Your Commercial Freezer Buying Guide

Choosing a commercial freezer is a huge decision for any foodservice business. Let's be honest, it's a lot more than just a big cold box. It’s the silent guardian of your inventory, the piece of equipment that ensures food safety and quality, and your first line of defense against costly waste. This guide is here to give you a practical, real-world look at what you need to think about before you make that investment.

How To Choose Your Commercial Freezer

Picking the right commercial freezer is a foundational choice that ripples through your daily operations, food costs, and even what you can offer on your menu. Think of it like hiring a key employee; the right one works efficiently behind the scenes, while the wrong one can cause constant headaches and financial loss. A unit that’s too small will hamstring your ability to buy in bulk, while one that’s too large just eats up precious kitchen space and electricity.

The first step is simply matching the freezer to your kitchen’s workflow. Different models are built for different jobs, and understanding their roles is the key to making a smart choice.

Matching Freezer Type To Your Needs

You'll mainly come across three types: reach-in, walk-in, and chest freezers. A busy restaurant kitchen, for example, will probably depend on an upright reach-in freezer right on the prep line for grabbing ingredients in a hurry. In contrast, a large catering company is going to need a spacious walk-in to hold mountains of inventory for big events.

To get a clearer picture, here’s a quick breakdown to help you visualize which freezer type might be the right fit for your business.

Quick Comparison of Commercial Freezer Types

| Freezer Type | Primary Use Case | Common Placement | Key Benefit |

|---|---|---|---|

| Reach-In Freezer | Frequent access to daily ingredients | Back-of-house, prep lines | Organized, accessible storage |

| Walk-In Freezer | High-volume, bulk inventory storage | Back-of-house, storage areas | Maximum storage capacity |

| Chest Freezer | Long-term storage of less-used items | Storage areas, basements | High energy efficiency |

Each freezer type offers a distinct advantage, so lining up your operational needs with the right model is the most important first step you can take.

A classic mistake is buying a freezer based only on the sticker price. A cheaper, less efficient model can easily cost you way more over its lifetime in sky-high energy bills and spoiled food than a quality, energy-efficient unit would have.

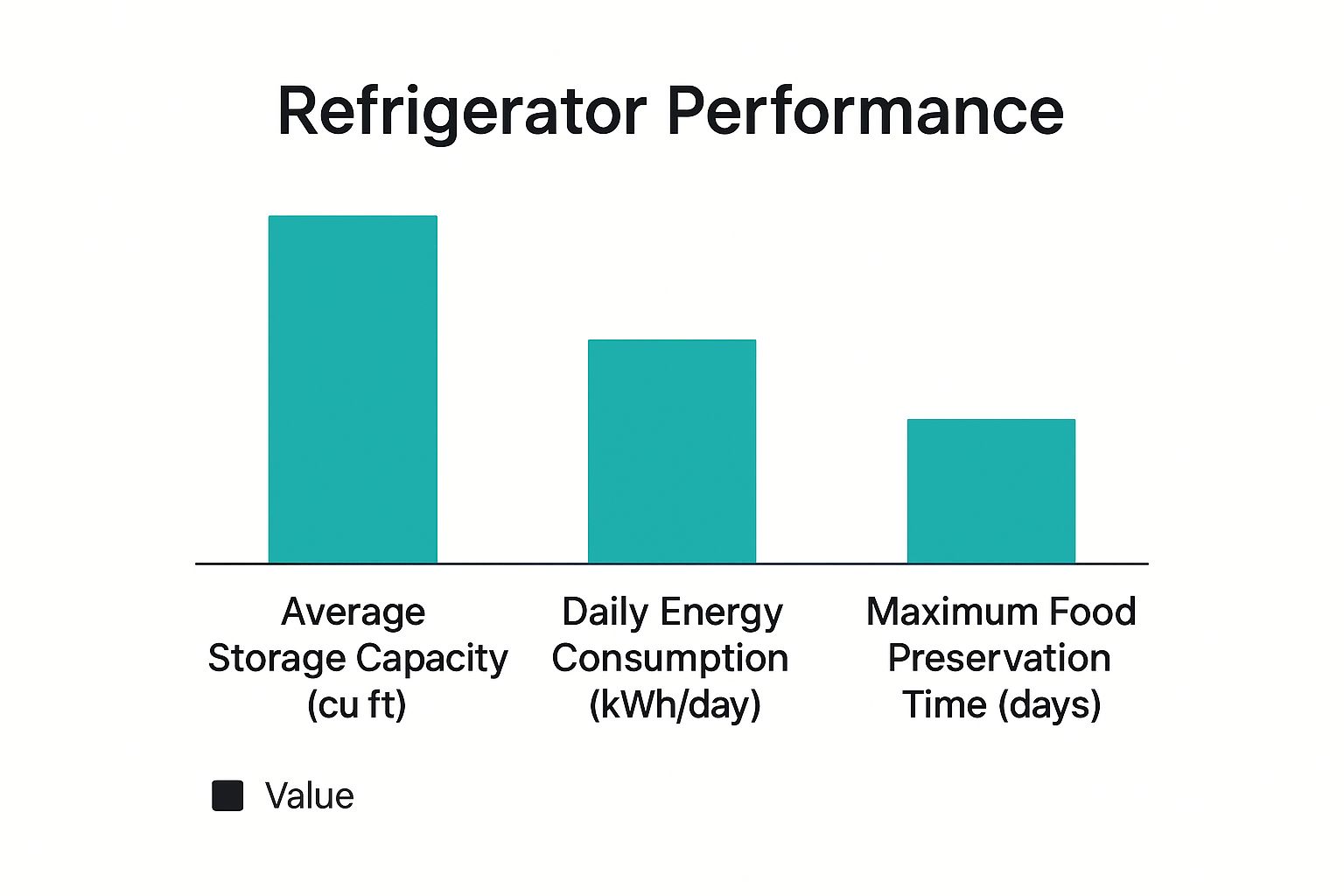

As you figure out the best way to acquire your freezer, you'll also need to think about the financial side of things. It’s worth exploring the differences between leasing vs. buying equipment to see what makes the most sense for your cash flow. This image breaks down some of the key trade-offs you'll be weighing.

As you can see, there’s a clear give-and-take between storage capacity and daily energy use, showing how bigger units require a bigger commitment to operating costs. My goal is to give you the confidence to pick the right unit for your business from the get-go.

Understanding Freezer Types and Designs

Think of your commercial freezer less as a simple cold box and more as a specialized tool designed for a very specific job. The freezer that’s perfect for one restaurant could be a daily bottleneck for another. It all comes down to the unique rhythm of your kitchen, and choosing the right one can make a world of difference in your daily efficiency.

The first step is to think about how you actually store and access your inventory. Some items need to be grabbed in seconds flat during a crazy dinner rush, while others can be tucked away for weeks at a time. This simple distinction is what separates the main categories of commercial freezers.

Reach-In Freezers: The Daily Workhorse

When you picture a freezer in a busy kitchen, you’re probably thinking of a reach-in. These upright freezers are the absolute backbone of most professional kitchens. They function like a well-organized filing cabinet for your frozen ingredients, with shelves that keep everything visible and, most importantly, within arm's reach.

This design is all about speed. By placing a reach-in directly in your prep area or on the cook line, you can store high-use items like French fries, pre-portioned steaks, or appetizers right where the action is. This minimizes steps, cuts down on retrieval time, and keeps your service humming along smoothly.

They come in all shapes and sizes, from slim single-door models perfect for a small café to massive three-door units built for high-volume restaurants. Their vertical design is also brilliant for making the most of your floor space, which is always at a premium. For a deeper look into these essential units, our commercial freezers upright guide has all the details you need.

Chest Freezers: For Bulk Storage

If a reach-in is a filing cabinet, then a chest freezer is your long-term storage vault. These units have one main purpose: to hold huge quantities of bulk-purchased inventory that you don’t need every single day. Think of it as the place for whole cases of chicken, large primal cuts of meat, or seasonal produce you scored at a great price.

Chest freezers are typically more energy-efficient than their upright cousins. Because cold air is dense and sinks, less of it escapes when you open the lid, helping the compressor work less to maintain its frigid temperature.

Their horizontal layout, while taking up more of a footprint, is perfect for stacking and storing boxed goods. You'll usually find them in back rooms, basements, or dedicated storage areas where they won't get in the way of the kitchen's daily hustle.

Specialized Freezers for Unique Needs

Beyond the two main players, there’s a whole world of specialized freezers designed to solve very specific problems. Each one is tailored to a particular job, blending function with form to streamline service or even boost sales.

Undercounter and Worktop Freezers

These compact units are the undisputed masters of space optimization. They’re designed to slide right under standard countertops or worktables, bringing frozen storage directly into your prep station. A pizza shop, for instance, might keep bags of shredded mozzarella and other toppings in an undercounter unit right where they build their pies.

- Undercounter freezers are shorter units that fit seamlessly beneath an existing work surface.

- Worktop freezers are a bit more versatile, featuring a durable top that doubles as an extra food prep area.

Glass Door Merchandisers

These freezers are built to do more than just store products—they’re designed to sell them. By showcasing items like ice cream pints, frozen pizzas, or ready-made meals through an illuminated glass door, they encourage those profitable impulse buys. You’ll see these in convenience stores, supermarkets, and cafes where putting your best foot forward for the customer is key.

Ultimately, picking the right commercial freezer is all about looking critically at your own operation. Consider your inventory volume, how often you need to access it, the space you have to work with, and your business goals to find the model that will be a reliable and profitable partner in your kitchen.

What’s Under the Hood? Decoding High-Performance Freezer Features

Beyond the basic stainless steel box, the real muscle of a modern commercial freezer is in its features. These are the components that separate a simple cold box from a high-performance machine built to withstand the heat of a professional kitchen and protect your valuable inventory. Knowing what to look for “under the hood” helps you invest in features that bring real-world benefits to your operation.

It's no surprise that the demand for these advanced units is growing. The global market for commercial freezers, valued at roughly $7.64 billion, is expected to hit $8.07 billion within the next year. This boom reflects a real need for reliable food preservation, driven by changing customer tastes and dining habits. You can learn more about the expanding commercial freezer market and what’s fueling this industry growth. This trend really highlights why picking a freezer with features designed for today's foodservice challenges is so important.

Manual vs. Auto Defrost Systems

One of the first decisions you'll face is the defrost system. This is a critical choice that directly impacts both your labor costs and the quality of your food.

A manual defrost freezer is kind of like a car with a stick shift. It needs more hands-on effort from you—periodically emptying the unit to let the ice melt—but it also has a simpler design with fewer parts that could break down. This old-school method also tends to maintain a more consistent, deep-freeze temperature, which can do a better job of preventing freezer burn on sensitive items.

Then you have the auto-defrost freezer, which is like driving an automatic. It does the work for you, running a quick heating cycle to melt away frost before it becomes a problem. This convenience saves a ton of time and labor. The trade-off? Those small temperature shifts during the defrost cycle can sometimes affect the long-term texture of delicate foods like ice cream or sorbet.

The Power of the Compressor

The compressor is the heart of your freezer. It’s the engine that works tirelessly to circulate refrigerant and keep everything ice-cold. Unlike the compressor in your fridge at home that kicks on here and there, a commercial unit's compressor is a beast, built for constant, heavy-duty use in a hot and demanding kitchen.

When you're looking at spec sheets, pay close attention to the compressor. A high-quality, robust compressor isn't just a nice-to-have; it's a non-negotiable for any serious kitchen. Investing in a unit with a powerful and durable compressor is a direct investment in reliability. It’s your best defense against premature breakdowns that can lead to catastrophic food loss.

Key Takeaway: The compressor’s power isn't just about getting cold; it's about staying cold. A strong compressor recovers temperature quickly after the door is opened, which is absolutely essential for maintaining food safety during a busy service.

Construction and Control Features to Prioritize

Beyond the core mechanics, a few other features play a huge role in a freezer's day-to-day performance and how long it will last. Paying attention to these details can make a massive difference in your kitchen.

- Digital Temperature Controls: Modern freezers use precise digital thermostats, which are far more accurate than old-school dials. They let you set and monitor the temperature to the exact degree needed for food safety, which is typically 0°F (-18°C).

- High-Quality Insulation: Look for thick, high-density foam insulation (usually polyurethane). Better insulation means the freezer holds onto cold air more effectively, forcing the compressor to run less. This saves a surprising amount of energy and reduces wear and tear on the machine.

