Bake It Till You Make It – Your Guide to Commercial Bakery Ovens

Why Commercial Bakery Ovens Are the Heart of Your Business

Bakery ovens commercial equipment represents the most critical investment for any successful baking operation. Whether you're opening a small neighborhood bakery or scaling up an existing restaurant's bread program, choosing the right oven determines everything from product quality to production capacity.

Quick Guide to Commercial Bakery Ovens:

- Convection Ovens - Best for cookies, pastries, and versatile baking ($2,000-$10,000)

- Deck Ovens - Ideal for artisan breads and pizza with crispy crusts ($5,000-$30,000+)

- Rack Ovens - Perfect for high-volume production of rolls and breads ($10,000-$50,000+)

- Key Features - Steam injection, programmable controls, independent deck temperatures

- Capacity Planning - Consider 2-4 deck options based on batch size and production needs

The oven truly is the heart of any bakery, as one industry expert puts it. It's where your creative vision transforms into golden-brown reality. But with so many options - from traditional deck ovens used by craft bakeries for over 80 years to modern rotating rack systems that can store up to 99 menu presets - the choice can feel overwhelming.

For budget-conscious operators, understanding the differences between oven types helps you invest wisely. A $2,000 convection oven might serve a coffee shop perfectly, while a busy production bakery needs the $30,000+ deck oven investment for consistent artisan results.

The good news? Modern commercial ovens are built for durability and efficiency. Leading manufacturers like Polin have been perfecting their designs for more than three generations, while companies like BRESSO offer 2-year warranties with 100% product inspection before delivery.

Bakery ovens commercial glossary:

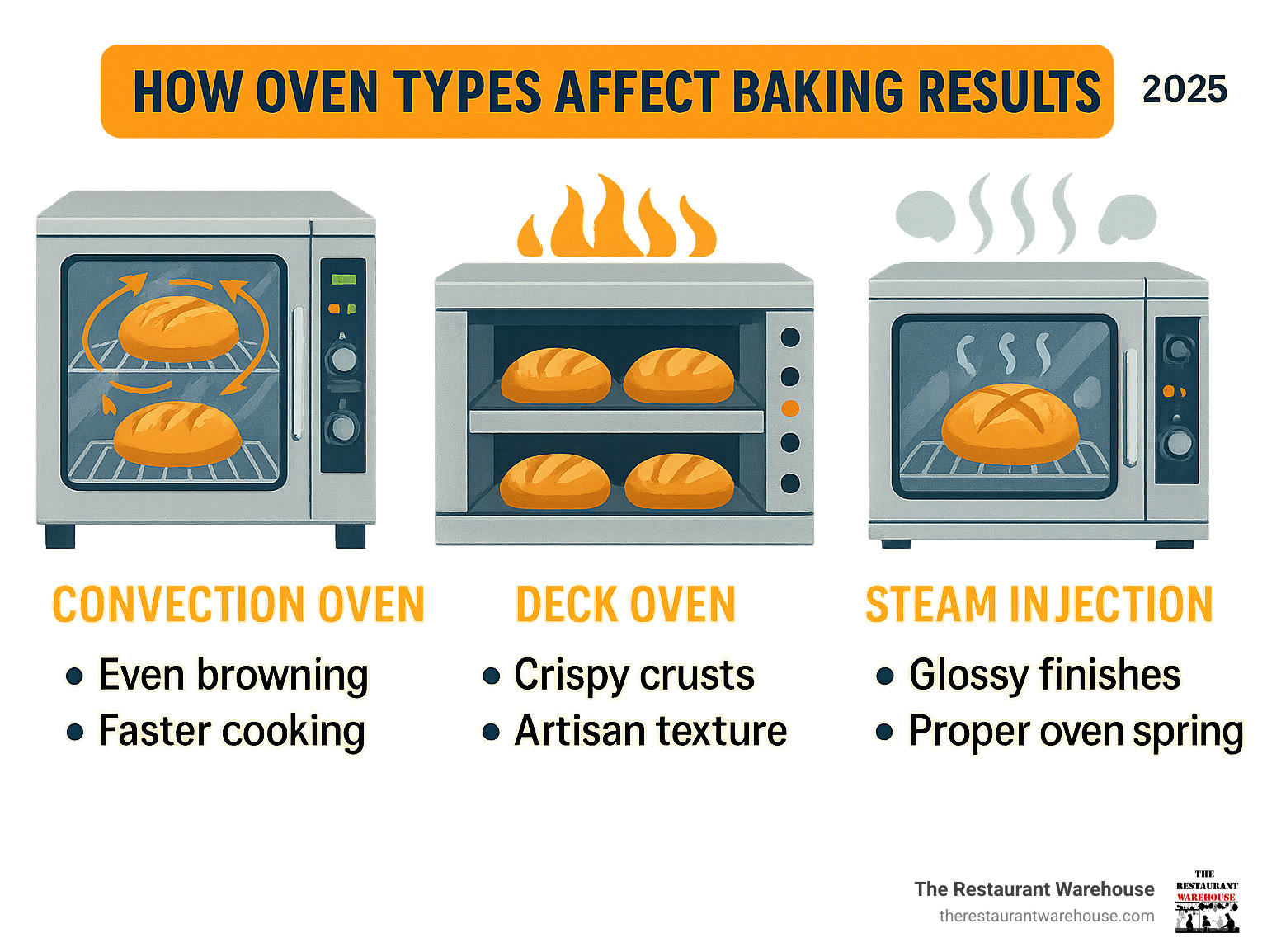

The Main Types of Commercial Bakery Ovens

Understanding the three main categories of bakery ovens commercial equipment helps you make an informed decision based on your specific needs. Each type offers distinct advantages in heat distribution, baking results, and production volume capabilities. Let's explore how these differences can impact your bakery's success with our Practical Guide To Comparing Commercial Oven Options.

Convection Ovens: The Versatile Workhorse

Convection ovens use powerful fans to circulate hot air, creating even heat distribution and faster cooking times. This fan-circulated air system makes them incredibly versatile for a wide range of baked goods, from delicate pastries to hearty muffins.

Why Commercial Bakeries Love Convection Ovens:

- Even heat distribution eliminates hot spots

- Faster cooking times boost productivity

- Energy efficient operation keeps costs down

- Perfect for cookies, muffins, and small-batch pastries

- Most energy-efficient choice among oven types

Pricing and Value: Commercial convection ovens typically range from $2,000 to $10,000, making them the most affordable entry point for many bakeries. This price range covers everything from countertop models perfect for coffee shops to full-size units capable of handling restaurant-level production.

Best Applications: Convection ovens excel at baking cookies, muffins, delicate pastries, and any items that benefit from uniform browning. However, they're not always ideal for souffles and custards, as the circulating air can dry them out or cause uneven rising.

Many commercial bakeries rely on convection ovens for their superior performance and consistent results. The versatility makes them perfect for operations that need to bake various products throughout the day. Learn more in our comprehensive Convection Ovens Guide.

Deck Ovens: The Artisan's Choice

Deck ovens are the gold standard for artisan baking, featuring stone or ceramic baking surfaces that provide intense radiant heat. These ovens create the perfect environment for developing crispy crusts while maintaining moist interiors - exactly what you need for exceptional bread and pizza.

The Deck Oven Advantage:

- Stone or ceramic decks provide superior heat retention

- Radiant heat creates crispy crusts with perfect texture

- Independent deck controls allow different temperatures simultaneously

- Ideal for artisan bread, baguettes, and pizza

- Professional-grade construction for durability

Investment Considerations: Deck ovens represent a significant investment, typically ranging from $5,000 to $30,000 or more, depending on size and features. However, this investment pays dividends in product quality and customer satisfaction. Many classic bakeries and restaurants choose deck ovens specifically for their ability to produce restaurant-quality baguettes, pizzas, and artisan breads.

Construction Features: Traditional brick bakery ovens feature 4-inch thick floor insulation and all-natural refractory clay brick floor tiles measuring 13 x 13 x 2.25 inches thick. These materials ensure perfect heat distribution and exceptional durability.

Production Flexibility: Available with two, three, and four decks, these ovens allow you to calculate the exact capacity needed based on your batch size and production logistics. Electric deck ovens offer the advantage of independent temperature control for each deck, while gas models typically operate all decks at the same temperature.

Find the perfect deck oven for your operation in our guide: Deck The Halls And Your Bakery With These Commercial Deck Ovens.

Rack Ovens: For High-Volume Production

Rack ovens are the workhorses of high-volume commercial baking, designed to handle large batches with consistent results. These ovens feature rotating racks that ensure even baking without the need to manually rotate pans, making them perfect for busy production environments.

High-Volume Benefits:

- Rotating racks ensure uniform baking results

- High capacity handles large production runs

- Consistent temperature throughout the chamber

- Perfect for rolls, bread loaves, and pastries

- Often feature steam injection for professional results

Investment and ROI: Rack ovens are often the most expensive option, ranging from $10,000 to $50,000+ for models with advanced features like steam injection. However, for high-volume operations, the efficiency and consistency they provide make them invaluable investments.

Advanced Features: Modern rotating rack ovens can store up to 99 menu presets for consistent results across different products. Some models feature sophisticated systems like the Doyon Jet Air System, where air moves in one direction for 2.5 minutes, pauses for 20 seconds, then reverses direction for another 2.5 minutes, ensuring perfectly even baking.

Ideal Applications: Rack ovens excel at producing pan bread, rolls, smaller bread loaves, pies, cookies, and pastries. They're particularly valuable for catering operations, commercial bakeries, and food production facilities that need to time multiple batches perfectly.

Learn more about industrial-scale solutions in our Industrial Ovens For Baking Your Recipe For Bakery Success guide.

Combination and Specialty Ovens

For bakeries with limited space or specific needs, combination ovens offer innovative solutions. Combi ovens combine steam and convection cooking in one unit, cooking up to 50% faster than traditional convection ovens while maintaining food's essential moisture.

Combination Oven Benefits:

- Steam, hot air, or combination modes

- Space-saving design for smaller operations

- Dual functionality reduces equipment needs

- Perfect for operations with diverse menus

Proofer Combinations: Oven/proofer combinations maximize efficiency by combining baking and proofing functions in one unit. These are particularly valuable for bakeries that regularly proof dough, providing consistent results while saving valuable floor space.

Specialty Applications: Some operations benefit from unique solutions like the Doyon Dual Fuel Gravity Charcoal Oven, which generates 60% of its heat from charcoal and 40% from electric elements, reducing charcoal consumption by 20% while providing authentic flavor profiles.

Explore space-efficient options in our Little Ovens That Could Commercial Oven Picks For Small Spaces guide.

How to Choose the Right Commercial Bakery Ovens for Your Business

Choosing the perfect bakery ovens commercial equipment can feel overwhelming, but focusing on four core factors—capacity, layout, energy, and features—turns the process into a simple checklist. Start with where you want your bakery to be in five years, then pick the oven that will get you there. For a full planning road-map, download our Open A Bakery Guide.

Capacity, Size, and Kitchen Layout

Picture your busiest day, then double it. That’s the production level your oven should comfortably handle. Remember to leave clear lanes for loading, unloading, and maintenance—an oven you can’t reach is an oven you can’t service.

Quick capacity guide:

- Two decks: niche menu or small café.

- Three decks: growing bakery needing flexibility.

- Four decks: high-volume operation running staggered batches.

Single or double stacking squeezes more production into expensive urban square footage, but confirm ceiling height and ventilation before ordering. Many modular deck ovens disassemble to pass through a 36-inch door; verify this early to avoid costly surprises. More layout tips are in our Commercial Bakery Equipment Guide.

Energy Efficiency and Fuel Type

Utility costs outlive your purchase price, so compare local gas and electric rates before you buy. Gas ovens heat fast and hold heat well, while electric ovens offer pinpoint temperature control and may be your only option in jurisdictions phasing out gas lines.

Look for thick insulation, programmable idle modes, and high-efficiency burners or elements. For additional savings, review the U.S. ENERGY STAR® program to see if rebates apply in your area. Better insulation and smart controls quickly offset a slightly higher upfront cost.

Advanced Features in Modern Commercial Bakery Ovens

Modern ovens let small teams bake like pros:

- Programmable controls storing up to 99 recipes

- Built-in steam injection for artisan crusts

- Bi-directional fans that banish hot spots

- Independent deck thermostats on electric models

- Touch-screen timers and audible alarms

These tools aren’t just “nice to have”—they protect consistency when staff changes or rush periods hit. Learn how steam in particular boosts quality in our guide: Learn why steam is key for bakeries.

How Your Oven Choice Impacts Baked Goods

The type of oven you choose directly affects the quality, consistency, texture, and appearance of your baked goods. Understanding these impacts helps you select equipment that produces the results your customers expect and love.

The Role of Heat: Convection vs. Radiant

Think of your oven as an artist's brush - different heating methods paint distinctly different results on your baked goods. The way heat moves through your oven chamber determines everything from crust color to interior texture.

Convection heat works like a gentle whirlwind, using powerful fans to circulate hot air throughout the chamber. This creates even browning across all surfaces and faster cooking times that boost your productivity. The constant air movement prevents those frustrating hot spots that can turn half your cookie batch golden while leaving the other half pale.

However, this same circulating air that makes convection ovens perfect for cookies can be too aggressive for delicate items like souffles and custards. The moving air can dry them out or cause uneven rising, which is why many bakers prefer gentler heat for these specialty items.

Radiant heat from deck ovens tells a completely different story. The stone or ceramic surfaces store and release heat gradually, creating that perfect crust development you see in artisan bakeries. This thermal mass maintains consistent temperature even when you're loading cold dough, giving you that authentic "brick oven" taste and appearance.

The gentle, intense heat from deck surfaces creates crispy, golden-brown crusts while keeping interiors moist and perfectly textured. This is why serious bread bakers swear by deck ovens for achieving superior oven spring - that magical moment when bread expands in the heat before the crust sets.

The Magic of Steam Injection

Steam injection might seem like a simple feature, but it's actually one of the most important advances in bakery ovens commercial technology. Understanding how steam transforms your products helps you choose equipment that delivers professional results.

When steam hits your dough, it creates the perfect environment for crust formation. The moisture delays crust development initially, allowing maximum expansion before the surface hardens. This process gives you that glossy finish and improved volume that makes artisan breads look so appealing.

Steam injection benefits extend far beyond appearance. For artisan breads and baguettes, steam improves the crumb structure and extends shelf life through better moisture retention. The controlled humidity prevents dryness while creating that professional look customers expect from high-quality bakeries.

Modern steam systems offer precise control over moisture levels, with some featuring independent steam settings for each deck. This means you can customize the humidity for different products - perfect steam for your sourdough while baking cookies without steam on another deck.

The timing matters too. Steam burst control allows you to add moisture at exactly the right moment, creating that perfect balance between oven spring and crust development. This precision is what separates professional bakeries from home kitchens.

For detailed information about steam's role in baking, Download our white paper to learn why steam is key to cooking. Download Here.

Maintenance and Cleaning for Longevity

Taking care of your bakery ovens commercial equipment isn't just about keeping things looking nice - it's about protecting your investment and ensuring consistent results day after day. Think of maintenance like caring for a reliable friend who works hard for you every single day.

Proper maintenance ensures your ovens deliver optimal performance while extending their lifespan significantly. More importantly, it maintains the food safety standards your customers depend on and prevents those heart-stopping moments when equipment breaks down during your busiest hours.

Following manufacturer guidelines and establishing consistent cleaning routines protects your investment while ensuring the consistent baking results that keep customers coming back. Nobody wants to explain to a customer why their favorite croissant tastes different today! Learn more about comprehensive equipment care in our Commercial Kitchen Equipment Guide.

Daily Cleaning Procedures

The secret to long-lasting oven performance lies in simple daily habits that become second nature. These routines keep your ovens operating at peak performance while maintaining the food safety standards that protect both your customers and your business reputation.

Start with the basics every day. Wipe down both interior and exterior surfaces with appropriate cleaners, paying special attention to areas where flour and grease tend to accumulate. Clean those door gaskets carefully and check for signs of wear - a damaged gasket can cost you energy and affect baking results.

Remove crumbs and debris from oven chambers before they become baked-on problems. This simple step prevents buildup that can create fire hazards and affect air circulation. Your future self will thank you for this small daily effort.

Clean and soak racks in soapy water regularly to prevent buildup and ensure smooth operation. Remove them completely for thorough cleaning, and check that they slide in and out easily. Sticky racks slow down production and create frustration during busy periods.

Don't forget the door seals - check that they close properly and create a tight seal. A poorly sealing door wastes energy and creates uneven baking temperatures that can ruin entire batches.

Clean food spills immediately to prevent buildup and potential fire hazards. Use non-abrasive sponges or cloths to protect interior surfaces, especially in ovens with porcelain enamel interiors. Harsh scrubbing can damage surfaces and create areas where bacteria can hide.

Keep control panels and displays clean but be careful to avoid excess moisture that could damage electronic components. A soft, slightly damp cloth usually does the trick. Keep control areas dry and free from flour dust and debris that can interfere with buttons and displays.

Deep Cleaning and Professional Service

While daily cleaning keeps things running smoothly, monthly deep cleaning and annual professional maintenance ensure your ovens continue operating efficiently and safely for years to come.

Monthly deep cleaning goes beyond surface care. Apply commercial oven cleaner according to manufacturer instructions, allowing cleaners to soften grease and buildup before scrubbing. This deeper approach tackles the stubborn residue that daily cleaning can't reach.

Clean exhaust systems and ventilation components to maintain proper airflow. Inspect heating elements and temperature sensors for signs of wear or damage. These components are crucial for consistent results, and catching problems early prevents costly repairs.

Calibrate temperature controls for accuracy - even small temperature variations can affect baking results significantly. A thermometer that reads 350°F when the actual temperature is 375°F can turn perfect croissants into disappointing disasters.

Professional maintenance should be scheduled at least once a year for optimal performance and longevity. This isn't just a suggestion - it's essential for protecting your investment. Professional technicians provide temperature calibration verification, heating element inspection and replacement, door seal and gasket replacement, electrical connection inspection, and safety system testing.

Regular professional maintenance prevents minor issues from becoming major problems. Experienced technicians can identify wear patterns, replace components before failure, and ensure your ovens meet current safety standards. They catch problems you might miss and fix them before they disrupt your business.

Warranty protection often requires proper maintenance. Many manufacturers, like BRESSO, offer 2-year warranty periods for component replacement, but proper maintenance is typically required to maintain warranty coverage. Keep maintenance records to protect your investment and ensure warranty claims are honored.

The time and money you invest in proper maintenance pays dividends in consistent performance, lower energy costs, and fewer emergency repairs. Your ovens work hard for you - returning the favor with proper care ensures they'll keep delivering excellent results for years to come.

Frequently Asked Questions about Commercial Bakery Ovens

Do commercial convection ovens require a hood?

Most bakery ovens commercial equipment requires proper ventilation, but the specific requirements depend on your oven type and what you're cooking. It's one of those details that can catch new bakery owners off guard if they don't plan ahead.

Heat and vapor management is the main concern here. When you're baking dozens of croissants or running continuous bread production, you're generating significant heat and moisture that needs to go somewhere. Type 1 hoods are typically required for ovens producing grease-laden vapors, while Type 2 hoods handle heat and steam management for most baking applications.

Here's where it gets interesting: some electric ovens may qualify for condensing canopies instead of full hood systems, which can save you money and space. However, this varies dramatically by location.

Local building codes are the final word on what you actually need. What works in one city might not fly in another, and these requirements can significantly impact your installation costs and timeline.

The smart move? Consulting professionals who understand both equipment requirements and your local codes before you make any equipment purchases. This prevents expensive surprises and ensures your beautiful new oven installation passes inspection the first time.

What is the best type of oven for baking bread?

The honest answer is: it depends on what kind of bread you're making and how much of it you need to produce. Each oven type has its sweet spot.

Deck ovens are the gold standard for artisan bread - there's really no substitute when you want that perfect crust and authentic texture. The radiant heat from stone surfaces creates the crispy crusts and great crumb and oven spring that customers expect from high-quality sourdough and artisanal loaves. If you're positioning yourself as a craft bakery, deck ovens are almost mandatory.

Convection ovens work beautifully for soft rolls and dinner breads where uniform browning matters more than that signature crispy crust. They're also more forgiving for newer bakers still perfecting their technique.

For high-volume bread production, rack ovens are your friend. They deliver consistent results across large batches while minimizing the labor of rotating pans and managing multiple small batches. Think commercial bakeries supplying restaurants or grocery stores.

Steam injection benefits every type of bread, regardless of your oven choice. Steam improves oven spring and creates those professional-looking glossy crusts that make customers reach for their wallets. It's one of those features that pays for itself in improved product quality.

Can I bake different products at the same time?

This is where multi-deck ovens really shine, especially if you choose electric models with independent temperature controls. You can literally bake sourdough on the bottom deck at 450°F, cookies in the middle at 350°F, and delicate pastries on top at 325°F - all simultaneously.

Electric deck oven advantages include this precise temperature control for each deck, giving you maximum flexibility during busy production periods. It's like having multiple ovens in the footprint of one.

Gas deck ovens have a limitation here - they typically operate all decks at the same temperature. You can still bake different products, but they need to work at similar temperatures or you'll need to time things carefully.

Staggering batches becomes an art form when you're maximizing multi-deck efficiency. Smart bakeries plan their production schedules around these capabilities, loading different products as others finish to keep the ovens running continuously.

The production efficiency gains are substantial. Instead of waiting for one batch to finish before starting another, you can keep multiple products moving through different stages. This approach is particularly valuable during morning rush periods when you need fresh croissants, muffins, and bread all ready at the same time.

Planning your typical production schedule and product mix helps determine whether single or multi-deck configurations make sense for your operation. The ability to multitask your oven can be a game-changer for productivity.

Conclusion: Final Thoughts on Commercial Bakery Ovens

This article concludes our in-depth series on commercial bakery ovens. We have explored every critical aspect, from the core types like convection, deck, and rack ovens to the nuances of installation, maintenance, and how your choice impacts the final product. Our goal has been to provide a complete resource, and with this final guide, we are concluding our focus on this topic.

We've covered:

- The main types: Convection for versatility, deck for artisan quality, and rack for high volume.

- Selection criteria: Balancing capacity, energy use, and advanced features.

- Baking impact: How heat type and steam injection create specific textures and crusts.

- Longevity: The importance of daily and professional maintenance.

This comprehensive overview should serve as your definitive guide. We believe we have covered the topic of commercial ovens thoroughly and will now shift our focus to other areas of essential kitchen equipment. We trust that this series has equipped you with the knowledge to select the perfect oven for your business's long-term success.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment