From Pantry to Warehouse: Your Complete Commercial Shelving Handbook

Why Commercial Wire Shelving is Essential for Your Foodservice Operation

Alt text: commercial wire shelving in a professional foodservice storage area, fully loaded with labeled boxes and ingredient containers, showing open-wire shelves and sturdy posts

Image metadata: commercial wire shelving, restaurant storage, foodservice organization, open-wire racks, heavy-duty shelves, warehouse shelving, restaurant storage solutions

Commercial wire shelving is a versatile, durable, and cost-effective storage solution for restaurants, bars, cafeterias, ghost kitchens, bakeries, institutional foodservice, and even light industrial operations. When choosing the right shelving, it's important to consider load capacity, finish type (chrome, epoxy, or stainless steel), NSF certification for health compliance, and configuration options like starter or add-on units.

Whether you're outfitting a new prep area, upgrading a walk-in cooler, or organizing a stockroom, wire shelving delivers superior air circulation, product visibility, and easy cleaning. These are all critical factors for maintaining sanitation, efficiency, and compliance with local health codes.

The open-wire construction prevents dust accumulation and promotes airflow, reducing the risk of mold and moisture damage. This makes it ideal for everything from dry pantry storage to temperature-controlled environments like coolers and freezers. The ability to see inventory at a glance speeds up service and reduces waste from forgotten stock, helping staff quickly identify what needs to be rotated or reordered.

I'm Sean Kearney from The Restaurant Warehouse. With years of experience in the foodservice industry, I've helped countless operators select the right commercial wire shelving to maximize storage efficiency while staying within budget. I understand what works in real-world commercial settings, not just what looks good in a catalog.

To see how the right shelving can integrate with your broader storage layout and workflow, explore our full range of solutions at The Restaurant Warehouse:

- https://therestaurantwarehouse.com/collections/wire-shelving

- https://therestaurantwarehouse.com/collections/restaurant-shelving

If you’re planning a remodel or opening a new concept and aren’t sure where to start, contact us to discuss a tailored storage plan: https://therestaurantwarehouse.com/pages/contact-us.

Why Choose Wire Shelving? The Core Benefits for Your Business

When optimizing storage in busy commercial environments, commercial wire shelving stands out. Its simple design offers a suite of benefits that improve efficiency, hygiene, safety, and cost control. This storage solution goes beyond merely holding items; it actively improves your operational flow and makes compliance with health regulations easier.

The superior strength and load capacity mean you can store a vast array of items, from heavy bulk ingredients and paper goods to cleaning supplies and smallwares. Many units boast capacities of up to 850 lbs per shelf, with total unit capacities often exceeding 2,500 lbs. This robust construction ensures a long-term investment capable of withstanding daily commercial use.

Beyond strength, the open-wire design is a game-changer for hygiene and visibility. Unlike solid shelving, it promotes excellent air circulation, which is critical in walk-in coolers, dry storage, and prep areas. Improved airflow means less moisture buildup, reducing the risk of mold and odors. According to the U.S. Food & Drug Administration's Food Code, proper storage and airflow help limit conditions that allow bacterial growth. This is a necessity for maintaining sanitary conditions and complying with health regulations.

The open design also reduces dust accumulation and dramatically increases product visibility. Everything is identifiable at a glance, saving time and improving inventory management. Clearly visible labels and product packaging help staff avoid duplication when pulling ingredients and make it easier to follow FIFO (first in, first out) rotation.

For more insights on optimizing your storage footprint and choosing the right sizes and finishes, review our comprehensive storage lineup at The Restaurant Warehouse: https://therestaurantwarehouse.com/collections/restaurant-shelving.

Durability and Strength

The backbone of commercial wire shelving is its durability, making it a sound long-term investment. These units are typically constructed from heavy-gauge steel with an extra-strength, welded wire design. This allows individual shelves to support substantial weight, commonly ranging from 600 to 850 lbs when evenly distributed. Total unit capacities can soar to 2,500 lbs or more, making them suitable for the heaviest inventory you're likely to store in a back-of-house or warehouse setting.

The strength isn't just about capacity; it's about resisting wear and tear. The steel material and welded frame are designed to resist sagging and bending. Unlike lighter, consumer-grade materials, commercial wire shelving maintains its structural integrity under constant heavy loads. This stability protects your products, reduces the risk of accidents, and extends the usable life of your storage system.

Thoughtful placement also matters. When planning, consider:

- The heaviest items should go on lower shelves to reduce tipping risk.

- Frequently used items should be stored between knee and shoulder height to reduce strain.

- Reserve top shelves for light or infrequently accessed items.

Hygiene and Maintenance

For any business where hygiene is paramount, the open-wire design of commercial wire shelving shines. Its structure promotes superior airflow, a powerful defense against moisture buildup that can contribute to mold and bacterial growth. This is especially beneficial in humid environments like walk-in coolers, dishwashing stations, or areas near ice bins and beverage service.

Ease of cleaning is another significant advantage. Unlike solid shelves, wire shelves offer minimal surface area for contaminants. Spills are easier to identify and wipe down, and there are fewer corners where debris can accumulate. Dust or grime is immediately visible and easily removed with a food-safe cleaner and cloth, promoting a higher standard of sanitation and reducing maintenance time.

Some advanced wire shelving finishes even incorporate antimicrobial agents into the coating, which actively inhibit the growth of bacteria and mold on the shelf surface. This provides an extra level of assurance in sensitive environments. Choosing commercial wire shelving with an open design and appropriate finish ensures a cleaner, safer storage solution, essential for passing health inspections.

To keep your shelving in top condition:

- Wipe down shelves on a regular schedule (e.g., weekly for dry storage, more often in coolers).

- Inspect posts and shelves for chips or damage to the finish, especially in humid areas.

- Avoid dragging heavy items across the shelves; lift and set them in place instead.

If you'd like help choosing the best combination of finish, size, and accessories for your space, schedule a storage consultation with our team: https://therestaurantwarehouse.com/pages/contact-us.

A Guide to Commercial Wire Shelving Types and Finishes

Choosing the right commercial wire shelving involves more than size; the material and finish are crucial for performance and longevity. Different finishes offer varying resistance to moisture and corrosion, impacting where they can be used. Understanding these differences is key to making an informed decision that aligns with your operational needs, local code requirements, and budget.

From the bright gleam of chrome to the robust protection of epoxy and the resilience of stainless steel, each finish has its own advantages. We'll explore these options to help you select the perfect shelving for your commercial space, whether it's a dry pantry, a humid walk-in cooler, or a hygienic healthcare or laboratory environment.

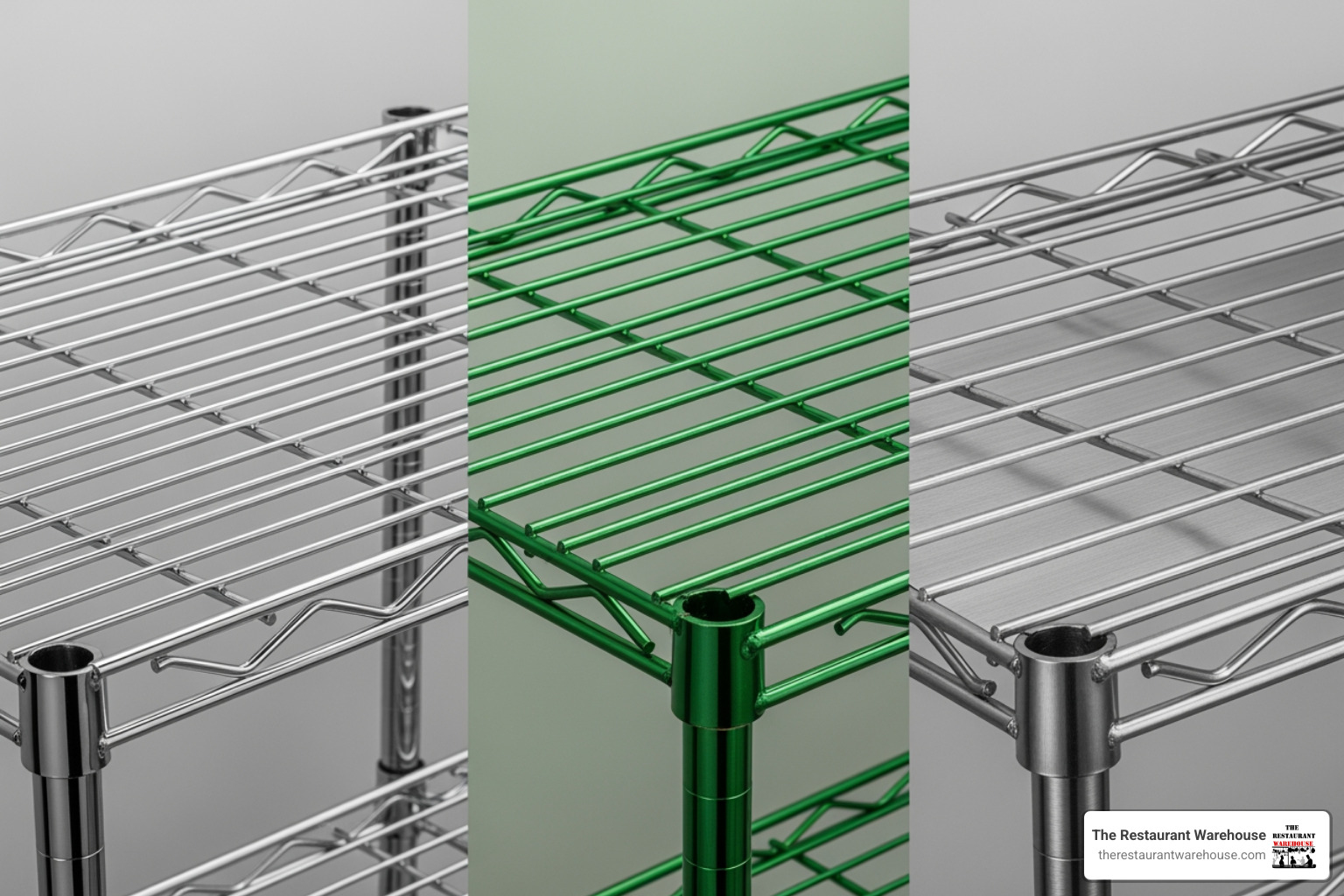

Alt text: three types of commercial wire shelving finishes displayed side-by-side, including shiny chrome, green epoxy-coated, and brushed stainless steel, illustrating their visual differences

Image metadata: chrome wire shelving, epoxy wire shelving, stainless steel wire shelving, shelving finishes comparison, corrosion-resistant shelves, commercial storage options

Chrome-Plated Shelving

Chrome-plated commercial wire shelving is a popular choice for dry environments. Its bright, modern aesthetic makes it attractive for customer-facing merchandising, front-of-house grab-and-go displays, office supply storage, or general pantry organization. The chrome finish provides a clean, professional look that complements various interiors.

However, chrome is best suited for dry conditions. It is not designed to withstand high humidity or direct contact with water, as it can eventually chip or rust over time. Therefore, we recommend chrome shelving for dry storage rooms, offices, retail spaces, or back-of-house paper goods storage. It's a cost-effective option for these applications and often the best value when moisture is not a concern.

When planning chrome shelving installations:

- Avoid placement directly adjacent to dishwashing or mop sinks.

- Keep away from floor drains where standing water can splash.

- Use clear labels and color-coding to make the most of the high visibility.

You can browse our chrome wire options here: https://therestaurantwarehouse.com/collections/wire-shelving.

Epoxy-Coated Shelving

For environments with moisture or temperature fluctuations, epoxy-coated commercial wire shelving is our go-to recommendation. These shelves feature a durable powder-coated finish, typically epoxy, that acts as a barrier against rust and corrosion, offering significantly better protection than chrome.

Epoxy-coated shelving is ideal for challenging settings like walk-in coolers, freezers, dishwashing areas, and humid warehouses. In many operations, this is the standard choice for any area where condensation, splashes, or regular washing are expected.

Some epoxy finishes, such as advanced polymer coatings, even incorporate antimicrobial agents to inhibit bacterial growth, making them excellent for foodservice and healthcare environments. While the initial cost may be slightly higher than chrome, the improved durability and extended service life in wet conditions offer better long-term value.

Key tips for epoxy shelving placement:

- Use in all refrigerated and freezer storage areas where permitted by code.

- Reserve bottom shelves for heavier products like liquids, dairy, or proteins stored in food-safe containers.

- Pair with shelf liners if you store small jars, bottles, or containers that might tip.

Stainless Steel Shelving

When the highest level of durability and hygiene is required, stainless steel commercial wire shelving is the undisputed champion. Crafted from high-grade stainless steel, these shelves offer exceptional resilience against moisture, extreme temperatures, and harsh cleaning chemicals. This makes them the premium choice for the most demanding applications.

We find stainless steel shelving indispensable in sterile environments like healthcare labs, pharmaceutical storage, and cleanrooms, as well as in food preparation zones with rigorous sanitation protocols. Stainless steel is non-porous, easy to clean, and inherently resistant to bacterial buildup when properly maintained. This aligns well with guidance from organizations like the U.S. Department of Agriculture (USDA), which emphasize smooth, cleanable surfaces for food-contact and adjacent areas.

While stainless represents the highest initial investment, its superior lifespan and minimal maintenance make it the most cost-effective solution in the long run, especially where corrosion or harsh cleaning agents would quickly degrade other finishes.

Use stainless steel shelving when:

- Local code or internal standards require stainless in specific zones.

- Strong chemicals or high-temperature cleaning are part of your sanitation routine.

- You want a long-term, low-maintenance solution in high-risk moisture environments.

To compare current stainless and epoxy models, visit: https://therestaurantwarehouse.com/collections/restaurant-shelving and filter by finish type.

If you're unsure whether chrome, epoxy, or stainless is best for a particular room or process, reach out to our team for a quick recommendation based on your floor plan and usage: https://therestaurantwarehouse.com/pages/contact-us.

Understanding Specifications: Load Capacity, Dimensions, and Key Features

Navigating commercial wire shelving requires attention to product specifications. An informed choice means selecting a system that meets your operational demands, adheres to safety standards, and offers the customization you need. The right specs prevent premature wear, tipping hazards, and overcrowded aisles.

From weight capacities to NSF certification and features like adjustability, every specification plays a role in the functionality and safety of your storage solution. If you're ever unsure about the best fit for your needs, you can always contact The Restaurant Warehouse for a custom storage recommendation: https://therestaurantwarehouse.com/pages/contact-us.

Deciphering Weight Capacity and Dimensions

Understanding weight capacity is paramount for safety. Consider two key metrics: capacity per shelf and total unit capacity. Individual shelves are strong, often rated to hold between 600 and 850 lbs when evenly distributed. However, it's crucial to distribute this weight evenly across the shelf surface to avoid damage or warping. The total unit capacity refers to the maximum weight the entire shelving unit can support, often up to 2,500 lbs or more.

Keep these best practices in mind:

- Never exceed the published per-shelf or total unit capacities.

- Place the heaviest items on the lowest shelves to reduce the risk of tipping.

- Avoid point loads (for example, placing a single very heavy box on one small area); instead, spread weight across the shelf.

Dimensions are equally important for space planning. Commercial wire shelving comes in various standard shelf sizes, with common depths like 14", 18", 21", and 24", and widths from 24" to 72". Post heights are also varied, typically ranging from 54" to 80" or higher. Careful measurement of your space is essential to ensure a perfect fit and to maximize your storage footprint.

When measuring:

- Confirm ceiling height and any obstructions (sprinkler heads, HVAC ducts, signage).

- Leave enough aisle width for safe traffic flow and cart movement.

- Consider door swing, emergency exits, and code-mandated clearance.

The Importance of NSF Certification

For any business in the foodservice or healthcare industries, NSF certification for commercial wire shelving is often a strict requirement. NSF International is an independent organization that certifies products to protect public health. When shelving is NSF certified, it has met stringent standards for safety and sanitation.

Specifically, look for certification to NSF/ANSI Standard 2 for food equipment, which focuses on materials, construction, and cleanability. This ensures the shelving is easy to clean, corrosion-resistant, and won't harbor bacteria. The open-wire design of commercial shelving inherently promotes these qualities by minimizing dirt-trapping surfaces.

Choosing NSF-certified shelving provides peace of mind. It assures you that your storage solutions meet high sanitary criteria, which is critical for food safety and simplifies health department inspections. Without this certification in relevant areas, you risk penalties and may compromise safety.

For detailed standards and current information, you can consult NSF directly.

Key Features for Your Commercial Wire Shelving Purchase

Beyond material and capacity, several key features improve functionality. These design details often determine how well your shelving integrates with day-to-day operations.

Adjustable shelves are one of the most valuable features. Most systems allow you to adjust shelf heights in 1-inch increments, letting you customize storage for items of varying sizes and maximize vertical space. This flexibility makes it easy to adapt as product mix or packaging changes.

Tool-free assembly is another major benefit. Many commercial systems use a snap-together design with split sleeve clips that lock shelves to the posts. This saves time and labor costs during installation and makes it easier to adjust shelf spacing later as your needs evolve.

For dynamic environments, mobile units are a must-have. Adding casters (wheels) transforms a stationary unit into a portable cart. Look for casters with an appropriate weight capacity and reliable braking systems to ensure the unit stays securely in place when parked. In areas where carts must cross thresholds or slightly uneven floors, larger casters can make movement smoother.

For stationary units, adjustable leveling feet are essential for stability on uneven floors. A level unit is less prone to rocking and reduces the chance of items shifting or falling. Combine leveling feet with thoughtful load distribution to create a robust, safe storage system.

To compare different post heights, shelf sizes, and mobility options, visit our wire shelving collection: https://therestaurantwarehouse.com/collections/wire-shelving.

Maximizing Your Storage: Assembly, Accessories, and Maintenance

Getting the most out of your commercial wire shelving involves proper assembly, leveraging accessories, and implementing best practices for maintenance. These steps will help you optimize your storage and protect your investment from day one, while also making it easier for staff to keep the space clean and organized.

Simple Assembly and Installation

One of the most appealing aspects of commercial wire shelving is its simple, tool-free assembly. The design often relies on a clever split sleeve clip system. These plastic clips snap onto the grooves on the posts, and the shelves slide down over them, locking securely into place. This intuitive method allows for rapid setup without specialized tools.

To assemble, follow these general steps:

- Lay out all posts, shelves, and clips, confirming shelf sizes and quantities.

- Attach the split sleeve clips to the desired height on each post for the bottom shelf, ensuring all four clips are aligned on the same groove.

- Slide the bottom shelf down over the tops of the posts until it rests firmly on the clips.

- Repeat the clip-and-shelf process for the remaining shelves, working upward.

- Once assembled, stand the unit upright and use a level to check for plumb and level.

- Adjust the leveling feet on the posts as necessary to ensure stability.

When planning for expansion, be strategic about starter units (four posts) and add-on units (two posts). Use a starter unit for the beginning of a row and add-on units to extend it cost-effectively by sharing posts. This approach saves space and reduces cost while maintaining strength.

Alt text: close-up of a person assembling commercial wire shelving by snapping split sleeve clips onto a post and sliding a wire shelf into place without tools

Image metadata: wire shelving assembly, split sleeve clips, tool-free shelving installation, commercial storage setup, adjustable wire rack

If you’re planning multiple rows, L-shapes, or U-shaped layouts, reach out to us for layout guidance before ordering: https://therestaurantwarehouse.com/pages/contact-us.

Essential Accessories to Improve Functionality

While functional on its own, commercial wire shelving can be enhanced with a wide array of accessories to create a specialized and efficient storage system. These additions improve organization, protect items, and streamline workflow.

Here are our Top 5 Must-Have Wire Shelving Accessories:

- Shelf Ledges and Dividers: These prevent items from falling and help categorize inventory by creating separate compartments. Use ledges along the back of shelves in coolers to prevent containers from being pushed into the wall, and dividers to organize by product category or date.

- In-lay Mats (Shelf Liners): Ideal for storing smaller items that might slip through the wire grid, these mats provide a solid, easy-to-clean surface. Clear or solid liners make it easier to store condiments, spice jars, squeeze bottles, or small packaging.

- Post Baskets: These wire baskets attach to the posts, providing quick-access storage for frequently used items and maximizing vertical space at the ends of shelving runs. They’re great for gloves, labels, markers, or other small, high-use supplies.

- Casters and Handles: Casters transform stationary units into mobile carts, while handles make maneuvering them easier and safer. Mobile units are especially useful in environments that require frequent deep cleaning behind and beneath equipment.

- Label Holders: These simple clips allow for clear identification of contents, which is crucial for efficient inventory management. Combine label holders with printed labels and color-coding to support FIFO rotation and make staff training easier.

Additional optional accessories include cantilever shelves, utility hooks for hanging light items, and corner protectors to reduce impact damage in high-traffic areas.

Ongoing Maintenance and Safety Checks

To protect your investment and maintain a safe work environment, build shelving inspection and cleaning into your regular schedule.

- Weekly or bi-weekly: Wipe surfaces, check for spills, and confirm labels are accurate.

- Monthly: Inspect for rust, chips, or bent wires, especially on heavily loaded shelves.

- Quarterly: Confirm casters, handles, and locking mechanisms are secure and functioning properly.

Always train staff to:

- Avoid climbing or standing on shelves.

- Report any damage immediately.

- Respect posted weight limits and load items evenly.

For replacement shelves, posts, or accessories compatible with your existing units, visit: https://therestaurantwarehouse.com/collections/wire-shelving.

Frequently Asked Questions about Commercial Wire Shelving

Choosing the right commercial wire shelving can bring up questions. Our goal is to provide clear answers to help you make the best decisions for your business. Here are some common inquiries we receive:

How do I know what weight capacity I need?

To determine the correct weight capacity, assess your inventory. Consider the heaviest items you plan to store and estimate the total weight per shelf. It's always best to choose shelving with a capacity higher than your estimated need to ensure a safety margin. The stated capacity (e.g., 800 lbs per shelf) assumes even weight distribution. Always check the manufacturer's specifications for both individual shelf and total unit capacity.

What is the difference between a starter unit and an add-on unit?

Understanding this distinction is key to designing a cost-effective shelving system. A starter unit is a complete, freestanding unit with four posts and your desired number of shelves. It stands on its own and forms the foundation of a shelving run. An add-on unit is designed to connect to a starter unit to extend a row. It includes only two posts and shares the posts of the adjacent unit. This approach is more economical as it eliminates redundant posts. To build a long row, you would purchase one starter unit and then as many add-on units as needed.

Can I use chrome shelving in a walk-in cooler?

We strongly advise against using chrome-plated commercial wire shelving in a walk-in cooler or any high-humidity environment. Chrome is designed for dry storage and is susceptible to rust when exposed to constant moisture and condensation. For wet environments, it is imperative to choose shelving specifically designed for such conditions. Your best options are epoxy-coated or stainless steel wire shelving. Epoxy offers a durable, rust-resistant powder coat, while stainless steel provides the ultimate in corrosion resistance and hygiene. Choosing the correct finish is crucial for longevity and sanitation.

Conclusion

Commercial wire shelving is a strategic investment that underpins the efficiency, hygiene, and organization of any commercial operation. Its benefits are clear, from superior strength and generous load capacities to excellent air circulation and easy cleaning. With the right layout and accessories, it helps your team work faster, safer, and more accurately.

The versatility of finishes—chrome for dry storage, epoxy for humid or refrigerated areas, and stainless steel for the most demanding conditions—ensures there is a solution for every zone of your business. Understanding specifications, NSF certification, and key features empowers you to make an informed decision tailored to your workflow and regulatory requirements.

At The Restaurant Warehouse, we focus on providing high-quality commercial wire shelving and storage solutions at wholesale pricing. Whether you need a single unit for a small backroom or an entire run of shelving for a high-volume operation, we can help you select the right components and accessories.

Ready to transform your storage and streamline your inventory management? Explore our complete wire shelving collection here:

- https://therestaurantwarehouse.com/collections/wire-shelving

- https://therestaurantwarehouse.com/collections/restaurant-shelving

If you’d like individualized guidance based on your floor plan, local code requirements, and budget, contact us to plan your storage upgrade today: https://therestaurantwarehouse.com/pages/contact-us.

About The Author

Sean Kearney

Sean Kearney is the Founder of The Restaurant Warehouse, with 15 years of experience in the restaurant equipment industry and more than 30 years in ecommerce, beginning with Amazon.com. As an equipment distributor and supplier, Sean helps restaurant owners make confident purchasing decisions through clear pricing, practical guidance, and a more transparent online buying experience.

Connect with Sean on LinkedIn, Instagram, YouTube, or Facebook.

Leave a comment