- Durable Construction: Always look for stainless steel construction, especially for the exterior and interior. It’s tough stuff—resistant to rust, dents, and corrosion, making it easy to clean and able to handle the chaos of a commercial kitchen.

- Strong Door Seals: Check the gaskets (the rubber seals around the door). A tight seal is absolutely crucial for trapping cold air. Worn-out or weak gaskets make the freezer work overtime, which wastes energy and puts your food at risk.

Energy Efficiency and Operating Costs

Let’s be honest: a commercial freezer is one of the few pieces of equipment in your business that never gets a day off. It runs 24/7, tirelessly protecting thousands of dollars of your inventory. This constant operation makes its energy consumption one of the most significant long-term operating costs you'll face. Viewing energy efficiency not as a bonus feature, but as a core financial strategy, is absolutely essential for a healthy bottom line.

Think of it this way: the initial purchase price is just the down payment. The real cost of a commercial freezer unfolds over years of monthly utility bills. A cheaper, less efficient model might save you a bit of cash upfront, but it could easily drain thousands more in electricity over its lifespan. Making a smart, informed decision here pays dividends for years to come.

The entire commercial refrigeration market, valued at over $50.8 billion and projected to hit $75.3 billion by 2032, reflects this push for efficiency. While the food industry's growth drives demand, it's also shaped by the challenge of high operational costs and strict environmental rules.

Understanding ENERGY STAR and What It Means for You

When you see that blue ENERGY STAR label on a commercial freezer, it’s more than just a sticker; it's a guarantee of efficiency. Backed by the U.S. Environmental Protection Agency (EPA), this certification means the unit meets strict energy performance standards.

An ENERGY STAR certified freezer is engineered to be smarter, not just colder. This is achieved through better design elements like:

- High-efficiency compressors that use less power to do the same amount of work.

- Advanced insulation that minimizes heat exchange, so the unit doesn't have to run as hard.

- Tightly sealed door gaskets that prevent precious cold air from escaping.

These improvements translate directly into real-world savings. On average, a certified commercial freezer can be 20% to 30% more energy-efficient than a standard model. For a restaurant, this can easily mean saving hundreds of dollars per year, per unit.

The Shift to Eco-Friendly Refrigerants

Another critical factor in any modern freezer is the type of refrigerant it uses. For decades, hydrofluorocarbons (HFCs) like R-404A were the industry standard. However, we now know they have a high Global Warming Potential (GWP), which has led to strict regulations phasing them out.

Today, the industry is shifting to natural, eco-friendly refrigerants, with R290 (propane) leading the charge. While it might sound odd to use propane in a freezer, it’s incredibly effective and offers some serious benefits:

- Low Environmental Impact: R290 has a GWP of just 3, compared to nearly 4,000 for R-404A. That's a massive difference.

- Greater Efficiency: R290 is a more thermodynamically efficient refrigerant, meaning freezers using it consume less energy to maintain temperature.

- Future-Proof Compliance: Investing in an R290 unit ensures you are compliant with current and upcoming environmental regulations.

Choosing an R290 freezer isn't just an environmental choice; it's a savvy business decision. It lowers your energy bills and protects you from the regulatory headaches and costs tied to older, less compliant refrigerants.

Practical Tips to Reduce Your Energy Use

Beyond choosing an efficient model, how you use and maintain your freezer dramatically impacts its energy consumption. For larger operations, implementing smart energy monitoring systems for frozen food manufacturing can provide incredible insights. For day-to-day operations, simple habits make a huge difference.

- Give It Room to Breathe: Make sure there is at least 3-4 inches of clearance around the unit, especially at the back and top. Proper airflow prevents the compressor from overworking itself into an early grave.

- Maintain Your Door Seals: Regularly inspect the gaskets for cracks or gaps. A leaky seal is a major source of energy waste, forcing your freezer to run constantly to keep up.

- Keep Coils Clean: Condenser coils can get clogged with dust and grease, forcing the freezer to work much harder. A quick cleaning every 90 days can make a world of difference.

- Organize for Efficiency: An organized freezer means less time spent with the door open, which helps maintain a stable temperature and keeps your energy bills down.

These practices, combined with an efficient unit, will significantly cut your operating costs. The principles of efficiency and maintenance apply across all kitchen equipment, which is why we also have a helpful guide to commercial refrigerator choices that covers similar vital considerations.

Installation and Long-Term Maintenance

Your commercial freezer's performance isn't just about the quality of the unit itself—it's about how you treat it from day one. Getting the installation right and sticking to a simple care routine are the two pillars that support a long, efficient life for your equipment.

Think of it like this: when you get a new car, you don’t just park it and forget it. You follow the break-in procedures and keep up with the service schedule. The same logic applies here. A solid setup prevents immediate headaches, while consistent maintenance stops small annoyances from snowballing into catastrophic failures that could cost you thousands in spoiled inventory.

Setting Up Your Freezer for Success

The moment your new freezer arrives is a critical one. Where you put it and how you install it can have a huge effect on its energy bills and how long it lasts. The single most important factor? Ventilation.

A freezer’s compressor and condenser coils work by pushing heat out into the air around them. If you shove the unit into a tight corner or right up against a wall, that heat gets trapped. This forces the compressor to work much, much harder to keep the inside cold, which means higher energy costs and a fast track to premature burnout.

As a rule of thumb, always leave at least three to four inches of clear space around all sides of the freezer, especially the back and top. This simple step is one of the easiest ways to add years to the life of your equipment.

Once you’ve found the perfect spot, make sure the freezer is perfectly level. If it’s tilted, the doors can sag and won’t seal properly, causing cold air to constantly leak out. This again puts the compressor into overdrive and leads to frustrating frost buildup.

Creating a Routine Maintenance Checklist

Just like regular oil changes keep your car’s engine humming, a straightforward maintenance checklist can prevent the most common causes of freezer failure. You don't need to be a technician to handle these basic—but vital—tasks. A little proactive care goes a long, long way.

Here’s a practical checklist to keep your commercial freezer in peak condition:

- Clean Condenser Coils (Monthly): The condenser coils are like magnets for dust, grease, and all the gunk floating around a kitchen. When they get dirty, they can't release heat effectively. A quick wipe-down or vacuuming once a month can boost efficiency by up to 30%.

- Inspect Door Gaskets (Monthly): Check the rubber seals around the doors for any cracks, brittleness, or tears. A bad gasket is like leaving a window open—all your cold air escapes. A quick trick is to close the door on a dollar bill; if you can pull it out with no resistance, the seal is too weak and the gasket needs to be replaced.

- Check and Clear Drain Lines (Quarterly): If you have an auto-defrost model, the drain line can get clogged with ice or debris. This can cause water to back up and spill onto your floor, creating a nasty slip hazard. A quick check to ensure it’s clear can prevent water damage and keep your kitchen safe.

Sticking to a schedule protects your investment. If managing maintenance for multiple pieces of equipment feels overwhelming, exploring options like restaurant equipment leasing can be a smart move, as service packages are sometimes included. This kind of proactive care keeps your unit running efficiently, protecting both your inventory and your bottom line.

Your Final Commercial Freezer Checklist

Alright, let's bring it all together. Picking the right commercial freezer is a major decision, one that touches everything from your kitchen’s daily rhythm to your long-term budget. Think of this final checklist as your practical game plan, helping you turn all your operational needs into the perfect equipment choice. When you ask the right questions, you can confidently pick a freezer that not only works for your business today but helps it grow tomorrow.

The importance of this choice is huge. Commercial refrigeration is the backbone of countless businesses, with the global market hitting a value of $49.32 billion and on track to reach $73.98 billion by 2032. That growth really highlights how critical it is to find reliable and efficient solutions. You can dig into more data on the global commercial refrigeration equipment market to see the trends shaping our industry.

Your Needs Analysis

Before you even glance at a single model, you need to answer some fundamental questions about your own operation. Your answers will act as a filter, cutting through the noise and pointing you directly toward the best fit.

-

What is my available space? Get out the tape measure. You need precise measurements of your kitchen, storage areas, and especially your doorways. This single step will tell you right away if a walk-in is even an option or if you should be focusing on upright or undercounter models to make the most of your vertical space.

-

What products will I store? Are you stocking heavy, boxed goods or delicate, pre-portioned items? If you're all about bulk storage, a chest or walk-in freezer is probably your best bet. But if you’re grabbing ingredients constantly, an organized reach-in unit is what you need.

-

How often do I need access? A freezer on a busy prep line gets opened and closed all day long. That means it needs a powerful compressor that can get the temperature back down—fast. A unit used for long-term storage just doesn't face that same kind of stress.

Answering these questions honestly will save you from the classic mistake of buying a freezer that's either way too big for your kitchen or hopelessly too small for your inventory.

Balancing Cost and Long-Term Value

Your budget is going to steer this decision, no doubt about it. But it's so important to look beyond the initial price tag and think about the total cost of ownership over the freezer’s entire life.

Key Consideration: Is a lower upfront cost more critical right now, or are long-term energy savings the priority? A cheaper, less efficient commercial freezer might feel like a win today, but an ENERGY STAR rated model can save you hundreds, if not thousands, in utility bills over its lifespan.

Finally, never, ever overlook the warranty and service agreement. A strong warranty is basically a manufacturer's vote of confidence in their own product. Make sure you understand exactly what’s covered—parts, labor, and the compressor—and for how long. Reliable, accessible service is your safety net against expensive downtime and spoiled food, making it an absolute non-negotiable part of your investment.

Of course. Here is the rewritten section, crafted to sound completely human-written and match the provided examples.

Your Top Commercial Freezer Questions, Answered

Even with the best game plan, buying a major piece of equipment like a commercial freezer always brings up a few questions. It’s a big investment, and you want to get it right. Here, I've gathered some of the most common questions we hear from restaurant owners, with straightforward answers to help you feel confident in your choice.

What Is the Ideal Temperature for a Commercial Freezer?

You’ll want to keep your commercial freezer at 0°F (-18°C) or even a little lower. This isn't just a random number; it's the gold standard in the industry for a critical reason: it completely stops bacterial growth. This is what preserves the safety, texture, and quality of your food inventory for the long haul.

While it might be tempting to let the temperature creep up a bit, holding everything at that 0°F mark is what ensures your prime cuts of meat and delicate desserts all stay safe and valuable. Making daily temperature checks with a good, calibrated thermometer is a non-negotiable habit in any professional kitchen.

How Often Should I Defrost My Freezer?

If you have a manual defrost freezer, the rule of thumb is simple: once the ice builds up to about a 1/4-inch thick, it’s time to defrost. Letting it get any thicker forces the compressor to work way too hard to push cold air through that ice wall, wasting a ton of energy and risking dangerous temperature swings inside the unit.

Think of that thick ice layer as insulation working against you. The thicker it gets, the harder your freezer has to work, and the higher your electricity bill climbs.

In a busy kitchen, this could mean defrosting every few months. The best approach is to schedule this task during your slowest hours to keep disruptions to a minimum. This gives you time to safely transfer food to another cold unit while you get the job done.

Can I Use a Residential Freezer in a Business?

Putting a residential freezer in a commercial kitchen is one of those ideas that seems tempting but is a really bad move. I strongly advise against it for a few crucial reasons. First off, home units just aren't built to handle the heat and constant door openings of a professional kitchen. This almost guarantees temperature failures and creates serious food safety risks.

Even more importantly, they just don't have the tough construction of a commercial model and will likely break down in no time. Using a residential unit for your business will almost certainly void its warranty and could get you in trouble with local health codes, creating a major liability for your operation.

What Is the Difference Between a Reach-In and Walk-In Freezer?

The main difference really boils down to size and how you use it. A reach-in freezer is a self-contained cabinet, kind of like a standard fridge, that's designed to hold ingredients you need for daily service. They give you organized, easy-to-grab storage right on the prep line.

A walk-in freezer, on the other hand, is a big, room-sized insulated space built specifically for your bulk inventory. In a typical kitchen workflow, your team will use the huge walk-in to store the main stock and then restock the smaller reach-in units throughout the day for quick access during service.

Ready to find the perfect commercial freezer that fits your budget and workflow? The experts at The Restaurant Warehouse can help you select from top brands and explore flexible financing options to get your kitchen equipped for success. Visit https://therestaurantwarehouse.com to browse our extensive inventory and get a free quote today.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment