Walk-In Cooler Costs: What to Expect for Your Commercial Kitchen

Why Understanding Walk-In Cooler Cost Matters for Your Business

Walk in cooler cost is one of the most important investments you'll make in your business. Whether you're launching a new restaurant, upgrading an existing space, or expanding your storage capacity, understanding what you'll actually pay—and why—can save you thousands of dollars and prevent costly mistakes.

Quick Answer: Walk-In Cooler Cost Ranges

- Small Units (6' x 6'): $5,000 - $10,000

- Medium Units (8' x 10'): $8,000 - $15,000

- Large Units (10' x 10'): $9,500 - $16,000

- Industrial Units (20' x 20'+): $25,000 - $40,000+

- Cost Per Square Foot: $100 - $150 on average

- Installation Labor: $2,000 - $7,000 additional

- Total Project Cost: Typically 20-40% more than equipment price alone

Walk-in coolers are essential for any operation that needs to keep large quantities of perishable items fresh, maximizing shelf life and maintaining food safety. But the sticker price rarely tells the whole story. The true cost includes the refrigeration unit, insulated panels, doors, flooring, electrical upgrades, site preparation, permits, and professional installation. Hidden costs like upgrading your electrical system can add thousands to your final bill.

Many business owners focus only on the cheapest upfront price, but this approach often leads to higher costs down the road. A poorly insulated or inefficient unit can drain hundreds of dollars monthly in wasted energy. I'm Sean Kearney TRW, and I've spent years helping restaurant owners steer commercial refrigeration purchases. My experience has taught me that the right investment pays for itself through efficiency and reliability.

This guide breaks down every cost factor you need to consider—from the basic equipment to installation, hidden expenses, and long-term ROI. You'll learn how size, insulation, and refrigeration systems affect pricing and how to make the smartest choice for your business.

Key Factors That Determine Walk-In Cooler Prices

When shopping for a walk-in cooler, you'll find prices vary widely. The final walk in cooler cost depends on a handful of core factors. Every walk-in includes insulated panels, a door, and a refrigeration system, but the specifics determine the price.

Size and dimensions are the most obvious factor. A compact 6' x 6' unit uses less material and a smaller refrigeration system than a 20' x 20' cooler. More square footage means more panels, more insulation, and a more powerful cooling system.

Insulation type and R-value are critical for long-term costs. The R-value measures resistance to heat transfer—higher is better. You'll typically choose between polyurethane and polystyrene panels. Polyurethane offers superior insulation, meaning your refrigeration system works less, saving you money on energy bills over time, even if the upfront cost is slightly higher.

Your refrigeration system is a major cost driver, often 30-40% of the total. You'll choose between self-contained units, where all components are housed in one box, or remote condenser units, where the noisy, heat-generating condenser sits outside. Each has pros and cons regarding kitchen heat, noise, and installation complexity.

Flooring choices also matter. Placing a cooler on an existing level concrete slab may allow you to skip an insulated floor, saving money. However, if you need the floor for insulation or structural reasons, it's an additional expense.

Finally, customization features tailor the cooler to your operation. Glass display doors, specialized shelving, durable finishes like stainless steel, and outdoor weather-proofing kits all add to the final price. Understanding these variables is key to creating a realistic budget. For a deeper dive, check out our comprehensive guide on walk-in coolers.

How Size and Customization Affect the Final Price

Bigger costs more. A small 6' x 6' unit is far less expensive than a massive 20' x 20' cooler. However, standard sizes (like 6'x6', 8'x10', or 10'x10') are your most cost-effective option. Manufacturers produce these quick-ship models in volume, keeping fabrication costs down. They generally range from $8,000 to $30,000 and arrive within 1 to 6 weeks.

If your layout is unique, a custom-built walk-in offers a perfect fit but comes at a premium, often between $10,000 and $40,000, with a longer wait of 10 to 12 weeks.

Beyond size, customization options impact your walk in cooler cost. Extra doors, glass display doors, and specific shelving types (epoxy-coated, aluminum, stainless steel) all add to the investment. Special finishes like stainless steel can add 10% to 40% to your cost but offer better durability. If you're installing your cooler outside, an outdoor weather-proofing kit is necessary and will add another 10% to 15%.

The Impact of Refrigeration Systems and Insulation

The refrigeration system is the heart of your cooler and a major factor in your utility bills. You have two main choices: self-contained units and remote condenser units.

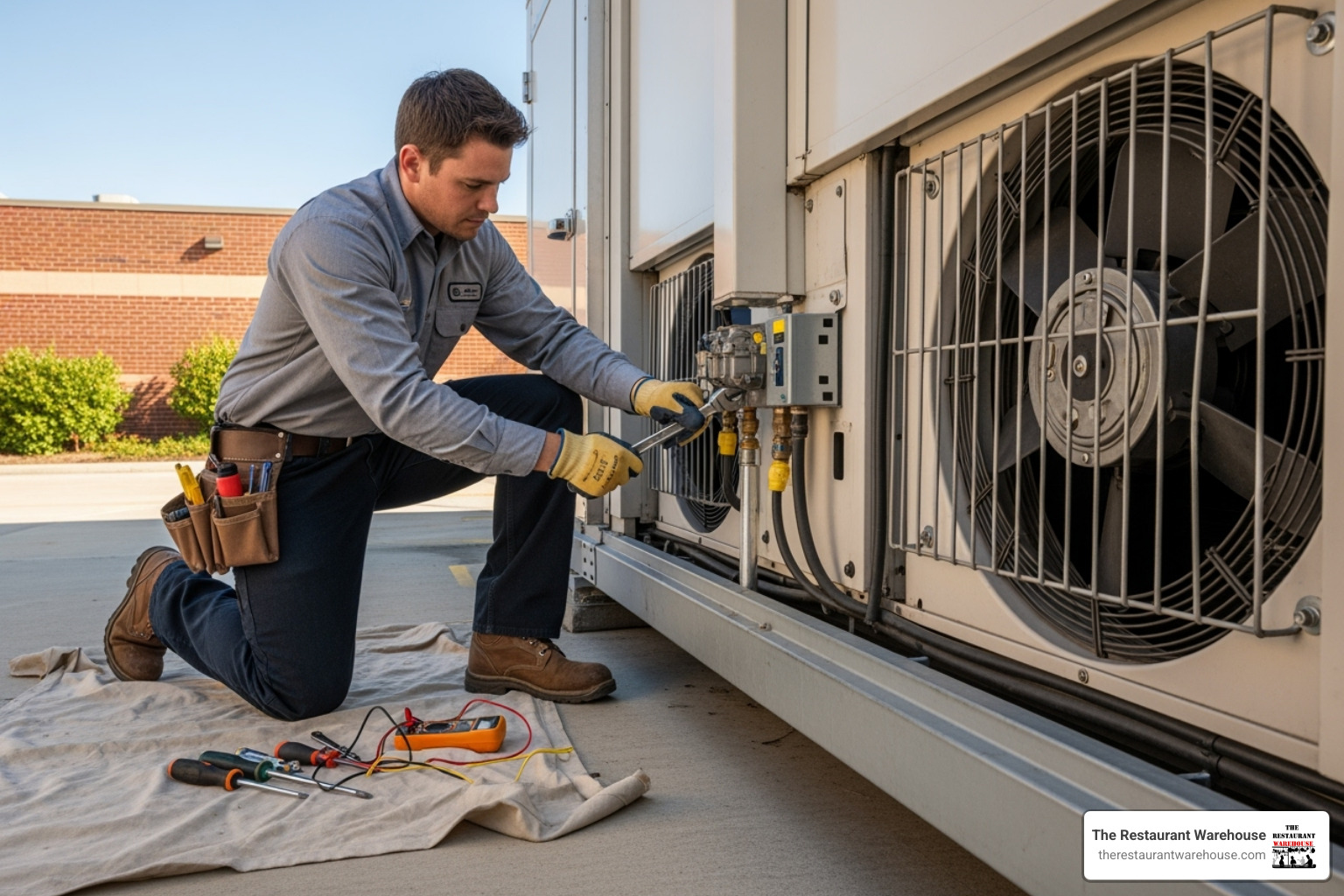

Self-contained units are simpler and cheaper to install. The entire system is in one box mounted on the cooler. The downside is that it releases heat and noise into your workspace. Remote condenser units place the hot, noisy condenser outside, keeping your work area cooler and quieter. However, they are more complex and expensive to install, requiring refrigerant lines to be run between the indoor and outdoor components.

Regardless of type, look for high Seasonal Energy Efficiency Ratio (SEER) ratings. A high-efficiency system might cost more upfront but can save you hundreds annually on your electric bill, offering significant savings over the unit's 15- to 20-year lifespan. The refrigeration unit typically represents 30% to 40% of your total walk in cooler cost, so it's not the place to cut corners.

Insulation is equally important for energy efficiency. Most walk-ins use 4-inch thick panels. For extremely hot climates or freezer applications, 6-inch panels offer superior insulation at a higher cost. The key metric is the R-value. Polyurethane panels have a higher R-value than polystyrene, making them more energy-efficient. While they may cost more initially, the energy savings over time are substantial. To optimize performance, it's also important to understand proper walk-in cooler temperature settings.

Breaking Down the Average Cost of a Walk-In Cooler

Let's talk real numbers. The walk in cooler cost involves three major components: the insulated box, the refrigeration system, and the installation labor. A complete project typically ranges from $5,000 for a small, basic unit to over $40,000 for a large, custom cooler. The total project cost, including installation and site prep, often adds 20% to 40% to the equipment price alone.

For the equipment itself, the insulated panels (walls, ceiling, and sometimes floor) make up 60% to 70% of the box material cost. The door assembly, including the frame, hinges, and latches, accounts for another 20% to 30%. The refrigeration system is a separate, significant cost, but its installation complexity is what heavily influences labor expenses.

Understanding the Average Walk in Cooler Cost by Size

Size is the most straightforward factor in your budget. Here's what to expect for different sizes, including the unit and basic installation:

- Small units (6' x 6' or 6' x 8') typically cost $5,000 to $10,000. These are great for coffee shops or small bakeries.

- Medium units (around 8' x 10') are popular for restaurants and usually run $8,000 to $13,000. This size offers a good balance of storage and footprint. Our guide to 8x10x7 walk-in units provides more detail.

- A 10' x 10' model is a workhorse size, providing 100 square feet of storage. Expect to invest $8,000 to $15,000.

- Large and industrial units (12' x 20' or larger) see costs climb significantly. A 12' x 20' unit might cost $18,000 to $27,000, while a 20' x 20' cooler can easily exceed $25,000 to $40,000.

These figures are a starting point; your specific choices will adjust the final price. For additional context on commercial refrigeration standards and energy efficiency requirements, the U.S. Department of Energy's commercial refrigeration guidelines provide valuable regulatory information that can impact your purchasing decisions.

What is the typical walk in cooler cost per square foot?

Thinking in terms of cost per square foot can be helpful for quick estimates. The complete installed walk in cooler cost typically runs between $100 and $150 per square foot. This includes the box, refrigeration system, and standard installation.

For example, a 10' x 10' unit (100 sq. ft.) would range from $10,000 to $15,000, aligning with our previous estimates. Smaller units often have a higher per-square-foot cost because fixed expenses like the door and refrigeration system are spread over less area. Customization and complex installation will also increase this metric.

While cost per square foot is a useful ballpark, always get detailed quotes that break down every component and service. Ready to get a custom quote for your specific needs? Contact The Restaurant Warehouse today for wholesale pricing and expert guidance.

Beyond the Sticker Price: Hidden Installation & Site Prep Costs

The advertised walk in cooler cost rarely includes everything. Installation, site preparation, and infrastructure upgrades often add 20% to 40% to your total project cost. I've seen owners budget $12,000 for a cooler, only to need another $5,000 for unanticipated electrical work and site prep.

A walk-in cooler isn't a plug-and-play appliance. It requires professional assembly, specialized refrigeration connections, and often significant site modifications. The complexity of your site—from delivery access to the levelness of your floor—directly impacts labor hours and your final bill.

Beyond labor, expect permit fees from $200 to over $500. Most jurisdictions require building, electrical, and mechanical permits. Skipping this step can lead to fines or removal orders. The FDA's Food Code guidelines provide essential standards for commercial refrigeration in businesses that handle food. If you're weighing different refrigeration solutions, our Commercial Refrigerators Buyer's Guide offers a complete overview.

Professional Installation Labor Costs

Professional installation is essential. You need certified HVAC/R technicians and licensed electricians. Labor costs typically range from $2,000 to $7,000 or more. This investment protects your equipment and ensures it runs efficiently.

This cost covers several critical steps:

- Assembly and Sealing: Panels must be perfectly aligned to create an airtight seal. Any gaps lead to constant energy waste and strain on the refrigeration system.

- Refrigeration Line Setup: For remote systems, technicians run and connect refrigerant lines between the indoor and outdoor units, a task requiring specialized expertise.

- Electrical Hookup: A licensed electrician must wire the unit to a dedicated circuit, meeting all local codes.

- System Testing and Calibration: Technicians charge the system, test all components, and verify temperatures to ensure peak performance.

Site conditions significantly impact these costs. Difficult access or working around existing equipment will increase labor hours. Always get a detailed quote that breaks down all included services. Ready to discuss your specific installation needs? Contact The Restaurant Warehouse today for expert guidance and a detailed quote.

Site Preparation and Structural Needs

Before your cooler arrives, your site may need significant work, adding several thousand dollars to your total walk in cooler cost. For an outdoor unit, a level concrete pad is essential for structural integrity, typically costing $1,000 to $3,000.

Adding a floor drain inside the cooler for cleaning costs $500 to $1,500 but simplifies sanitation. The biggest potential expense is electrical system upgrades. Walk-in coolers require dedicated circuits, and your existing panel may lack capacity. A simple new circuit might cost a few hundred dollars, but a full service upgrade could run several thousand, sometimes exceeding the cooler's cost. I always recommend having an electrician assess your site before you buy.

Don't forget permits and inspections. Your contractor should help steer the requirements, but you are responsible for the fees. Proper site preparation is an investment that prevents future problems, ensures efficiency, and helps you avoid costly code violations.

Long-Term Value: Operational Costs, ROI, and Lifespan

The true walk in cooler cost extends far beyond the initial purchase. The total cost of ownership (TCO) includes what it costs to run and maintain the unit year after year. An inefficient cooler is a constant drain on profits through high energy bills and spoiled inventory, while an energy-efficient unit pays you back through lower operating costs.

Operational ownership involves two main areas: monthly energy consumption and ongoing maintenance. When managed correctly, your walk-in cooler delivers a substantial return on investment (ROI) by dramatically reducing food spoilage and extending product shelf life.

Energy Consumption and Ongoing Maintenance

Your walk-in cooler runs 24/7, making its energy efficiency a major factor in your utility bills. High R-value insulation and tight door seals are your first line of defense against energy waste. When these are effective, your refrigeration system works less.

Modern, high-efficiency refrigeration systems with high SEER ratings can reduce your energy use by 10% to 20% annually compared to older systems. They cost more upfront but the savings add up quickly. Switching to LED lighting inside your cooler also cuts energy costs and reduces heat, further lessening the load on your refrigeration system.

Don't skip regular maintenance. Budget $300 to $600 per year for professional preventative service. This service should include coil cleaning, refrigerant level checks, and door seal inspections. Regular maintenance extends your unit's lifespan, controls energy costs, and ensures consistent, safe temperatures. For more details, see our Tips for walk-in cooler maintenance.

Lifespan and Return on Investment

A quality, well-maintained walk-in cooler has a typical lifespan of 15 to 20 years. This longevity spreads your initial investment across many years of reliable service.

The ROI comes from several directions. The most direct is reducing food spoilage. A reliable cooler can save thousands of dollars annually by preventing inventory loss. Energy savings are another key component. An efficient unit that saves $100-$150 per month can pay for its higher initial cost in just a few years, then continue delivering savings for its entire lifespan.

Beyond direct financial returns, a good cooler improves operational efficiency. Your staff can work faster, inventory management becomes easier, and food quality improves. Most importantly, it ensures you meet health codes and protect your business's reputation. A single food safety incident can be far more costly than the cooler itself.

Investing in a high-quality, efficient walk-in cooler is a strategic move that protects inventory, reduces operating costs, and boosts profitability. Ready to explore your options? Contact The Restaurant Warehouse today for wholesale pricing and expert guidance.

Frequently Asked Questions about Walk-in Cooler Cost

We understand that purchasing a walk-in cooler raises many questions. Here, we address some of the most common inquiries regarding walk in cooler cost.

How can I save money on a walk-in cooler purchase?

Saving money means making smart decisions to reduce both upfront and long-term costs, not just chasing the lowest sticker price. Here are four key strategies:

- Choose the Right Size: Avoid oversizing. A cooler that's too large costs more to buy and more to run. Accurately assess your storage needs to select the most efficient size for your operation.

- Opt for Energy-Efficient Models: While they may have a higher initial walk in cooler cost, high-efficiency refrigeration systems and well-insulated panels will drastically cut your monthly energy bills, leading to significant savings over the unit's 15-20 year lifespan.

- Compare Detailed Quotes: Always get several quotes from different suppliers. This allows you to compare not just the price, but also the components, warranty, and included services. The details matter when calculating the true total investment.

- Omit the Insulated Floor (When Possible): If your cooler is installed indoors on a level, ground-level concrete floor and you don't require temperatures below 38°F, omitting an insulated floor can save you 10% to 20% on the overall cost.

What are the cost implications of choosing a new walk-in cooler?

Choosing a new walk-in cooler means a higher initial walk in cooler cost, but it provides significant long-term value. The primary benefits include:

- Full Warranty Coverage: New units come with manufacturer warranties (typically 1 year for parts/labor, 5 years for the compressor), protecting your investment against unexpected early repairs.

- Modern Technology and Efficiency: New coolers feature the latest advancements in refrigeration and insulation, leading to lower operational costs from day one.

- Peak Performance and Reliability: A new unit operates at peak performance without the wear and tear or hidden issues of a used model, reducing the risk of costly downtime.

Over the unit's lifespan, the accumulated energy savings from a new, high-efficiency model can make it a more economical choice than a cheaper, inefficient used unit.

Is it better to buy a prefabricated walk-in cooler kit or attempt a DIY build?

For nearly all commercial applications, buying a prefabricated walk-in cooler kit is the superior choice. While a DIY build might seem cheaper upfront, the long-term costs and risks are significantly higher.

Prefabricated kits are precision-engineered in a factory for optimal insulation, structural integrity, and tight seals. These tight seals are critical for energy efficiency, as even tiny gaps can lead to substantial energy loss. This means your refrigeration system works less, saving you money on energy bills and reducing wear and tear. Prefab kits also come with manufacturer warranties and are designed for faster, more predictable professional installation, which can lower labor costs.

The risks of a DIY build are numerous. Achieving airtight seals is extremely difficult, leading to inefficient operation and high energy consumption. A DIY project is also more likely to have code compliance issues and safety concerns related to improper electrical or structural work. The higher total cost of ownership from increased energy bills and potential repairs almost always makes a professionally installed prefab kit the better investment. Book a strategy call with our team to explore the right walk-in solution for your operation.

Conclusion

When you're ready to make this investment, understanding the true walk in cooler cost means looking at the complete picture. The real investment encompasses the unit, refrigeration system, insulation quality, customization, and all crucial additional expenses—professional installation, site preparation, electrical upgrades, and long-term operational costs.

We've explored how factors like size and efficiency influence your upfront investment and highlighted the often-underestimated costs of labor and site prep. But the smartest investment focuses on long-term value. Prioritizing energy efficiency and committing to regular maintenance drastically reduces your monthly costs, extends the unit's 15-20 year lifespan, and minimizes product spoilage.

A walk-in cooler is a critical asset that safeguards thousands of dollars in perishable inventory. It's the backbone of your cold storage strategy and a cornerstone of your daily operations. For any serious business in the food industry, making an informed decision now—weighing the walk in cooler cost against quality and long-term value—ensures your cooler will be a reliable, cost-effective partner for decades.

Ready to find the right walk-in cooler for your budget? Contact The Restaurant Warehouse today for wholesale pricing and expert advice. We're here to help you steer every aspect of this important investment. Book a strategy call to discuss your specific needs and get a custom quote for your business, space, and budget.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment