Warm Welcome: Essential Electric Food Warmers for Your Eatery

Why Every Foodservice Operation Needs a Commercial Food Warmer

When you run a busy kitchen, keeping food hot and ready to serve is key. That's where commercial restaurant food warmers come in. These essential pieces of equipment help us:

- Maintain food safety: They keep cooked food above the "danger zone" temperature. This stops bad bacteria from growing.

- Ensure food quality: Food stays fresh, moist, and delicious, just like when it was first made. No more dried-out dishes!

- Boost efficiency: You can prepare food ahead of time. This speeds up service during busy hours and keeps your kitchen running smoothly.

- Improve customer satisfaction: Hot food equals happy customers. You deliver fresh, ready-to-eat meals quickly.

No matter the size of your eatery, having reliable food warmers can make a big difference. They are a smart investment for any foodservice business aiming for top-notch quality and smooth operations.

Important commercial restaurant food warmers terms:

Imagine a busy service where every dish is cooked to order from scratch. This scenario highlights the role of commercial restaurant food warmers as unsung heroes. They work behind the scenes to ensure smooth operations by preserving food quality, ensuring safety, and boosting efficiency.

The Critical Role in Food Safety and Quality

Food safety is a legal and ethical imperative for any reputable foodservice operation. The FDA Food Code recommends holding hot food at a minimum of 135°F (57°C) or above. This is because temperatures between 40°F (4°C) and 135°F (57°C) are the "danger zone," where harmful bacteria can multiply rapidly. Our commercial restaurant food warmers are designed to keep cooked food consistently above this critical threshold, preventing bacterial growth and safeguarding customer health.

Beyond safety, it's about maintaining the integrity of your culinary creations. A good food warmer helps maintain the texture and moisture of dishes. For example, Bain-Marie warmers use gentle wet heat, perfect for delicate items like sauces or mashed potatoes, keeping them moist without drying out. Dry heat warmers, conversely, can keep fried foods crispy. This consistent product delivery means every plate meets the high standards customers expect, enhancing their dining experience.

Boosting Efficiency and Profitability

In foodservice, time is money. Commercial restaurant food warmers allow you to prepare food ahead of peak hours. During a lunch rush, instead of cooking every component of a dish, you can have items prepped and held at optimal serving temperatures. This significantly reduces ticket times, meaning customers get their food faster, and you can turn tables more quickly.

This advance preparation optimizes labor, allowing staff to multitask on plating or customer service instead of just cooking during peak times, leading to labor cost savings. Holding food at the correct temperature also minimizes spoilage, reducing waste and protecting your bottom line. A streamlined workflow with hot, fresh food always ready means you can serve more customers, increasing revenue. It's an investment that pays for itself.

To dig deeper into equipping your kitchen for peak performance, explore our insights on Catering Equipment Essentials.

A Guide to the Different Types of Commercial Restaurant Food Warmers

Just as a chef needs different knives, a kitchen needs various commercial restaurant food warmers for specific tasks. Understanding the types is crucial for choosing the right equipment for your cafe, buffet, or catering business. This section will help you choose the Best Food Warmer for your specific needs.

Countertop Warmers and Steam Tables

Countertop warmers are compact, versatile units designed to sit on a counter, making them perfect for smaller establishments like cafes and food trucks, or as supplementary warming stations in larger kitchens. They typically hold one or more food pans and are ideal for keeping sauces, gravies, soups, or small batches of prepared food like chili or nacho cheese warm and ready for service. Their small footprint makes them an easy addition to any prep line or service area.

Steam tables, also known as hot food tables, are larger, more robust units essential for high-volume applications like buffets, cafeterias, and catering lines. They feature multiple wells designed to hold full-size or fractional food pans, allowing you to offer a variety of dishes simultaneously. Many steam tables use a Bain-Marie design, which employs a hot water bath ("wet heat") to provide gentle, even heat. This method is excellent for maintaining the quality of moist foods like soups, stews, pasta dishes, and delicate sauces, preventing them from drying out or scorching over long service periods.

Alternatively, some steam tables and countertop units offer "dry heat" operation, using direct heating elements without water. This is preferred for foods where crispiness is desired, such as French fries, onion rings, or fried chicken. Dry heat is also a more convenient option where managing a water supply is impractical. The choice between wet and dry heat often comes down to your menu; many establishments use both to ensure every item is held perfectly.

Drawer Warmers

Drawer warmers are a fantastic solution for saving space while precisely controlling the holding environment for different food items. These units are typically designed to be built-in below a counter or stacked, integrating seamlessly into the kitchen line. The magic of drawer warmers lies in their individual controls; each drawer often operates as an independent zone, allowing for separate temperature and humidity settings. This makes them incredibly versatile for complex menus.

For example, in a busy burger joint, one drawer can be set to a higher temperature with low humidity to keep cooked burger patties hot and juicy without steaming, while the drawer below can be set to a lower, moist temperature to keep buns soft and warm. Another drawer could hold crispy bacon. They are also excellent for holding side dishes, steamed vegetables, dinner rolls, or even for proofing dough. Their ability to hold a variety of foods at their unique ideal serving temperatures makes them a staple in restaurants aiming for consistency and quality.

Holding and Proofing Cabinets

For high-capacity warming, holding and proofing cabinets are the undisputed workhorses of the commercial kitchen. These are typically freestanding, often mobile units on casters, designed to hold large quantities of food on sheet pans or hotel pans at precise temperatures for extended periods. They come in various sizes, from compact half-height models that can fit under a counter to full-height models that can hold dozens of pans, making them indispensable for banquets, large-scale catering, and institutional foodservice.

An important distinction is between insulated and non-insulated cabinets. Insulated models feature robust insulation within their walls, which allows them to maintain consistent temperatures more effectively, recover heat faster after the door is opened, and operate with greater energy efficiency. They are the superior choice for long holding times or frequent transport. Non-insulated models are a more economical upfront choice, suitable for shorter holding periods where energy loss is less of a concern. Many cabinets also offer pass-through capabilities, with doors on both the front and back. This design is brilliant for improving kitchen workflow, allowing kitchen staff to load cooked food from one side while service staff retrieve it from the other, minimizing traffic and confusion.

Strip Heaters and Heat Lamps

These commercial restaurant food warmers maintain the temperature of plated dishes right before they go to the customer. Strip heaters, often mounted above a kitchen pass-through or carving station, use infrared heat to keep food warm from above. This radiant heat ensures plated meals remain hot while waiting for pickup.

Heat lamps serve a similar purpose, providing focused heat. They are common at carving stations where meats are sliced to order, ensuring each portion is served warm. Some models offer long warranties, indicating their durability. These warmers are crucial for the "hot out of the kitchen" experience. When choosing, look for certifications like UL Sanitation to NSF to ensure compliance with safety and sanitation standards.

Key Features to Look for When Buying Your Food Warmer

Investing in commercial restaurant food warmers is a significant step. It's about finding the right fit for efficiency, safety, and longevity. To help steer the options, our Commercial Food Warmer Guide focuses on the features that matter most for your kitchen.

Capacity, Size, and Configuration

First, consider the practicals: how much food do you need to hold, and how much space do you have?

Consider capacity: how much food a warmer holds. For countertop models and steam tables, this is measured by the number and size of food pans it accommodates. Holding cabinets are rated by the number of sheet or steam table pans they can hold. Estimating your peak volume needs correctly is crucial.

Next, measure your available space to determine the warmer's footprint. This will guide your choice between countertop vs. freestanding models. Countertop units are great for tight spaces, while freestanding units offer higher capacity and are often mobile, a plus for catering.

For off-site events, portability is key. Look for sturdy casters and a lightweight design. Finally, consider pan configuration. Ensure the warmer supports the pan sizes (full-size, half-size, etc.) you use to maintain an efficient workflow.

Temperature Control and Energy Efficiency in commercial restaurant food warmers

Precise temperature control is a must-have for food safety and quality.

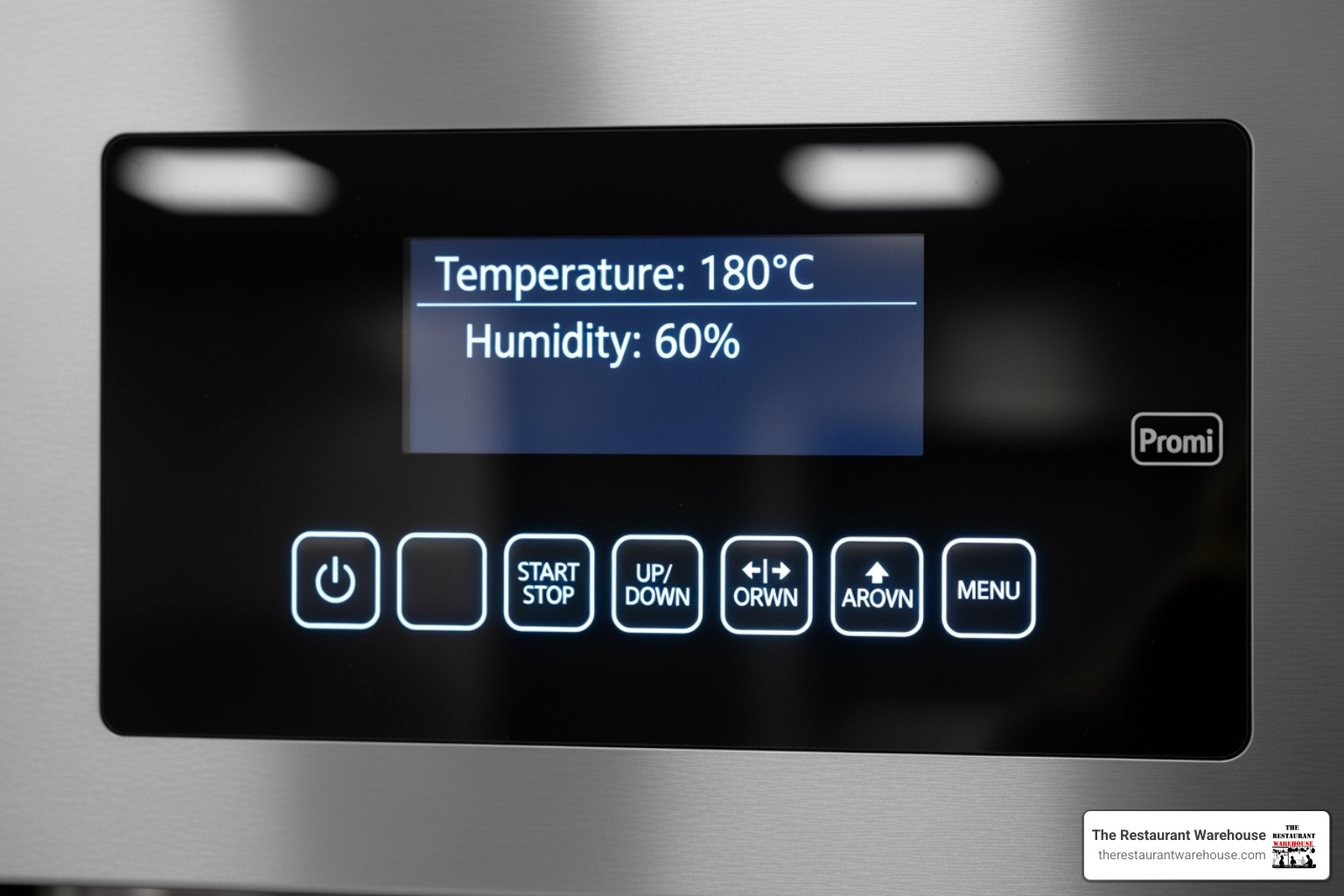

Look for warmers with accurate thermostatic controls. While some have analog dials, digital displays offer more precision and ease of use. For foods that dry out, humidity settings are a game-changer, adding moisture to keep items like meats and bread succulent.

Energy efficiency is also important. Look for ENERGY STAR® certified commercial restaurant food warmers to lower operating costs. Good insulation quality is also key, as it helps maintain consistent temperatures and reduces heat loss, saving more energy. An insulated cabinet will use less power than a non-insulated one.

Finally, check the power consumption (watts/amps) to ensure your electrical system can handle the load. Commercial warmers range from 350 to over 2,850 watts, so understanding these numbers prevents overloaded circuits and ensures safe operation.

Construction, Durability, and Safety Certifications

Durability is essential for equipment in a busy kitchen.

Stainless steel construction is the industry standard because it's durable, rust-resistant, and easy to clean. For holding cabinets, consider the door types: solid doors offer better insulation, while clear glass doors let you see contents without opening the door. Pass-through doors can streamline workflow in a busy kitchen.

Look for important safety features like overheat protection and heat-resistant handles to protect your staff and equipment. Finally, check for crucial certifications. NSF certification ensures the equipment meets strict public health standards for sanitation. UL/ETL certification indicates that the electrical components meet strict safety standards, reducing electrical hazards.

For even more detailed guidance on acquiring the right gear for your kitchen, be sure to check out our comprehensive article on More on buying commercial kitchen equipment.

Best Practices for Cleaning and Maintenance

A clean kitchen is a safe kitchen, and this applies to your commercial restaurant food warmers. Proper cleaning and maintenance are vital for food safety, equipment lifespan, and optimal performance. A well-maintained warmer has a long, productive life. If you're looking to save, you might explore how to Warm Up Your Kitchen Savings With Used Food Warmers.

Daily Cleaning for Optimal Hygiene

Daily cleaning is your first line of defense. At the end of each service, thoroughly wipe down all exterior and interior surfaces with a food-safe cleaner. Pay special attention to high-touch areas and spills. Clean spills immediately once it's safe to do so, as dried-on food is harder to remove and can harbor bacteria.

Don't forget the accessories. Any food pans and inserts should be removed, washed, rinsed, and sanitized according to standard procedures to prevent cross-contamination. Most importantly, always follow the manufacturer's instructions for cleaning. Different models have different requirements, and following guidelines protects your warranty and prevents damage. Some models have easily detached components to simplify daily cleaning.

Long-Term Maintenance for Longevity

Regular deep maintenance will keep your commercial restaurant food warmers operating reliably for years.

Start by inspecting the heating elements for grime or wear. For wet heat warmers, check for scale buildup from water, which can reduce efficiency, and descale as recommended by the manufacturer.

Next, check the gaskets and seals on holding cabinets and drawer warmers for any cracks or tears. Damaged seals allow heat to escape, increasing energy use and compromising food safety. Replace them if they are worn.

It's a good idea to periodically calibrate your thermostats. Thermostats on commercial restaurant food warmers can drift over time. Use a calibrated thermometer to check the internal temperature against the display. If there's a significant difference, the thermostat may need recalibration or replacement to ensure food is held at a safe, accurate temperature.

Finally, schedule professional service for annual check-ups or complex issues. A qualified technician can inspect electrical components and controls, catching small problems before they become costly breakdowns. This preventative maintenance ensures your warmers are always ready for service.

Frequently Asked Questions about Commercial Food Warmers

Choosing and using commercial restaurant food warmers can bring up questions. Here are answers to the most common ones we hear from foodservice professionals.

What is the ideal temperature for holding hot food?

The magic number is 135°F (57°C) or above. This is the standard recommended by the FDA Food Code to ensure food safety.

The temperature range between 40°F and 135°F is the "danger zone," where harmful bacteria can multiply rapidly. Keeping your commercial restaurant food warmers at 135°F or higher prevents this growth.

Most quality food warmers are designed to maintain this temperature consistently. However, you should still check your equipment regularly with a calibrated thermometer to ensure it's operating correctly.

Can I use a food warmer to cook or reheat food?

The short answer is no. Commercial restaurant food warmers are designed only to hold already cooked food at a safe serving temperature, not to cook or reheat it.

Food warmers do not get hot enough or heat food quickly enough to safely bring it through the temperature danger zone and kill bacteria. Using them for cooking or reheating is unsafe for customers and can damage the equipment, as it's not built for the intensity of those processes.

Always ensure food is fully cooked or properly reheated in appropriate cooking equipment before transferring it to a food warmer.

What is the difference between a wet heat and a dry heat warmer?

The main difference is moisture, which affects food texture.

Wet heat warmers (Bain-Maries) use a hot water bath for gentle, moist heat. This is ideal for delicate items like sauces, gravies, and mashed potatoes, preventing them from drying out.

Dry heat warmers use direct heating elements without water. This method is best for keeping fried foods like French fries, onion rings, or fried chicken crispy by preventing sogginess.

The choice depends on your menu; many kitchens use both types of commercial restaurant food warmers to handle their full menu perfectly.

Conclusion

It's clear that commercial restaurant food warmers are more than just "hot boxes"; they are vital tools for a successful foodservice operation. They ensure customer safety by holding food at precise temperatures and improve kitchen efficiency by allowing for advance prep. The benefits are undeniable!

Choosing the right equipment is a smart investment. We've explored various options, from versatile countertop warmers and high-capacity holding cabinets to specialized drawer warmers and efficient strip heaters. Each type is designed to fit unique operational needs.

Remember the crucial features: the right capacity and size, precise temperature controls (with humidity if needed), and energy efficiency (look for ENERGY STAR®!). Also prioritize durable construction and proper safety certifications like NSF and UL. And don't forget that diligent cleaning and maintenance are key to your equipment's longevity.

Here at The Restaurant Warehouse, we understand the demands of the foodservice industry. That's why we offer high-quality commercial restaurant food warmers and other essential equipment at affordable prices. We do this by cutting unnecessary retail overhead and hefty commissions. Our goal is to provide you with wholesale pricing so you can make the smart investments your business needs without breaking the bank.

By carefully choosing and maintaining your commercial restaurant food warmers, you're investing in better food safety, a more efficient kitchen, less food waste, and delighted customers. It's a warm welcome to better business!

Ready to make sure your kitchen is perfectly equipped for success? We invite you to Explore our complete restaurant kitchen equipment checklist.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment