Deck the Halls (and Your Bakery) with These Commercial Deck Ovens

The Artisan's Secret: Why Commercial Deck Ovens Deliver Superior Results

A commercial deck oven is a specialized baking chamber that uses conduction heat from stone or steel decks to produce exceptional baked goods with perfect crusts and ideal internal textures. If you're looking to purchase a commercial deck oven, here's what you need to know:

Quick Guide to Commercial Deck Ovens: - Price Range: $1,000 (single countertop) to $80,000+ (multi-deck with features) - Types: Electric, gas, steam-tube, thermal oil, or hybrid models - Key Benefits: Superior crust development, even baking, energy efficiency (up to 75% fuel savings) - Best For: Artisan breads, pizza, pastries, and high-volume bakery production

Unlike convection ovens that circulate hot air, deck ovens transfer heat directly from heated surfaces to your products. This creates that coveted crispy exterior while maintaining a soft, perfectly developed interior that professionals demand.

The design is remarkably simple yet effective—heat radiates from the stone or steel deck upward, mimicking traditional brick ovens but with precise temperature control. Many models offer independent heat zones for top and bottom, allowing you to dial in the perfect baking environment for different products.

For busy bakeries and restaurants, the versatility is key. With configurations ranging from single countertop units to massive four-deck systems, there's a deck oven scaled for every operation.

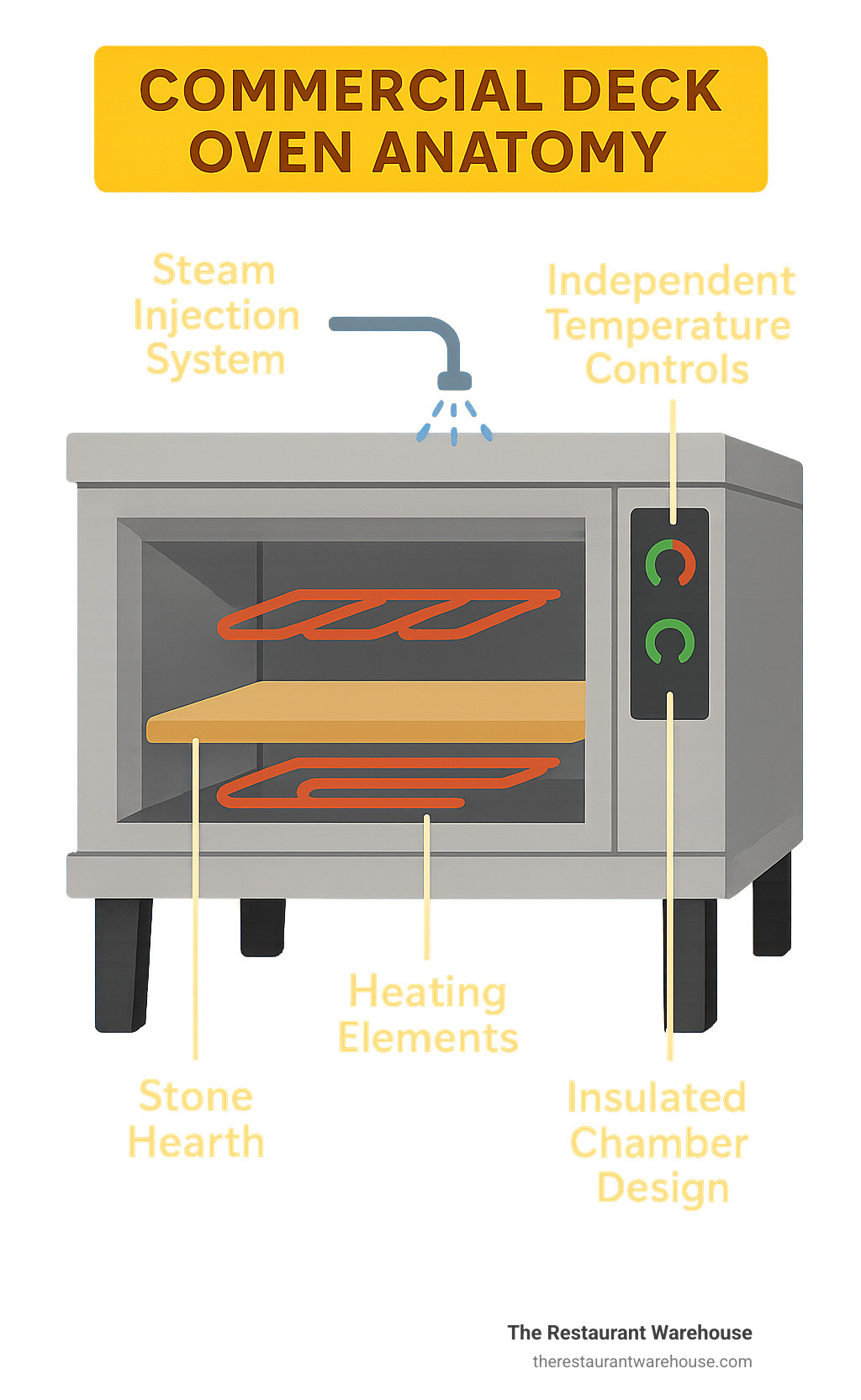

Modern commercial deck ovens also feature innovations like steam injection systems (essential for artisan bread), digital controls, and modular designs that can fit through standard doorways and expand as your business grows.

What Is a Commercial Deck Oven & How It Works

At its heart, a commercial deck oven works on a beautifully simple principle: direct heat transfer. Unlike commercial ovens that blow hot air around, deck ovens let the heat travel straight from a heated surface (the "deck") right into your dough, creating magic that other ovens simply can't match.

The deck itself—usually made of stone, ceramics like cordierite, or heavy-duty steel—acts like a heat battery, storing thermal energy and releasing it evenly into whatever you're baking. When dough touches this hot surface, immediate "oven spring" kicks in, creating that perfect balance of crispy exterior and tender interior.

What makes commercial deck ovens special is their thoughtful design. Most feature thick thermal mass that maintains steady temperatures even when opening doors between batches. They have heating elements positioned above and below the deck, creating balanced heat zones you can control independently. Many include steam injection systems essential for glossy, crackling crusts on artisan breads.

This heat-retaining design means these ovens bounce back quickly between batches—perfect for busy production environments. It's also why they're surprisingly energy-efficient, with studies showing commercial deck ovens can cut fuel consumption by up to 75% compared to other oven types.

Heat Transfer Science Behind Deck Ovens

The science that makes a commercial deck oven produce such amazing results involves a three-dimensional heat system:

- Conduction—direct heat travels from the hot stone straight into your dough's bottom surface, creating proper lift and that perfectly crisp base.

- Radiation—heat waves from both the deck and ceiling elements penetrate deep into your product, developing beautiful color and finishing the top surface.

- Ambient heat—the sealed chamber creates a stable temperature cocoon around your entire product, ensuring even development throughout.

This three-part heating system creates what professional bakers call the "perfect bake zone"—that magical place where crust formation and internal structure develop in perfect harmony.

Commercial Deck Oven vs. Convection & Rotary Alternatives

When deciding between oven types, understanding how they cook makes all the difference:

Deck ovens transfer heat directly from the stone or steel surface into your dough. This direct contact creates distinctive crusts that customers recognize instantly. The sealed chamber naturally retains moisture, giving excellent control over your final product.

Convection ovens blow hot air around with fans. This speeds up cooking and creates uniform results, but that moving air can remove moisture and create a different texture and crust.

Rotary/rack ovens move your product through hot air, ensuring even baking for large batches. They're workhorses for high-volume production but might sacrifice some of those special artisanal qualities.

For a deeper dive into convection options, check out our Convection Ovens Guide.

Types & Key Features to Compare Before You Buy

Shopping for a commercial deck oven is exciting, but with so many options, it helps to understand what makes each type special.

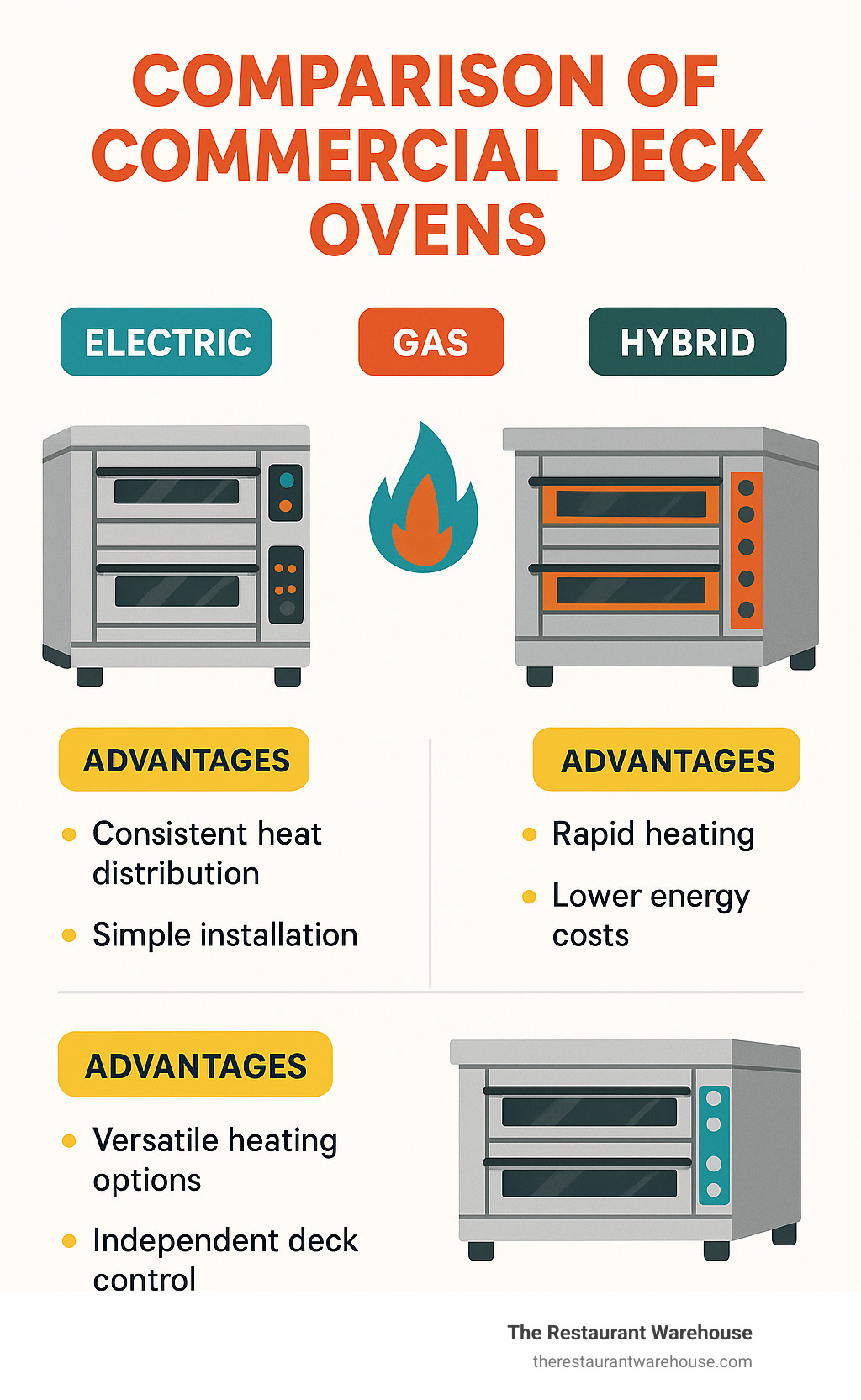

Electric Deck Ovens

Electric models give you incredible control over your baking environment. Each deck can be set to its own temperature, and you can fine-tune both top and bottom heat separately. The temperature responds quickly to adjustments, making these ovens incredibly versatile. Plus, since there's no combustion, you won't need special venting systems, which can make installation much simpler.

Gas Deck Ovens

Gas-powered deck ovens are workhorses with impressive staying power. Their higher thermal mass means once they're heated, they maintain steady temperatures beautifully—even during busy service when doors are opening frequently. In many regions, gas costs less than electricity, making these models more economical to run day-to-day. They also typically reach higher maximum temperatures, which is crucial for authentic Neapolitan pizza.

Steam Tube Deck Ovens

For serious bread bakers, steam tube models offer something special. These ovens use steam-filled tubes running through the deck to distribute heat with remarkable evenness. The result is a gentle, consistent baking environment that produces exceptional artisan loaves with perfect crusts.

Thermal Oil Deck Ovens

These sophisticated ovens use heated oil circulating through the deck to create an incredibly even baking surface. Though they represent a higher initial investment, thermal oil ovens typically consume less energy over time and create a gentler baking environment that's forgiving with delicate products.

Hybrid Models

Hybrid ovens combine multiple heating methods to give you the best of both worlds. Many feature independent controls for top deck heating elements, allowing you to give pastries the perfect finish while bread bakes steadily below.

Beyond heating methods, consider these important features:

Construction style: Modular ovens can be taken apart to fit through standard doorways and expanded later. Fixed units offer greater structural integrity but require more planning for installation.

Deck height options typically range from 3" to 7.5"—choose based on what you'll be baking most frequently. Taller chambers are necessary for high-rising breads, while shorter ones work well for pizza and flatbreads.

Control systems range from simple manual dials to sophisticated digital interfaces with recipe storage. Digital controls cost more upfront but can improve consistency and reduce training time for staff.

Steam injection systems are essential for artisan bread but optional for pizza operations. Look for models that offer steam on each deck individually for maximum flexibility.

Selecting the Right Number of Decks & Stone Material

To calculate required deck capacity: (Production × Bake Time) ÷ 60 minutes

For example, 50 loaves per hour with a 30-minute bake time: (50 × 0.5) ÷ 60 = 0.42 × deck capacity

This means you need space for about 25 loaves at once. If each deck holds 8 loaves, you'd need at least 3 decks.

The material of your deck significantly impacts how your products bake:

- Cordierite stone offers excellent heat retention and distribution—perfect for artisan bread and pizza.

- Firebrick is the traditional choice with superior thermal mass.

- Steel decks transfer heat more quickly, making them better for products requiring faster baking times.

Energy Efficiency & Operating Costs

Modern models include impressive energy-saving features:

- AC Guard Technology limits simultaneous power draw

- Economy Mode automatically reduces power consumption during slow periods

- Improved insulation keeps heat inside the oven, not heating your kitchen

The natural heat retention of deck ovens means they can maintain baking temperatures with minimal energy input once heated. Industry data suggests commercial deck ovens can save up to 75% in fuel consumption compared to other oven types.

For detailed specifications and energy consumption data, review manufacturer documentation similar to this technical user manual example.

Product Roundup: Best Commercial Deck Oven Categories for Every Operation

Here at The Restaurant Warehouse, we've handpicked a collection of commercial deck ovens that deliver professional-quality results without the premium price tag. Whether you're running a cozy café or a busy bakery, we have options perfectly suited to your needs and budget.

Countertop & Small-Footprint Commercial Deck Oven Picks

Best for: Cafés, small bakeries, pizza shops with limited space, and operations looking to add specialty baking capacity.

Space comes at a premium in most food establishments, which is why our compact commercial deck ovens are such customer favorites. These space-saving wonders pack professional performance into footprints under 30 inches wide, making them perfect for tight kitchens and operations testing new menu items.

What makes these smaller models special is their accessibility—many run on standard 120V power, meaning no special electrical work is needed. Despite their modest size, they feature the same professional-grade cordierite stones and independent temperature controls as their larger cousins.

Look for models with digital PID temperature controllers that maintain precise heat levels and quick recovery times between batches. The best compact options still reach temperatures up to 750°F—plenty hot for authentic pizza and artisan breads with that perfect crust.

High-Volume Multi-Deck Commercial Deck Oven Picks

Best for: High-volume bakeries, busy restaurants, and production facilities requiring continuous baking capacity.

When your business depends on consistent, high-volume output, our multi-deck commercial deck ovens deliver the capacity and reliability you need. These production powerhouses feature three to four independently controlled baking chambers, allowing you to run different products simultaneously without compromising quality.

With the right loading system, a single staff member can manage multiple decks at once, dramatically boosting your production capacity without proportionally increasing labor costs. Many of our customers report being able to double or even triple their output while adding minimal staff.

These professional models include features like independent steam injection systems for each deck—essential for achieving that glossy, crackling crust on artisan loaves. Look for energy-saving modes that reduce consumption during slower periods, helping manage operating costs during your production cycles.

Pizza-Focused Commercial Deck Oven Picks

Best for: Pizzerias, Italian restaurants, and operations specializing in authentic pizza production.

Pizza demands special consideration, which is why we offer commercial deck ovens specifically engineered for pizza perfection. These specialized models reach the blazing temperatures (800-900°F) needed for authentic Neapolitan-style pies, with extra-thick stone hearths that deliver that coveted crisp-yet-tender crust.

What sets pizza-focused deck ovens apart is their heat distribution pattern. They feature improved ceiling heat for proper cheese melting and top browning, while the specialized stone compositions ensure the bottom cooks perfectly—no more soggy centers or burnt edges!

The door heights on these models are specifically designed for pizza operations, making it easier to slide pies in and out quickly during busy service. Many feature stackable designs, allowing you to expand capacity as your business grows without sacrificing valuable floor space.

For the complete pizza-making setup, pair your oven with the right prep equipment—check out our Pizza Prep Table Guide to create the most efficient workflow.

Buying, Installing & Maintaining Your Commercial Deck Oven

Let's face it—buying a commercial deck oven is a significant investment that requires careful planning. Here's everything you need to know before bringing one home:

Pre-Purchase Planning

Before you click "buy" on that beautiful commercial deck oven, take a deep breath and grab your measuring tape. Your future self will thank you for checking that your space can actually accommodate your new kitchen centerpiece.

Start with a thorough site survey—measure everything from floor space to ceiling height. Doorways are often the biggest hurdle since many full-sized deck ovens are wider than standard doorways.

Floor strength matters too. A multi-deck oven can tip the scales at several thousand pounds. Have a structural assessment done if you're not on a concrete slab or if your building is older.

Your utilities need careful consideration as well. Electric models require specific voltage, amperage, and phase configurations, while gas models need proper gas type, pressure, and BTU availability.

Installation Considerations

Getting your commercial deck oven through the door is often the first major challenge. If you've chosen a non-modular model, you might need to temporarily remove door frames or even portions of walls.

Ventilation requirements vary based on your oven type: - Gas ovens need Type I hoods with proper fire suppression systems - Electric models often can use Type II hoods, saving you money - Some newer electric models feature clever condensing canopies that recirculate air

When positioning your oven, allow at least 6 inches of clearance for proper heat dissipation. Also consider your workflow; your oven should be positioned so that products can move efficiently from preparation to baking to cooling.

Daily, Weekly & Annual Maintenance Checklist

Your commercial deck oven is a workhorse, but even workhorses need care. Establishing a regular maintenance routine not only extends your oven's life but ensures those croissants come out perfect every time.

Daily love for your oven is simple but crucial. Brush or scrape debris from stone decks after your baking day ends. Wipe down exterior surfaces and check that door seals are closing properly. Empty crumb trays daily.

Weekly attention involves a bit more elbow grease. Deep clean the chamber (following manufacturer guidelines), inspect and clean steam nozzles, and check door mechanisms. A quick temperature verification with a separate thermometer can catch calibration issues before they affect your products.

Monthly care extends to ventilation systems, electrical connections, and moving parts. If you have a gas model, this is a good time to check connections for potential leaks.

Annual professional service is non-negotiable. Have a certified technician inspect heating elements, calibrate controls, descale steam systems, and verify all safety features.

Sizing Formula & Space Planning Tips

Finding the right-sized commercial deck oven is a bit like Goldilocks—too small and you'll limit growth; too large and you're heating empty space and wasting money.

Start by being honest about your production needs. Calculate your peak hourly output and multiply it by your average bake time. If you'll be making 40 loaves per hour with a 30-minute bake time, you need capacity for at least 20 loaves at any given time. Then add 20-30% for unexpected demand or future growth.

Space requirements vary by product: - Bread loaves generally need 36-40 square inches each - Pizza requires 150-200 square inches per pie - Pastries need specific spacing based on their size and rising characteristics

For growth-minded businesses, modular or stackable ovens offer the flexibility to expand capacity as your customer base grows.

For comprehensive kitchen planning beyond just your oven, check out our Restaurant Kitchen Equipment Checklist to make sure you've covered all the bases.

Frequently Asked Questions about Commercial Deck Ovens

How does steam injection improve crust quality?

When it comes to baking artisan bread, steam is nothing short of magical. In a commercial deck oven, steam injection transforms ordinary dough into bakery-quality bread with that perfect crust we all love.

Here's what happens: When you hit that steam button at the start of baking, you're creating an environment where dough can reach its full potential. The moisture keeps the outer surface of your dough soft and flexible while the inside begins to cook. This allows for that beautiful "oven spring" – the dramatic rise that happens in the first few minutes of baking – before the crust sets.

The science is fascinating too. Steam causes the starches on the dough surface to gelatinize, creating that glossy appearance. Later, as the steam vents and the surface dries, you get that wonderfully crisp texture. Plus, steam conducts heat more efficiently than dry air, kickstarting the baking process and promoting those rich Maillard reactions that give bread its appetizing golden-brown color.

Timing matters tremendously. Most bakers add steam during just the first 5-10 minutes of baking. After that, the steam needs to vent away so the crust can dry and crisp up properly.

Do deck ovens require a dedicated exhaust hood?

The answer depends on what type of commercial deck oven you're using, but ventilation is always something you'll need to address.

For gas-powered deck ovens, the answer is a clear yes – they always require a Type I hood with fire suppression. These hoods must vent combustion byproducts outside the building, and you'll need mechanical exhaust fans rated appropriately for your oven's BTU output.

Electric commercial deck ovens have more flexible requirements, but don't think you can skip ventilation entirely. While many jurisdictions allow Type II hoods (without fire suppression) for electric models, you're still dealing with heat, moisture, and food aromas that need somewhere to go.

Always check your local building codes and health department regulations before installation. Some areas have specific requirements for bakery and pizza operations.

What's the learning curve for new staff?

Commercial deck ovens aren't quite as forgiving as some alternatives, but the superior results make the learning curve worthwhile.

When training new staff, expect to spend time teaching them about heat zones and temperature management. Unlike convection ovens where heat circulates evenly, deck ovens have distinct hot and cool spots that experienced bakers learn to use to their advantage.

Proper loading techniques are another key skill. Using peels (those long-handled tools for loading and unloading) takes practice, and staff need to learn proper spacing to allow for product expansion while maximizing capacity.

The typical learning timeline looks something like this: basic operation takes 1-2 days to grasp, consistently quality production develops over 1-2 weeks, and advanced techniques and troubleshooting skills build over 1-2 months.

Creating standardized recipe cards with specific placement instructions, temperature settings, and visual cues for doneness can dramatically speed up the learning process. Many manufacturers also offer training programs with purchase – definitely take advantage of these if available.

Conclusion

Investing in a commercial deck oven isn't just about buying equipment—it's about making a statement about your commitment to quality. Every perfectly crisp loaf and beautifully blistered pizza that emerges from your deck oven tells your customers you care about craftsmanship.

At The Restaurant Warehouse, we understand that premium baking equipment often comes with premium price tags. That's why we've built our business around eliminating unnecessary markups and passing those savings directly to you. Our commercial deck ovens deliver professional results at wholesale prices that make sense for bakeries, pizzerias, and restaurants of all sizes.

The beauty of modern deck ovens goes beyond just incredible food. With energy savings of up to 75% compared to conventional alternatives, your investment continues paying you back with every batch you bake. Those lower utility bills add up quickly, especially when paired with the premium prices that authentic artisan products can command in today's market.

Whether you're just starting your baking journey, expanding your current operation, or replacing aging equipment, we have commercial deck ovens perfectly matched to your needs. From compact single-deck models that fit in tight spaces to impressive multi-deck systems for high-volume production, we've carefully selected equipment that delivers exceptional value at every price point.

Ready to take your baking to the next level? For more guidance on selecting the perfect commercial oven for your specific needs, check out our comprehensive Restaurant Oven for Sale Guide.

Contact our friendly team at The Restaurant Warehouse today. We're not just equipment suppliers—we're partners in your culinary success, ready to help you find the perfect commercial deck oven at a price that works for your business.

About The Author

Sean Kearney

Sean Kearney is the Founder of The Restaurant Warehouse, with 15 years of experience in the restaurant equipment industry and more than 30 years in ecommerce, beginning with Amazon.com. As an equipment distributor and supplier, Sean helps restaurant owners make confident purchasing decisions through clear pricing, practical guidance, and a more transparent online buying experience.

Connect with Sean on LinkedIn, Instagram, YouTube, or Facebook.

Leave a comment