The Cold Hard Facts: Exploring Industrial Freezers for Your Business

Why Industrial Freezers Are the Backbone of Every Successful Food Business

Industrial freezers are specialized commercial refrigeration units designed for large-scale food storage, maintaining consistent freezing temperatures under heavy use. Unlike residential models, they are built for the demands of continuous commercial operation.

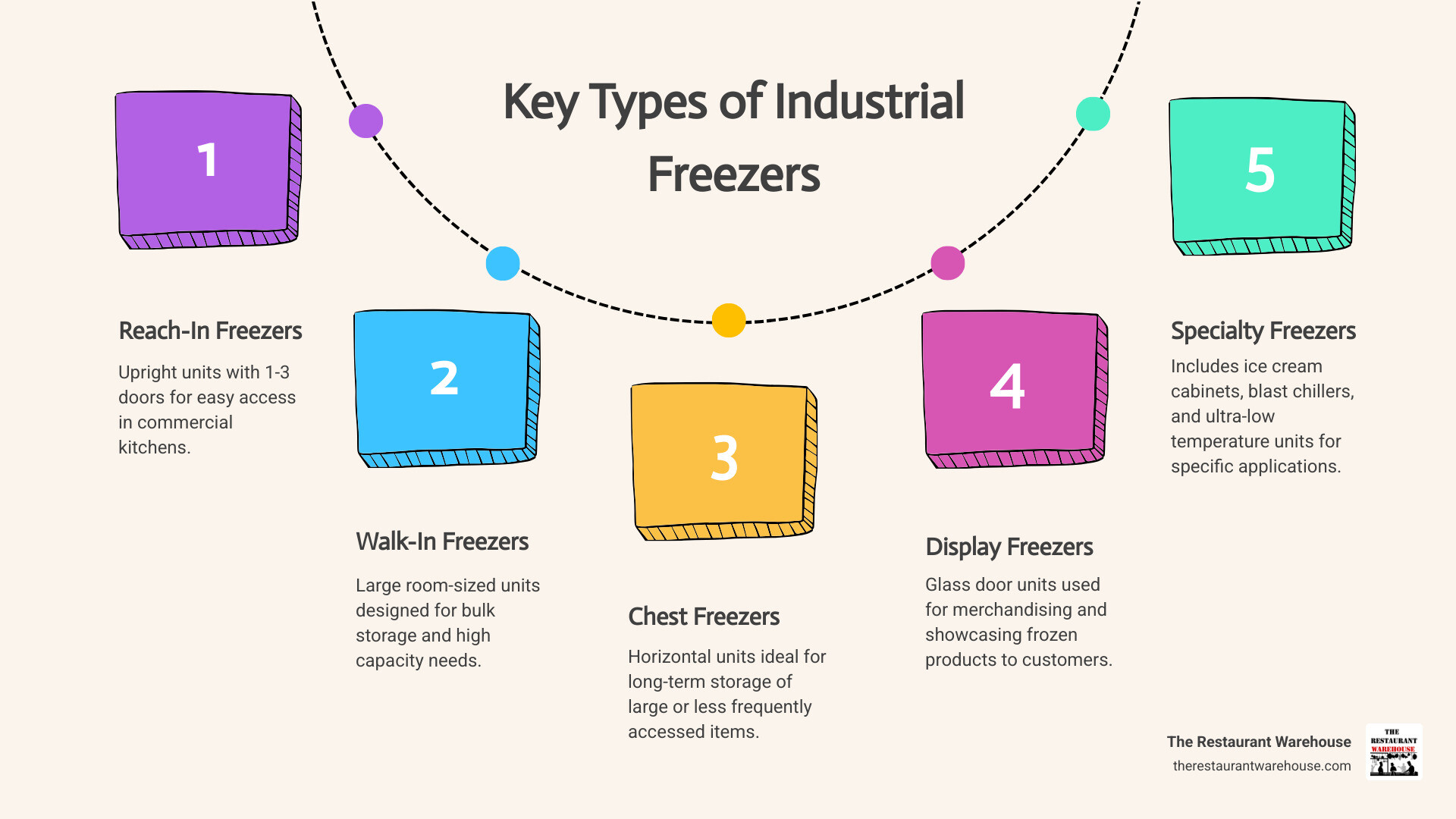

Key types of industrial freezers include:

- Reach-in freezers: Upright units for easy access.

- Walk-in freezers: Room-sized units for bulk storage.

- Chest freezers: Horizontal units for long-term storage.

- Display freezers: Glass-door units for merchandising.

- Specialty freezers: Includes ice cream cabinets, blast chillers, and ultra-low temperature units.

The global industrial freezers market reached $15.2 billion in 2022 and continues to grow, reflecting how critical this equipment is for restaurants, grocery stores, and other food businesses. Choosing the right freezer impacts food safety, storage capacity, energy costs, and workflow efficiency. The wrong choice can lead to spoiled inventory and unnecessary expenses.

This guide breaks down industrial freezers into practical advice. We'll explore the different types, essential features, and how to make a smart purchasing decision that protects your investment.

Decoding the Types of Commercial Freezers

When shopping for industrial freezers, understanding the different types helps you select the perfect unit for your business needs.

Reach-in freezers are the workhorses of most commercial kitchens. These upright units, available with one to three doors, allow staff to organize and quickly access ingredients. Their design prioritizes accessibility without sacrificing capacity, with some models offering up to 72 cubic feet of storage.

Walk-in freezers are the ideal solution for serious bulk storage. These refrigerated rooms can be customized to fit your space and often feature remote compressors to keep heat and noise out of the kitchen. Their insulated panels and specialized gaskets ensure consistent temperatures.

Chest freezers are horizontal units known for energy efficiency. Since cold air sinks, less of it escapes when the lid is opened, making them perfect for long-term storage of bulk items you don't need to access frequently. They range from compact 5 cubic foot models to larger 15 cubic foot units.

Undercounter and worktop freezers are space-savers for compact kitchens. Undercounter models fit beneath standard counters, while worktop freezers add a durable prep surface on top. These dual-purpose units are invaluable for maximizing efficiency in smaller operations.

Specialty freezers address unique business needs:

- Blast chillers rapidly cool hot foods to safe temperatures, which is crucial for preventing bacterial growth in high-volume settings.

- Ice cream dipping cabinets maintain the perfect scooping temperature while displaying flavors to customers.

- Countertop freezers are small units (4-6 cubic feet) perfect for driving impulse sales of frozen novelties near checkout areas.

- Outdoor ice merchandisers are built to withstand the elements while keeping bagged ice frozen, essential for gas stations and outdoor venues.

Upright vs. Chest Freezers: Which is Right for You?

The choice between an upright and a chest freezer depends on your daily workflow.

- Organization: Upright freezers excel with shelves and door compartments, making it easy to implement a "first-in, first-out" inventory system. Chest freezers offer a large open space, which is great for bulk items but can make finding specific products difficult.

- Accessibility: Upright models offer easy, ergonomic access. Chest freezers require more bending and reaching.

- Footprint: Upright freezers have a smaller floor footprint but require more vertical space. Chest freezers are wide and low.

- Energy Consumption: Chest freezers are generally more energy-efficient because cold air doesn't spill out when the lid is opened. However, modern uprights have improved with better insulation.

- Long-term Storage: The stable temperature environment of chest freezers makes them ideal for items you won't access daily.

| Feature | Upright Freezers | Chest Freezers |

|---|---|---|

| Capacity | Good for organized, segmented storage (e.g., 49-72 cu/ft reach-ins) | Excellent for bulk, long-term storage (e.g., 5-15 cu/ft units) |

| Footprint | Smaller horizontal, taller vertical | Larger horizontal, shorter vertical |

| Accessibility | Easy, front-facing access to all items | Requires reaching in and potentially digging |

| Energy Use | Can lose more cold air when opened; improving with technology | Generally more energy-efficient due to cold air retention |

| Cost | Often higher initial cost due to complex design | Generally lower initial cost for comparable capacity |

Glass Door vs. Solid Door: Visibility vs. Efficiency

This decision depends on whether the freezer is for customer-facing merchandising or back-of-house storage.

Glass door freezers are designed for merchandising. They allow customers to see products, which encourages impulse purchases and can turn a storage unit into a profit center. In delis and convenience stores, they also help staff and customers quickly locate items, speeding up service.

Solid door freezers prioritize insulation and energy efficiency. They are the economical choice for back-of-house storage in kitchens and prep areas where visibility is not a concern. Their superior insulation leads to better temperature stability and lower energy costs over time. For many businesses, the best strategy is to use both: glass doors for front-of-house display and solid doors for back-of-house storage.

The Ultimate Buying Checklist for Industrial Freezers

Choosing the right industrial freezer is a long-term decision that affects your daily operations, food safety, and profitability. This checklist covers the fundamentals to help you make a smart choice.

Capacity & Size

Getting the size right is critical. Too small, and you'll struggle with storage; too large, and you'll waste energy. First, assess your cubic feet needs based on your inventory volume. Then, measure your available space, including doorways, ceiling height, and floor space, ensuring you leave room for necessary ventilation clearances. Finally, consider your kitchen workflow. Place the freezer where it allows for efficient access without creating traffic jams during peak hours.

Energy Efficiency

Industrial freezers run 24/7, so energy efficiency directly impacts your operating costs. Look for the ENERGY STAR certification, which guarantees the unit meets strict efficiency standards that can save you hundreds of dollars annually. Models using natural refrigerants like R290 are more environmentally friendly and often more efficient. A slightly higher upfront cost for an energy-efficient model can pay for itself in lower utility bills over the unit's lifetime.

For more details, refer to the ENERGY STAR Commercial Food Service Equipment guidelines.

Temperature Control & Range

Precise temperature control is essential for food safety. Modern digital controllers offer precise adjustments and clear displays to monitor the internal temperature. Look for units with forced-air circulation to ensure temperature consistency and prevent hot spots. While most applications require a standard 0°F (-18°C), some businesses, like ice cream shops or labs, may need different ranges, including ultra-low temperature storage down to -85°C.

Construction & Durability

Commercial environments demand robust equipment. Stainless steel construction is the industry standard, as it resists corrosion and is easy to clean. High-quality insulation, such as high-density, CFC-free polyurethane foam, is crucial for temperature stability and energy savings. Pay attention to build quality details like heavy-duty hinges, tight-sealing magnetic door gaskets, and self-closing doors, which indicate a durable, long-lasting unit.

Common Applications for Industrial Freezers

- Restaurants and Food Service: Use solid-door reach-ins for daily prep, walk-ins for bulk storage, and undercounter units at prep stations.

- Grocery and Convenience Stores: Rely on glass-door display freezers for merchandising and driving impulse sales.

- Ice Cream Shops: Require specialized dipping cabinets that maintain the perfect temperature for scooping.

- Pharmaceutical and Laboratories: Need ultra-low temperature storage with advanced monitoring for sensitive biological samples and materials.

Key Differences Between Commercial and Residential Freezers

Understanding the gap between commercial and residential units justifies the investment in proper industrial freezers.

- Design and Durability: Commercial units are built with heavy-duty components to withstand constant use and hundreds of door openings a day.

- Performance and Power: Commercial compressors offer rapid temperature recovery after doors are opened or warm food is loaded, a capability residential units lack.

- Food Safety Standards: Commercial freezers must meet strict NSF certification for public health, which ensures they are made with safe materials and are easy to clean.

- Continuous Use: They are designed to run efficiently 24/7 for years, unlike residential models built for lighter duty cycles.

Maximizing Your Investment: Safety, Maintenance, and Innovation

Owning the right industrial freezer is just the first step. Maximizing its value involves understanding its role in food safety, performing regular maintenance, and leveraging modern innovations.

Food Preservation & Safety

Your freezer is a guardian of food safety. At the critical temperature of 0°F (-18°C), the growth of harmful bacteria is halted. This makes HACCP compliance easier, as the freezer acts as a critical control point in your food safety plan. By preventing spoilage, freezers reduce waste and protect your bottom line. Properly frozen conditions make bacterial growth virtually impossible, protecting both your customers and your business. For more information, consult the FDA's Safe Food Handling Guidelines.

Longevity

A quality industrial freezer is a long-term asset, with an expected lifespan of 10 to 20 years with proper care. Some well-maintained units can last even longer. The impact of maintenance is significant; regular attention can add years to your equipment's life, saving you thousands in premature replacement costs.

Innovations

The world of industrial freezers is constantly evolving with practical improvements that boost efficiency and simplify operations.

- Smart technology and remote monitoring allow you to receive alerts on your phone for temperature fluctuations or open doors, preventing inventory loss.

- Variable speed compressors adjust their power based on cooling needs, resulting in more consistent temperatures and lower energy bills.

- Natural refrigerants like R290 are eco-friendly and often improve energy efficiency.

- Advanced insulation and door design, such as double gaskets and high-density foam, reduce energy consumption by keeping cold air sealed in.

Maintenance Checklist for Industrial Freezers

Regular maintenance is essential for preventing costly breakdowns and extending the life of your industrial freezer.

- Coil Cleaning: Dirty condenser coils force the compressor to work harder, increasing energy use. Clean them with a brush and vacuum every 1-3 months, depending on your kitchen's environment.

- Gasket Inspection: Check rubber door seals for cracks or gaps. A poor seal lets warm air in, causing ice buildup and wasting energy. Replace worn gaskets promptly.

- Temperature Monitoring: Regularly check that your freezer maintains 0°F (-18°C). Digital displays and alarms on modern units make this easy.

- Defrosting: Even automatic defrost systems need occasional checks to prevent excessive ice buildup, which reduces efficiency and storage space.

- Professional Servicing: An annual check-up by a qualified technician can identify potential issues before they become emergencies.

Simple Weekly Maintenance Routine:

- Wipe down all surfaces.

- Check door seals for tightness.

- Verify temperature readings.

- Clear air vents of obstructions.

- Ensure food is stored with adequate air circulation.

Acquisition Strategies: New, Refurbished, and Financing

How you acquire your industrial freezer is as important as the model you choose. Understanding your purchasing options helps you make the best financial decision for your business.

New vs. Refurbished

Both new and refurbished units have their merits, depending on your budget, risk tolerance, and long-term plans.

New Industrial Freezers offer the latest in energy-efficient technology, advanced controls, and comprehensive warranty coverage—often one year for parts and labor, with up to five years for the compressor. This provides peace of mind but comes at a premium price.

Refurbished Industrial Freezers provide a significant cost-saving alternative. Reputable suppliers put these units through a rigorous reconditioning process, and many come with a limited warranty (e.g., 90 days). This is a sustainable choice that extends the life of existing equipment. The main trade-offs are potentially limited selection and shorter warranty periods.

For those who need cutting-edge features and maximum warranty protection, new is the best bet. For businesses seeking proven reliability at a lower cost, certified refurbished industrial freezers offer exceptional value.

Financing & Leasing

Financing and leasing are excellent options for acquiring quality equipment without a large upfront cash payment.

Preserving your working capital is a major benefit. By financing or leasing, you keep cash available for inventory, marketing, or other business needs. Payments are often structured on a weekly or monthly basis, making expenses predictable and manageable.

Leasing also offers potential tax advantages, as rental payments are typically 100% tax-deductible as an operating expense. This can significantly reduce the net cost of the equipment.

Rent-to-own programs provide maximum flexibility. You can use the equipment in your operation for a set period, and if you decide to purchase it, a portion of your rental payments often counts toward the purchase price. This allows you to test a unit before committing and adapt your equipment as your business evolves.

Spreading costs over time improves cash flow and preserves the reserves every business needs. At The Restaurant Warehouse, we work with customers to find financing and leasing solutions that fit their unique financial situation, from 0% financing to flexible rental programs.

Matching your acquisition strategy to your business goals is key. Whether you pay cash, finance, or lease, understanding your options allows you to make the most strategic choice.

Frequently Asked Questions

Here are answers to the most common questions business owners have about industrial freezers.

How long do commercial freezers typically last?

With proper care, a quality commercial freezer should last 10 to 20 years. Some well-maintained units can even exceed that. Build quality is a major factor, but regular maintenance is the key to achieving this long lifespan. Simple tasks like cleaning coils and inspecting gaskets can add years to your unit's life. Neglecting maintenance can lead to a much shorter lifespan of only 5-7 years.

What is the ideal temperature for a commercial freezer?

The ideal temperature for most food service applications is 0°F (-18°C) or colder. This temperature is recommended by food safety agencies like the FDA to halt the growth of harmful bacteria and preserve food quality. Modern digital controllers make it easy to set and maintain this precise temperature. Some specialized applications, such as in laboratories or for certain pharmaceuticals, require ultra-low temperature freezers that can reach -85°C.

How often should I clean my freezer's coils?

We recommend cleaning your industrial freezer's condenser coils every three months. However, if your kitchen is particularly busy, greasy, or dusty, you should clean them more frequently—perhaps even monthly. Clogged coils force the compressor to work harder, which increases energy bills and shortens the equipment's lifespan. Regular cleaning has an immediate performance impact, leading to lower energy costs and more reliable cooling.

Conclusion

Choosing the right industrial freezer is a critical investment that impacts your food safety, operational efficiency, and profitability. This guide has covered the essential factors, from selecting the right type and size to understanding the importance of energy efficiency and durability.

Whether you need an upright, chest, or walk-in model, there is a freezer designed for your specific business needs. A well-chosen industrial freezer works quietly in the background, protecting your inventory and supporting your daily workflow.

Maximizing this investment requires a commitment to maintenance. Regular coil cleaning and gasket checks will ensure your equipment serves you reliably for its full 10 to 20-year lifespan.

We've also explored how financing and leasing can make top-tier equipment accessible without straining your cash flow, allowing you to preserve capital for other areas of your business.

At The Restaurant Warehouse, our business model is built on providing quality equipment at affordable prices by cutting out retail markups. We believe you shouldn't have to compromise on quality to stay within your budget.

Our goal is to provide straight answers and real value so you can find the equipment that's right for your business. We are committed to helping you succeed with reliable equipment that fits your operational needs and financial reality.

Ready to find the industrial freezer that's right for your business? We can help you explore options that fit your needs and budget.

Explore our selection of Atosa freezers for your business needs

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment