A Practical Guide to Comparing Commercial Oven Options

Why Commercial Ovens Are the Heart of Your Kitchen Success

Commercial ovens are the powerhouse equipment that can make or break your foodservice operation. Unlike home ovens, these workhorses are built to handle high-volume cooking day after day, delivering consistent results that keep customers coming back.

Quick Commercial Oven Overview:

- Main Types: Convection, deck, combi, conveyor, rack ovens

- Fuel Options: Gas (instant heat, lower operating costs) or Electric (precise control, easier installation)

- Key Features: Programmable controls, steam injection, energy recovery systems

- Capacity Range: Countertop units to industrial tunnel ovens

- Price Range: $1,500-$50,000+ depending on size and features

- Expected Lifespan: 10-20 years with proper maintenance

The wrong oven choice costs you money every single day through wasted energy, inconsistent food quality, and constant repairs. The right one becomes your most reliable kitchen partner.

With manufacturers bringing decades of experience to oven design, today's commercial ovens deliver both performance and savings. Some models reduce energy consumption by 20% while maintaining quality.

But with dozens of oven types, fuel options, and features to consider, making the right choice feels overwhelming. This guide cuts through the complexity to help you find the perfect oven for your concept and budget.

Common commercial ovens vocab: - commercial deck oven - commercial smoker oven - deck oven for pizza

Understanding Commercial Ovens

Commercial ovens are purpose-built machines designed for the demanding environment of professional kitchens. While your home oven might bake a few cookies, commercial units handle hundreds of portions daily without missing a beat.

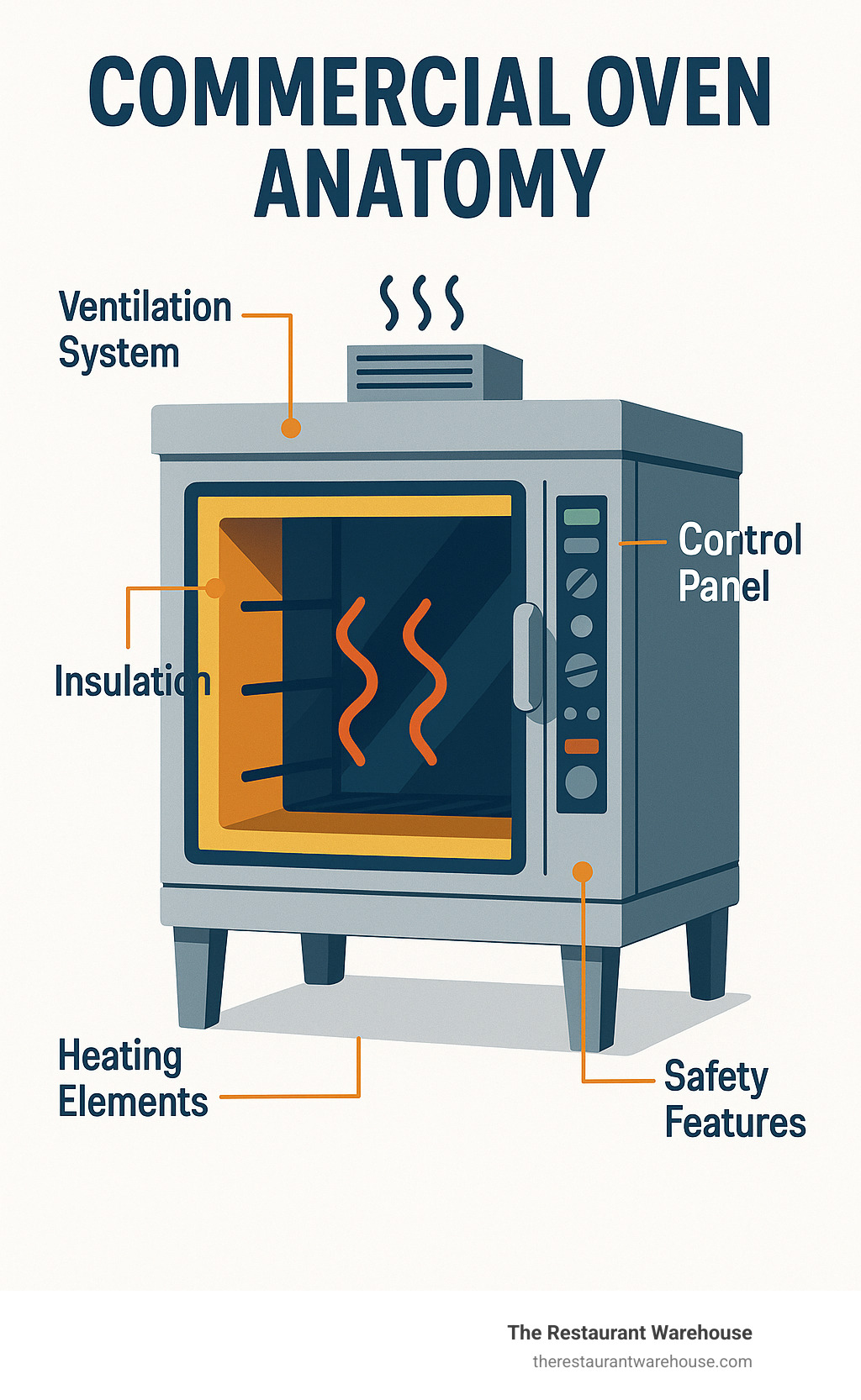

The key differences start with construction. Commercial ovens feature heavy-duty insulation that maintains consistent temperatures even when doors open frequently. Their heating elements deliver significantly more power - while home ovens typically max out around 5,000 BTU, commercial gas ovens commonly produce 50,000-60,000 BTU or more.

Ventilation requirements also differ dramatically. Commercial units generate substantial heat and moisture that must be properly exhausted through commercial hood systems. Many commercial electric ovens require 208V or 480V three-phase power unavailable in residential settings.

Durability separates commercial from residential equipment. Commercial ovens use stainless steel construction, reinforced door hinges, and components rated for continuous operation.

How commercial ovens outperform home models

Commercial ovens feature sophisticated heat recovery systems that maintain temperature stability even during heavy use. When you open a home oven door, it might take 10-15 minutes to recover temperature. Commercial units bounce back in 2-3 minutes.

Consistency is another major advantage. Commercial ovens maintain temperature within 5-10 degrees throughout the cooking chamber. This means your first batch bakes identically to your twentieth batch.

Throughput capabilities make commercial ovens essential for volume operations. A commercial convection oven might accommodate 12-18 full-size sheet pans compared to 2-3 in a home oven.

Key types of commercial ovens and their best uses

Convection ovens use fans to circulate hot air, creating even heat distribution and faster cooking times. They're versatile workhorses perfect for baking, roasting, and reheating.

Deck ovens feature stone or steel decks that provide intense bottom heat. They're the gold standard for artisan bread, pizza, and baked goods requiring crispy crusts.

Combi ovens combine steam and dry heat in one unit. They cook up to 50% faster than conventional ovens while maintaining moisture.

Conveyor ovens use moving belts to transport food through heated chambers. They're ideal for high-volume operations like pizza shops where speed and consistency matter.

Rack ovens accommodate rolling racks loaded with multiple sheet pans. They're popular in bakeries and large-volume operations.

Pizza ovens include wood-fired, gas, and electric models designed specifically for pizza production, reaching extremely high temperatures (800°F+).

Smoker ovens allow indoor smoking using wood chips or pellets, perfect for barbecue operations without outdoor space limitations.

More info about restaurant ovens

Fuel Choices: Gas vs. Electric Commercial Ovens

| Feature | Gas Commercial Ovens | Electric Commercial Ovens |

|---|---|---|

| Upfront Cost | Generally lower purchase price | Higher purchase price |

| Operating Cost | Lower fuel costs in most areas | Higher electricity costs |

| Heat Recovery | Faster temperature recovery | Slower temperature recovery |

| Installation | Requires gas line, more complex | Easier installation, needs proper electrical |

| Temperature Control | Good control, instant adjustment | Precise digital control |

| Maintenance | Gas line inspections, burner cleaning | Element replacement, electrical checks |

| Power Outages | Can operate during outages | Cannot operate without electricity |

| ENERGY STAR | Available on some models | More models qualify |

Choosing between gas and electric commercial ovens often comes down to your specific situation - what utilities are available, your local energy costs, and what type of cooking you're doing most.

Pros and cons of gas commercial ovens

Gas commercial ovens respond instantly when you need them to. Turn up the heat, and those burners roar to life immediately. There's no waiting around for elements to warm up, which gives you incredible control over your cooking process.

The BTU power of gas ovens is impressive. They can pump out serious heat fast and maintain those high temperatures without breaking a sweat. This makes them perfect for operations that need quick temperature changes or high-heat cooking like pizza or artisan bread.

Your wallet will probably thank you for choosing gas too. In most areas, natural gas costs significantly less per BTU than electricity. Over a year of heavy use, those savings really add up. Plus, when the power goes out, your gas oven keeps running.

But gas ovens aren't without challenges. Installation requirements are more complex since you need proper gas line sizing and upgraded ventilation systems. Ventilation needs are also more demanding with gas units, as they produce combustion byproducts requiring proper exhaust systems.

Pros and cons of electric commercial ovens

Electric commercial ovens are precision instruments. Their digital controls can hold temperatures within just a few degrees, making them fantastic for delicate baking where consistency is everything.

Installation is typically much simpler - you need the right electrical supply, but there's no gas line work or special ventilation beyond standard commercial requirements. Electric ovens also have longer element lifespan compared to gas burners that need more frequent cleaning.

More electric models qualify for ENERGY STAR certification, which can mean rebates and tax incentives. They also produce no direct emissions, making them suitable for locations with strict air quality requirements.

The main drawbacks are higher operating costs in most areas and slower response times. When you adjust temperature, electric elements take time to heat up or cool down. During power outages, electric ovens become completely useless.

Scientific research on energy-efficient commercial ovens

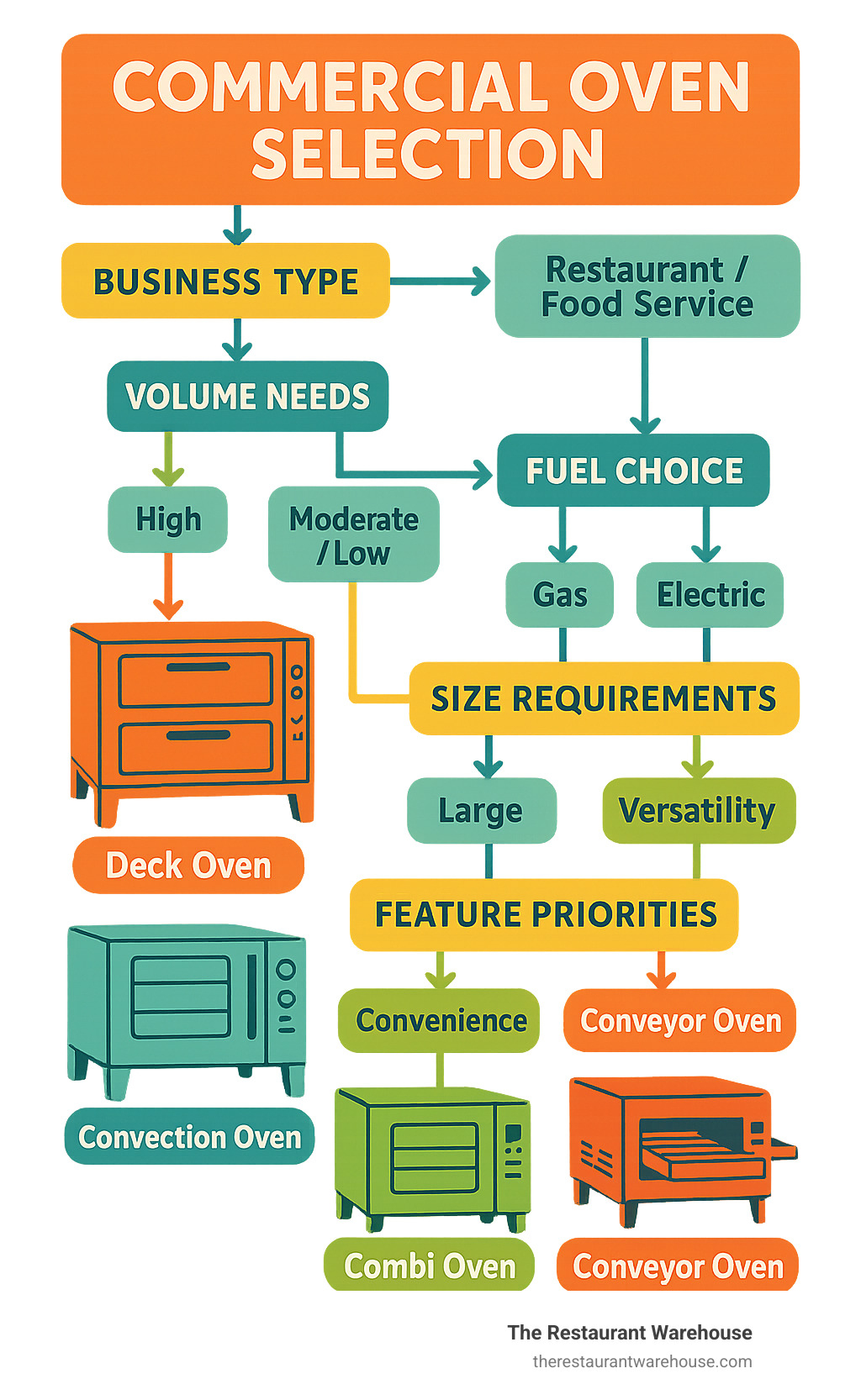

Matching the Right Commercial Oven to Your Concept

Your concept drives everything. A bakery needs the intense bottom heat of deck ovens to create perfect crusty artisan loaves. The stone decks conduct heat directly to bread bottoms, creating the oven spring and crust customers expect. Most successful bakeries pair deck ovens with convection units.

Restaurant kitchens typically thrive with versatile convection ovens. One well-chosen convection oven roasts proteins, bakes sides, reheats soup, and handles the constant variety a full menu demands. Combi ovens shine here too - they steam vegetables perfectly and keep proteins moist during busy service.

Pizzerias live or die by high heat. You need 600-800°F temperatures that only deck ovens with stone surfaces can deliver consistently. That intense heat creates the leopard-spotted crusts and perfectly melted cheese that separate great pizza from mediocre.

Catering operations face unique challenges - cooking large quantities while maintaining quality. Cook-and-hold ovens excel here, preparing proteins hours ahead while keeping everything at perfect serving temperature.

Food trucks need compact efficiency above all else. Space and power limitations usually mean countertop convection ovens or small deck units.

Here's the critical insight: size for your peak hour needs, not your average day. If Friday night requires 200 pizza slices but Tuesday afternoon only needs 50, your oven must handle that Friday rush.

Sizing and capacity planning for commercial ovens

Sheet pan capacity provides the easiest sizing metric. Count how many full-size 18" x 26" pans you need during your busiest hour. Standard convection ovens hold 5-6 pans, while larger models accommodate 10-12 pans.

Throughput calculations prevent expensive surprises. Need 100 hamburger buns per hour? If your oven bakes 24 buns in 12 minutes, you can produce 120 buns hourly - adequate capacity with a safety buffer.

Growth projections deserve consideration. Buying slightly larger capacity upfront often costs less than adding a second oven later. However, avoid massive overcapacity that wastes energy daily.

Feature checklist before you buy

Steam injection transforms ordinary ovens into professional baking powerhouses. Those first few minutes of steam create the glossy, crispy crusts that separate artisan breads from home-baked loaves.

Programmable menus eliminate guesswork and training headaches. Advanced models store up to 99 menu programs with precise time, temperature, and steam settings.

ENERGY STAR certification indicates 20-30% better efficiency than standard models. ENERGY STAR certified convection ovens save approximately $165 annually in gas costs or $660 in electric costs compared to standard units.

Warranty coverage varies dramatically between manufacturers. Comprehensive coverage on major components protects your investment better than basic parts warranties.

More info about Combined Oven features

Common mistakes to avoid with commercial ovens

Overcapacity burns money every single day. Oversized commercial ovens consume more energy heating unused space while costing more upfront. Size for realistic peak needs.

Wrong fuel choice creates ongoing operational headaches. Verify utility availability and costs before making fuel decisions.

Ignoring ventilation requirements causes expensive surprises during installation. Factor ventilation system costs into your total project budget from the beginning.

Focusing only on purchase price ignores total cost of ownership. Energy-efficient models cost more upfront but save substantial money over their 15-20 year lifespan.

Maintenance, Safety & Longevity

Commercial ovens are like high-performance cars - they'll run forever with proper care, but neglect them and you'll face expensive breakdowns at the worst possible moments.

Your daily routine should become second nature. After each shift, wipe down interior surfaces with gentle cleaners. That burnt cheese or bread crumb carbonizes over time and affects flavor. Clean door gaskets too - they're your first line of defense against heat loss.

Weekly deep cleaning separates the pros from amateurs. Pull out racks and trays for proper washing. Monthly maintenance catches problems before they catch you. Use an accurate thermometer to verify oven temperatures - commercial ovens should stay within 5-10 degrees of settings.

Quarterly professional inspections are worth every penny. Gas ovens need burners cleaned and combustion checked. Electric ovens require element inspection and electrical connection verification.

Routine care that extends commercial oven lifespan

Smart operators understand that commercial ovens reward consistency with decades of trouble-free service. The secret is staying ahead of problems instead of reacting to them.

Temperature probes are unsung heroes of consistent cooking. Test them monthly against certified thermometers and recalibrate when needed. A faulty probe might only be off by 25 degrees, but that's the difference between perfect bread and disappointing results.

Door seals deserve more attention than they usually get. These rubber gaskets prevent energy waste and temperature swings. Check them monthly for tears, hardening, or compression loss. Replace damaged seals immediately.

Service logs document cleaning dates, calibration results, and any issues. This information helps service technicians diagnose problems faster and might be required for warranty claims.

Operating safely with high-heat equipment

Commercial ovens demand respect. They operate at temperatures that can cause severe burns instantly, and proper safety procedures protect both your staff and business.

Personal protective equipment isn't optional. Heat-resistant gloves rated for oven temperatures are completely different from regular kitchen gloves. Safety glasses protect against sudden steam bursts.

Training your staff properly prevents most accidents. Everyone should understand where hot surfaces are located, how to open oven doors safely, and proper loading techniques.

Gas ovens require special attention to carbon monoxide safety. Install CO detectors in kitchen areas and ensure your ventilation system works properly.

More info about Commercial Kitchen Exhaust Hoods

Innovations & Future Trends in Commercial Ovens

The commercial oven world is getting exciting. New technologies are solving real problems that restaurant owners face every day - high energy bills, staffing challenges, and the quest for consistent food quality.

Dual fuel systems give you the best of both worlds. These clever machines combine traditional fuel sources with electric convection, cutting fuel use by 20% while keeping authentic flavor.

Touch screens are replacing old-school knobs and dials. These intuitive interfaces make staff lives easier. Modern commercial ovens can store hundreds of cooking programs and walk operators through complex procedures step by step.

The Internet of Things is showing up in commercial kitchens. Connected ovens can text you when something's wrong, alert you to temperature problems, or predict when maintenance is needed.

Energy recovery systems are turning waste heat into savings. These smart systems capture hot air that would normally disappear up the exhaust and use it to preheat incoming air or water. Some operations see 30-40% energy savings.

Rapid cook technology combines convection, microwave, and infrared heating to cook food incredibly fast without sacrificing quality. It's perfect for operations where speed matters.

Ventless technology is opening doors - literally. Advanced filtration systems clean exhaust air so thoroughly that some ovens don't need traditional hood systems.

Scaling up with industrial and tunnel commercial ovens

When your operation grows beyond what regular commercial ovens can handle, it's time to think bigger. Industrial and tunnel ovens are designed for businesses that need to produce massive quantities consistently.

Continuous bake systems work like a delicious assembly line. Products move through controlled temperature zones on conveyor belts, cooking perfectly without constant supervision. These systems can run 24/7, which is a game-changer for large bakeries.

Modular designs mean you don't have to replace everything when you grow. Many industrial oven systems use sections that snap together. Start with what you need now, then add sections as your business expands.

The numbers that matter for these big systems focus on throughput per labor hour and energy efficiency per unit produced. Yes, industrial ovens cost more initially, but they can dramatically lower your cost per item produced.

Frequently Asked Questions about Commercial Ovens

What is the typical lifespan and warranty for a commercial oven?

Most commercial ovens will serve your kitchen faithfully for 10-20 years when you take good care of them. Some well-maintained units keep going strong for 25+ years.

Your oven's lifespan depends on how hard you work it and how well you maintain it. A pizza shop running ovens 12+ hours daily will naturally see more wear than a bakery using theirs for 6 hours.

Most manufacturers offer 1-2 year warranties covering parts and labor, with longer protection on major components. Extended warranties for 3-5 years make sense for high-volume operations.

How do I finance or lease a commercial oven without straining cash flow?

Equipment financing lets you spread costs over 3-7 years while keeping working capital intact for daily operations and inventory. Many suppliers offer financing programs with competitive rates.

Lease options typically mean lower monthly payments, though you'll pay more over the life of the agreement. Consider your seasonal cash flow when structuring payments.

Don't forget to check for energy efficiency rebates and tax incentives. ENERGY STAR certified commercial ovens often qualify for utility rebates ranging from $20 to $5,000.

What shipping and installation steps should I prepare for large commercial ovens?

Start by measuring everything - doorways, hallways, stairwells, and elevator dimensions. You'd be surprised how many ovens arrive only to find they won't fit through the back door.

Get your utilities ready before delivery day. Commercial ovens often need 208V or 480V three-phase power that requires professional electrician work. Gas units need properly sized gas lines with shut-off valves.

Professional installation is usually required and often mandatory for warranty coverage. The installation team will walk you through basic operation and maintenance.

Coordinate with your ventilation contractor too. Your oven installation must align perfectly with exhaust hood placement and ductwork.

Conclusion

That perfect loaf emerging from a commercial oven represents everything we've discussed - consistency, quality, and the confidence that comes from choosing the right equipment for your operation.

Your oven decision will echo through your kitchen for the next 15-20 years. Get it right, and you'll have a reliable partner that cranks out consistent results day after day. Get it wrong, and you'll face daily frustrations with uneven baking, higher energy bills, and repair headaches.

The fundamentals we've covered aren't just technical details - they're the building blocks of your success. Understanding why commercial ovens outperform home models helps you appreciate the investment. Knowing whether gas or electric fits your operation saves money on both purchase and operating costs.

Those energy savings add up faster than most operators realize. An ENERGY STAR certified convection oven puts real money back in your pocket. We're talking about $165 annually for gas models or $660 for electric units compared to standard ovens. Over that 15-year lifespan, you're looking at thousands in savings.

The maintenance habits we discussed aren't busy work - they're insurance policies. Those daily wipe-downs and monthly calibrations can double your oven's lifespan.

At The Restaurant Warehouse, we see operators make these decisions every day. The smart ones don't just look at the sticker price - they calculate the total cost of ownership and choose equipment that makes sense for their specific operation. Our wholesale pricing model exists because we believe quality commercial ovens shouldn't be available only to operators with deep pockets.

We work directly with manufacturers to eliminate the markup layers that inflate equipment costs elsewhere. Our approach puts more money back in your operation where it belongs.

Your next step is putting this knowledge to work. Start with your menu and volume requirements, then work through fuel options, sizing, and features systematically. Don't rush the decision - test equipment when possible and talk to other operators with similar concepts.

The best oven is the one that matches your needs, fits your space, works within your budget, and delivers consistent results for years to come. Your customers might never see your oven, but they'll taste the difference it makes in every dish you serve.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment