Stainless Steel Workstation: A Buyer's Guide

You know you need a new prep table, but the options can feel overwhelming. Terms like "16-gauge," "Type 304," and "galvanized undershelf" can make choosing the right equipment a challenge. Making the wrong decision can lead to a workstation that doesn't fit your workflow or fails under pressure, wasting your time and money. This guide is here to demystify the process. We will explain these specifications in simple terms and show you how to evaluate your needs. By the end, you’ll know exactly how to select the perfect stainless steel workstation for your kitchen’s unique demands and budget.

Why Your Kitchen Needs a Stainless Steel Workstation

A stainless steel work station is the undisputed backbone of any professional kitchen. It serves as the central hub for a multitude of critical tasks, from the initial stages of food preparation and intricate assembly to final plating and temporary storage. The right workstation is not merely a piece of furniture; it is a strategic asset that directly impacts a kitchen's efficiency, safety, and overall workflow. In an environment where cleanliness and long-term performance are paramount, choosing stainless steel is a foundational decision for any serious food-related operation, including restaurants, catering businesses, bakeries, and institutional food service settings.

Top Reasons to Choose a Stainless Steel Work Station:

- Superior Hygiene: The hallmark of stainless steel is its non-porous surface. Unlike wood or certain plastics, it provides no microscopic crevices for bacteria, mold, or other pathogens to hide. This makes the sanitization process incredibly effective and straightforward, ensuring you can meet and exceed health code standards with confidence.

- Exceptional Durability: Built to withstand the rigors of a high-volume kitchen, stainless steel resists corrosion from acidic foods and harsh cleaning chemicals. It also stands up to heat from hot pans and the inevitable impacts of heavy pots and utensils, preventing the dents and dings that would compromise lesser materials.

- Easy Maintenance: The smooth, resilient surface is remarkably simple to clean and maintain. A daily regimen of wiping with mild soap and water, followed by proper sanitizing, is all it takes to keep the workstation in pristine condition, preserving its professional look and hygienic properties.

- Long-Term Value: While the initial investment may be higher than some alternatives, a quality stainless steel work station can last for decades. Its longevity and minimal need for repair or replacement translate into a lower total cost of ownership, making it one of the smartest financial decisions for your operation.

- Professional Appearance: A gleaming stainless steel surface conveys a sense of cleanliness, order, and professionalism. This clean, modern aesthetic is not only preferred by chefs but is also looked upon favorably by health inspectors, reinforcing the high standards of your establishment.

- Versatile Applications: The inherent strengths of stainless steel make it the ideal material for a wide range of settings beyond traditional restaurants. It is perfectly suited for catering operations, ghost kitchens, food trucks, school cafeterias, hospital food services, and any environment where food safety and durability are non-negotiable.

Modern stainless steel workstations are available in a vast array of configurations, from basic flat-top tables to highly specialized units featuring integrated shelving, drawers, and mobile casters. To select the perfect workstation for your specific needs and budget, it is crucial to understand the differences in material grades, thickness (gauge), and available features. This guide will walk you through everything you need to know to make an informed and confident purchase decision.

Improving Workflow and Preventing Cross-Contamination

In a professional kitchen, efficiency and safety are completely intertwined. A stainless steel workstation is essential for maintaining both, especially when it comes to preventing cross-contamination. The key is its non-porous surface, which leaves no microscopic hiding spots for bacteria, mold, or other pathogens. This feature makes sanitization incredibly effective, allowing your team to clean surfaces thoroughly and confidently meet health code standards. You can also designate specific zones for different tasks—like one for raw meat and another for fresh vegetables—to create a more organized kitchen, streamline operations, and drastically reduce the risk of foodborne illness. Because stainless steel resists corrosion from acidic foods and harsh cleaning chemicals, the work surface remains intact and hygienic, ready for service day after day.

Why Pros Choose Stainless Steel for Their Workspaces

Step into any high-functioning restaurant kitchen, and you will be surrounded by the gleam of stainless steel. From prep tables to wall shelves, its prevalence is no accident. This is a deliberate, strategic choice driven by the intense demands of professional food environments. When cleanliness, durability, and presentation are critical to success, a stainless steel work station is not just an option—it is an essential component. The material's unique combination of properties elevates it far above alternatives like wood, plastic, or laminate. Let's delve into the scientific and practical reasons why this material has become the undisputed gold standard for professional workspaces.

A Cleaner Surface for Safer Food Prep

In any foodservice operation, the primary concern is preventing the growth and spread of harmful bacteria that can lead to foodborne illness. This is where the material science of your work surface becomes critically important. Porous materials, most notably wood, contain microscopic pores and grain patterns. These tiny crevices can trap food particles, moisture, and germs, making complete sanitization a near-impossible task. Even with rigorous scrubbing, contaminants can remain embedded deep within the material. Similarly, plastic surfaces, while initially non-porous, quickly develop knife scars and scratches that become breeding grounds for bacteria.

Stainless steel completely eliminates this fundamental risk with its smooth, dense, and completely non-porous surface. There are simply no openings for food residues or microbes to penetrate. When you clean the surface, you are truly cleaning the entire surface, leaving no sanctuary for contaminants. This characteristic makes the sanitization process remarkably simple and effective. A quick wipe with a mild detergent, a rinse, and an application of an approved sanitizer is all that is required to achieve a level of cleanliness that satisfies the most stringent public health standards. This is precisely why health inspectors are reassured when they see well-maintained stainless steel surfaces throughout a kitchen. For any business serving the public, this is a cornerstone of protecting both your customers and your hard-earned reputation.

To ensure you are getting a product that meets these high standards, look for items with NSF Certification. This mark indicates that the product has been rigorously tested by an independent third party to meet strict public health and safety standards for use in food environments. These tests evaluate everything from material safety to the cleanability of the design. You can learn more about the importance of this certification at the NSF Certification explained page. The inherent hygienic properties of stainless steel make maintaining a sterile and safe environment an achievable daily goal, not an exhaustive chore.

Durability That Stands Up to Kitchen Chaos

Commercial kitchens are unforgiving environments. Heavy stock pots are dropped, acidic ingredients like lemon juice and vinegar are spilled, and surfaces are subjected to constant, aggressive scrubbing multiple times a day. Stainless steel is specifically engineered to withstand this relentless abuse. Its incredible durability stems from its alloy composition, which crucially includes chromium. When the surface of the steel is exposed to oxygen in the air, the chromium reacts to form a thin, invisible, and inert passive layer of chromium oxide. This layer acts as a powerful, continuous shield, protecting the underlying steel from rust, corrosion, and staining.

What makes this protective layer truly remarkable is that it is self-healing. If the surface is scratched or abraded, the newly exposed chromium immediately reacts with oxygen to instantly reform the protective shield. This means your stainless steel work station maintains its exceptional corrosion resistance throughout years of hard use, effortlessly handling constant exposure to moisture, acidic foods, and powerful cleaning chemicals without degrading. In high-traffic areas, stainless steel also boasts superior impact resistance that would permanently dent, crack, or gouge other materials.

This resilience translates directly into significant long-term savings. While the upfront cost of a high-quality stainless steel work station may be greater than some alternatives, its lifespan will outlast them many times over, eliminating the recurring costs and operational disruptions of replacement. It is a classic example of the wisdom in buying once and buying right. The long-term investment value becomes undeniable when you consider the minimal maintenance required. There is no need for refinishing, resealing, or recoating—it simply continues to perform, year after year. This makes it one of the most intelligent and cost-effective investments for your operation's future. See how these workhorses can transform your workspace by checking out how to Steel the Show in Your Kitchen with Commercial Stainless Steel Tables.

How to Choose the Right Stainless Steel Workstation

Selecting the ideal stainless steel work station is a critical decision that goes far beyond simply picking a shiny table. To ensure your choice enhances your kitchen's workflow and serves as a durable asset, you must carefully consider its material composition, dimensions, structural integrity, and features. Making an informed decision will not only improve your workspace but also boost productivity and safety. Think of it as choosing the perfect tool for a master craftsman—the workstation must be perfectly matched to the demands of your kitchen. Our comprehensive Stainless Tables Buyers Guide offers an excellent overview to help guide your decision-making process.

Decoding Steel Grade and Gauge

The true quality and suitability of a stainless steel work station are largely defined by two key specifications: its material grade and its gauge. These factors directly influence its durability, resistance to corrosion, and, consequently, its price. Understanding them is essential to avoid overpaying for features you don't need or, worse, under-investing in a table that will fail under pressure.

The most prevalent grades in the foodservice industry are Type 304 and Type 430. Type 304, often referred to as 18/8 stainless steel due to its 18% chromium and 8% nickel content, is the undisputed gold standard for most applications. The higher nickel content provides superior resistance to corrosion from acids, chlorides (salt), and moisture, making it the ideal choice for wet environments and any surface with direct food contact, especially when preparing acidic items like tomato sauces or citrus-based marinades. Type 430 is a more budget-friendly, nickel-free alternative. While still durable and corrosion-resistant, it is best suited for drier environments and general utility tasks, such as holding appliances or storing dry goods, where it won't face constant moisture or corrosive substances.

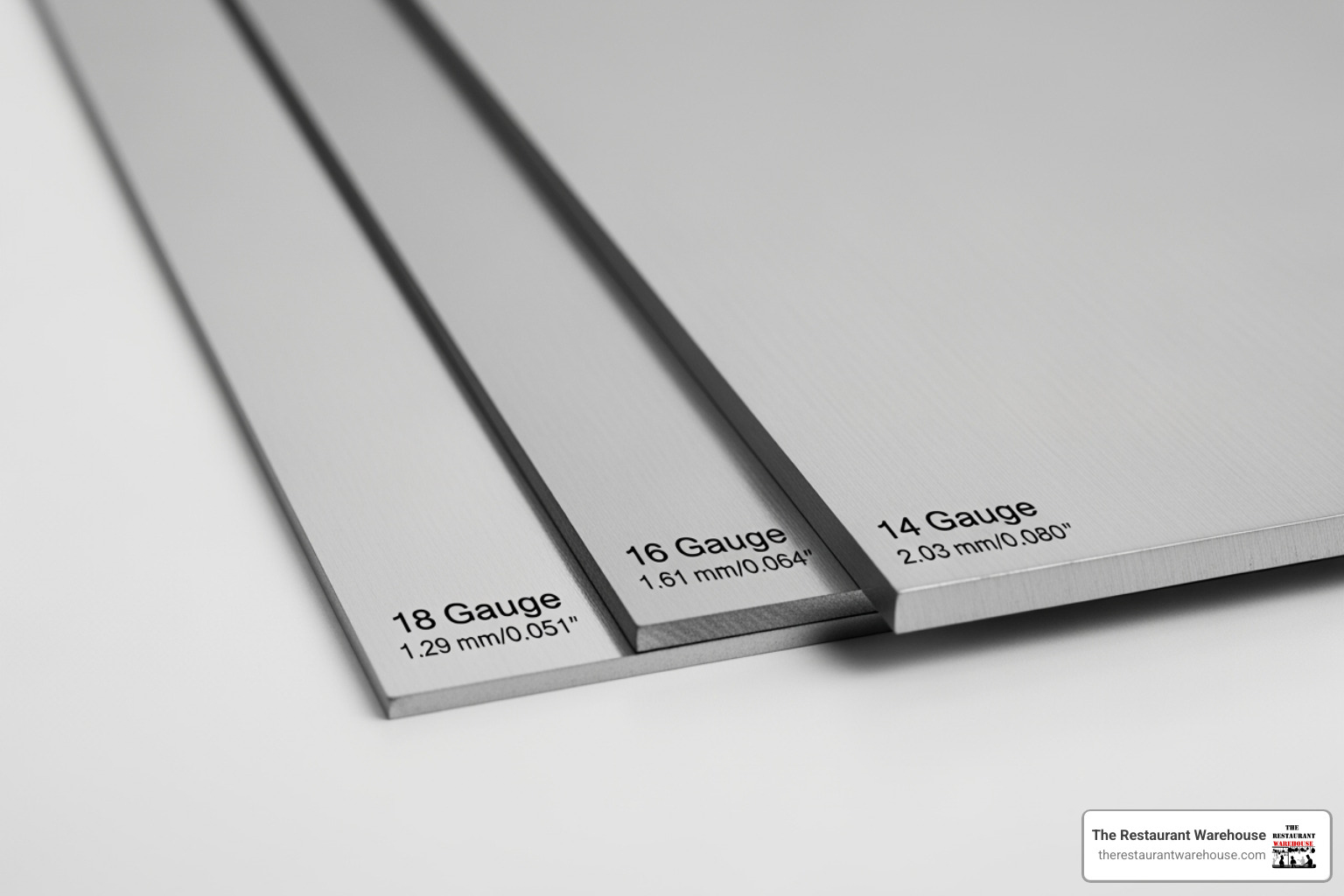

The "gauge" of the steel refers to its thickness, and it operates on an inverse scale—the lower the gauge number, the thicker and stronger the steel. 18-gauge is a common and economical choice, perfectly adequate for standard-duty applications like light prep work, salad assembly, or as a landing area. 16-gauge represents a significant step up in strength and durability, making it the preferred choice for most busy commercial uses that involve heavier items or more intensive work. 14-gauge is the heavy-duty champion, providing maximum durability and dent resistance for the most demanding environments, such as butcher shops or kitchens where heavy countertop appliances are used extensively. Choosing the right grade and gauge is a crucial balance between your operational needs and your budget. For more details, explore our Table with Stainless Steel Top Guide.

Understanding Stainless Steel Composition (18/10 vs. 316)

When you start looking at premium equipment, you’ll encounter grades like 18/10 and 316 stainless steel. These represent a higher tier of quality, and the difference lies in their specific alloy composition. The label "18/10 stainless steel" is a straightforward recipe: the alloy contains 18% chromium and 10% nickel. That high nickel content is key, as it gives the steel excellent resistance to rust and corrosion, making it a fantastic material for direct food contact. It’s durable, holds a brilliant finish, and stands up well to acidic ingredients. For most professional kitchens, a workstation made from 18/10 steel is a top-tier choice that provides exceptional performance and a lasting professional look.

Taking durability a step further is 316 stainless steel. While its chromium and nickel content is similar to 18/10, it includes a crucial addition: molybdenum. This element gives 316 steel superior protection against corrosion, particularly from chlorides (like salt and brine) and harsh chemicals. This makes it the ultimate choice for the most demanding environments. If your kitchen is in a coastal area with salty air, frequently works with brines and acidic marinades, or uses aggressive cleaning agents, 316 is the ideal material. While 18/10 is more than enough for most, 316 offers peace of mind in specialized, high-corrosion settings. You can explore the differences in these alloys to see how that small amount of molybdenum provides a significant advantage.

Matching Size and Strength to Your Needs

The physical attributes of your stainless steel work station are just as critical as its material composition. Before anything else, carefully measure your available space, ensuring you leave adequate clearance (typically 36-48 inches) for traffic flow and for opening the doors of nearby appliances. Standard workstation heights are typically around 34-36 inches, designed for comfortable standing work, but it's important to consider the ergonomic needs of your staff.

Value-added features can transform a simple table into a multifunctional productivity hub. Undershelves are a must-have, nearly doubling your storage capacity without consuming more floor space; they are perfect for holding mixing bowls, ingredient bins, or small appliances. A backsplash is another essential feature, preventing water, food particles, and utensils from falling behind the table, which simplifies cleanup and protects your walls. Integrated drawers provide organized, enclosed storage for essential tools like knives, whisks, and thermometers. For ultimate flexibility, a mobile stainless steel work station equipped with heavy-duty, locking casters can be easily repositioned for cleaning, reconfiguring your layout, or bringing the workspace to where it's needed most.

Finally, weight capacity is a crucial safety consideration that must not be overlooked. You must ensure your chosen workstation can safely support the total weight of everything you plan to place on it, including heavy countertop appliances, full stock pots, and bulk ingredients. This capacity is determined by the steel's gauge, the design and number of legs, and the overall construction. Always check the manufacturer's specified weight capacity to ensure it comfortably exceeds your requirements, guaranteeing both safety and longevity. For context on common sizes, our 72x30 Stainless Steel Table Guide can be a helpful resource.

Beyond Steel: Exploring Other Materials and Finishes

While stainless steel reigns supreme, understanding why other materials don't measure up in a professional kitchen is key to appreciating its value. The choice of material directly impacts food safety, durability, and the daily workflow of your staff. Let's look at some common alternatives and why they ultimately fall short of the industry standard.

Alternative Workstation Materials

Wood surfaces, while aesthetically pleasing in a home setting, present a serious hygiene challenge in a commercial kitchen. As a porous material, wood has microscopic pores and grain patterns that act like tiny traps for food particles, moisture, and bacteria. This makes complete sanitization nearly impossible and is a significant concern for health code compliance. Plastic or laminate workstations face a different but equally critical issue. Though non-porous when new, these softer surfaces are prone to damage. Every knife cut and scrape creates permanent scars that become breeding grounds for germs, compromising the integrity of your food prep area. In contrast, the smooth, dense, and non-porous surface of stainless steel eliminates this risk entirely, ensuring a truly clean and safe workspace.

A Look at Finishes and Colors

The gleaming, metallic finish of stainless steel is more than just an aesthetic choice; it’s a direct reflection of its functionality. A clean, polished surface conveys a sense of professionalism and order that is valued by chefs and health inspectors alike. You won't find stainless steel workstations in a variety of colors because any applied finish, like paint or a powder coat, would inevitably fail. The relentless abuse of a commercial kitchen—from scraping pans to harsh cleaning chemicals—would cause coatings to chip, peel, and scratch. These imperfections would create the same unsanitary crevices found in damaged plastic, trapping bacteria and compromising safety. The inherent durability of a stainless steel work table means its finish is the material itself, built to withstand the chaos without compromising its hygienic properties.

How Much Should You Spend?

Prices for a stainless steel work station can vary widely, influenced by a combination of the factors discussed above. The material grade, gauge, size, and any additional features all contribute to the final cost. A larger, 14-gauge, Type 304 table with drawers and casters will naturally be a more significant investment than a smaller, 18-gauge, Type 430 table with a basic undershelf. While it can be tempting to opt for the cheapest option available, it is vital to consider the long-term value. A higher-quality workstation is a durable, one-time purchase that will serve your business reliably for years, if not decades, making it a far wiser investment in the long run. At The Restaurant Warehouse, we are committed to providing exceptional value by offering affordable, wholesale pricing that cuts out the middleman, ensuring you get the highest quality for your budget. Explore our options in our Restaurant Prep Table Guide.

What to Expect in Terms of Price and Variety

When you start shopping for a stainless steel workstation, you'll quickly discover a huge variety of options. They range from simple, flat-top tables perfect for basic prep to highly specialized units designed with integrated undershelves for bulk storage, drawers for organizing essential tools, and even heavy-duty casters to make them mobile. This variety is a major advantage, as it allows you to find a workstation that fits your kitchen's specific workflow and physical layout perfectly. Whether you need a compact station for a small bakery, a long assembly line table for a high-volume restaurant, or a mobile unit for a catering business, there's a configuration out there that will feel like it was made just for you.

This variety in design also means a wide range in price. You can find basic tables for just over a hundred dollars, while larger, heavy-duty models with all the bells and whistles can cost over a thousand. The final price tag depends on the steel grade, its thickness, the overall size, and any extra features you choose. While it might be tempting to go for the lowest price, remember that a quality workstation is a one-time purchase that will serve your kitchen for years, maybe even decades. Investing in durability is always a smart move. If a larger upfront cost is a concern, looking into restaurant equipment financing can make it easier to get the high-quality table your team deserves without straining your budget.

Which Type of Stainless Steel Workstation is for You?

The remarkable versatility of the stainless steel work station is one of its greatest assets. Manufacturers have developed a wide range of configurations, each tailored to solve specific challenges and optimize different workflows within a food service environment. Whether you are outfitting a bustling restaurant, a dynamic catering business, a specialized bakery, or any other food-focused facility, there is a stainless steel solution designed to enhance your workspace while upholding the highest standards of hygiene and durability. Our Stainless Tables Guide is an excellent resource for exploring the full spectrum of available options and finding the perfect match for your operation.

Standard Work Tables: The Kitchen Staple

The standard flat-top table is the quintessential workhorse and the foundational building block of most professional kitchens. These tables provide a clean, expansive, and durable surface for an endless variety of tasks, from chopping vegetables and mixing dough to assembling dishes and plating for service. Most standard workstations are equipped with an undershelf—a simple yet invaluable feature that dramatically increases storage efficiency by keeping bulk ingredients, containers, and less-frequently used items off the main work surface but still within easy reach. These tables are available in a vast range of sizes, from compact 24-inch models perfect for tight spaces to massive 96-inch or even 120-inch tables that can serve as a central island for multiple chefs. Our Stainless Steel Kitchen Table guide dives deeper into these essential pieces of kitchen architecture.

Need More Flexibility? Try Mobile or Adjustable Tables

For modern kitchens that demand agility and flexibility, a mobile stainless steel work station is a true game-changer. Outfitted with heavy-duty, locking casters, these tables can be effortlessly moved wherever they are needed most. Use one to create an additional prep station during a dinner rush, roll it out of the way for thorough floor cleaning, or completely reconfigure your kitchen layout for a special event. Once in position, the casters lock firmly in place, providing a stable and secure work surface that is just as reliable as a stationary table.

Adjustable height workstations directly address the critical issue of kitchen ergonomics. Different tasks, from fine detail work to heavy chopping, are best performed at different heights. Furthermore, a diverse staff will have varying physical statures. An adjustable table allows each team member to set the work surface to their ideal height, reducing physical strain on the back, neck, and shoulders. This adaptability is a direct investment in your team's health and well-being, which pays dividends in reduced fatigue, higher morale, and greater long-term productivity.

Workstation Sinks: The All-in-One Prep Area

Beyond the standard prep table, the workstation sink represents a significant evolution in kitchen efficiency. This isn't just a basin for washing produce; it's a fully integrated prep station designed to consolidate multiple tasks into one compact, streamlined area. By building a system of ledges directly into the sink, manufacturers have created a multifunctional hub where you can chop, rinse, strain, and stage ingredients without ever leaving your spot. This design is a game-changer for kitchens where space is at a premium, as it effectively transforms your sink area into a productive workspace, freeing up valuable counter space for other essential restaurant equipment and minimizing the need to move between different stations. It’s a smart solution for keeping your workflow contained and your kitchen organized.

Key Features and Accessories

The magic of a workstation sink lies in its integrated ledge system. Many models feature a "Dual-Tier Ledge" design with two tracks that allow accessories to slide over the sink basin independently. This clever setup lets you customize your workspace on the fly. Imagine rinsing vegetables in a colander on the bottom track while you chop them on a cutting board positioned on the top track—all the mess is contained within the sink. Common accessories include solid hardwood cutting boards, stainless steel colanders, mixing bowls that fit into a platform, and roll-up drying racks. This transforms a simple sink into a dynamic area for every stage of food prep, keeping your main countertops clean and available for plating or other tasks.

Design and Construction Details

Just like a high-quality prep table, a workstation sink must be built to last. Look for models constructed from heavy-duty, 16-gauge T-304 stainless steel. This specific alloy contains chromium and nickel, giving it superior protection against rust and corrosion, which is essential for a wet environment. The commercial-grade brushed finish is not just for looks; it helps mask minor scratches and scuffs from daily use, maintaining a professional appearance over time. Smart design is also key. A well-designed workstation sink will have a gently sloped bottom, ensuring water and food debris flow directly toward the drain. This prevents pooling water, simplifies cleaning, and contributes to a more hygienic workspace.

Installation and Certification Considerations

Most workstation sinks are designed for an undermount installation, which creates a seamless transition from the countertop to the sink. This not only looks clean but also makes it incredibly easy to wipe crumbs and liquids directly into the basin without getting caught on a lip or rim. When purchasing, check that the sink includes the necessary mounting clips and a cutout template to ensure a proper fit. Most importantly, verify that the sink is cUPC certified. This mark indicates that the product complies with both U.S. and Canadian plumbing standards, a critical requirement for passing health inspections and guaranteeing the product's safety and reliability. It’s a non-negotiable feature for any professional foodservice establishment.

When You Need a Custom Solution

Sometimes, an off-the-shelf product doesn't perfectly align with your unique operational needs or physical space. This is where specialized and custom-built workstations provide tailored solutions. Custom fabrication opens up a world of possibilities, allowing you to design a table with integrated sinks for seamless prep and washing, unique dimensions to fit into an awkward alcove, or precise cutouts for drop-in food warmers or cold wells. You can also add built-in shelving, pot racks, or ticket holders configured to your exact specifications, transforming previously wasted space into a highly functional and efficient work zone. A custom solution ensures that every square inch of your kitchen is optimized for your specific workflow, delivering a level of efficiency that standard options simply cannot match. To learn more about shelving options that can complement your workstation, see our Stainless Steel Kitchen Shelves Guide.

Ready to explore custom options that perfectly fit your space and workflow? Contact us today to discuss your specific requirements and find out how a custom-built workstation can transform your operation.

Wood Top Tables for Bakeries

While stainless steel reigns supreme in most kitchen areas, there's a notable exception where another material shines: the bakery. For any operation that involves serious dough work, a wood top table, often called a baker's table, is an invaluable asset. The natural wood surface is ideal for kneading, rolling, and shaping dough because it's less prone to sticking and helps maintain a consistent, cool temperature. Many of these specialized tables come with practical features designed for bakers, such as raised sides to contain flour and prevent spills, or built-in ingredient drawers for easy access to essentials. This makes the entire baking process more efficient and organized, turning a simple surface into a dedicated pastry station. When you shop restaurant equipment, considering these task-specific solutions can make a huge difference in your daily workflow.

Enclosed Base Tables for Secure Storage

Moving beyond the standard open undershelf, an enclosed base workstation offers a significant upgrade in both organization and security. These tables feature cabinet-style doors that conceal the storage area, creating a clean, streamlined appearance in your kitchen. More importantly, this enclosed space protects valuable items from the inevitable dust, splashes, and grease of a busy kitchen environment. It’s the perfect spot to store sensitive small appliances, expensive bulk ingredients, or clean linens, keeping them secure and sanitary until they are needed. By providing a protected and organized storage solution right at the point of use, these tables help reduce clutter on your main work surface and contribute to a safer, more efficient kitchen layout.

Specialized Features for Unique Needs

The right features can transform a basic table into a multifunctional productivity hub tailored to your exact needs. A backsplash is one of the most practical additions, acting as a simple barrier that prevents food, water, and utensils from falling into the hard-to-clean gap between the table and the wall. This not only protects your walls from damage and stains but also makes daily cleanup much faster. Integrated drawers are another game-changer, providing organized, enclosed storage for essential tools like knives, whisks, and thermometers. Having these items neatly stored and within arm's reach eliminates wasted time searching for tools and keeps your primary work surface clear. Investing in these features doesn't have to strain your budget, especially when you explore options like restaurant equipment financing to get the perfect setup for your kitchen.

How to Keep Your Stainless Steel Looking New

One of the most celebrated attributes of a stainless steel work station is its remarkable ease of maintenance. However, "easy" should never be mistaken for "no care required." A consistent and proper cleaning regimen is absolutely essential, not only for upholding critical hygiene standards but also for preserving the professional, polished appearance and maximizing the lifespan of your valuable investment. Unlike porous wood tables that can absorb liquids and become a permanent haven for bacteria, stainless steel is incredibly forgiving and resistant to contamination. That said, it still requires a disciplined approach to cleaning to prevent the buildup of water spots, fingerprints, and stubborn stains that can mar its finish over time.

Think of this maintenance not as a chore, but as a crucial practice for protecting your asset. A well-cared-for stainless steel work station will serve your operation reliably for decades, maintaining both its flawless functionality and its impressive shine. The best part is that the entire process is straightforward and does not require expensive, specialized products or extensive training. It's all about consistency and using the right techniques.

Your Simple Daily Cleaning Routine

For day-to-day upkeep, keeping your stainless steel work station in top condition is simple. The key to success lies in consistency and gentle techniques rather than infrequent, aggressive scrubbing. A quick daily routine is all it takes to keep your workstation looking pristine and performing at its best.

- Clear and Scrape: Begin by clearing the surface of all tools, containers, and loose food debris. Use a plastic or rubber scraper to remove any stuck-on particles.

- Wash with Mild Soap: Prepare a cleaning solution of warm water mixed with a gentle, pH-neutral dish soap or detergent. Avoid harsh, abrasive cleaners or anything containing chlorine, as these can damage the steel's protective layer. Apply the solution with a soft cloth, microfiber towel, or non-abrasive sponge.

- Wipe with the Grain: This is a critical technique. Look closely at the surface of the steel and you will see very fine lines—this is the "grain." Always wipe and scrub parallel to these lines. Wiping against the grain can create micro-scratches and cause streaks, diminishing the polished look.

- Rinse Thoroughly: After washing, rinse the surface completely with clean, warm water to remove all soap residue. Any soap left behind can dry into a film, creating streaks and attracting dirt.

- Dry Immediately: This is the secret to a spot-free finish. Use a clean, dry microfiber cloth or paper towels to dry the workstation completely. This simple step prevents water spots and mineral deposits from forming as the water evaporates.

- Sanitize: In any food service environment, the final step is sanitizing. Apply an approved food-safe sanitizing solution according to the manufacturer's instructions, paying attention to the required contact time. Allow the surface to air dry or wipe with a clean cloth as directed.

This daily ritual ensures your stainless steel work station remains hygienic, gleaming, and ready for the demands of your busy operation.

Removing Stains and Minimizing Scratches

While stainless steel is incredibly resilient, it is not entirely immune to tough stains or minor scratches. Don't panic—with the right approach, you can address most of these cosmetic issues and keep your stainless steel work station looking its best for years to come.

For tough, stuck-on stains like grease, coffee rings, or burnt-on food residue, a simple paste made from baking soda and water is a powerful yet gentle solution. Apply the paste to the stain, let it sit for 15-20 minutes, and then gently scrub in the direction of the grain with a soft cloth or nylon scrubber. For more persistent discoloration or hard water spots, a solution of equal parts white vinegar and water can be effective. Apply it, let it sit briefly, then rinse and dry thoroughly.

Fingerprints are a common annoyance, especially on high-polish surfaces. The easiest way to remove them is with a glass cleaner or a dedicated stainless steel cleaner applied to a microfiber cloth. Wiping with the grain will quickly restore the uniform shine.

When it comes to minor scratch repair, it's important to set realistic expectations. Very light surface scuffs can often be buffed out using a non-abrasive cleaner and a microfiber cloth. For slightly more noticeable scratches, specialized stainless steel scratch repair kits are available. These kits typically include fine-grit abrasive pads and a blending lubricant to help you essentially re-grain the surface in the affected area. This process requires patience and a gentle touch. Deep gouges, however, are very difficult to remove completely without professional refinishing. The best strategy is always prevention: consistently use cutting boards and avoid dragging heavy or rough-bottomed items across the surface.

What should you absolutely avoid? Never use steel wool, abrasive scouring pads, or any cleaners containing chlorine (like bleach). Steel wool can break apart and leave tiny iron particles embedded in the surface, which will then rust and create stubborn brown stains. Chlorine-based cleaners can chemically attack the passive layer of the steel, leading to pitting and permanent discoloration. Protecting the finish of your workstation or your Stainless Steel Kitchen Tools through regular, gentle maintenance is the key to ensuring it remains a valuable, attractive, and long-lasting asset for your operation.

Frequently Asked Questions about Stainless Steel Workstations

When you are investing in foundational pieces for your professional kitchen, it's natural to have questions. Over my years at The Restaurant Warehouse, I've helped countless operators navigate their choices, and I've heard just about every question imaginable regarding stainless steel work station options. To help you move forward with confidence, I've compiled answers to the most common inquiries.

What's the Best Grade of Stainless Steel for a Workstation?

The "best" grade is entirely dependent on your specific application and budget. For the vast majority of foodservice operations, Type 304 stainless steel is the highly recommended choice. Its significant nickel content provides superior corrosion resistance, making it the ideal material for wet environments, frequent cleaning, and direct contact with all types of food, including acidic ones. If you are working with a tighter budget or the workstation will be used primarily in a dry area for storage or holding appliances, Type 430 stainless steel is a very durable and economical alternative. It's a solid, reliable choice for general utility work where extreme corrosion resistance isn't the top priority. Contact our team, and we can help you analyze your needs to choose the perfect grade.

How Much Weight Can a Stainless Steel Workstation Hold?

Weight capacity is not a one-size-fits-all number; it varies significantly based on the table's construction. Key factors include the gauge (thickness) of the steel top and undershelf, the diameter and material of the legs, and the overall engineering and bracing of the unit. Standard commercial worktables are typically rated to hold between 500 and 700 pounds of uniformly distributed weight, which is more than sufficient for most prep work and countertop appliances. However, for heavy-duty applications—such as supporting very heavy appliances or large quantities of dense ingredients—reinforced models with higher weight capacities are available. Always check the manufacturer's specifications to ensure the model you choose can safely support your intended load. Proper selection is a key part of maintaining a safe kitchen, a principle emphasized by food safety authorities like the USDA Food Safety and Inspection Service.

Can You Cut Directly on a Stainless Steel Surface?

No, you should never cut directly on a stainless steel work station. This practice is detrimental for two reasons: it will very quickly dull your expensive knives, and it will inevitably scratch the tabletop. While stainless steel is self-healing in terms of corrosion, deep scratches can mar the finish and create tiny grooves that, while still cleanable, can be more difficult to sanitize perfectly. Always use a dedicated cutting board made of wood or plastic to protect both your knife edges and your work surface. This simple habit is essential for keeping your blades sharp and your workstation in pristine condition for years to come. Browse our selection of prep tables designed to work seamlessly with all your other essential kitchen tools.

What's the Difference Between a Stainless Steel and Galvanized Undershelf?

This is a great question that gets to the heart of balancing cost and function. A stainless steel undershelf is made from the same high-quality material as the tabletop, offering excellent corrosion resistance. It is the best choice if you plan to store food items, wet pots and pans, or anything that might spill. A galvanized steel undershelf is made of carbon steel that has been coated with a layer of zinc for corrosion protection. It is a more cost-effective option but is not as resistant to rust and corrosion as stainless steel, especially if the zinc coating gets scratched. Therefore, galvanized undershelves are best suited for storing dry goods, packaged items, or equipment in a dry environment.

Should You Get Casters (Wheels) for Your Workstation?

Casters can be an excellent addition, but it depends on your kitchen's needs. The primary benefit is mobility. If you have a dynamic kitchen that requires frequent layout changes, or if you prioritize the ability to easily move the table for deep cleaning, then casters are invaluable. The main considerations are stability and weight capacity. Always choose workstations with heavy-duty, locking casters to ensure the table is completely stable when in use. Be aware that adding casters can sometimes slightly reduce the overall weight capacity of the table compared to stationary legs, so be sure to check the specifications if you plan to support very heavy loads.

Your Foundation for a Better Kitchen

Choosing the right stainless steel work station is more than just a purchase; it is a strategic investment in your operation's core efficiency, its commitment to hygiene, and its long-term success. As we have explored, stainless steel stands as the superior material for professional workspaces, primarily due to its non-porous surface that guarantees cleanability, its exceptional durability that withstands the toughest kitchen environments, and its clean, professional appearance that signals quality to both staff and inspectors.

By carefully considering the key factors—such as material grade (Type 304 vs. 430), gauge thickness, and essential features like undershelves, backsplashes, or casters—you can select a workstation that is perfectly tailored to your unique workflow and spatial constraints. Whether your operation calls for a standard prep table, a flexible mobile unit for a dynamic space, or a fully custom-built solution to maximize efficiency, there is a stainless steel option that will work as hard as you do. And with a simple, consistent daily care routine, your investment will continue to perform and shine for decades to come.

At The Restaurant Warehouse, we are dedicated to the success of foodservice professionals. We understand the pressures of running a kitchen and the importance of reliable, high-performing tools. That is why we provide a wide selection of high-quality stainless steel workstations at true wholesale prices. By eliminating the high commissions and retail overhead that inflate costs elsewhere, our mission is to equip your business with durable, dependable, and affordable solutions that empower you to thrive.

A quality stainless steel work station is not an expense; it is an asset that pays daily dividends in time saved, simplified cleaning, and the assurance of safer food handling.

Ready to upgrade your workspace and build a stronger foundation for your kitchen? Explore our complete collection of stainless steel tables and prep stations today! Let our team help you find the perfect fit for your operation and get you set up with a workstation that will serve you well for many years to come.

Key Takeaways

- Prioritize Hygiene and Durability: Choose stainless steel for its non-porous surface, which prevents bacteria buildup and makes sanitizing simple. It’s a smart, long-term investment that resists rust, stains, and the general chaos of a professional kitchen.

- Select the Right Grade and Gauge: Match the table to your tasks. Opt for Type 304 steel for any surface with direct food contact, and select a thicker gauge (16 or 14) for heavy-duty prep work or supporting weighty equipment.

- Protect Your Investment with Proper Care: Keep your workstation looking new with a simple daily routine. Always wipe in the direction of the steel's grain and, most importantly, dry the surface completely after cleaning to prevent water spots and maintain its professional shine.

Related Articles

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment