A Strategist's Guide to Commercial Kitchen Shelving

Commercial kitchen shelving is one of those things that’s easy to overlook, but get it wrong, and you’ll feel it every single shift. This isn’t just a place to stash boxes and cans; it’s a strategic system that dictates how smoothly your kitchen runs, how well you control inventory, and whether you’re staying on the right side of the health inspector. The right setup can turn a chaotic space into a picture of productivity.

Why Your Shelving Is the Backbone of Your Kitchen

Think of your kitchen's layout as its skeleton and your staff as the muscles. In that picture, your shelving is the connective tissue holding it all together. When it’s well-planned, every movement is fluid and intuitive. But when it’s an afterthought, the whole system feels strained, leading to bottlenecks, safety hazards, and a ton of wasted time.

A disorganized storeroom forces your crew to hunt for ingredients, breaking their rhythm and slowing down ticket times. On the flip side, a thoughtfully arranged system puts frequently used items right where they need to be, creating a seamless path from storage to prep station to the line. This isn't just about making life easier; it's about creating an environment where every second counts.

The Impact on Operations and Safety

Good commercial kitchen shelving has a direct, measurable impact on your daily grind in a few critical ways:

- Workflow Efficiency: When things are organized logically, your staff takes fewer steps and moves with purpose. This means faster prep, quicker service, and happier customers.

- Inventory Management: Clear sightlines on your stock prevent you from over-ordering and help slash food waste. It also makes a First-In, First-Out (FIFO) system a breeze to implement, ensuring ingredients get used before they expire.

- Health Code Compliance: Health inspectors have a sharp eye for storage. The right shelving—made from non-porous, easy-to-clean materials and set up to allow for proper airflow—is absolutely essential for passing inspections and preventing cross-contamination.

An organized kitchen is an efficient kitchen. Investing in a strategic shelving plan isn't an expense; it's an investment in operational excellence that pays dividends through reduced waste, improved staff morale, and a safer working environment.

More Than Just Storage

The key is to stop seeing your shelving as a passive storage unit and start seeing it as a dynamic part of your kitchen's infrastructure. It’s a tool you can use to solve common problems before they even start. Struggling with high staff turnover? A frustrating, cluttered workspace could be part of the problem. Are your food costs creeping up? Disorganized shelves are probably hiding expired products.

By starting with a solid foundation of well-chosen and smartly placed shelving, you’re setting the stage for success. Every other decision you make, from menu planning to staff training, becomes easier when your physical space is optimized for peak performance. This guide will walk you through how to transform your storage from a cluttered mess into a powerhouse of productivity.

Choosing the Right Shelving Material for Your Environment

Picking the right material for your commercial kitchen shelving is a lot like choosing the right tires for a car. You wouldn't put racing slicks on a farm truck, and you definitely shouldn't put chrome shelving in a steamy walk-in cooler. The environment is the deciding factor, and matching the material to the job is critical for durability, safety, and your budget.

Each material comes with its own set of trade-offs—balancing strength, rust resistance, and cost. If you understand these differences, you can avoid overspending on features you don’t need or, even worse, buying shelves that will rust and fall apart in less than a year. A smart choice here is a real investment in your kitchen's long-term health.

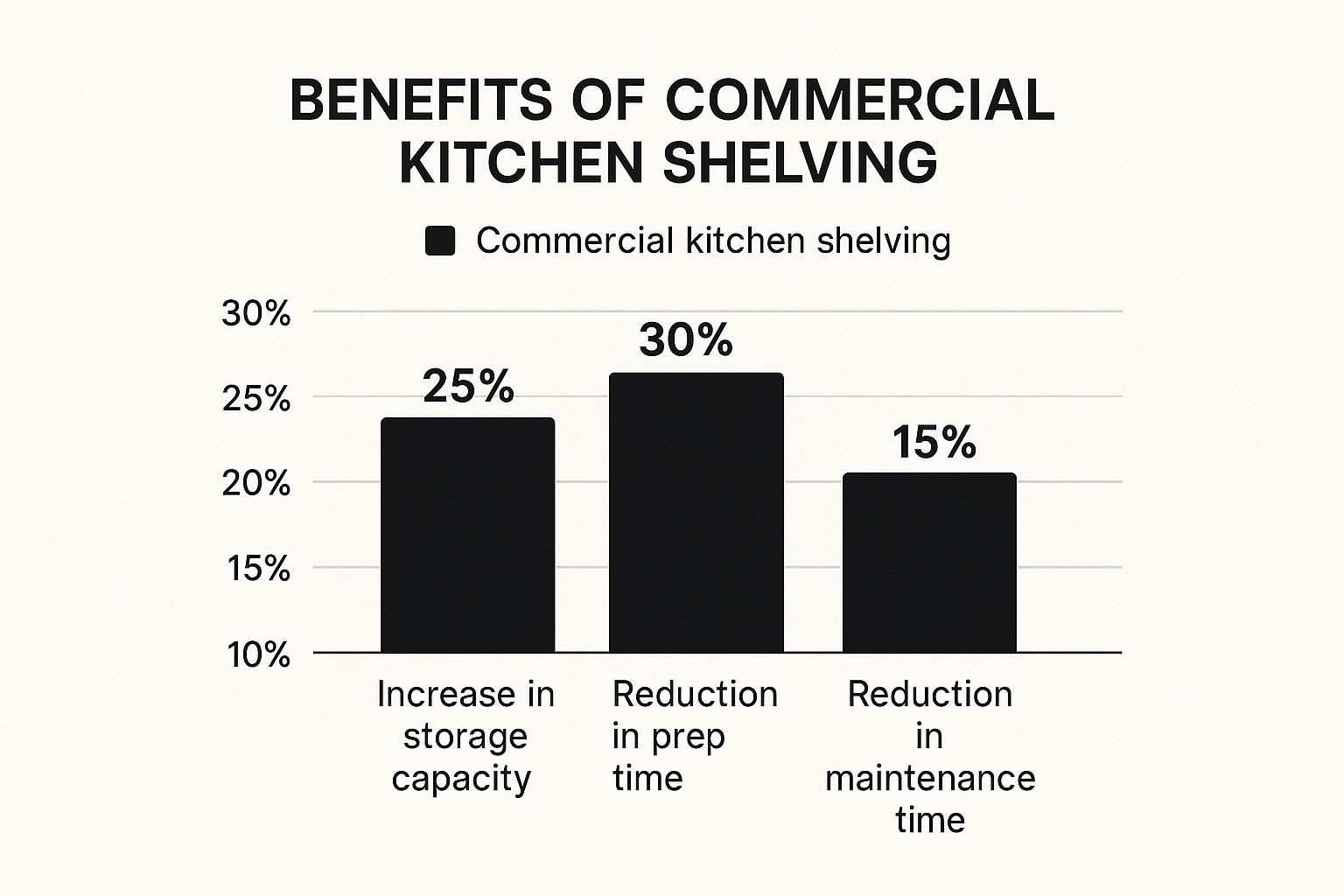

This quick visual shows just how much the right shelving can move the needle on key kitchen metrics.

As you can see, smart shelving choices directly boost efficiency, proving it’s more than just storage—it’s a fundamental tool for a productive kitchen.

Commercial Shelving Material Comparison

To make the decision a bit easier, here’s a quick side-by-side look at the most common shelving materials. This table breaks down where each one shines and what you can expect in terms of durability and cost.

| Material Type | Best For | Durability/Corrosion Resistance | Average Cost |

|---|---|---|---|

| Stainless Steel | Any environment, especially wet/humid areas and heavy-duty storage. | Highest | $$$ (Highest) |

| Chrome-Plated Steel | Dry storage only (pantries, storerooms). | Low (will rust in humidity). | $ (Lowest) |

| Epoxy-Coated Steel | Cold and damp environments (walk-in coolers, freezers, dish areas). | High (coating protects from rust). | $$ (Mid-Range) |

| Polymer/Composite | Any environment; great for harsh chemicals and wet areas. | Highest (cannot rust). | $$$ (High) |

Think of this as your cheat sheet. Now, let's dig into the details of what makes each of these materials tick.

Stainless Steel: The Heavy-Duty Champion

When you need absolute, no-compromise strength and hygiene, stainless steel is the undisputed king. It’s the go-to material for heavy-duty storage in any part of the kitchen, from dry pantries to damp prep stations. Health inspectors love it because its non-porous surface is incredibly easy to clean and sanitize.

Its biggest selling point, though, is its incredible resistance to rust and corrosion, making it perfect for just about any application. The main drawback? It’s the most expensive option upfront. But its sheer durability often makes it the most cost-effective choice over the long haul. To learn more, check out this complete stainless shelves guide for a deeper dive.

Chrome-Plated Steel: The Dry Storage Workhorse

Chrome shelving gives you a brilliant, shiny finish and excellent strength, making it a super popular choice for dry storage areas. It’s the perfect fit for pantries, storerooms, and any spot where humidity isn’t an issue. You get a high-end look at a much more budget-friendly price compared to stainless steel.

But here’s the catch: chrome’s kryptonite is moisture. In damp or humid spots like walk-in coolers, dish pits, or steamy prep zones, the chrome plating can start to chip or peel. Once the steel underneath is exposed, rust is just a matter of time.

Key Takeaway: Chrome shelving is a fantastic, economical choice for dry goods and equipment. Just be sure to keep it far, far away from water and steam to prevent rust and get a long service life.

Epoxy-Coated Shelving: The Cold and Damp Specialist

For those humid and cold environments, epoxy-coated shelving is the answer. These units are typically made of a steel core that’s been coated with a thick layer of epoxy, which acts like a protective shield against moisture and rust. This makes them the ideal choice for walk-in coolers, freezers, and dishwashing stations.

This material strikes a great balance between durability and cost for those tougher spots in the kitchen. It’s not quite as tough against physical damage as stainless steel—a deep scratch can break the protective seal—but its performance in damp conditions is top-notch. Many epoxy shelves even come with antimicrobial coatings, which adds another layer of food safety.

Polymer and Composite Shelving: The Modern Alternative

Polymer shelving is the modern approach, offering a lightweight yet surprisingly strong alternative to metal. Made from heavy-duty plastic composites, these shelves are completely immune to rust and corrosion, making them perfect for any environment, whether it's soaking wet or bone dry.

A huge perk is that many models have removable shelf plates that are dishwasher-safe, which makes cleaning a breeze. Polymer units might have a slightly lower weight capacity than their all-metal cousins, but they truly excel where harsh cleaning chemicals are used. Their versatility and easy maintenance are their biggest advantages, though their initial cost can be higher than epoxy-coated options.

Finding the Perfect Shelving Type for Your Space

Alright, you’ve figured out the best material for your kitchen’s environment. Now for the fun part: matching the shelving type to the specific job it needs to do. Commercial kitchen shelving isn't just one product; it's a whole toolkit of different setups, each designed to solve a unique storage problem.

Choosing the right configuration is all about understanding the flow of your kitchen and putting the right tool in the right place. Think of it like a mechanic organizing their toolbox. You wouldn’t just toss wrenches, sockets, and screwdrivers into one big pile. You'd give each tool its own spot to make your work fast and efficient. The same idea applies here—the right shelving turns your kitchen into a well-oiled machine.

Freestanding Units: The All-Purpose Foundation

Freestanding wire shelving is the undisputed workhorse of most commercial kitchens. These are the versatile units you can place pretty much anywhere you have floor space, making them the backbone of your dry storage pantry, walk-in cooler, and equipment areas.

Their open-wire design is a huge plus, promoting crucial air circulation that helps keep produce fresh and prevents moisture from building up. And because they aren't bolted to the walls, you can easily shift your layout around as your needs change. That flexibility is a lifesaver for a growing business or for adapting to seasonal menu updates.

Wall-Mounted Shelves: The Space-Saving Solution

In a packed kitchen where every square foot is prime real estate, looking up is often the best way to find more room. Wall-mounted shelves are the champions of vertical storage, letting you keep essential tools and ingredients within arm's reach without cluttering up your valuable work surfaces.

Picture a busy prep station. Slapping a wall shelf directly above the counter is a total game-changer. It’s the perfect spot for spices, oils, mixing bowls, and other go-to items. This simple move clears the prep table, giving your chefs more room to work and making them way more efficient.

Pro Tip: Always, always mount these shelves into wall studs or use heavy-duty anchors. A poorly secured wall shelf loaded with heavy cans or equipment is a serious safety hazard just waiting to happen.

Dunnage Racks: The Heavy Lifters

So, what about those seriously heavy, bulky items? We’re talking 50-pound bags of flour, giant sacks of potatoes, or full cases of canned goods. Standard shelving isn’t built for that kind of weight, and putting them directly on the floor is a major health code no-no.

This is where dunnage racks come in. These low-profile, incredibly sturdy platforms are designed for one job: keeping heavy stuff safely off the floor. Health departments require at least six inches of clearance to prevent contamination from pests, spills, and mop water. Dunnage racks are the simplest, most effective way to meet that rule for your heaviest inventory.

They are an absolute must-have in any:

- Dry Storage Pantry: For holding bulk bags of flour, sugar, and grains.

- Walk-In Cooler: To elevate cases of produce or large containers of liquids.

- Receiving Area: As a temporary, safe spot for newly arrived shipments.

Mobile Shelving: The Flexible Organizer

Finally, we have the shelving that comes to you. Mobile shelving, or rolling racks, puts your storage on wheels for the ultimate flexibility. They’re perfect for kitchens where the layout needs to adapt or where deep cleaning is a top priority. Instead of moving dozens of boxes to clean the floor, you just roll the entire unit out of the way.

If you have dynamic storage needs, exploring mobile shelving solutions can be a game-changer for optimizing space and sanitation. They’re especially useful for creating high-density storage. You can place units close together and simply move them to create an aisle when you need access, maximizing your storage footprint without sacrificing accessibility.

Designing a Kitchen Layout for Maximum Efficiency

Let's be honest, having the best shelving in the world won't do you any good if it’s crammed into a chaotic, poorly planned space. Your commercial kitchen shelving is only as good as the layout it lives in. The key is to think like a logistics expert, creating a kitchen where every single item has a purpose-driven home.

When you get this right, your storage areas transform from cluttered afterthoughts into dynamic zones that actively support a faster, safer workflow. It’s all about creating a system that cuts down on wasted steps, prevents costly mistakes, and just makes sense for your entire team.

Creating Dedicated Storage Zones

First things first: stop thinking of your storeroom as one giant closet. You need to divide it into distinct zones based on what you’re storing and what temperature it needs to be. This simple act of separation is the bedrock of good kitchen organization and, more importantly, food safety.

By creating dedicated areas, you slash the risk of cross-contamination. Storing cleaning chemicals next to dry pasta is a disaster waiting to happen, but a zoned system makes that kind of dangerous mistake almost impossible.

Your main zones should include:

- Dry Goods Storage: For all your non-perishables like flour, sugar, canned goods, and pasta. This area needs to be cool, dry, and have good air circulation.

- Cold Storage: This is your walk-in and your reach-in fridges and freezers. It’s the essential home for perishables like meat, dairy, and produce.

- Chemical Storage: A totally separate, secure area for all your cleaning supplies, sanitizers, and pest control products—far away from any food.

- Equipment and Utensil Storage: Designated shelves for pots, pans, small appliances, and other tools, usually placed near the prep or cooking stations where they’ll be used.

Implementing the FIFO System

Once your zones are set, it’s time to implement the First-In, First-Out (FIFO) system. This inventory rotation method is non-negotiable. It ensures your older stock gets used before the new stuff, which is absolutely essential for cutting down on food waste and spoilage.

A properly executed FIFO system can reduce food spoilage costs by 10-15%. It’s not just an organizational trick; it’s a direct boost to your bottom line that ensures you sell what you buy and serve only the freshest ingredients.

The right shelving makes maintaining FIFO a breeze. With clear, accessible shelves, your staff can see what they have at a glance. The process is simple: new inventory goes to the back, pushing older items to the front. This visual cue makes the whole system practically automatic.

Measuring for Success and Safety

Before you even think about ordering a single shelf, you have to measure your space with absolute precision. This is about more than just the length and width of the room. A truly efficient layout considers workflow, safety clearances, and all that valuable vertical space.

Measure Twice, Order Once

- Map Out Your Floor Plan: Sketch out the room, making sure to note where doors, windows, support columns, and utility lines are. For a deeper dive, check out our guide to creating a complete commercial kitchen floor plan.

- Account for Aisle Clearance: You absolutely must leave enough room between shelving units for people to move. Aim for a minimum of 36 inches for main aisles. This allows staff to walk freely and safely, even when they’re carrying bulky boxes or pushing carts.

- Use Vertical Space: Don't forget to measure your ceiling height! Using taller shelving units is one of the smartest ways to maximize storage in a small footprint. Just make sure the top shelf is still safely within reach for your team.

Optimizing kitchen space is a huge deal in the foodservice industry. In fact, the kitchen storage market, which includes commercial kitchen shelving, was valued at USD 131.43 billion in 2023 and is projected to hit USD 182.08 billion by 2030. You can find more insights on this growing market from the experts at Grand View Research.

Mastering Safe Installation and Assembly

Alright, you’ve picked the perfect material and the best configuration for your commercial kitchen shelving. Now for the most important part: putting it all together. A shoddy installation isn’t just an annoyance; it’s a serious safety hazard that can lead to collapsed shelves, ruined inventory, and even injuries.

Think of it like the foundation of a house. It doesn’t matter how strong the walls are if the base isn’t solid and level. Proper installation turns your shelving into a reliable asset instead of a ticking time bomb.

Building a Stable Foundation

Assembling most freestanding units is pretty straightforward, but you have to be precise. One of the most common mistakes we see is failing to get the unit perfectly level. Even a tiny wobble puts uneven stress on the posts and shelves, which can weaken the whole structure over time.

Grab a spirit level and check each shelf as you build. If your floor is uneven—which is common in a lot of kitchens—use the adjustable feet on the posts to eliminate any rocking. Make sure it's stable and level from every angle. This small step is what prevents dangerous swaying and makes sure the weight is distributed exactly as it was designed to be.

A wobbly shelf is a dangerous shelf. The number one cause of shelving failure isn't overloading but improper, uneven assembly that creates weak points. Taking an extra five minutes to level the unit is the best safety investment you can make.

Securing Wall-Mounted Units Safely

With wall-mounted shelves, the stakes are even higher. These units absolutely must be anchored directly into wall studs—those vertical wood or metal beams that frame the wall. Trying to hang a heavy shelf loaded with equipment on drywall alone is just asking for a disaster.

Use a stud finder to pinpoint these support beams. Mark their locations so you can line up your mounting brackets perfectly.

- Choose the Right Hardware: Forget about the small plastic anchors you use for hanging pictures. You need heavy-duty lag bolts that bite deep into the studs to create an unshakeable hold.

- Check for Levelness: Just like with the freestanding units, use a level to ensure the shelf is perfectly horizontal. A slanted shelf is an invitation for items to slide off, creating an unstable and dangerous load.

- Respect the Load Limits: Wall-mounted shelves can’t hold nearly as much as floor units. Be mindful of their weight capacities and use them for lighter, frequently accessed items.

Critical Safety Checks and Common Mistakes to Avoid

Beyond the basics, a safe installation requires some common sense and awareness of your surroundings. Your shelving doesn’t exist in a vacuum; it’s part of a busy, fast-paced kitchen.

One of the most overlooked safety rules is making sure your layout doesn't create new hazards. Never place shelving where it could block fire exits, sprinkler heads, or emergency equipment. You need to maintain clear, wide aisles—at least 36 inches—to prevent trips and allow for a quick evacuation if necessary.

Finally, always post the maximum weight capacity for each shelf where it’s clearly visible. This simple reminder helps prevent the all-too-common mistake of accidental overloading by busy staff.

Keeping Your Shelving in Top Shape for the Long Haul

Think of your commercial kitchen shelving as a serious investment, because it is. But its real value isn't just what you paid for it. Proper maintenance isn't just another task to check off a list; it's how you protect that investment, make sure it lasts, and stay on the right side of health inspectors. Let it go, and you're looking at premature rust, wobbly legs, and potential dings on your next inspection report.

When you treat your shelving with consistent care, it stops being just a piece of metal and becomes a core part of your kitchen's hygiene program. A simple, repeatable routine is all it takes to stop a tiny rust spot or a loose post from turning into a major headache.

Nailing Down Your Maintenance Schedule

Consistency is everything here. A proactive cleaning and inspection schedule keeps you ahead of any issues and ensures your storage areas are always ready for a surprise inspection. It doesn't need to be a complicated system—a simple two-part approach works wonders.

Weekly Quick Cleans:

- Wipe down all the easy-to-reach shelf surfaces with a food-safe sanitizer.

- Get a broom and mop under any freestanding units to clear out dust and debris.

- Wipe up spills the second you see them. This prevents staining and stops corrosion before it starts.

Monthly Deep Dives:

- Take everything off the shelves. This is the only way to really clean and inspect every inch.

- Scan for any signs of rust, paying close attention to chrome units or any spots where epoxy might be chipped.

- Give the posts, casters, and connections a good look to make sure everything is tight and stable.

- Look for any bending or sagging in the shelves—that’s a dead giveaway you’re overloading them.

By setting aside just a little time for regular upkeep, you'll get years more out of your shelving and build a kitchen-wide culture of safety and cleanliness. It’s a practice that pays off big time when the health inspector walks in.

How to Clean Different Types of Shelving

Different materials need slightly different care to stay in great shape. Using the wrong cleaner can be just as bad as not cleaning at all. For a much deeper look at this, our guide on cleaning restaurant equipment has even more specific tips.

For stainless steel, grab a soft cloth and some mild detergent or a cleaner made specifically for stainless. The key is to always wipe in the direction of the grain to avoid putting tiny scratches on the surface. Whatever you do, don't use abrasive stuff like steel wool. It’ll create little grooves where bacteria can hide and rust can get a foothold.

When it comes to epoxy-coated shelving, a gentle touch is best. A non-abrasive sponge with simple soap and water is all you need. Harsh chemicals or scouring pads are a no-go, as they can scratch that protective epoxy coating. Once that seal is broken, moisture gets to the steel underneath, and rust is sure to follow. If you do spot a chip, deal with it right away using a touch-up kit from the manufacturer to stop rust in its tracks. Spotting these small problems early is absolutely critical.

Final Questions on Kitchen Shelving

Alright, you've got the basics down, but a few nagging questions might still be bouncing around your head. That's completely normal. Let's tackle some of the most common ones that pop up right before you pull the trigger on new shelving.

Think of this as the final check-in. Getting these last details right is what separates a good setup from a great one—and ensures your investment works with you, not against you.

What Does NSF-Certified Mean for Commercial Shelving?

When you see that little NSF (National Sanitation Foundation) logo on a shelf, it's basically a seal of approval for your kitchen. It means the unit has been put through the wringer and certified to meet some seriously strict public health standards. For your kitchen, this isn't just a nice-to-have; it's a non-negotiable feature that health inspectors are trained to look for.

NSF certification is your guarantee that the shelving material is:

- Non-porous, so it won’t become a breeding ground for bacteria.

- Corrosion-resistant, meaning it can handle moisture and the tough cleaning chemicals you use every day.

- Easy to clean and sanitize, with a smooth surface that has no cracks or crevices for germs to hide in.

Honestly, using NSF-certified equipment is a cornerstone of food safety and is almost always required by local health departments. It's the simplest way to know your storage is compliant right out of the box.

How Do I Calculate the Weight Capacity I Need?

Figuring out the weight capacity you need is a crucial step, but it's pretty straightforward. Just start by thinking about exactly what you plan to store on each shelf and then do a rough calculation of its total weight. For a little perspective, a single case of those big #10 cans can weigh 40-50 pounds.

Always, and I mean always, choose shelving with a capacity that’s comfortably above your heaviest estimated load. Manufacturers list this capacity on a per-shelf basis, and that number assumes you've spread the weight out evenly.

Crucial Tip: Don't make the mistake of piling all your heaviest items right in the middle of a shelf. Distributing the load evenly is key to preventing the shelf from bowing over time, which can lead to a sudden, dangerous collapse.

Can I Use Residential Shelving in My Commercial Kitchen?

I get asked this a lot, and the answer is always a firm no. It is a terrible idea to use residential-grade shelving in any kind of commercial foodservice setting. While it might feel like a smart way to save a few bucks upfront, I promise you, it's a decision that will cost you far more down the road.

Shelving from a big-box store just isn't built for the abuse of a professional kitchen. It doesn't have the durability to handle heavy loads day after day, and it will quickly break down from the constant use and harsh cleaning chemicals required for sanitation. Most importantly, it's not NSF-certified, which means you're looking at an automatic health code violation during your next inspection. Investing in proper commercial kitchen shelving is absolutely essential for safety, durability, and staying compliant.

For all your commercial kitchen needs, from durable shelving to heavy-duty cooking equipment, trust The Restaurant Warehouse to provide high-quality solutions with fast delivery. Equip your kitchen for success by visiting https://therestaurantwarehouse.com.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment