Reducing Food Waste in Restaurants: Practical Tips

Reducing food waste in your restaurant is about so much more than just throwing away less food—it's a direct line to slashing operational costs and seriously boosting your profitability. When you start looking at the hidden expenses like wasted labor, energy, and disposal fees, you can turn what was a major financial drain into a huge opportunity for efficiency.

The Real Cost of Food Waste in Your Kitchen

Let’s be honest, food waste is a silent profit killer. Many operators only see the cost of the ingredients they discard, but the true financial hit goes way deeper than that. Every pound of food you toss carries a whole bundle of invisible costs that can quietly eat away at your bottom line.

Think about a single case of tomatoes that goes bad before you can use it. You've lost the initial purchase price, sure, but that’s just the start. You also paid an employee to receive it, store it, and eventually haul it to the dumpster. Then there are the energy costs to keep it refrigerated and the fees you pay for waste disposal.

Suddenly, that one box of spoiled tomatoes represents a much bigger financial loss. These small, daily losses snowball fast, turning into a significant annual deficit that chips away at your margins.

Beyond The Bin: Uncovering Hidden Costs

The financial drain from food waste extends far beyond what you see in the trash can. To really get the full picture, you have to consider all these interconnected expenses that often fly under the radar:

- Wasted Labor: Time your staff spends prepping food that never gets sold is time they could have spent on tasks that actually generate revenue.

- Inflated Utility Bills: Your refrigerators and cooking equipment burn energy for every single ingredient, whether it ends up on a plate or in the bin. Wasted food equals wasted electricity and gas.

- Disposal Fees: The more you throw away, the more you pay for waste hauling. For many restaurants, this can be a surprisingly high operational cost.

- Missed Opportunity: Every spoiled ingredient is a missed chance to create a profitable dish and make a customer happy.

The scale of this issue is massive. In the United States, foodservice is responsible for a huge chunk of food surplus. Full-service restaurants alone generated about 5.76 million tons of waste in 2023, part of a national problem that costs hundreds of billions of dollars. You can dig into more food waste statistics over at ReFED.org.

The real challenge isn't just seeing the waste, but understanding its full story. It’s the story of over-ordering, inefficient prep, and untapped potential. Addressing it head-on is one of the most effective ways to improve operational efficiency.

Shifting Your Perspective on Waste

The first step toward real change is to stop seeing food waste as an unavoidable cost and start seeing it as a massive opportunity. It’s not just part of doing business; it's a key performance indicator for the health of your kitchen.

Beyond your daily practices, keeping your kitchen equipment in top shape can make a huge difference. A malfunctioning walk-in cooler, for instance, can lead to catastrophic spoilage literally overnight. Understanding how regular refrigeration maintenance can prevent major food loss is crucial for any operator looking to cut down on spoilage and protect their inventory.

By focusing on reducing food waste, you not only improve your bottom line but also build a brand that customers can admire. In an era where diners are more eco-conscious than ever, a real commitment to sustainability can be a powerful marketing tool. And, of course, this journey also involves impeccable kitchen hygiene, which helps prevent spoilage from cross-contamination, as we cover in our guide on commercial kitchen cleaning tips.

How to Run a Practical Food Waste Audit

Let’s be honest: you can't manage what you don't measure. Before you can get serious about cutting down on food waste, you need a crystal-clear picture of what's being tossed, where it’s coming from, and—most importantly—why. A food waste audit is the first step, and it turns pure guesswork into a real, data-driven strategy. The best part? You don’t need any fancy, expensive tech to get started.

The goal here is simple: make the invisible visible. A good audit tracks and categorizes waste across three key areas, giving you the full story of your kitchen’s operations. This process will quickly shine a spotlight on costly patterns you might not have even known were there.

Setting Up Your Manual Audit System

To kick things off, you just need a few basic tools and a straightforward system. The key to making this work is consistency. Dedicate a specific period for your audit—a full week is ideal because it gives you a look at everything, from the crazy busy weekend rushes to the slower weekdays.

You'll want to set up separate, clearly labeled bins for each waste category. This physical separation is the secret sauce for accurate tracking and helps get your team into the habit of sorting waste properly from the get-go.

- Bin 1: Storage Spoilage: This is for any ingredient that spoils before it ever gets a chance to be used. Think produce that’s wilted in the walk-in, dairy that’s past its date, or meat that’s gone bad.

- Bin 2: Prep Trimmings: This bin is for all the scraps generated during food preparation. We’re talking vegetable peels, meat and fish trimmings, and anything else that doesn't make it past the prep line.

- Bin 3: Plate Waste: This bin is for all the food that comes back uneaten from the dining room. It’s a direct signal about your portion sizes, how much a dish is resonating with customers, and overall satisfaction.

Next to these bins, you'll want a simple daily log sheet. Just a clipboard with a spreadsheet printout near the waste station will do the trick. This log is where the magic happens, turning what was once just trash into incredibly valuable data. This simple act of tracking can help slash your food costs by 2% to 6% just by making everyone more aware.

The most powerful insights come from understanding the "why" behind the waste. Was the fish overcooked? Did the supplier send bruised avocados again? An audit without context is just a number.

Collecting and Analyzing the Data

With your bins and log sheets ready, it's time to get your kitchen and service staff on board. Make it clear that this isn't about pointing fingers; it’s a team effort to make the business stronger and more efficient. The process should be dead simple: when something gets thrown out, it gets sorted into the right bin and noted on the log.

A good log sheet doesn’t need to be complicated, but it should capture a few key details for each item. If you’re not sure where to start, a simple manual tracking log is a great first step.

Here's a template for a Daily Food Waste Audit Log you can use to identify problem areas.

| Item/Dish | Waste Type (Spoilage, Prep, Plate) | Weight/Volume (Approx.) | Reason for Waste | Estimated Cost |

|---|---|---|---|---|

| Romaine Lettuce | Spoilage | 1 case | Browned before use | $25.00 |

| Salmon Filet Trimmings | Prep | 2 lbs | Standard prep | $18.00 |

| Burger & Fries | Plate | 1/2 portion | "Too much food" | $7.50 |

| Chicken Breast | Spoilage | 5 lbs | Over-ordered for special | $15.00 |

| Onion Peels/Ends | Prep | 3 lbs | Standard prep | $2.00 |

After your audit period is over, sit down with your team and go over the logs. You’ll be surprised how quickly patterns start to jump out. Maybe you’re consistently tossing a specific vegetable because of over-ordering, or one particular menu item comes back half-eaten more often than not. These aren't problems—they're opportunities.

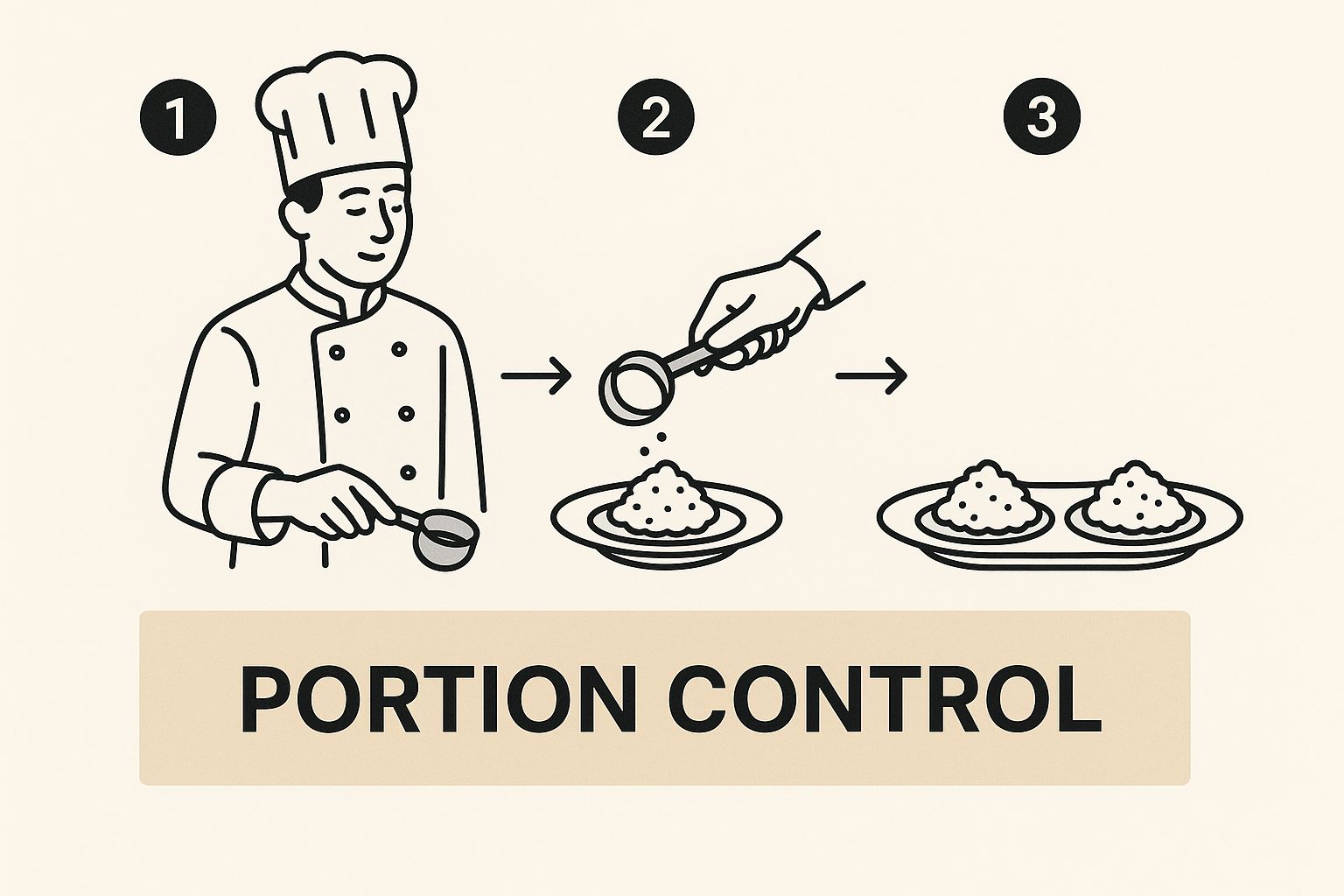

This visual shows how getting your portioning right, a direct result of insights from an audit, can immediately cut down on plate waste.

The image drives home a core principle: controlling what actually goes onto the plate is one of the most powerful ways to stop waste before it even happens.

For example, if plate waste for your signature steak dish is always high, that's a clear sign to maybe rethink the portion size of the sides. If you’re constantly seeing fresh herbs in the spoilage bin, it might be time to find a supplier who can do smaller, more frequent deliveries. This initial audit gives you the roadmap for every single waste-reduction strategy you'll use from here on out.

Smarter Purchasing and Inventory Control

Preventing food waste doesn’t begin at the prep station or the pass—it starts the moment you place an order with your supplier. Think about it: proactive purchasing and disciplined inventory control are the absolute foundation of any real strategy for reducing food waste in restaurants. When you treat your storeroom with the same precision as your hotline, you can turn what is often a major source of loss into a driver of profitability.

This is about more than just buying less; it’s about buying smarter. When you align your purchasing decisions directly with your actual sales data, you stop guessing. That guesswork is exactly what leads to overstocked shelves and spoiled ingredients. It’s a shift from just-in-case ordering to a predictive, data-informed approach.

The financial stakes are surprisingly high. Industry-wide reports show that between 4% and 10% of all food purchased by restaurants never even makes it to a customer's plate. A huge chunk of that waste happens before a single dish is cooked, all thanks to overproduction and messy inventory management. For a deeper look at the numbers, check out these insights on food waste from industry experts.

Mastering the First-In, First-Out Method

One of the most effective—and frankly, simplest—inventory strategies is the First-In, First-Out (FIFO) method. The concept is easy: older stock gets used before newer stock. While most kitchens know the principle, strict execution is what separates the pros from the amateurs.

To make FIFO work, your team has to treat it as a non-negotiable part of daily operations. Every new delivery is immediately dated and placed behind existing products on the shelf. This system forces a natural rotation of ingredients, minimizing the chances of finding something expired in a dark corner of your walk-in.

- Label Everything Clearly: Use a simple, consistent labeling system with delivery dates or use-by dates front and center.

- Organize Your Storage: Designate specific areas for different food categories. Make sure shelves are never so crowded you can't see what's hiding in the back.

- Train Consistently: Make FIFO a core part of your onboarding for everyone, from porters to line cooks. It has to become muscle memory.

Set Par Levels Based on Real Data

Setting accurate par levels—the minimum amount of an item you need on hand—is crucial for avoiding over-ordering. Too many restaurants set these levels based on gut feelings or old sales figures, which is a recipe for waste. Your POS system is a goldmine of data that can make this process way more precise.

Dig into your sales reports. See exactly how much of each ingredient you use on different days of the week or during certain seasons. If you sell an average of 20 salmon filets every Friday, your par level should reflect that, with just a small buffer for an unexpected rush. This data-driven approach stops you from overbuying specialty items that just sit on the shelf and spoil.

A well-managed storeroom is a direct reflection of a well-managed kitchen. When inventory is tight, organized, and aligned with sales, your team becomes more creative and your food costs drop.

Work With Suppliers for Greater Flexibility

Building strong relationships with your suppliers can play a huge role here. Instead of locking yourself into large, infrequent orders just to get a slight discount, see if you can arrange smaller, more frequent deliveries. The per-unit cost might be a tiny bit higher, but the savings you’ll gain by eliminating spoilage will almost always win out.

For example, a restaurant might order a month's worth of a specialty cheese to save 5% but end up throwing away 20% of it. A much better approach? Arrange twice-weekly deliveries for that item. You get maximum freshness and minimal waste. Many suppliers are willing to be flexible for reliable partners. This strategy keeps your inventory lean and your cash flow healthier. For a deeper dive into sourcing, check out our comprehensive restaurant supply guide to learn more about optimizing your procurement process.

Designing a Waste-Efficient Menu and Kitchen

Your menu is so much more than a list of dishes—it’s the single most powerful tool you have for slashing food waste. Every single ingredient that comes through your kitchen doors should have a clear purpose, and a thoughtfully designed menu makes sure it does. With some strategic menu engineering and a few clever prep techniques, you can transform your kitchen from a source of waste into a model of efficiency.

This whole process starts with a shift in mindset. It’s about teaching your entire kitchen crew to see the full potential and value in every part of every ingredient. From the moment an item is prepped to the way it’s presented on the plate, every step is an opportunity to minimize waste and maximize flavor.

Embrace Root-to-Stem and Nose-to-Tail Cooking

The concepts of root-to-stem (for vegetables) and nose-to-tail (for proteins) aren't just trendy buzzwords; they're foundational principles for any waste-conscious kitchen. This approach challenges your team to find creative, delicious uses for parts of ingredients that usually end up in the bin.

Just think about the piles of vegetable trimmings your kitchen generates every day. Instead of getting tossed, those scraps can become the foundation for rich, flavorful stocks and broths that elevate your entire menu.

- Vegetable Scraps: Onion peels, carrot ends, celery tops, and mushroom stems can all be simmered into a versatile vegetable stock.

- Herb Stems: Those parsley and cilantro stems that are often discarded can be blended into vibrant pestos, marinades, or infused oils.

- Meat and Fish Trimmings: Bones and less-desirable cuts can be used for incredible stocks, sauces, or even ground for specialty dishes like sausages or terrines.

This philosophy doesn't just cut down on waste; it adds an incredible depth of flavor to your dishes at virtually no extra cost. When you use the whole ingredient, you’re extracting every last bit of value from your food purchases.

The most creative kitchens are often the most resourceful. Viewing every scrap as a potential ingredient, rather than trash, unlocks new flavors and drastically cuts down on your food costs.

Engineer Your Menu for Maximum Ingredient Overlap

A truly smart menu is one where ingredients are cross-utilized across multiple dishes. This is a cornerstone of efficient menu design because it ensures your inventory moves quickly and consistently, minimizing the chances of spoilage. When you build your menu around a core group of versatile ingredients, you simplify purchasing and cut down on the need to stock specialty items that might go unused.

For instance, a kitchen that brings in fresh basil can feature it in a caprese salad, blend it into a pesto for a pasta dish, and muddle it for a signature cocktail. This ensures the entire case of basil gets used up promptly. Look for opportunities to create this kind of synergy across your entire menu.

Standardize Portions and Recipes

Inconsistency is a massive driver of both food waste and unhappy customers. Standardized recipes and strict portion control are non-negotiable for eliminating guesswork and making sure every dish that leaves the kitchen is consistent in size, quality, and cost. When line cooks are left to eyeball portion sizes, the result is often overly large servings that contribute directly to plate waste.

Put these simple but incredibly effective tools in place:

- Portioning Tools: Use specific scoops, ladles, and scales for every single component of a dish.

- Recipe Cards: Provide clear, visual recipe cards with exact measurements at every station.

- Regular Training: Consistently train your team on portioning standards until it becomes second nature.

This level of precision not only slashes plate waste but also gives you predictable food costs, which is absolutely critical for managing your bottom line.

Use Daily Specials to Your Advantage

Daily or weekly specials are the perfect outlet for using up ingredients that are nearing their peak freshness. This is your kitchen’s safety valve, allowing you to move product proactively before it turns into waste. Train your chefs to check inventory every single day and build specials around items that need to be used up.

A special doesn't have to be complicated. It can be as simple as a "market fish" feature using the freshest catch or a unique soup created from surplus vegetables. This approach not only keeps your menu exciting for regular customers but also serves as a practical, profit-generating tool for managing inventory and reducing even more food waste.

Give Surplus Food a Second Life

Let's be realistic. Even with the sharpest inventory management and a perfectly engineered menu, some surplus food is just unavoidable. But that doesn't mean it has to end up in the bin. The final, and arguably most important, step in a smart waste strategy is giving that food a second life. This isn't just about doing the right thing—it’s about strengthening your restaurant's place in the community and even unlocking new revenue.

The impact of this goes way beyond your kitchen walls. Globally, food loss and waste are responsible for a shocking 8–10% of the world’s annual greenhouse gas emissions. That's a figure nearly five times higher than the entire aviation industry. By finding a better home for your surplus, you’re taking real action against a massive contributor to climate change.

Creative Repurposing in the Kitchen

Before you look outward, see what can be transformed right inside your own four walls. This is where your culinary team's creativity can really shine, turning potential waste into profitable menu items. It’s all about shifting your perspective and viewing every ingredient as a valuable asset.

- Stale Bread: Yesterday's loaves are the foundation for tomorrow's signature croutons, a rich bread pudding, or the perfect base for a panzanella salad.

- Overripe Fruit: Don't toss that fruit just because it's a little soft. Cook it down into incredible house-made jams, vibrant syrups for your cocktail program, or flavorful compotes to top desserts.

- Vegetable Trimmings: We’ve already talked about using these for stocks, but you can also dehydrate them and grind them into unique vegetable powders for seasoning meat or finishing plates.

This approach costs next to nothing and adds those authentic, from-scratch elements to your menu that guests truly notice and appreciate.

Building a Food Donation Partnership

When you have perfectly good, wholesome food that you simply can't use, donation is the best next step. Partnering with a local food bank, shelter, or community charity is a powerful way to support those in need and make sure good food nourishes people, not landfills.

A lot of owners I talk to worry about liability when donating food. The Bill Emerson Good Samaritan Food Donation Act provides federal protection against civil and criminal liability for businesses that donate food in good faith to non-profits.

Setting up a donation program that works is pretty straightforward.

First, find a local partner. Reach out to food rescue organizations in your area; many will even arrange for regular pickups, making the whole process incredibly simple for your team.

Next, establish clear guidelines with them. Work together to understand exactly what they can and cannot accept. This usually includes any unserved food that has been properly stored and handled safely from the get-go.

Finally, create a simple internal process. Designate a specific spot in your walk-in for donated items and make a simple log sheet. Train your staff on the right procedures for handling and packing to maintain food safety during transport. A key part of this includes making sure any transport containers are spotless, a topic we cover in our restaurant dishwasher guide.

Donating surplus food does more than just fight food insecurity—it’s a huge boost for team morale and your restaurant's public image. To invest even further in these practices, you can also look into funding opportunities like grants for waste prevention. These actions show a real commitment to being a responsible community partner, building a brand that both your employees and customers can be proud of.

Got Questions About Restaurant Food Waste? We’ve Got Answers.

Jumping into a waste reduction plan is a great move, but it almost always brings up a few practical questions. You get the “why,” but what about the day-to-day realities of making it happen?

Let's cut through the noise and get straight to the answers you need to start tackling food waste with confidence.

Where Should I Start If I Have a Limited Budget?

Starting a food waste program doesn't have to hit your wallet hard. In fact, some of the most powerful first steps cost nothing more than a bit of time and attention. The best place to begin is with a simple, low-tech food waste audit.

Grab a few bins and label them for spoilage, prep waste, and plate waste. For one full week, use a clipboard and a log sheet to track what’s getting tossed, how much, and why. This manual audit costs next to nothing but gives you invaluable data on where your biggest problems are. Once you see the patterns, you can focus on training your staff in smarter prep techniques and enforcing a strict FIFO (First-In, First-Out) inventory system.

These foundational steps require zero financial investment but can deliver immediate insights and savings.

How Do I Get My Staff to Care About Food Waste?

Getting your team on board is everything, and it all starts with how you frame it. This isn't about pointing fingers; it's about working together to make the restaurant stronger and more successful. When the business does better, it creates a more stable work environment and more opportunities for everyone.

Kick things off with some honest communication. In a team meeting, explain the financial impact of food waste in terms your staff can relate to—like how many dollars worth of profit is literally going into the trash each week.

- Make It a Team Goal: Set a clear, achievable target, like, "Let's cut our weekly food waste by 15%." When you hit it, celebrate! A small bonus or a team pizza party can go a long way.

- Ask for Their Ideas: Your line cooks and servers see the waste up close every single day. They often have brilliant, practical suggestions for improvements, so make them part of the solution.

- Lead by Example: If your team sees you and your managers diligently sorting waste and finding creative uses for scraps, that behavior will become the new standard.

A culture of resourcefulness isn't built overnight. It’s the result of consistent training, positive reinforcement, and making everyone feel like a valued partner in the restaurant's success.

Can We Legally Donate Leftover Food?

Yes, you absolutely can. This is a common worry, but federal law provides strong liability protection for businesses that donate food in good faith. The Bill Emerson Good Samaritan Food Donation Act, passed back in 1996, was created specifically to encourage food donation.

This act protects you from both civil and criminal liability if someone were to get sick from donated food, as long as it was donated in good faith to a non-profit organization. The key is to follow standard food safety practices when handling and storing the food you plan to donate. The best first step is to partner with a reputable local food bank or shelter; they'll have clear guidelines on what they can accept and how it needs to be packaged.

Is Investing in Waste-Tracking Technology Worth It?

For many restaurants, tech can be a game-changer, but it’s not a mandatory first step. A manual audit is a fantastic way to get started, but technology automates the process and can uncover much deeper insights.

Modern POS systems and specialized AI-powered platforms can analyze your sales data to generate incredibly accurate purchasing forecasts. They can help predict how much of each ingredient you’ll need on any given day, which is a huge help in eliminating over-ordering—a major source of spoilage. While there's an upfront cost, these systems often pay for themselves surprisingly fast. One restaurant even reported adding 2% to their bottom line almost immediately just by using AI for forecasting.

Think of technology as a powerful tool to bring in once you’ve mastered the basics and are ready to fine-tune your operations with precision data.

What Is the Single Most Effective Strategy to Reduce Waste?

If you could only do one thing, the most impactful strategy would be to design a waste-efficient menu. Your menu is the command center for your entire operation. It dictates every ingredient you buy, every prep task your kitchen staff performs, and every plate that goes out to a customer.

Focus on creating a menu with smart ingredient overlap, where a core group of items is used across multiple dishes. This ensures your inventory moves quickly and doesn't have time to spoil. Combine this with standardized recipes and strict portion controls, and you’ll slash plate waste while ensuring cost consistency. When your menu is engineered for efficiency, it creates a powerful ripple effect across your entire restaurant, from purchasing all the way to the final plate.

Equipping your kitchen with the right tools is a critical part of any waste reduction strategy. From efficient refrigeration to high-quality cooking equipment, The Restaurant Warehouse provides the durable, energy-efficient products you need to run a smarter, more profitable kitchen. Explore our extensive catalog and flexible financing options to modernize your operations today at https://therestaurantwarehouse.com.

About The Author

Sean Kearney

Sean Kearney is the Founder of The Restaurant Warehouse, with 15 years of experience in the restaurant equipment industry and more than 30 years in ecommerce, beginning with Amazon.com. As an equipment distributor and supplier, Sean helps restaurant owners make confident purchasing decisions through clear pricing, practical guidance, and a more transparent online buying experience.

Connect with Sean on LinkedIn, Instagram, YouTube, or Facebook.

Leave a comment