Little Ovens That Could: Commercial Oven Picks for Small Spaces

Why Small Commercial Ovens Are Big Business for Tight Spaces

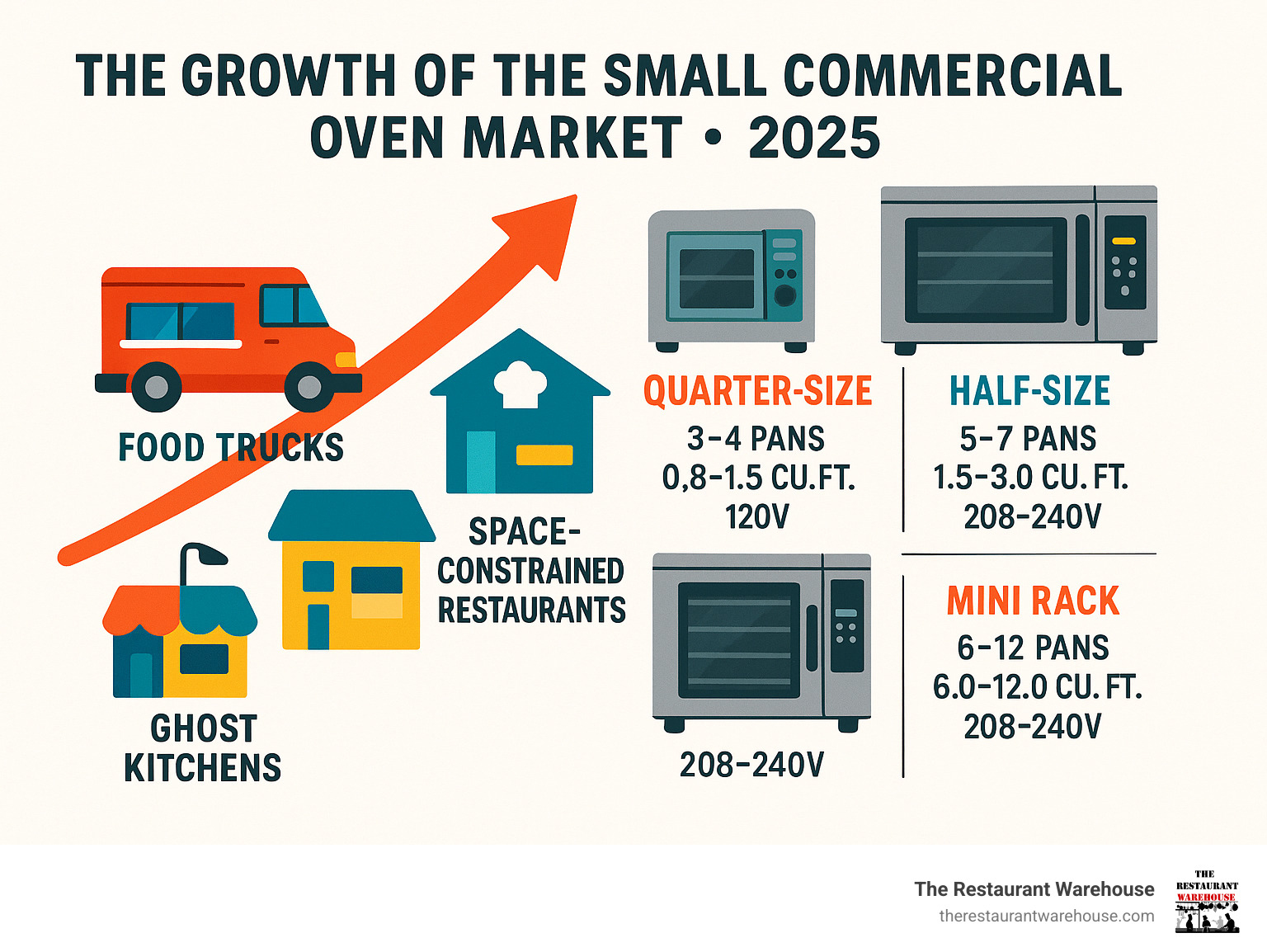

Commercial oven small options are revolutionizing how restaurants, cafés, and food trucks operate in cramped quarters. These compact powerhouses deliver professional-grade cooking performance without the massive footprint of full-size commercial units.

Quick Answer for Small Commercial Oven Buyers:

- Quarter-size convection ovens: 0.8-1.5 cu ft capacity, fits 3-4 half-size sheet pans

- Countertop models: Run on standard 120V outlets, perfect for food trucks

- Mini rack ovens: Hold 6-12 pans with rotating airflow for even baking

- Combi ovens: Steam + convection in compact 32" width units

- Pizza ovens: Heat up to 570°F, accommodate 16" frozen pizzas

The numbers tell the story. Small commercial convection ovens like the Avantco CO-16 pack 1.5 cubic feet of cooking space into a countertop unit that holds four half-size sheet pans. Meanwhile, mini rack ovens such as the Baxter OV310 can accommodate 6-12 pans in a footprint barely larger than a standard convection oven.

Why the shift to smaller? Rising real estate costs, food truck popularity, and ghost kitchen concepts are driving demand for space-efficient equipment. These ovens aren't just scaled-down versions of their bigger siblings - they're engineered specifically for tight spaces while maintaining the durability and performance standards your business demands.

From the Cadco OV-003's quarter-size design that plugs into any standard outlet, to countertop pizza ovens that can reheat frozen pies in 15-20 minutes, small commercial ovens are proving that good things really do come in small packages.

Find more about commercial oven small:

Why Size Matters: Defining the Small Commercial Oven

When we talk about a commercial oven small enough for tight spaces, we're not just talking about something that fits on your counter. These units are engineered to deliver commercial-grade performance while respecting the reality of limited kitchen real estate.

The key difference between small commercial ovens and their residential counterparts lies in their duty cycle and construction. While a home oven might bake a few batches of cookies on weekends, commercial units are built to handle continuous operation throughout busy service periods. They feature heavy-duty stainless steel construction, superior insulation, and NSF compliance for food safety.

Heat recovery is another crucial factor. Small commercial ovens maintain consistent temperatures even when doors are opened frequently - something residential units struggle with. This is achieved through improved airflow systems and thermal mass that acts as a heat reservoir.

At The Restaurant Warehouse, we've seen how these compact units transform kitchen operations. Our Commercial Electric Ovens Guide breaks down the technical specifications that separate professional equipment from consumer-grade alternatives.

What Makes a "Commercial Oven Small"?

The definition of "small" in commercial kitchens is quite specific. We're typically looking at units with interior capacities ranging from 0.8 to 2.33 cubic feet. Quarter-size convection ovens like the Cadco OV-003 offer 0.83 cubic feet of cooking space, while half-size models can accommodate up to 1.5 cubic feet.

Pan capacity is the real measuring stick. Quarter-size ovens hold 3-4 quarter-size sheet pans, while half-size units accommodate 4 half-size sheet pans. This translates to real cooking capacity - enough to bake several dozen cookies, reheat multiple casserole portions, or toast sandwiches for a busy lunch rush.

Many small commercial ovens are designed to run on standard 120V outlets, making them incredibly versatile for locations with limited electrical infrastructure. The Avantco CO-16, for example, operates at 1600W on a standard household circuit, while still delivering commercial-grade performance.

Key Features & Benefits Over Residential Units

Commercial units are built for punishment - they feature duty cycles that allow for continuous operation at high temperatures, something that would quickly burn out a home oven.

Fan-assisted convection is standard in commercial units, ensuring even heat distribution across all rack positions. This eliminates the hot spots common in residential ovens and reduces the need for tray rotation during baking.

Rapid preheat capabilities are another commercial advantage. While a home oven might take 15-20 minutes to reach temperature, commercial units often achieve full heat in under 10 minutes through higher-powered heating elements and superior insulation.

Durable stainless steel construction isn't just about looks - it's about longevity and sanitation. Commercial ovens are designed to withstand daily cleaning with commercial-grade chemicals and maintain their performance over years of heavy use.

Top Applications for a Commercial Oven Small Footprint

The beauty of small commercial ovens lies in their versatility. We've seen these units transform operations in settings where traditional commercial ovens simply wouldn't fit or make economic sense.

Food trucks represent perhaps the most obvious application. Space is at an absolute premium, and every square inch must earn its keep. A countertop convection oven that runs on 120V can handle baking, reheating, and finishing work without requiring expensive electrical upgrades.

Cafés and coffee shops are another perfect fit. These establishments need the capability to bake pastries, warm sandwiches, and prepare light meals, but they rarely have the space or volume to justify a full-size commercial oven.

Ghost kitchens - those delivery-only operations that have exploded in popularity - rely heavily on compact, efficient equipment. Small commercial ovens allow these operations to maximize their limited square footage while maintaining the cooking capabilities needed for diverse menus.

"Commercial Oven Small" for Bakeries & Cafés

Bakeries and cafés have unique requirements that make small commercial ovens particularly valuable. Even baking is crucial for pastries, breads, and delicate items that can't tolerate hot spots or temperature fluctuations.

The rotating rack systems found in mini rack ovens eliminate the need for manual tray rotation. The LBC LMO Mini uses tri-directional airflow combined with rack rotation to ensure consistent results across all levels. This is particularly important for bakeries where product consistency directly impacts customer satisfaction and food costs.

Steam injection capabilities in compact combi ovens open up additional possibilities. A burst of steam at the beginning of the baking cycle creates the crusty exterior that customers expect from artisan breads, while the convection mode ensures even browning and proper texture development.

Our Convection Ovens Guide provides detailed information on how these features translate to real-world baking performance.

"Commercial Oven Small" on Wheels: Food Trucks & Pop-Ups

Food trucks face unique challenges that make small commercial ovens not just convenient, but essential. Power limitations are a constant concern - most food trucks operate on generators or limited electrical hookups that can't support the massive power draws of full-size commercial equipment.

The 120V requirement of many small commercial ovens is a game-changer for mobile operations. The Cadco OV-003, drawing just 12 amps, can operate on standard generator power without overwhelming the electrical system.

Ventless operation is another crucial advantage. Many small commercial ovens produce minimal smoke and steam, reducing the complexity and cost of ventilation systems. This is particularly important for pop-up operations that might not have access to permanent ventilation infrastructure.

Types of Small Commercial Ovens & How to Choose

The variety of small commercial ovens available today is impressive, each designed for specific applications and cooking styles. Understanding the differences helps you choose the right unit for your operation.

Convection ovens remain the workhorses of small commercial cooking. They use fans to circulate hot air, ensuring even cooking and reducing baking times. These units excel at baking, roasting, and reheating, making them ideal for cafés, bakeries, and general food service applications.

Combi ovens combine steam and convection cooking in a single unit. They can operate in steam mode for vegetables and delicate proteins, convection mode for baking and roasting, or combination mode for items that benefit from both moisture and dry heat.

Deck ovens use radiant heat from stone or steel surfaces to create the high-temperature environment needed for pizza and artisan breads. Small deck ovens bring this capability to operations that couldn't accommodate full-size pizza ovens.

Pizza ovens designed for countertop use focus on reheating frozen pizzas and similar items. The Avantco CPO16TS can heat 16-inch pizzas in 15-20 minutes, making it perfect for snack bars and concession operations.

| Oven Type | Best For | Capacity | Power | Key Features |

|---|---|---|---|---|

| Quarter-size Convection | Baking, reheating | 0.8 cu ft | 120V | Even heat, compact |

| Half-size Convection | Higher volume baking | 1.5 cu ft | 120V | More capacity, versatile |

| Mini Combi | Steam + baking | 5-12 pans | 208V/240V | Moisture control, programmable |

| Countertop Pizza | Pizza, snacks | 16" diameter | 120V | High heat, fast reheat |

| Mini Rack | Bakery production | 6-12 pans | Gas/Electric | Rotating racks, even baking |

Sizing & Capacity Checklist

Choosing the right size requires careful consideration of your actual needs versus your available space. Pan count is often the most practical way to evaluate capacity. A quarter-size oven holding 3-4 quarter-size sheet pans might seem small, but that's enough capacity for 3-4 dozen cookies or 12-16 individual pastries.

Chamber height affects what you can cook. Most small commercial ovens accommodate standard sheet pans, but if you're planning to roast whole chickens or bake tall items, you'll need to verify the internal clearance.

Door swing is often overlooked but critically important in tight spaces. A door that swings down takes up less horizontal space than one that opens to the side, but it might interfere with prep work or storage below the unit.

Power Source & Utility Considerations

Power requirements can make or break an installation. The appeal of 120V units is obvious - they plug into standard outlets and don't require expensive electrical work. However, higher-capacity units often require 208V or 240V power.

Amperage draw is equally important. A 1600W unit on 120V draws about 13.3 amps, which is close to the limit for a standard 15-amp circuit. If you're planning to run other equipment on the same circuit, you'll need to calculate the total load carefully.

Gas options are available in some small commercial ovens, particularly mini rack ovens. Gas units often provide faster heat-up times and lower operating costs, but they require gas lines and proper ventilation.

Must-Have Features & Add-Ons

Modern small commercial ovens pack impressive technology into compact packages. Programmable controls allow you to store recipes and ensure consistent results across different operators.

Steam injection capabilities in compact combi ovens open up cooking possibilities that would otherwise require separate equipment. A steam delivery system enables everything from crusty artisan breads to perfectly steamed vegetables.

Removable racks and easy-clean interiors aren't just convenience features - they're essential for maintaining food safety standards in commercial operations.

Ventless operation is increasingly important as operators seek to reduce installation costs and complexity. Many small commercial ovens produce minimal smoke and steam, reducing ventilation requirements.

Our Combined Oven Guide provides detailed information on how these advanced features work together to create versatile, efficient cooking systems.

Maintenance, Challenges & Energy Efficiency Hacks

Small commercial ovens require consistent maintenance to deliver their promised performance and longevity. The good news is that their compact size makes most maintenance tasks quick and straightforward.

Daily maintenance should include wiping down the interior with a non-abrasive cleaner and soft cloth. The stainless steel surfaces common in commercial units resist staining and corrosion, but they still need regular cleaning to maintain their appearance and sanitary condition.

Door gaskets deserve special attention. These seals prevent heat loss and maintain cooking efficiency, but they're also vulnerable to damage from repeated opening and closing. A damaged gasket can increase cooking times and energy consumption significantly.

Descaling is crucial for units with steam capabilities. The mineral buildup from water can clog steam injection systems and reduce their effectiveness. Most manufacturers recommend descaling every 30-90 days depending on water hardness and usage levels.

Heat loss prevention is one of the most effective ways to improve energy efficiency. Keeping doors closed when not loading or unloading, maintaining proper gasket seals, and ensuring adequate clearance around the unit all contribute to efficient operation.

Many modern small commercial ovens include eco-modes that reduce energy consumption during idle periods. These systems automatically lower temperatures or shut down heating elements when the oven isn't in active use.

ENERGY STAR certification is available for some commercial ovens and indicates superior energy efficiency. While the upfront cost might be higher, the long-term savings in utility costs often justify the investment.

Common Limitations & Troubleshooting

Capacity bottlenecks are the most common challenge with small commercial ovens. The compact size that makes them attractive for tight spaces also limits their throughput. Planning your menu and production schedule around these limitations is crucial for success.

Hot spots can develop in any oven, but they're particularly problematic in small units where there's less room for heat to equalize. Regular calibration with an oven thermometer helps identify temperature variations.

Voltage drops are common in older buildings or locations with marginal electrical service. Small commercial ovens are sensitive to voltage variations, which can affect cooking times and temperature accuracy.

Fan failures are among the most common mechanical issues in convection ovens. Regular cleaning of fan blades and housings can extend motor life, but eventual replacement is inevitable in high-use applications.

Extending Lifespan & Warranty Insights

The average lifespan of a well-maintained small commercial oven ranges from 7-12 years, depending on usage intensity and maintenance quality.

Parts coverage varies significantly between manufacturers and models. Basic warranties typically cover parts for 1-2 years, while premium units might include extended coverage for critical components.

Preventative service logs are essential for warranty compliance and optimal performance. Documenting cleaning schedules, maintenance performed, and any issues encountered helps identify patterns and can be crucial for warranty claims.

Product Roundup: Little Ovens That Could

After extensive research and hands-on experience with various models, we've identified the standout performers in each category of small commercial ovens. These units represent the best combination of performance, reliability, and value for space-constrained operations.

Our selection criteria focused on real-world performance, build quality, and suitability for commercial applications. We considered factors like temperature accuracy, heat recovery time, ease of cleaning, and long-term reliability based on user feedback and our own experience at The Restaurant Warehouse.

For more comprehensive information on commercial baking equipment, our Industrial Ovens for Baking: Your Recipe for Bakery Success guide provides detailed insights into selecting the right equipment for your specific needs.

Best "Commercial Oven Small" Convection Choice

The quarter-size convection oven category is dominated by units that balance capacity with convenience. Our top pick combines 0.8 cubic feet of cooking space with 120V operation, making it suitable for virtually any location with standard electrical service.

This category excels at versatility - these ovens handle everything from baking cookies and pastries to reheating prepared foods and toasting sandwiches. The 3-rack configuration provides flexibility for different product sizes while maintaining the compact footprint.

Temperature accuracy is crucial in this category, and the best units maintain ±10°F accuracy across their operating range. The forced-air convection system ensures even heat distribution, eliminating the hot spots that plague residential ovens.

Best Space-Saving Combi Option

Combi ovens represent the pinnacle of cooking versatility, combining steam and convection capabilities in a single unit. The best compact combi ovens pack this functionality into units suitable for countertop installation or small floor footprints.

Steam plus hot air operation allows these units to handle an incredible variety of cooking tasks. Steam mode is perfect for vegetables and delicate proteins. Convection mode handles traditional baking and roasting. Combination mode creates the perfect environment for items that benefit from both moisture and dry heat.

Programmable controls are essential in this category. The ability to store multi-step cooking programs ensures consistent results regardless of operator skill level.

Best Mini Rack Performer

Mini rack ovens bring the performance advantages of full-size rack ovens to space-constrained operations. The rotating rack system combined with precision airflow eliminates the need for manual tray rotation while ensuring even baking across all levels.

The 6-pan capacity represents significant throughput for compact operations. This capacity is perfect for bakeries, cafés, and restaurants that need consistent, high-quality baking results without the space requirements of larger equipment.

The proofer base option transforms these units into complete bakery systems. The ability to proof dough in the base while baking in the oven above creates an integrated workflow that maximizes efficiency in minimal space.

Best Countertop Pizza Specialist

Countertop pizza ovens serve a specific niche but do it exceptionally well. The ability to heat 16-inch frozen pizzas in 15-20 minutes makes these units perfect for snack bars, concession stands, and operations that need quick, consistent pizza service.

The 150-570°F temperature range provides the flexibility needed for different products. Lower temperatures work well for delicate items like pastries, while the high-heat capability ensures proper pizza crust development and cheese melting.

The removable crumb tray is a crucial feature for maintaining cleanliness and food safety. The stainless steel construction makes cleaning quick and thorough.

Frequently Asked Questions about Small Commercial Ovens

How much clearance do I need around a small commercial oven?

Proper clearance is crucial for both safety and performance. Most small commercial ovens require at least 6 inches of clearance on all sides for adequate ventilation. However, this can vary based on the specific model and installation requirements.

For countertop units, ensure at least 12 inches of clearance above the unit to prevent heat buildup and allow for proper ventilation. Side clearances should be sufficient to allow door operation without interference from walls or other equipment.

Heat-producing equipment generates significant thermal loads, and inadequate clearance can lead to overheating, reduced performance, and potential fire hazards. Always consult the manufacturer's installation guidelines for specific clearance requirements.

Can a small commercial oven run on a standard household outlet?

Many small commercial ovens are designed specifically to operate on standard 120V household outlets, making them incredibly versatile for installations where electrical upgrades aren't feasible. However, amperage requirements can still be significant.

A typical 1600W unit draws approximately 13.3 amps, which is close to the limit for a standard 15-amp household circuit. If you're planning to run other equipment on the same circuit, you'll need to calculate the total load carefully to avoid overloading the circuit.

For optimal performance and safety, we recommend dedicated circuits for commercial ovens, even those designed for household outlets. This ensures consistent power delivery and prevents interference from other equipment.

What accessories boost productivity in compact ovens?

Sheet pans sized specifically for your oven maximize capacity and ensure proper airflow. Quarter-size and half-size pans are standard, but having the right sizes for your specific oven model improves efficiency and results.

Wire racks that allow airflow around products are superior to solid pans for most baking applications. The improved air circulation reduces cooking times and ensures more even results.

Timers and thermometers help maintain consistency, especially in high-volume operations. Digital timers with multiple channels allow operators to track several items simultaneously, while oven thermometers verify temperature accuracy.

Steam pans for combi ovens expand cooking possibilities significantly. Having a selection of different sizes and depths allows you to maximize the versatility of steam cooking capabilities.

Conclusion

The world of commercial oven small solutions has evolved dramatically, offering space-constrained operations genuine alternatives to compromising on cooking capability. From quarter-size convection ovens that pack professional performance into countertop footprints, to mini rack ovens that deliver bakery-quality results in compact packages, these units prove that size doesn't determine capability.

At The Restaurant Warehouse, we've seen how the right small commercial oven can transform operations. Food trucks gain the ability to offer fresh-baked items, cafés can handle morning rushes with confidence, and even traditional restaurants find these compact units invaluable for specialized tasks and backup capacity.

The key to success lies in matching the oven to your specific needs. Consider your menu requirements, available space, power limitations, and growth plans. A quarter-size convection oven might be perfect for a coffee shop's pastry needs, while a mini combi oven could revolutionize a food truck's menu possibilities.

Energy efficiency and operating costs deserve careful consideration. While the upfront investment in commercial-grade equipment might seem significant, the long-term savings in energy costs, maintenance, and replacement cycles often justify the expense.

Maintenance and proper care ensure these investments deliver their promised performance and longevity. Regular cleaning, gasket maintenance, and professional service when needed protect your investment and ensure consistent results.

The compact commercial oven market continues to evolve, with manufacturers developing increasingly sophisticated solutions for space-constrained operations. From programmable controls that ensure consistency to steam injection systems that expand cooking possibilities, these "little ovens that could" are proving that innovation isn't limited by size.

Whether you're outfitting a food truck, upgrading a café, or adding specialized capability to an existing kitchen, small commercial ovens offer the performance and reliability your operation demands. With affordable wholesale pricing and the expertise to guide your selection, The Restaurant Warehouse is your partner in finding the perfect compact cooking solution.

For more information on commercial cooking equipment, explore our comprehensive Restaurant Ovens for Sale Guide to find the full range of options available for your foodservice operation.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment