Is a Conveyor Pizza Oven Right for Your Restaurant? A Complete Guide

Let’s talk about your kitchen’s biggest challenges: labor costs, ticket times, and consistency. A commercial conveyor pizza oven isn't just another piece of equipment; it's a strategic solution to all three. By automating the cooking process, you can train any staff member to produce perfect pizzas in minutes, drastically reducing your need for highly paid, specialized cooks. Faster cooking means quicker table turnover and more delivery orders out the door. This guide breaks down how this machine delivers a powerful return on investment by increasing your kitchen's output and efficiency, directly impacting your restaurant's bottom line.

Could a Conveyor Pizza Oven Transform Your Restaurant?

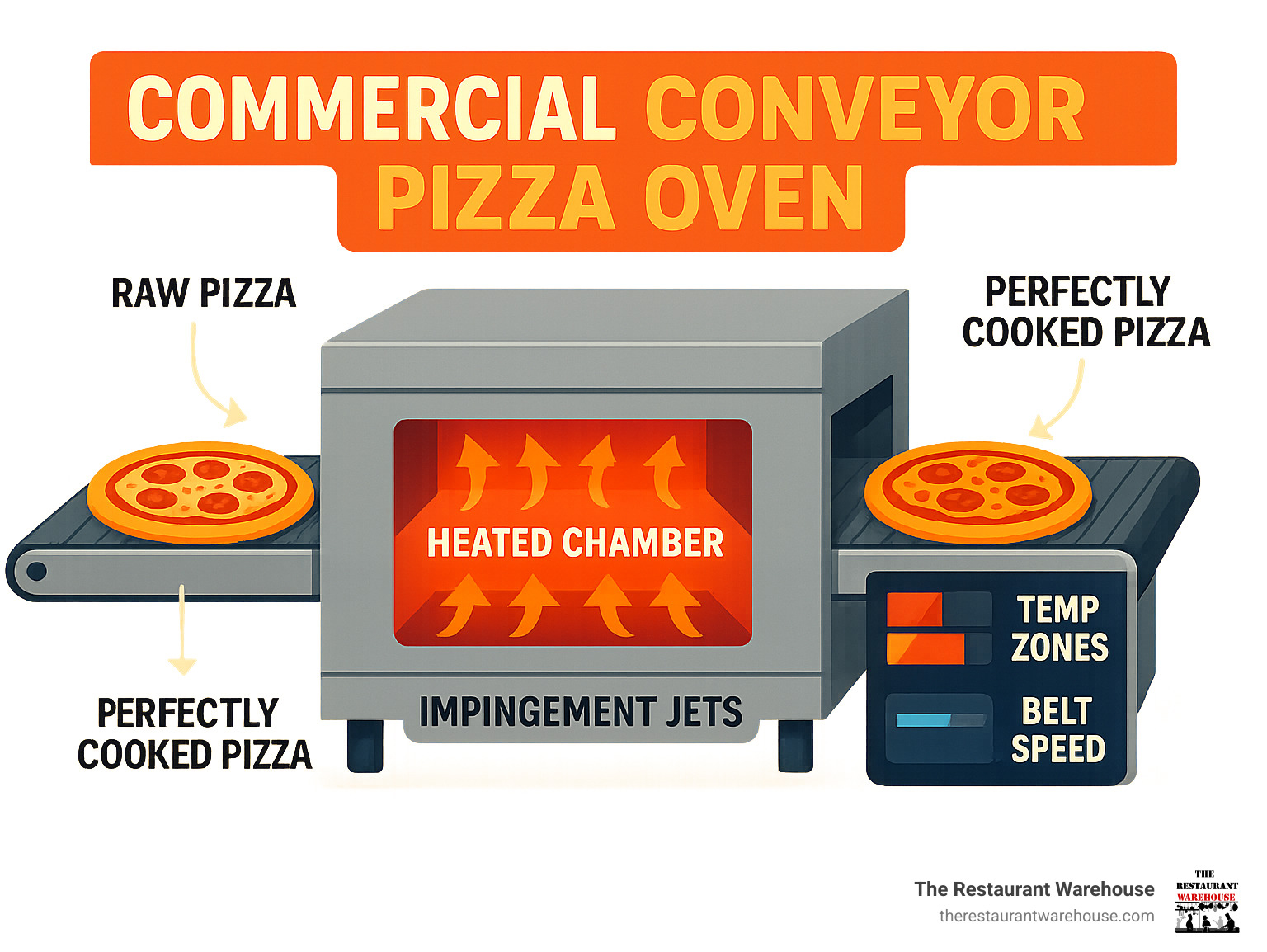

A commercial conveyor pizza oven transforms your pizza production from labor-intensive guesswork into automated precision. These ovens use a moving belt system to transport pizzas through heated chambers, delivering consistent results without constant monitoring.

Quick Answer for Buyers:

- What it is: Automated oven with moving belt that cooks pizzas as they travel through heated chamber

- Key benefits: Consistent quality, reduced labor, 60-120 pizzas per hour capacity

- Price range: $9,000-$50,000+ depending on size and features

- Best for: High-volume operations, chains wanting consistency, kitchens with limited skilled labor

- Top brands: Middleby Marshall, XLT, Lincoln, Hot Rocks, TurboChef, Edge

Unlike traditional deck ovens that require skilled operators, conveyor ovens let you "set it and forget it." The TurboChef High h Conveyor 2020 can cook up to 60 12-inch pizzas per hour, while the Middleby Marshall PS360 pushes out 80 or more 14-inch pizzas hourly.

These machines solve three critical restaurant challenges:

Labor shortage solutions - Single operators can manage high volumes without pizza-making expertise

Consistency problems - Every pizza gets identical heat exposure and timing

Space constraints - Stack up to three units to triple capacity in the same footprint

The automation comes from precise belt speeds, independent top and bottom heating zones, and impingement air jets that cook faster than traditional methods. Gas models offer rapid heating, while electric versions provide precise temperature control. Stone conveyor surfaces add authentic flavor by removing moisture for crispier crusts.

Commercial conveyor pizza oven further reading:

Not Just for High-Volume Pizzerias

It's easy to picture a conveyor oven churning out endless pizzas for a busy chain, but their capabilities go far beyond that. Think of them as a multi-tool for your kitchen. These ovens are incredibly versatile and can perfectly cook a wide range of menu items, from toasted sandwiches and chicken wings to fish and even steak. This adaptability makes them a fantastic asset for more than just pizzerias; cafes, delis, and fast-casual spots can all benefit from the consistent, automated cooking process. By using a conveyor oven, you can expand your menu offerings without needing a whole new line of specialized equipment, making it a smart and efficient addition to almost any commercial kitchen.

How Do Conveyor Pizza Ovens Actually Work?

Picture a commercial conveyor pizza oven as your kitchen's most reliable employee - one that never calls in sick and always delivers perfect results. These machines work on beautifully simple principles that transform pizza making from an art form into a science.

The heart of the system is a mechanized belt that carries your pizzas through a heated chamber like a gentle conveyor of deliciousness. But here's where it gets interesting: instead of just surrounding food with hot air like traditional ovens, these machines use impingement jets that blast heated air directly onto your pizzas from above and below.

Think of it like having dozens of tiny hair dryers focused on your pizza, creating incredibly efficient heat transfer. This direct air contact cooks food much faster than conventional methods while ensuring every inch gets consistent attention.

Gas heat systems fire up burners that warm air before circulation, giving you rapid temperature recovery when you're cranking out pizza after pizza during rush periods. Electric coils offer their own advantages with precise, steady heating that some operators prefer for delicate items.

The real magic happens with dual-zone control. You can set different temperatures for top and bottom heating elements, letting you crisp the bottom while perfectly melting cheese on top. It's like having two ovens working in perfect harmony.

Stone conveyor surfaces add another layer of sophistication. These systems combine the speed of impingement technology with moisture removal that creates authentically crispy crusts. The stones literally pull moisture from your dough while cooking, delivering that perfect texture customers crave.

Airflow dynamics and moisture removal work together to solve the soggy crust problem that plagues many high-speed cooking methods. The precisely angled air jets don't just heat - they actively remove steam that would otherwise make crusts limp and disappointing.

Impingement vs. Radiant Technology

When you start looking at conveyor ovens, you'll quickly run into two main terms: impingement and radiant. These aren't just fancy marketing words; they describe two fundamentally different ways of cooking your food. Understanding the distinction is key to choosing an oven that matches your kitchen's pace and your pizza's desired finish. One method uses powerful, targeted airflow for speed, while the other relies on a more traditional heating method. Let's break down what each technology brings to the table so you can make the best choice for your restaurant.

The Power of Impingement Ovens

Impingement technology is the secret sauce behind the incredible speed of most modern conveyor ovens. These ovens use strong jets of hot air that blast directly onto the food from above and below. This process does something brilliant: it pushes away the pocket of cold, insulating air that naturally surrounds any item you're cooking. By stripping away this "cold air bubble," the hot air makes direct contact with the pizza's surface, transferring heat with incredible efficiency. This direct approach is why an impingement oven can cook food 20% to 25% faster than other conveyor models, making it a powerhouse for high-volume kitchens that need to keep up with demand without sacrificing quality.

Understanding Radiant Ovens

Radiant ovens operate on a more traditional principle. Instead of using forced air, they rely on heating elements, often using infrared technology, positioned above and below the conveyor belt. These elements radiate heat, which is then absorbed by the pizza as it passes through the chamber. Think of it like standing near a campfire—you feel the heat radiating toward you. This infrared energy penetrates the food to cook it thoroughly. While typically not as fast as impingement models, radiant ovens are reliable workhorses that provide consistent, even heat, making them a solid choice for various menu items beyond pizza. When deciding, consider your budget and needs; options like restaurant equipment financing can make even the most advanced technology accessible.

Breaking Down the Key Components

The belt drive system forms the mechanical foundation of these workhorses. A variable speed motor controls how fast pizzas travel through the chamber, giving you complete control over cooking time. Need faster turnover during lunch rush? Speed up the belt. Working with thick-crust specialty pizzas? Slow things down for thorough baking.

The bake chamber houses all the heating magic. Top and bottom heaters work independently, creating different temperature zones for various pizza styles. You might run the bottom hotter for crispy crusts while keeping the top moderate for gentle cheese melting.

This chamber design explains why these ovens outperform traditional alternatives. Instead of relying on radiant heat from oven walls, the controlled environment ensures consistent results regardless of how many pizzas you're cooking simultaneously.

The Conveyor Belt: Material Matters

It’s easy to think of the conveyor belt as just a simple moving track, but its design and material are critical to your final product. The belt's composition directly changes how heat reaches the food. Most standard conveyor ovens use a wire mesh belt, which is fantastic for allowing the hot impingement air to circulate all around the pizza, cooking it evenly from top to bottom. This is the workhorse option that delivers speed and consistency for a wide variety of menu items. However, for pizzerias aiming for that next level of crust perfection, stone conveyor surfaces offer a significant upgrade. These belts combine the rapid cooking of impingement technology with the authentic, moisture-wicking properties of a traditional pizza stone. The result is a beautifully crisp, never-soggy crust that can rival what comes out of a classic deck oven. When you're comparing different types of restaurant equipment, the belt material is a detail you won't want to overlook.

Conveyor vs. Deck vs. Brick: Which Is Right for You?

Hands-off cooking changes everything about pizza production. Once you dial in your belt speed and temperatures, the oven handles the rest automatically. No more hovering over deck ovens, rotating pizzas, or worrying about hot spots that burn one side while leaving the other underdone.

This automation frees your staff for other tasks like customer service, prep work, or handling multiple orders simultaneously. It's like adding an extra employee who never needs breaks and always performs perfectly.

Batch consistency solves the quality control nightmare that keeps restaurant owners awake at night. Every pizza gets identical heat exposure and timing, eliminating the variations that come with manual cooking methods. Your customers get the same great pizza whether it's made during slow Tuesday lunch or crazy Friday night rush.

The reduced skill gap transforms your hiring possibilities. Instead of searching for experienced pizza makers - who command higher wages and are increasingly hard to find - you can train almost anyone to load pizzas and retrieve finished products. This expands your hiring pool dramatically while reducing labor costs.

Stackable decks offer the ultimate solution for space-constrained kitchens. You can literally double or triple your pizza production capacity by stacking units vertically, turning a single oven footprint into a high-volume production powerhouse that grows with your business success.

What to Look for in a Conveyor Pizza Oven

Shopping for a commercial conveyor pizza oven feels overwhelming with so many options, but focusing on a few key factors makes the decision much clearer. Think of it like buying a car - you need to match the specs to how you'll actually use it.

Fuel type shapes both your monthly bills and installation headaches. Gas models heat up faster and typically cost less to operate, but you'll need a gas line installed. Electric units give you precise temperature control and work anywhere with adequate power, though they'll bump up your electricity bill.

Output capacity needs to handle your busiest nights, not your average Tuesday. The EDGE-3270's 32-inch wide conveyor lets you cook multiple large pizzas side by side, while the TurboChef High h Conveyor 2020 cranks out 60 12-inch pizzas per hour. Calculate your Friday night rush demand and add 20% breathing room.

Physical dimensions matter more than you'd think. Chamber length affects cooking time - longer chambers let you run slower belt speeds for thorough baking. Belt width determines how many pizzas fit at once. Measure your kitchen space carefully, including clearances for loading and unloading.

Temperature range flexibility opens up menu possibilities. Models spanning 250°F to 600°F handle everything from warming appetizers to high-heat pizza baking. Some specialized units push even higher for unique cooking applications.

Ventless options can save thousands in installation costs. The TurboChef High h Conveyor 2020 uses dual catalytic converters for ventless operation, perfect when traditional hood systems aren't practical or affordable.

Warranty length reveals how much the manufacturer believes in their product. XLT backs their units with an industry-leading 10-year warranty and 24/7/365 lifetime technical support, while Hot Rocks offers 5-year parts coverage and 1-year labor protection.

| Feature | Gas Models | Electric Models | Stone Conveyor |

|---|---|---|---|

| Heat-up time | Fast (15-20 min) | Moderate (25-35 min) | Fast with flavor |

| Operating cost | Lower fuel costs | Higher electricity costs | Premium pricing |

| Installation | Gas line required | 208-240V power needed | Special stone maintenance |

| Temperature control | Rapid response | Precise control | Natural heat retention |

| Flavor impact | Clean heat | Neutral | Authentic stone taste |

For deeper insights into different oven types, our guide to comparing commercial oven options breaks down the pros and cons of each style.

Choosing Your Fuel Source: Gas, Electric, or Propane

Choosing your fuel source is a big decision that affects your kitchen's workflow, your utility bills, and your initial setup expenses. Gas models are the sprinters of the kitchen, heating up fast and generally costing less to operate. This makes them ideal for high-volume pizzerias that need to keep up with a relentless dinner rush, thanks to their rapid temperature recovery. The main catch is that you'll need a dedicated gas line. Electric ovens, on the other hand, are masters of precision. They offer incredibly stable temperature control, which is a huge plus if you plan to cook a variety of items beyond pizza. They can be installed almost anywhere you have the right power hookup, but be prepared for a higher electricity bill. If ventilation is a concern, some models like the TurboChef High h Conveyor 2020 are ventless, which can save you a ton on hood installation.

A Note on Electrical Needs for Gas Ovens

Here’s a crucial tip that can prevent a major installation day headache: even gas-powered conveyor ovens require electricity. While the gas provides the heat, a standard electrical outlet is necessary to power the oven's brain and muscles. This includes the digital control panel where you set your temperatures and belt speed, the ignition system that sparks the burners to life, and the motor that keeps the conveyor belt moving. When you plan your kitchen layout, make sure to account for an electrical hookup near your gas oven. Forgetting this small detail can lead to frustrating delays and extra costs to bring in an electrician after the fact. Thinking through your full utility needs upfront ensures a smooth and efficient setup from day one.

How to Choose the Right Oven Size

Getting the size right prevents two expensive mistakes: buying too small and creating bottlenecks, or buying too big and wasting money on unused capacity.

Production volume calculations start with your peak demand periods. Don't size based on your slow Monday lunch - size for Saturday night when you're slammed. A pizzeria pushing 100 pizzas during Friday rush needs an oven rated for at least 120 pizzas per hour to avoid creating customer wait times.

Peak demand planning requires honest assessment of your busiest periods. If you're consistently backed up during dinner rush, undersized equipment is costing you sales and frustrating customers. Better to have extra capacity than to turn away hungry customers.

Future growth considerations matter more than most operators realize. If you're planning expansion, additional locations, or expect business growth, choose models that offer modular stacking options. Starting with a single unit and adding capacity beats replacing entire systems later.

Modular stacking transforms space efficiency. Three stacked units triple your output while occupying the same floor footprint as a single oven. In expensive real estate markets, this vertical approach maximizes every square foot.

Considering Countertop Models for Smaller Spaces

If you're working with a smaller kitchen, a food truck, or a bar with a limited menu, a full-sized conveyor oven might seem out of reach. This is where countertop models shine. They deliver the same game-changing automation and consistency as their larger cousins but in a compact footprint. You still get the benefits of reduced labor needs and perfectly cooked products every time, solving critical operational challenges without a massive overhaul. Many of these units are also stackable, allowing you to double or even triple your output vertically as your business grows. This means you can turn a small corner of your counter into a high-volume production station, making them a smart investment for any space-conscious operator looking at new kitchen equipment.

Your Essential Feature Checklist

Smart features separate good ovens from great ones, but focus on what actually improves your operation rather than getting distracted by bells and whistles.

Independent zones give you cooking flexibility that single-zone ovens can't match. Set higher bottom heat for crispy crusts while maintaining moderate top heat for proper cheese melting. This control accommodates different pizza styles without compromising quality.

ECO/idle mode cuts energy costs during slow periods. Senoven ovens offer energy-saving ECO mode that stops the conveyor and reduces fan speed when no pizza is detected. This feature pays for itself over time through reduced utility bills.

Smart controls provide operational insights that help optimize performance. Advanced models offer USB data transfer for remote fault diagnostics before technician visits, reducing downtime and service costs. Some systems even track cooking data to help refine your recipes.

Reversible belt options extend equipment life and reduce maintenance expenses. Instead of replacing worn belts, flip them to use the fresh side, effectively doubling belt lifespan. This simple feature saves hundreds in replacement costs.

Split-belt capability maximizes equipment utilization by allowing different products with varying cook times in the same oven. Cook wings on one side while finishing pizzas on the other, keeping your commercial conveyor pizza oven busy throughout service.

The Payoff: Efficiency and Profit

The real magic of a commercial conveyor pizza oven shows up in your monthly profit and loss statements. These machines don't just cook pizza - they transform your entire operation's economics in ways that often surprise restaurant owners.

Labor cost reduction delivers the biggest financial punch. Think about it: instead of paying experienced pizza makers $18-22 per hour, you can train any kitchen staff member to operate a conveyor oven in about 30 minutes. Our research shows potential savings of over $30,000 per year by eliminating the need for specialized pizza makers. That's real money that drops straight to your bottom line.

Faster ticket times create a ripple effect throughout your restaurant. When pizzas cook in 2-4 minutes instead of 8-12 minutes, everything moves faster. Tables turn quicker, delivery orders get out the door sooner, and customers leave happier. This increased throughput translates directly to higher revenue without expanding your dining room or hiring more servers.

Energy savings might seem small individually, but they add up over months and years. Modern conveyor ovens with heavy insulation and smart air recirculation systems minimize heat loss. When you're running ovens 12-14 hours daily, those efficiency gains become meaningful cost reductions.

The throughput metrics tell an impressive story. High-capacity models can produce up to 200 pizzas per hour with proper stacking while maintaining consistent quality. This capacity opens doors to catering contracts and high-volume events that weren't previously feasible. Suddenly, you're not just a neighborhood pizzeria - you're a serious player in the local food service market.

Financing alternatives make these investments accessible without crushing your cash flow. Rent-try-buy programs let you test equipment with manageable weekly payments while applying 60% of net rental payments toward purchase. This reduces risk while preserving cash for other business needs. You can literally try before you buy, ensuring the oven fits your operation perfectly.

The rent-try-buy model particularly benefits growing operations. As your business expands, you can upgrade equipment to match demand without over-investing early on. It's like having training wheels for major equipment purchases.

For scaling multi-unit chains, conveyor technology becomes a game-changer. Standardized cooking processes ensure identical results across locations, maintaining brand consistency while simplifying staff training and quality control. Every location produces the same great pizza, every time.

Achieving Perfect, Consistent Pizza Every Time

Even heat distribution eliminates those frustrating hot spots and cold zones that plague traditional ovens. Impingement air jets create uniform cooking environments where every pizza receives identical treatment. No more rotating pizzas or dealing with one side cooking faster than the other.

This consistency builds customer trust and reduces waste from overcooked or undercooked products. When customers know exactly what to expect every time they order, they become loyal repeat customers who recommend you to friends.

Crust crispiness improves dramatically through controlled moisture removal. Stone conveyor surfaces actively draw moisture from dough while heated air circulation prevents sogginess. The result is consistently crispy crusts that customers rave about - the kind that makes people drive across town for your pizza.

Cheese melt uniformity ensures perfect browning and texture every single time. Independent top and bottom heating zones let you optimize temperatures for proper cheese melting without burning crusts. This precision eliminates the guesswork that leads to inconsistent results and customer complaints.

Reduced waste from consistent cooking saves money and improves food costs. When every pizza comes out perfectly, you eliminate expensive remakes and unhappy customers. This reliability particularly benefits operations with tight margins where every dollar counts.

Finding the Sweet Spot: Time and Temperature

Dialing in the perfect time and temperature is where your conveyor oven truly shines, turning good pizza into great pizza. Most recipes thrive in a range of 400°F to 600°F; setting your oven between 500°F and 520°F, for instance, can cook a pizza to perfection in just four to five minutes. The real control, however, comes from dual-zone heating. This feature lets you set different temperatures for the top and bottom elements, allowing you to blast the bottom for a crispy, golden-brown crust while using gentler heat on top to perfectly melt the cheese. This precision, combined with impingement air jets that actively remove moisture to prevent sogginess, ensures you get consistent, delicious results every single time. This reliability reduces waste and builds customer trust, proving that investing in the right restaurant equipment is a cornerstone of operational success.

Saving Time and Reducing Labor Costs

Single-operator flow transforms pizza production from a skilled craft requiring years of experience into a manageable process anyone can learn quickly. One person can load pizzas, monitor cooking, and handle finishing tasks without specialized training. This simplifies scheduling and reduces your dependence on hard-to-find experienced staff.

Cross-training ease means any kitchen staff member can operate the oven effectively. Unlike traditional pizza making that requires months of practice to master, conveyor ovens need minimal training. Your prep cook can jump on pizza duty during rush periods, your dishwasher can help with lunch orders, and scheduling becomes infinitely more flexible.

Simplified workflow reduces kitchen stress during those crazy busy periods when orders are flying in faster than you can think. Staff can focus on preparation, customer service, and other tasks instead of constantly monitoring cooking pizzas. This improved efficiency benefits your entire operation, creating a calmer, more productive kitchen environment where everyone performs better.

How Fast Are They? A Look at Cooking Speed

The speed of a conveyor oven is a true game-changer for any busy kitchen, directly impacting your ticket times and customer satisfaction. Forget the long waits that lead to backed-up orders and frustrated diners. With a conveyor oven set between 500°F and 520°F, you can slide a raw pizza in one end and have a perfectly cooked one emerge in just four to five minutes. This rapid turnaround is what allows high-performance models to achieve such impressive outputs. For example, the TurboChef High h Conveyor 2020 can produce up to 60 12-inch pizzas per hour, while a powerhouse like the Middleby Marshall PS360 can handle 80 or more 14-inch pizzas in the same timeframe. This level of efficiency means you can confidently manage the busiest dinner rushes without breaking a sweat or sacrificing quality.

Beyond Pizza: Expanding Your Menu with a Conveyor Oven

Don't make the mistake of thinking conveyor ovens are a one-trick pony. While they are masters of pizza, this single piece of restaurant equipment is one of the most versatile workhorses you can add to your kitchen. The same technology that delivers a perfectly crisp pizza crust can also be used to toast sandwiches, roast vegetables, bake pasta dishes, and even cook proteins like fish, chicken wings, and steak. This incredible flexibility allows you to expand your menu and experiment with new offerings without cluttering your valuable kitchen space with a dozen different appliances. It’s an investment that pays off by opening up new revenue streams and creative possibilities for your culinary team.

The secret to this versatility lies in the oven's precise control and advanced cooking technology. Impingement air jets create a remarkably uniform cooking environment, ensuring every item receives the same consistent heat from every angle. This means you get reliable, repeatable results whether you're cooking a single appetizer or a full batch of entrees. With wide temperature ranges, often from 250°F to 600°F, you have the control to handle everything from gently warming breadsticks to searing items at high heat. You can even use it to complement your other equipment, like finishing wings with a perfect, crispy skin after they come out of your deep fryers.

Top Conveyor Oven Brands to Consider

Once you've decided a conveyor oven is right for your kitchen, the next step is choosing a brand. The market is full of excellent options, and the right choice often comes down to your specific needs for volume, menu flexibility, and budget. Investing in a top-tier brand is a significant decision, but it's one that pays off in reliability and performance for years to come. Remember that quality equipment is an investment in your business's future, and flexible restaurant equipment financing can make it much more accessible. Let's look at some of the leading names you'll encounter.

EDGE Ovens

If you value American manufacturing and energy efficiency, EDGE Ovens should be on your radar. Produced in Pennsylvania, these ovens have built a solid reputation for being fast, durable, and incredibly efficient. You can find them in both gas and electric models, giving you the flexibility to choose the fuel source that works best for your setup and utility costs. The fact that major national and international pizza chains trust EDGE ovens in their kitchens speaks volumes about their reliability and consistent performance under pressure. For a busy restaurant, that kind of proven dependability is priceless.

Lincoln and Middleby Marshall

When you think of high-volume pizza production, the names Lincoln and Middleby Marshall almost always come to mind. These brands are the workhorses of the industry, designed for demanding environments like pizzerias, fast-food chains, and large institutional kitchens. Their power lies in continuous, high-speed cooking. Because the belt is always moving, your team can load pizzas one after another, dramatically increasing your kitchen's output. But their utility doesn't stop at pizza; these ovens are also perfect for toasting sandwiches, bagels, and other menu items, making them a versatile piece of restaurant equipment that can support various parts of your menu.

Moretti Forni, Star, and Vollrath

For chefs and restaurant owners who prioritize culinary flexibility, brands like Moretti Forni, Star, and Vollrath offer compelling options. These ovens are celebrated for their adaptability, with designs that can be easily configured to bake almost any kind of pizza you can dream up. Whether your menu features classic thin crust, hearty deep-dish, or artisanal flatbreads, you can adjust the settings to achieve perfect results. This level of control allows you to experiment with different pizza styles without needing multiple types of ovens. Best of all, this versatility doesn't come at the expense of speed; they are fully capable of handling high-volume production during your busiest shifts.

Installation, Care, and Planning for Growth

Getting a commercial conveyor pizza oven running is straightforward when you plan ahead.

What to Know Before Installation Day

- Space: Most models need only 6 in. side/back clearance.

- Power or gas: Electric units typically require 208-240 V, 3-phase; gas versions need the correct line and regulator.

- Ventilation: Standard ovens sit under a hood, but ventless units such as the TurboChef use catalytic converters. Always confirm local codes first—rules vary by city.

Understanding Ventilation: The Type I Hood Requirement

Let's talk about ventilation, because getting this right is non-negotiable for safety and air quality. Most commercial conveyor pizza ovens, especially gas models that produce combustion byproducts, are considered 'medium-duty' cooking appliances. According to the International Mechanical Code, this classification often requires a Type I hood for proper exhaust. This is the system that captures grease, smoke, and heat, keeping your kitchen safe and comfortable. Before you purchase any equipment, always check with your local health department or fire marshal first, as regulations can differ from one city to another. If installing a full hood system isn't feasible for your space, ventless models like the TurboChef High h Conveyor 2020 offer a fantastic alternative by using catalytic converters to clean the air, saving you thousands on installation.

Keeping Your Oven in Top Shape

- Brush the belt and empty crumb trays every shift.

- Soak jet plates weekly to keep air holes clear.

- Clean stone or steel conveyors with manufacturer-approved products.

- Schedule a tech quarterly to calibrate temps and check belt tension; easy parts access and 24/7 support keep downtime minimal.

Essential Accessories and Replacement Parts

Your conveyor oven is the star of the show, but the right accessories are the supporting cast that ensures a flawless performance. From the pans that carry your pizzas to the systems that keep your kitchen air clean, these components are essential for maximizing your oven's potential. Thinking about these parts from the beginning helps create a smoother, safer workflow for your team and guarantees you get the most out of your big investment. It’s all about setting your kitchen up for success from day one.

Pizza Pans and Screens

To keep up with high demand, you need tools that ensure consistency and easy handling. Pizza pans and screens are fundamental for getting perfect results from a conveyor oven. Screens are fantastic for creating an extra-crispy crust, as they allow the hot impingement air to circulate directly under the dough. Pans, on the other hand, are ideal for deep-dish pizzas or catching loose toppings. Using the right tools helps improve cooking operations by preventing pizzas from sticking and ensuring they cook evenly on their journey through the oven, which is a must for any busy pizzeria.

Low CFM Extraction Hoods

A high-output conveyor oven produces significant heat and smoke, making proper ventilation a top priority. A low CFM extraction hood is essential for keeping your kitchen safe, comfortable, and compliant with health codes. These systems are designed to effectively manage the heat and airborne particles your oven produces. For restaurants where traditional ductwork is a challenge, ventless options are a game-changer. These systems can save thousands in installation costs, offering a practical solution for kitchens with space constraints or for operators looking to minimize upfront expenses without compromising on safety.

Features That Grow With Your Business

- Remote diagnostics and USB logs let technicians solve many issues before stepping on-site.

- Low-profile and stackable designs add one or two more ovens without widening the footprint, so capacity grows with demand.

Frequently Asked Questions about Commercial Conveyor Pizza Ovens

How many pizzas per hour can I expect?

A single mid-range conveyor oven turns out about 60 12-inch pizzas per hour; wide-belt units reach 80+ 14-inch pies. Stack two or three ovens and you can push 150–200 pizzas an hour.

Do ventless conveyor ovens really eliminate the need for a hood?

Yes—if local codes allow it. Dual catalytic converters strip smoke and grease so the oven can run without traditional exhaust, saving thousands on installation. Always confirm requirements with your health and building departments.

Can the same oven cook sandwiches, wings, and flatbreads?

Absolutely. Adjust belt speed and temperature to toast subs in about a minute, finish wings in four, or bake flatbreads in two—turning the oven into an all-day workhorse.

Is a Conveyor Pizza Oven Right for You?

Choosing a commercial conveyor pizza oven isn't just about buying equipment - it's about changing how your kitchen operates. These automated workhorses solve the three biggest headaches facing pizza operations today: finding skilled labor, maintaining consistency during rush periods, and scaling up without taking over your entire kitchen.

The numbers tell the story. When you can eliminate skilled pizza maker positions and still increase output, the math works in your favor. Add in the consistency that builds customer loyalty and reduces waste, and you're looking at an investment that pays for itself through multiple channels.

What really sets conveyor technology apart is its reliability. No more wondering if your Friday night rush will overwhelm your cooking capacity. No more training new hires for months before they can make decent pizza. The oven handles the skill part - your team just loads and unloads.

The sustained quality becomes your secret weapon. While competitors struggle with inconsistent results during busy periods, your pizzas come out perfect every single time. That consistency lets you charge premium prices and build the kind of reputation that keeps customers coming back.

At The Restaurant Warehouse, we've seen too many operations struggle with equipment that costs more than it delivers. Our wholesale pricing approach cuts out the middleman markups and commission costs that inflate equipment prices elsewhere. When you're investing in productivity-boosting technology, every dollar saved on the purchase price improves your return on investment.

The modular stacking approach means you're not gambling on future growth. Start with what you need today, then add capacity as your business expands. It's like having an upgrade path built right into your initial purchase.

Whether you're replacing aging deck ovens, planning a new location, or just tired of inconsistent results, conveyor technology offers a proven solution. The combination of automation, reliability, and scalability makes these ovens essential tools for any serious pizza operation.

Ready to explore financing options that won't strain your cash flow? Our rent-to-own equipment guide shows you how to upgrade your equipment while preserving working capital for other business needs.

Key Takeaways

- Solve Labor and Consistency Issues with Automation: A conveyor oven removes the need for highly skilled pizza makers and guarantees every pizza is cooked the same. This cuts down on training time, reduces labor costs, and eliminates expensive food waste from inconsistent results.

- Expand Your Menu, Not Your Kitchen Footprint: This single piece of equipment is a workhorse that can toast sandwiches, cook wings, and bake appetizers. Its versatility allows you to diversify your offerings, while stackable designs let you increase output without sacrificing more floor space.

- Make a Smart Purchase by Focusing on Key Specs: Before buying, determine the output capacity you need for your busiest rush hours. Then, choose between gas or electric based on your utility setup and consider ventless or stackable models to save on installation costs and plan for future growth.

Related Articles

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment