Skin in the Game – Best Commercial Vegetable Peelers Reviewed

Why Every Commercial Kitchen Needs a Commercial Vegetable Peeler

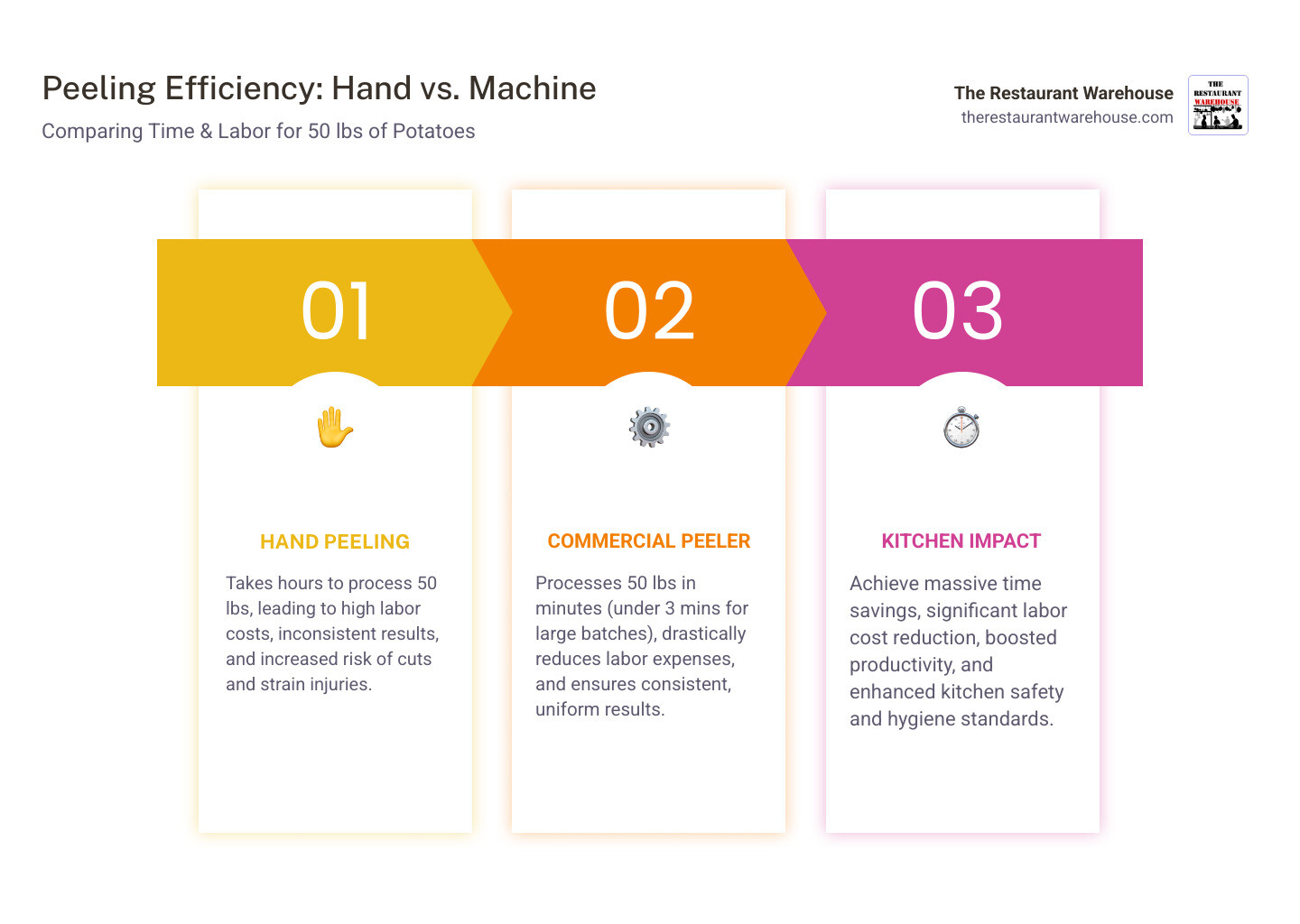

A commercial vegetable peeler is a specialized kitchen machine designed to remove the outer skin of vegetables quickly and efficiently in high-volume foodservice operations. Unlike hand peeling, these powerful machines can process large batches of produce in minutes rather than hours.

Quick Answer: Best Commercial Vegetable Peeler Options

- Abrasive Peelers: Handle 15-60 lbs of potatoes in under 3 minutes - ideal for restaurants and cafeterias

- Knife Peelers: Process up to 1,000 kg/hour with minimal waste - perfect for continuous operations

- Heavy-Duty Handheld: Professional-grade manual peelers for precision work and small batches

- Key Features: Stainless steel construction, NSF certification, easy cleaning, safety interlocks

The numbers tell the story. Research shows that commercial peelers can process up to 1,000 kg per hour of fresh products, while some models peel large batches of potatoes in under three minutes. Compare that to hand peeling, and you're looking at massive time savings.

For budget-conscious restaurant owners, this isn't just about speed. It's about labor cost reduction. When your prep cook can peel 50 pounds of potatoes in minutes instead of hours, that's real money back in your pocket.

Commercial peelers also deliver consistent results every time. No more uneven peeling or excessive waste from tired hands during the dinner rush. These machines are built for the demands of professional kitchens - from busy pizzerias to high-volume cafeterias.

The safety benefits matter too. Repetitive hand peeling leads to cuts and strain injuries. Commercial peelers eliminate these risks while maintaining the hygiene standards your operation demands.

Commercial vegetable peeler glossary:

The Core Benefits: Why Your Kitchen Can't Afford to Be Without One

When you're running a busy kitchen, every minute counts. That's exactly why a commercial vegetable peeler isn't just nice to have—it's absolutely essential for staying competitive and profitable.

Let's talk about the elephant in the room: massive time savings. Picture this: your prep cook can peel 50 pounds of potatoes in under three minutes instead of spending hours hunched over a sink with a knife. These machines can handle anywhere from 15 to 60 pounds of vegetables at once, changing what used to be your biggest prep bottleneck into a quick, efficient process.

This speed directly impacts your labor cost reduction. When your staff can complete peeling tasks in minutes rather than hours, you're looking at real money back in your pocket. Those saved labor hours add up fast, especially during busy seasons when every dollar matters.

But here's where it gets even better: increased productivity across your entire operation. With peeling handled efficiently, your skilled cooks can focus on what they do best—creating amazing dishes instead of mindlessly peeling vegetables. This means you can serve more customers during peak hours without adding extra staff.

The consistency factor is huge too. A commercial vegetable peeler delivers consistent results every single time. No more unevenly peeled potatoes or vegetables that look like they were attacked by a dull knife. This uniformity leads to better presentation and more predictable cooking times.

You'll also see higher product yield and reduced food waste. These machines are designed to remove just the skin, not chunks of the actual vegetable. That means more usable product from each batch and less money literally going into the trash.

For more ways to upgrade your kitchen efficiency, check out our guide on Pro Kitchen Tools.

Boosting Kitchen Safety and Hygiene

Safety isn't just about following rules—it's about protecting your team and your business. A commercial vegetable peeler makes your kitchen significantly safer in ways you might not expect.

First up: reduced risk of cuts. Think about how many times you've seen prep cooks nick themselves while peeling vegetables by hand. With a commercial peeler, those sharp knives stay in the drawer more often. Less hand-to-blade contact means fewer trips to the first aid kit and fewer workers' compensation claims.

The ergonomics benefits are equally important. Manual peeling puts serious strain on wrists, hands, and backs. Hour after hour of repetitive peeling motions can lead to repetitive strain injuries that sideline your best workers. Commercial peelers eliminate this risk entirely, keeping your team healthy and productive for the long haul.

From a hygiene standpoint, these machines are built with stainless steel construction—the gold standard for commercial kitchens. This material is naturally resistant to bacteria and corrosion, making it incredibly easy to sanitize. Most models feature removable parts that break down for thorough cleaning, ensuring every surface gets properly washed.

Look for NSF-certified models when shopping. This certification means the equipment meets strict public health standards for design and construction. These machines are specifically engineered to prevent food contamination and maintain the highest levels of improved food safety in your operation.

The cleaning process is straightforward too. Most commercial peelers can be cleaned with low-pressure water and food-safe sanitizers, making your end-of-day routine faster and more thorough.

For comprehensive information about creating safer work environments, the National Institute for Occupational Safety and Health (NIOSH) offers excellent resources on kitchen ergonomics.

A Guide to the Best Commercial Vegetable Peeler Types

Finding the perfect commercial vegetable peeler for your kitchen isn't a one-size-fits-all decision. Your menu, volume, and prep style all play a role in determining which type will serve you best. Think of it like choosing the right chef's knife - you need the tool that matches your specific cutting style and ingredients.

The good news? There are three main categories of commercial peelers, each designed to excel in different situations. Whether you're cranking out massive batches of French fries or delicately preparing garnishes for fine dining, there's a peeler that's perfect for your operation.

Abrasive Peelers: The High-Volume Powerhouse

When your kitchen goes through potatoes like there's no tomorrow, an abrasive peeler becomes your best friend. These machines are the workhorses of batch processing - you dump in your vegetables, hit the button, and watch the magic happen.

Picture a large rotating drum lined with silicon carbide - the same abrasive material used in sandpaper, but food-safe. As the drum spins, your potatoes tumble around inside, gently rubbing against the abrasive walls. It sounds rough, but it's surprisingly gentle and incredibly effective.

The clever part is the water jet for waste removal system. As the skins come off, water continuously flushes them away through a separate drain, keeping your machine clean and preventing any clogging issues. No more standing around scraping potato peels out of a bowl.

These powerhouses are ideal for high-volume restaurants, cafeterias, and any operation where potatoes are a daily staple. We're talking about peeling 15 to 60 pounds of potatoes in just a few minutes. That's the kind of efficiency that can transform your prep routine.

Knife Peelers: For Maximum Yield and Precision

If waste reduction is your priority - and let's face it, it should be - then knife peelers are where you want to focus your attention. These precision machines use continuous feed systems that process vegetables one at a time, giving you maximum control over the peeling process.

The secret is in the stationary blades that shave off just the thinnest layer of skin. While abrasive peelers remove skin through friction, knife peelers use surgical precision to remove only what's necessary. This means significantly less waste than abrasive models and more usable product from every batch.

The trade-off? You'll face a higher initial cost due to the precision engineering involved. But for operations processing large volumes of carrots, cucumbers, or other long vegetables, the waste savings can pay for the machine quickly. This is why knife peelers are the best choice for produce wholesalers and any operation where maximizing yield is crucial.

Heavy-Duty Handheld Peelers: Essential for Every Prep Station

Don't let the word "handheld" fool you - these aren't the flimsy peelers you'd find in a home kitchen. Heavy-duty commercial handheld peelers are built to withstand the demands of professional kitchens, and they're absolutely essential for tasks that require a human touch.

You'll typically choose between Y-peelers (where the blade sits perpendicular to the handle) and straight peelers (with the blade running parallel). Many feature serrated blades for tackling softer fruits or vegetables with delicate skins. The best models come with ergonomic grips designed to reduce hand fatigue during extended use.

These manual tools shine when you're working with small batches or delicate produce that might get damaged in a machine. They're perfect for creating intricate garnishes or adding those finishing touches that lift a dish from good to great. Every prep station should have a few high-quality handheld peelers within arm's reach.

For a complete rundown of essential manual tools, check out our guide on Must-Have Kitchen Utensils.

Abrasive vs. Knife Peelers: A Quick Comparison

| Feature | Abrasive Peeler | Knife Peeler |

|---|---|---|

| Best For | Root Vegetables (Potatoes, Turnips) | Long Vegetables (Carrots, Cucumbers) |

| Speed | Very Fast (Batches in minutes) | Fast (Continuous feed) |

| Yield | Good (Slightly more waste) | Excellent (Minimal waste) |

| Mechanism | Abrasion | Cutting Blades |

How to Choose the Right Machine for Your Menu

Picking the perfect commercial vegetable peeler isn't about going for the biggest, flashiest model on the market. It's about finding the sweet spot between your kitchen's actual needs and your budget. Think of it as matchmaking for your prep station.

Start by taking a hard look at your menu. Are you serving hundreds of french fries daily? Then you'll need serious potato-peeling power. Running a farm-to-table restaurant with delicate root vegetables? You might need something more precise. Your menu analysis should include not just what you're peeling, but how much and how often.

Daily volume is your next reality check. Track how many pounds of vegetables you're currently peeling by hand during your busiest days. This gives you a baseline for what your machine needs to handle. Don't forget to factor in growth - if business is booming, you might want to size up slightly.

Kitchen space is often the forgotten factor until delivery day. Measure your prep area carefully. A massive floor-standing peeler won't help if it blocks your workflow or doesn't fit through the door. Sometimes a countertop model that integrates seamlessly with your existing setup is the smarter choice.

For more insights on optimizing your prep workflow, check out our Restaurant Prep Table Guide.

Understanding Capacity and Throughput

Here's where the rubber meets the road. Capacity and throughput determine whether your commercial vegetable peeler will be a kitchen hero or a expensive paperweight.

Batch size tells you how much the machine can handle at once. Small operations might thrive with a 15-20 lb capacity unit, while busy cafeterias need the muscle of 50-60+ lb monsters. Some industrial models can process an incredible 1,000 kg per hour - that's serious vegetable-peeling firepower.

The key is matching machine to output without creating bottlenecks. Picture your busiest prep time. If your team is waiting around for the peeler to finish while other tasks pile up, you've got a problem. On the flip side, buying a machine that's way too powerful for your needs means you're paying for capacity you'll never use.

Think about your pounds per hour requirements during peak times. A machine that handles your average day beautifully might buckle under holiday rush pressure. It's better to have a little extra capacity than to find your limitations when you're slammed.

Key features of a commercial vegetable peeler

Not all peelers are created equal, and the devil's in the details. Motor power measured in horsepower (HP) ranges from 1/3 HP for smaller units to 1 HP for heavy-duty workhorses. More power means consistent performance even when you're pushing the machine hard.

Stainless steel construction isn't just about looking professional - it's about survival in a commercial kitchen. These machines face constant moisture, cleaning chemicals, and daily abuse. Stainless steel laughs at corrosion and cleans up beautifully.

Durability should be non-negotiable. You're making an investment that needs to pay off over years, not months. Look for robust construction and quality materials that can handle the daily grind of commercial service.

Ease of cleaning can make or break your relationship with any kitchen equipment. The best peelers feature removable parts that come apart quickly for thorough cleaning. Some components are even dishwasher safe, making your closing routine much smoother.

Smart features like built-in timers give you precise control over peeling duration, ensuring consistent results every time. Safety interlocks prevent the machine from running unless all guards are properly in place - a crucial feature that protects your team from accidents.

Don't overlook the water inlet/outlet configuration. A well-designed system efficiently flushes away peeled skins while connecting seamlessly to your existing plumbing. Rear-mounted water inlets often work better for tight spaces and workflow optimization.

Maintenance needs for your commercial vegetable peeler

Let's be honest - maintenance isn't the fun part of equipment ownership, but it's what separates a great investment from an expensive headache. Your commercial vegetable peeler needs regular attention to keep performing at its best.

Daily cleaning procedures become part of your closing routine. After each use, disassemble removable parts like silicon carbide disks and liners, flush the system thoroughly, and sanitize with food-safe cleaners. It sounds tedious, but it becomes second nature quickly.

Sanitation goes beyond just looking clean. Any food residue left behind becomes a breeding ground for bacteria, which can shut down your operation faster than a broken freezer. Thorough cleaning protects both your customers and your reputation.

Depending on your peeler type, you'll need to budget for replacing abrasive liners as they wear down or sharpening or replacing blades on knife peelers. These aren't emergency repairs - they're predictable maintenance that keeps your machine running efficiently.

Motor care is surprisingly simple but often overlooked. Listen for unusual noises or vibrations that might signal problems. Catching issues early prevents expensive breakdowns during your busiest times.

The long-term value of proper maintenance can't be overstated. A well-maintained peeler can serve your kitchen for years, while neglect turns even the best equipment into scrap metal. It's a small daily investment that pays huge dividends.

For smart strategies on kitchen equipment investments, explore our guide on Affordable Kitchen Essentials: Finding Quality Used Food Prep Equipment.

Frequently Asked Questions about Commercial Peelers

When it comes to commercial vegetable peelers, we hear the same questions time and again from restaurant owners and kitchen managers. Let's explore the most common concerns and give you the straight answers you need to make smart decisions for your kitchen.

How much food waste does a commercial peeler create?

This is probably the biggest concern we hear, and rightfully so. Every bit of wasted produce hits your bottom line directly. The good news? The amount of waste depends heavily on which type of commercial vegetable peeler you choose and how you operate it.

Abrasive peelers do create slightly more waste than their knife counterparts. The tumbling action against the silicon carbide walls can remove a bit more flesh along with the skin. Think of it like using sandpaper - it's thorough, but not surgical. Our comparison shows these machines deliver "good" yield with "slightly more waste."

Knife peelers are the precision champions here. They shave off just the thinnest layer possible, giving you "excellent" yield with "minimal waste." It's like having a skilled prep cook who never gets tired or makes mistakes.

Here's the key: proper operation makes all the difference. Over-peeling happens when vegetables tumble too long in abrasive machines. Many modern peelers include water jets that instantly flush away skins, preventing this over-processing. Some machines even offer a gentler polishing mode that cleans the outer layer without full peeling, perfect for reducing waste while maintaining that fresh appearance.

Can I peel vegetables other than potatoes?

Absolutely! While potatoes might be the star of the show, commercial vegetable peelers are surprisingly versatile workhorses. Most abrasive models handle almost any spherical root vegetable beautifully - think beets, turnips, and parsnips. The key is that round, tumbling action works best with similarly shaped produce.

Knife peelers really shine with longer vegetables like carrots and cucumbers. They're also fantastic for fruits - apples and even pineapples process beautifully through these machines. The continuous feed system handles these elongated items with precision that abrasive peelers simply can't match.

Different models have different strengths, so it's worth checking the manufacturer's specifications for your specific needs. Some specialized peelers are designed specifically for certain produce types, maximizing efficiency for high-volume operations focused on particular ingredients.

What are the cleaning and sanitation requirements?

Keeping your commercial vegetable peeler spotless isn't just about following health codes - it's about protecting your investment and ensuring consistent performance. The cleaning process is actually more straightforward than many kitchen managers expect.

Daily breakdown should become second nature. Most quality peelers feature removable parts like abrasive disks, liners, and catch trays that come apart easily. These components wash in warm, soapy water, rinse clean, and sanitize with food-safe sanitizers. Many parts are even dishwasher safe, making the process even simpler.

The machine interior needs thorough flushing with water. Those built-in water jet systems that help remove skins during operation? They're your best friend during cleanup too. The key is ensuring no residue gets left behind in crevices or connection points where bacteria could hide.

NSF-certified models are designed with cleaning in mind. They meet strict public health standards for materials and construction, which means easier sanitation and better food safety compliance. The waste disposal systems, often featuring separate filters, prevent buildup that could create hygiene problems down the line.

Regular, thorough cleaning doesn't just keep inspectors happy - it keeps your peeler running efficiently and extends its lifespan significantly.

Conclusion: Boost Your Kitchen's Prep Power with the Right Tools

After diving deep into commercial vegetable peelers, one thing becomes crystal clear: these machines aren't just nice-to-have gadgets. They're game-changers that can completely transform how your kitchen operates.

Think about it - when you can peel 50 pounds of potatoes in minutes instead of hours, you're not just saving time. You're freeing up your talented staff to focus on what they do best: creating amazing dishes that keep customers coming back. That prep cook who used to spend half their shift hunched over a pile of vegetables? Now they can tackle more complex tasks that actually add value to your menu.

The safety benefits alone make these machines worth considering. We've all seen the nicks and cuts that come from repetitive peeling work. With a commercial vegetable peeler, those risks practically disappear. Your team stays healthier, and you avoid the headaches that come with workplace injuries.

But here's what really gets us excited: the consistency these machines deliver. Every potato comes out perfectly peeled, every carrot looks uniform, and your food waste drops dramatically. When you're running a tight operation, that kind of reliability is priceless.

Whether your kitchen would benefit most from a high-volume abrasive peeler for those mountain-sized potato orders, a precision knife peeler for delicate produce work, or simply upgrading your handheld peelers for finishing touches, the right choice depends on your specific needs. Look for features like stainless steel construction, easy cleaning capabilities, and proper safety interlocks - these details matter when you're investing in equipment that needs to perform day after day.

The bottom line? A commercial vegetable peeler represents smart money spent for any kitchen serious about efficiency and quality. At The Restaurant Warehouse, we understand that every dollar counts in this business. That's why we provide top-quality equipment at wholesale prices, helping you maximize your return on investment without the markup you'd find elsewhere.

Ready to take your prep game to the next level? Explore our complete Commercial Kitchen Equipment Guide and find all the tools that can help your kitchen run like a well-oiled machine.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment