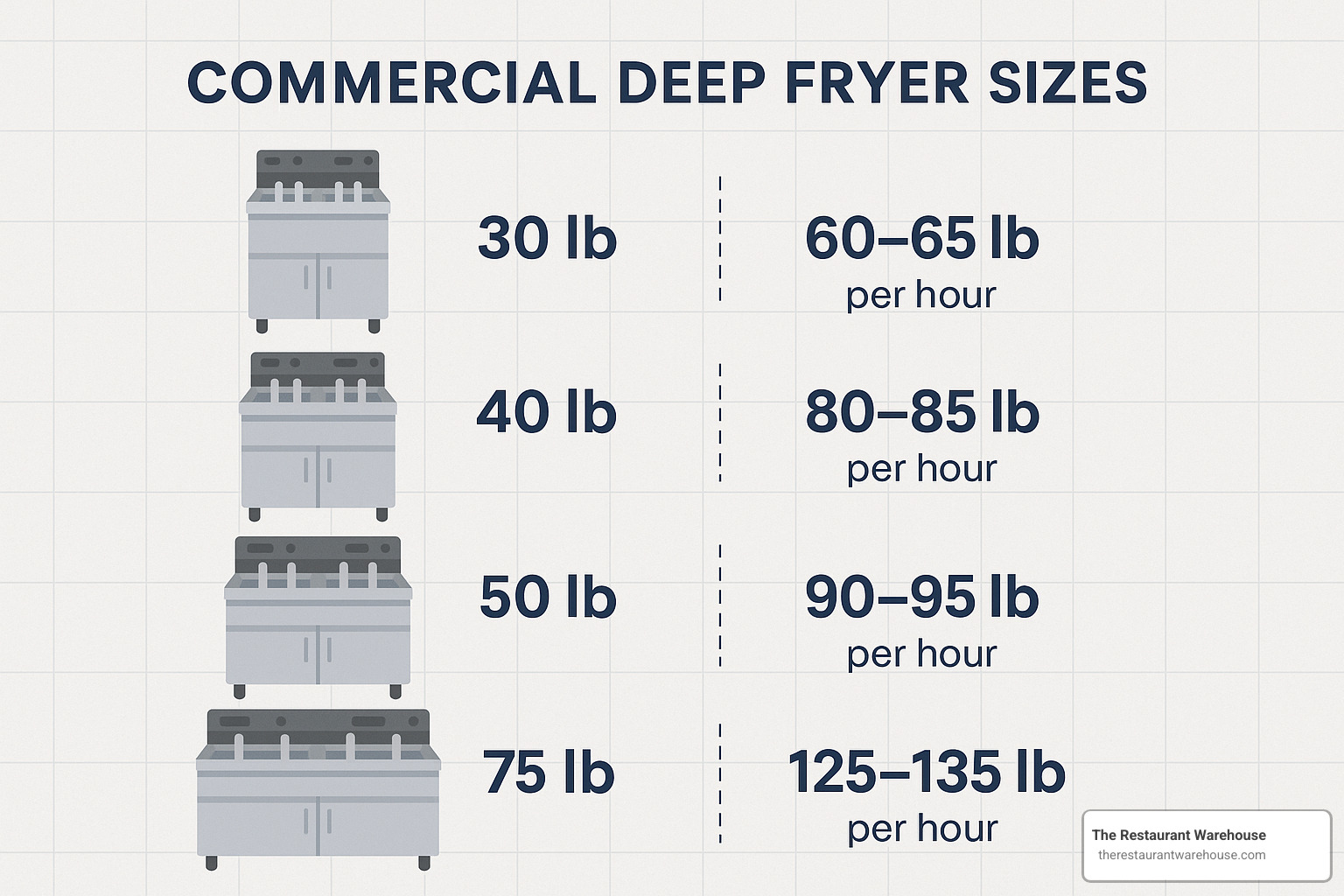

Think about your busy periods and how much food you'll need to pump out. A handy rule of thumb is the pounds-per-hour calculation. Your fryer should produce about 1.5-2 times its oil capacity in food per hour. So that 50-pound fryer sitting in your cart? It should handle between 75-100 pounds of crispy goodness every hour. Planning for this capacity ensures you won't be left with a line of hungry customers and a fryer that can't keep up.

The relationship between oil and food is like a delicate dance. Overload your fryer with too much food, and your oil temperature plummets, leaving you with soggy, greasy products that nobody wants. A good oil-to-food ratio keeps your temperatures steady and your customers happy.

Now for the big question: gas or electric? Gas fryers heat up faster and typically cost less to operate in most areas, making them popular in high-volume kitchens. But they need proper ventilation and gas hookups. Electric fryers offer more precise temperature control and often easier installation, especially if you're working with limited space or don't have gas lines available.

Speaking of space – don't forget about your hood! Standard commercial deep fryers need to be installed under a Type I hood system. If hood space is at a premium or nonexistent in your location, you might need to explore ventless fryers. They're pricier, but they offer flexibility when traditional ventilation isn't an option.

For kitchens serving diverse menus, consider a split-pot fryer. These versatile units let you fry onion rings in one section and fish in another without your dessert fritters tasting like today's catch. Built-in filtration systems are another game-changer, extending oil life and saving your staff from the dreaded end-of-night manual filtering process.

If you're dealing with high staff turnover or want foolproof consistency, look into models with programmable controls, automatic basket lifts, and preset cooking programs. These features might cost more upfront but can pay for themselves in consistent quality and reduced training time.

Want more in-depth guidance custom to your specific operation? Check out our comprehensive guide on choosing a commercial deep fryer.

Matching Oil Capacity to Menu Demand

Sizing your commercial deep fryer correctly is like finding the right pair of shoes – too small and you'll be uncomfortable; too large and you're wasting money. Here's how to find your perfect fit:

Small operations, food trucks, or kitchens needing a secondary fryer for specialty items will do well with 10-30 lb countertop fryers. These compact workhorses typically produce 15-60 pounds of food hourly and won't hog your limited counter space.

Most single-unit restaurants start with 40-50 lb mid-range floor fryers. These reliable performers handle 60-100 pounds of food per hour, making them ideal for standard restaurant service without breaking the bank.

Running a busy sports bar or fast-food restaurant where fried foods are the stars? You'll want to look at 75-90 lb high-volume fryers that can crank out 110-180 pounds of food hourly without breaking a sweat.

Always size slightly above your current needs. The restaurant that plans for growth never has to tell customers, "Sorry, we're backed up on fries." A properly sized fryer maintains consistent temperatures when food is added, ensuring crispy, properly cooked food even during your busiest rush.

Essential Features Checklist

Not all commercial deep fryers are created equal. These key features separate the good from the great:

Precision thermostats are the unsung heroes of consistent cooking. The best models maintain oil temperature within ±2°F, ensuring your second batch of fries is just as perfect as the first.

Safety should never be an afterthought. A high-limit safety switch automatically shuts down your fryer if temperatures climb too high, preventing potential fires and giving you peace of mind during hectic service.

The cool zone design creates a cooler area at the bottom of the tank where food particles settle instead of burning. This seemingly simple feature extends oil life dramatically and prevents that bitter, burnt taste that can ruin perfectly good food.

An automatic filtration system transforms the dreaded oil filtering task from "nobody wants to do it" to "it's already done." This encourages more frequent filtering, which significantly extends oil life and improves food quality.

Programmable timers ensure consistent cooking times regardless of who's working the station. Your newest employee can produce the same perfectly golden fries as your veteran cook.

Look for the ENERGY STAR certification if you're keeping an eye on utility costs. These models use less energy while maintaining performance, putting money back in your pocket month after month.

Casters with locks might seem minor until the first time you need to clean behind your fryer. This feature allows for easy movement during cleaning while keeping the unit firmly in place during operation.

Splash guards protect your staff from painful oil splashes and reduce cleanup time around your frying station. Your closing crew will thank you for this thoughtful addition.

Cost Considerations & Financing Options

When it comes to commercial deep fryers, prices range from $1,200 for a basic countertop model to $15,000 for a fully-loaded, automated system. Most standard floor model gas fryers hover around $2,900 – but remember, the sticker price isn't the whole story.

Smart buyers look at the total cost of ownership. An ENERGY STAR certified fryer might cost more initially but can save hundreds of dollars annually on your utility bills. Similarly, models with advanced filtration systems and cool zone designs can reduce your oil costs by 30-40% by extending oil life from days to weeks.

Higher-quality fryers typically need less maintenance and have longer service lives. When you amortize the cost over years of service, that premium model often becomes the more economical choice.

Don't overlook the labor savings from automated features. Built-in filtration systems and programmable controls reduce the time your staff spends managing the fryer, letting them focus on other tasks that drive revenue.

At The Restaurant Warehouse, we understand that upfront costs can be challenging for many food service operations. That's why we offer flexible financing options that help you get the equipment you need while keeping your cash flow healthy.

Our lease-to-own programs feature simple qualification processes and terms ranging from 12 to 60 months. Many of our customers find that the monthly payment for a premium fryer with advanced oil-saving features is completely offset by the reduced operational costs they enjoy.

Ready to explore financing options for your new commercial deep fryer? Click APPLY NOW! for instant pre-approval and take the first step toward equipping your kitchen for success.

Top Commercial Deep Fryers Reviewed by Category

I've spent countless hours in commercial kitchens watching chefs battle with their fryers during the dinner rush. That experience, combined with our extensive testing and feedback from real restaurant owners, has helped us identify the truly outstanding commercial deep fryers that deliver when it matters most.

We didn't just look at specifications on paper. Our recommendations come from evaluating how these fryers perform when the tickets are piling up – their recovery speed after dropping in frozen foods, how evenly they cook, how easy they are to clean at the end of a long shift, and whether they're still running strong after months of heavy use.

Best Countertop Electric Commercial Deep Fryers

Space comes at a premium in most kitchens, which is why a quality countertop electric fryer can be such a valuable addition. These compact workhorses are perfect for smaller operations or as dedicated stations for specific menu items.

The best countertop commercial deep fryers feature 10-15 pound oil capacities and plug right into standard 120V outlets – though you'll find 208-240V options available if you need more firepower. What separates the good from the great is the heating element design. Look for ribbon-style elements that wrap around the tank, providing faster recovery times when you drop in cold food.

I'm particularly impressed with models that offer completely removable tanks. After a long day of frying, being able to lift the entire tank out for cleaning is a back-saver your staff will thank you for. Pair that with precision thermostatic controls that maintain temperatures between 120°F-375°F, and you've got a winning combination.

A quality 10-pound countertop unit should comfortably produce 15-30 pounds of food per hour – perfect for cafes, food trucks, or as a dedicated station for appetizers or desserts. The best part? You can move these units around as your kitchen needs evolve, giving you flexibility that floor models simply can't match.

Best Floor Model Gas Commercial Deep Fryers

When volume is king, nothing beats a floor model gas fryer. These are the true workhorses of busy kitchens, capable of handling the Friday night rush without breaking a sweat.

The gold standard in this category features oil capacities between 50-75 pounds and impressive BTU ratings from 136,000 to 170,000. This power translates directly to recovery speed – the critical factor that determines whether your fries come out perfectly crisp or disappointingly soggy during peak service.

What truly separates exceptional commercial deep fryers from average ones is the burner design. The best models use tube-type burners that efficiently transfer heat throughout the oil, maintaining consistent temperatures even when you're constantly dropping in frozen products. Look for tanks with 7-10 year warranties – a clear sign the manufacturer stands behind their welding and construction quality.

I've seen how a well-designed cool zone at the bottom of the tank can dramatically extend oil life. These cooler areas allow food particles to settle without burning, preventing that bitter, acrid taste that develops in poorly designed fryers. It's a feature that pays for itself in reduced oil costs alone.

With production capacities between 75-150 pounds per hour, these powerhouses keep pace with the demands of sports bars, busy restaurants, and high-volume operations where the fryers rarely get a break.

Best Ventless Commercial Deep Fryer for Hoodless Locations

"We'd love to add fried items, but we don't have hood space." I hear this lament from restaurant owners constantly. Fortunately, ventless technology has evolved dramatically in recent years, creating new possibilities for locations previously limited by ventilation constraints.

Modern ventless commercial deep fryers incorporate sophisticated filtration systems that capture grease, smoke, and odors, allowing for installation in non-traditional spaces. The magic happens through multi-stage filtration, typically including a catalytic converter that breaks down smoke particles at the molecular level.

The best models feature completely sealed cooking chambers and vertical cooking technology that not only prevents flavor transfer between different foods but also improves crispiness by allowing better air circulation. Many now include IoT connectivity for remote monitoring – a game-changer for multi-unit operations wanting to ensure consistency across locations.

Yes, these technological marvels come with a premium price tag ($10,000-$21,000), but they create revenue opportunities in spaces that previously couldn't support frying operations – from mall kiosks to convenience stores, hotel lobbies to office buildings.

The efficiency gains are impressive too. The leading ventless systems reduce cooking times by up to 27% while cutting oil consumption by 37% through advanced filtration – making them not just a solution for ventilation challenges but potentially a smarter investment overall.

Best Specialty Commercial Deep Fryer (Donut, Funnel Cake, Chicken)

Sometimes the standard fryer just won't cut it. For specialty items that drive your business, purpose-built commercial deep fryers can make all the difference between good and exceptional results.

Donut fryers are a perfect example. The best models feature carousel or conveyor systems that gently turn these delicate pastries, ensuring even cooking without the need for constant attention. Their flat-bottom design allows proper floating, while their temperature ranges are specifically calibrated for the unique requirements of yeast-raised products.

For funnel cakes and elephant ears, width matters more than depth. Top-performing specialty fryers feature extra-wide, shallow tanks that accommodate these irregularly shaped treats, with temperature ranges optimized for batter cooking (325°F-375°F). The extended cool-down zones around the perimeter prevent burning while allowing the centers to cook through perfectly.

Pressure chicken fryers represent perhaps the most specialized category. Their sealed cooking chambers with locking lids create the perfect environment for juicy, crispy chicken. By cooking under pressure (up to 12 PSI), these fryers reduce cooking times while locking in moisture – the secret behind that perfect balance of crispy exterior and juicy interior that keeps customers coming back.

For operations that have built their reputation on signature fried items, these specialized units deliver results that general-purpose fryers simply can't match. The investment pays off in product quality, consistency, and operational efficiency that directly impacts your bottom line.

Using, Cleaning & Maintaining Commercial Deep Fryers

Taking good care of your commercial deep fryer isn't just about keeping it shiny—it's the secret to tastier food, longer equipment life, and a safer kitchen. Think of fryer maintenance as an investment that pays delicious dividends!

The heart of proper fryer care is oil management. Throughout your busy day, take a moment to skim off those floating food bits with a mesh skimmer. These little particles are troublemakers that accelerate oil breakdown and create off-flavors. Those crumb screens at the bottom of your fryer? They're not just decorative—empty and clean them regularly to prevent debris from burning and turning your beautiful golden oil into a smoky, bitter mess.

Filtration is your oil's best friend. Most successful kitchens filter their oil after each major meal period, which can extend oil life dramatically. Yes, it takes a few minutes, but your wallet will thank you when you're buying less oil each month. Plus, your customers will notice the difference in taste—consistently clean oil means consistently delicious fried foods.

For a thorough approach to daily maintenance, check out our Essential Daily Cleaning Guide for Commercial Fryers. It's packed with practical tips that won't slow down your operation.

Daily & Weekly Maintenance Schedule

Creating a simple maintenance routine for your commercial deep fryer helps your team stay consistent and prevents those "Oops, when did we last clean that?" moments. Here's a practical schedule that won't overwhelm your staff:

Every day, wipe down those exterior surfaces with food-safe sanitizer—fingerprints and oil splatter can make even a great fryer look neglected. Filter your oil at least once, ideally after your busiest period when it's had the most use. Throughout the day, keep an eye on those crumb screens and clean them before they overflow. A quick check of your thermostat with a reliable thermometer ensures you're cooking at the temperature you think you are.

Once a week, schedule a complete boil-out procedure. This deep-cleaning process removes the stubborn gunk that daily cleaning can't reach. Drain the cooled oil, fill with water and an approved cleaning solution, bring to a gentle boil for about 20 minutes, then drain, rinse thoroughly, and dry completely. While you're at it, check those gaskets and seals for wear—small cracks now can lead to big leaks later.

Monthly, take time for a more thorough inspection. Check gas connections on gas models, examine electrical connections on electric units, and test that high-limit shutoff to make sure it's protecting your kitchen from potential overheating situations. This is also a good time to inspect your baskets for damage—those little breaks in the mesh can tear delicate food items.

Scientific research isn't just for laboratories—it applies to your fryer too! Studies show proper filtration can extend oil life by 30-50%. According to research documented in a comprehensive fryer management guide, filtering oil at 160°F-180°F hits the sweet spot—hot enough to flow smoothly but not so hot it damages your filtration equipment.

Best Practices for Fryer Oil Management

Let's talk dollars and sense—your commercial deep fryer's oil is likely one of your kitchen's most significant ongoing expenses. Managing it well isn't just good practice; it's good business.

Testing regularly takes the guesswork out of oil changes. Those inexpensive oil test strips provide objective measurements so you're not changing oil too early (wasting money) or too late (serving inferior food). Some savvy kitchen managers keep a simple log of oil changes to spot patterns and optimize their schedule.

Filtration frequency makes a huge difference in oil quality and lifespan. The best kitchens filter at least daily, but busy operations often find filtering after each major meal period provides the best results. When filtering, timing matters—let oil cool to 160°F-180°F before the process. It's still fluid enough to flow well at this temperature but won't damage your filtration equipment.

Technology can help extend your oil's useful life. Low-oil-volume fryers use sophisticated engineering to maintain smaller amounts of oil, saving you money while delivering excellent results. If your fryers lack built-in filtration, consider investing in a portable filtration cart—they pay for themselves surprisingly quickly through oil savings.

Responsible disposal completes the oil lifecycle. Establish relationships with local oil recycling services—many municipalities now offer rebates for proper disposal, and some services will even collect used oil for free because they can convert it to biodiesel. It's a rare win-win-win for your budget, your conscience, and the environment.

For step-by-step guidance on setting up an efficient filtration system, our guide on How to Set Up the Atosa Fryer Oil Filtration System provides clear instructions even your newest kitchen staff can follow.

Safety First: Certifications and Built-In Protections

When you're working with equipment that combines extremely hot oil, open flames, and electricity, safety isn't just important—it's essential. Modern commercial deep fryers come equipped with impressive safety features that protect both your staff and your business.

Look for key certifications that verify your equipment meets industry standards. NSF certification ensures your fryer meets strict food safety requirements. ETL listing confirms compliance with North American safety standards. For electric models, UL certification verifies electrical safety, while Canadian operations should look for CSA approval.

Today's best fryers include built-in protections that prevent dangerous situations before they develop. High-limit thermostats automatically shut down the fryer if oil temperature exceeds maximum safe levels—think of them as vigilant guardians working 24/7. Self-reset protection devices allow operation to resume once temperatures return to safe levels, minimizing downtime while maximizing safety.

The physical design of quality fryers also incorporates thoughtful safety elements. Splash guards prevent painful oil splashes when adding food. Cool-touch handles stay at safe temperatures even when the oil is scorching hot. Automatic shutoff systems power down the unit if they detect abnormal conditions—a feature that has prevented countless kitchen disasters.

Beyond the fryer itself, consider your kitchen setup. Position fryers away from water sources to prevent dangerous oil-water reactions that can cause dangerous splattering. Make sure your units are compatible with your kitchen's fire suppression system. And don't forget about the human element—provide proper personal protective equipment including heat-resistant gloves and face shields for staff handling hot oil.

With the right equipment and proper procedures, your commercial deep fryer will be not just a productive kitchen workhorse, but a safe one too.

Frequently Asked Questions about Commercial Deep Fryers

What size commercial deep fryer do I need?

Finding the right fryer size is one of the most common questions we hear from restaurant owners. The answer depends on your specific needs, but here's a helpful guideline: multiply your expected hourly output (in pounds of food) by 0.5-0.7 to determine your minimum oil capacity.

For example, if your busy dinner rush requires 100 pounds of french fries per hour, you'll want a fryer with at least a 50-70 pound oil capacity to handle the load without temperature recovery issues.

Our smaller countertop models typically hold between 10-30 pounds of oil and work beautifully for operations producing up to 60 pounds of food hourly. They're perfect for cafes, food trucks, or as dedicated stations for specific menu items. Floor models, with their 40-90 pound capacity, can handle the demands of busy restaurants producing 60-180 pounds of fried foods each hour.

One piece of advice we always share: size slightly larger than your current needs. This gives you room to grow and helps handle those unexpected rushes. Many of our customers find that multiple smaller fryers offer more menu flexibility than a single large unit, especially when frying different foods that might transfer flavors.

How often should I filter or change fryer oil?

Think of your fryer oil as an investment that needs proper management. At minimum, filter your oil once daily – though in our experience, high-volume operations see much better results filtering 2-3 times daily, typically after each major meal period.

The difference proper filtration makes is remarkable. Our customers report extending oil life by 30-50% simply by implementing a consistent filtration routine. That's significant savings going straight to your bottom line!

Complete oil changes will depend on your specific situation. With diligent filtration, most kitchens can change oil every 5-7 days. However, if you're frying heavily battered foods or items with high sugar content (which accelerates oil breakdown), you might need more frequent changes.

Don't guess about oil quality – it affects both your food taste and your profits. Use oil test strips or electronic testers to objectively determine when oil needs changing. Watch for warning signs like oil darkening, smoking at normal cooking temperatures, excessive foaming, or an unpleasant smell or taste in your food.

For those looking to maximize oil life, our low-oil-volume fryers with advanced filtration systems can dramatically extend usability – some customers report needing complete changes only every 2-3 weeks despite continuous use.

Are gas or electric commercial deep fryers more energy-efficient?

The gas versus electric debate isn't as straightforward as you might think. Both commercial deep fryers have their efficiency advantages, and the right choice often comes down to your local utility rates.

Gas fryers shine with faster initial heat-up times and can reach higher maximum temperatures, making them ideal for high-volume operations. They're typically more cost-effective in regions with lower natural gas prices. For certification as ENERGY STAR compliant, gas fryers must demonstrate at least 50% cooking efficiency and idle energy rates of 9,000 BTU/hour or less.

Electric fryers offer more precise temperature control and often recover more quickly once they're up to temperature. They convert nearly 100% of energy input to heat (compared to 70-80% for gas models), but electricity costs are frequently higher per BTU equivalent. ENERGY STAR certified electric fryers must achieve at least 85% cooking efficiency with idle energy rates of 1kW or less.

From a pure efficiency standpoint, electric models typically have a slight edge, but the lower cost of natural gas in many regions often makes gas fryers more economical day-to-day. We recommend checking your local utility rates before making a decision if energy costs are a primary concern for your operation.

Both types are available in ENERGY STAR certified models that can reduce energy consumption by 15-30% compared to standard units. Many of our customers find these higher-efficiency models pay for themselves within 1-3 years through utility savings alone – not to mention the environmental benefits.

Conclusion

Choosing the perfect commercial deep fryer isn't just about buying equipment—it's making a strategic investment that directly impacts your food quality, kitchen efficiency, and ultimately, your profits. After exploring commercial fryers together, you're now equipped to make a choice that perfectly balances your needs with your budget.

Throughout this guide, we've peeled back the layers on what makes commercial fryers different from residential units, explored the various types available for different cooking needs, and shared practical wisdom on selection, operation, and maintenance. This knowledge puts you ahead of the game when it comes to making this important kitchen decision.

If there's one thing to remember, it's that proper sizing matters tremendously. A fryer that's too small will struggle during rush periods, while one that's too large wastes energy and oil. The 1.5-2.0× capacity formula we discussed gives you a reliable starting point for matching your production needs with the right equipment.

Smart operators look beyond the price tag to consider the complete picture. While a budget fryer might seem appealing initially, premium models with advanced filtration systems and energy-efficient designs often pay for themselves through reduced oil and utility costs. Think of it this way—saving $50 in oil costs every week adds up to $2,600 annually, quickly offsetting a higher initial investment.

Your maintenance routine will determine how long your fryer serves your business. A well-maintained fryer can deliver a decade or more of reliable service, while neglected equipment often fails prematurely. The daily skimming, regular filtering, and weekly deep cleaning we outlined aren't just good practices—they're essential investments in your equipment's longevity.

At The Restaurant Warehouse, we understand that every dollar counts in the foodservice industry. That's why we've built our business model around eliminating unnecessary markups and passing those savings directly to you. Our direct sourcing approach means you get premium commercial deep fryers at wholesale prices that traditional equipment suppliers simply can't match.

Whether you're launching a new concept, upgrading tired equipment, or expanding your menu offerings, we're here to help you steer the options and find the perfect fit for your operation's unique needs. Our commitment goes beyond just selling equipment—we want to be your partner in building a more profitable kitchen.

For even more detailed information about selecting, installing, and maximizing your fryer investment, check out our comprehensive Commercial Deep Fryer Guide.

The right commercial deep fryer does more than just cook food—it helps create the signature items customers come back for again and again. Choose wisely, maintain diligently, and watch as your perfectly crispy offerings become a cornerstone of your menu's success.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment