Open Sesame: Top Walk-In Freezer Doors for Your Business

Why Your Freezer Door is More Than Just an Entryway

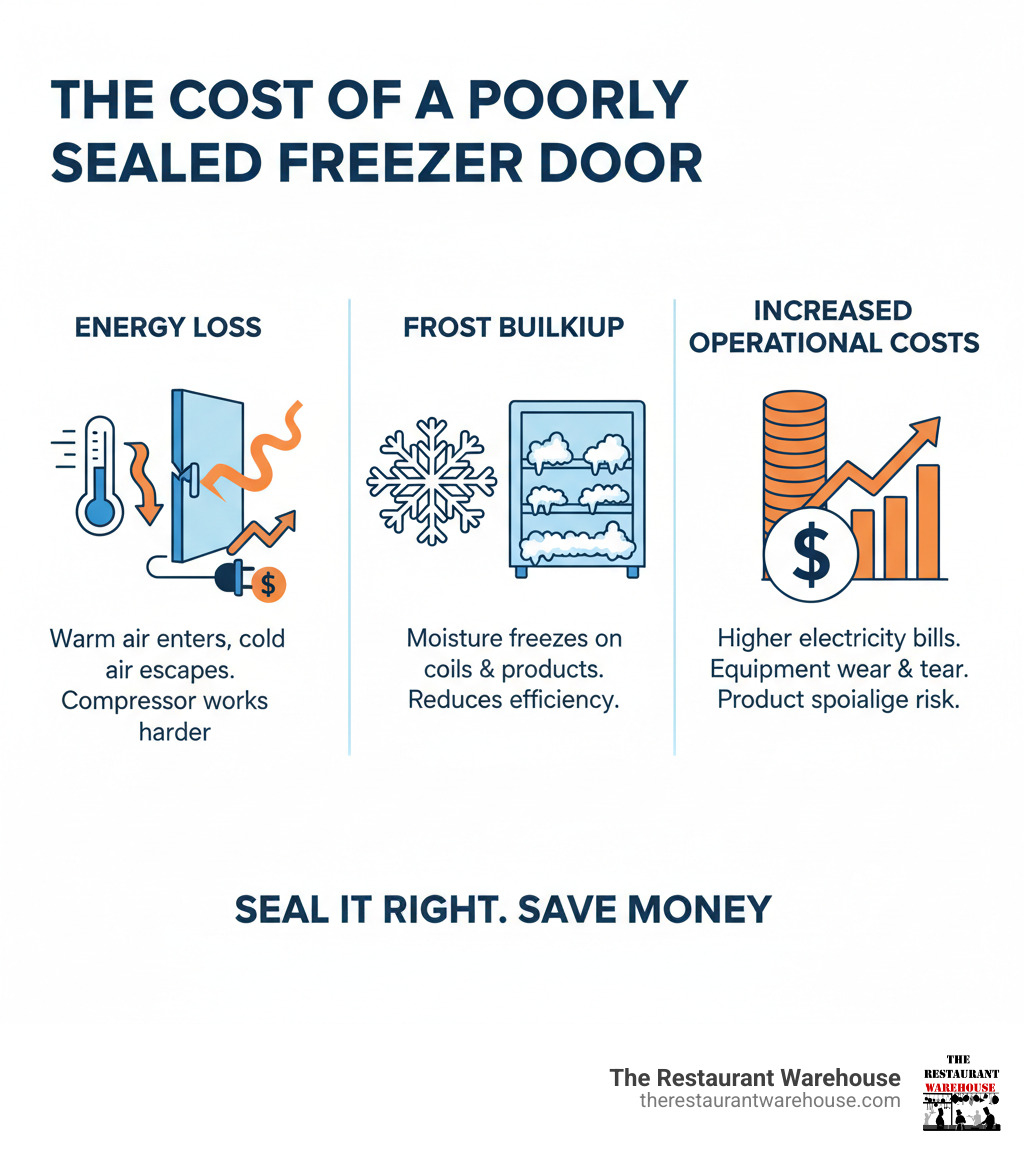

A walk in freezer door is a critical component of your cold storage system, directly impacting energy costs, food safety, and daily operations. The right door minimizes energy loss, while the wrong one becomes the weakest link in your refrigeration system, causing compressors to work overtime and energy bills to climb. In practical terms, your door governs how much warm, humid air enters the box, how often your system defrosts, how stable your product temperatures remain during rushes, and even how smoothly staff can flow in and out without bottlenecks.

Well-specified doors also protect product integrity. Rapid temperature swings from frequent, lengthy openings lead to frost, ice crystals, and potential quality degradation. A properly insulated door with tight gaskets, a heated frame, and pressure relief significantly reduces those swings, helping keep product at safe holding temperatures. For a deeper background on safe cold holding and why tight temperature control matters, see the USDA’s guidance on Refrigeration and Food Safety.

Key Considerations for Walk-In Freezer Doors:

- Type: Swinging (most common), sliding (space-saving), and roll-up fabric (high-traffic).

- Insulation: Minimum 4" thick foamed-in-place urethane with a high R-value.

- Essential Features: Heated frames, magnetic gaskets, pressure relief ports, and an interior safety release.

- Energy Impact: Over 80% of a freezer's refrigeration load comes from door opening events.

Why this matters: every opening allows infiltration of warm, moist air. That moisture condenses and freezes, creating frost on coils, thresholds, and gaskets. Frost isn’t just a nuisance—it increases defrost frequency, reduces evaporator efficiency, and accelerates wear on components. High-performance doors counter this with superior thermal breaks, continuous gaskets, and frame heat that prevents ice from forming on the jamb.

For operators, the difference between a basic door and a high-performance model shows up month after month on the utility bill. It also shows up on the floor—literally—because tight seals and proper heat keep ice off the threshold, reducing slip hazards. Whether you’re replacing a worn-out door or outfitting a new walk-in, a thoughtful door choice supports profitability, uptime, and safety.

Ready to stop energy leaks at the source? Contact our team for a custom recommendation and wholesale pricing. Prefer to start with numbers? We can estimate your potential savings based on door type and traffic—just contact us today.

Decoding the Door: Types of Walk-In Freezer Doors

Choosing the right walk in freezer door can reshape your operational flow. Each type offers distinct advantages depending on your space, traffic, and budget. Understanding these options is the first step toward a smart investment that affects everything from staff efficiency to your monthly electricity bill.

The Classic Choice: Swinging Doors

The most common sight in commercial kitchens, swinging doors are the workhorses of cold storage. They operate on a simple hinge mechanism and are typically pre-hung for straightforward installation.

- Pros: When opened, they provide a full, unobstructed entryway. Their compression and magnetic gaskets create an excellent airtight seal, which is critical for maintaining sub-zero temperatures. With fewer moving parts, they are generally easier and more affordable to maintain. Self-closing hinges and robust latches keep the seal consistent, even under heavy use.

- Cons: Swinging doors require significant clearance. In a cramped kitchen or narrow corridor, the swing radius can block pathways and create awkward traffic patterns. If space is tight, this design may work against you. Additionally, frequent impacts from carts can misalign hinges over time if kick plates or guards are not used.

Best for: standard restaurant layouts with adequate approach space, consistent but moderate traffic, and frequent hand-carry or cart use.

The Space-Saver: Sliding Doors

For operations with tight squeezes, sliding doors are an ideal solution. Instead of swinging out, they glide horizontally along a track, saving valuable floor space.

- Pros: They are perfect for narrow corridors, busy prep areas, and loading docks. Available in manual and automatic versions, they can accommodate wide openings (up to 12 feet) for moving pallets or large inventory racks, improving traffic flow and safety. Because they don’t swing, they reduce the chance of blocking aisles or colliding with staff.

- Cons: The track system requires regular cleaning and lubrication to prevent debris or ice from interfering with operation. They have a higher upfront cost than swinging doors and may require more maintenance over time. Proper alignment is critical to maintain sealing performance.

High-Tech & High-Speed: Roll-Up Fabric Doors

For high-traffic facilities where a freezer door opens hundreds of times a day, roll-up fabric doors are a game-changer. They address the single biggest energy drain in cold storage: door opening events.

- Pros: These doors operate vertically at high speeds, reducing open time by up to 75% compared to traditional doors. This minimizes the infiltration of warm air, significantly lowering energy consumption. The ROI can be as little as six months in high-traffic applications, with potential energy savings of around $2,000 per year for a single freezer door. Their compact footprint keeps floor space clear and reduces collision risk.

- Cons: They come with a much higher initial investment. Their mechanical complexity also means maintenance and repairs may require specialized knowledge and be more costly. They are best justified where traffic and door cycles are very high.

Specialized Solutions: Vertical-Lift and Bi-Parting Doors

For unique situations, specialized walk in freezer door designs are available.

- Vertical-lift doors move straight up, making them ideal for facilities with high ceilings but limited horizontal space.

- Bi-parting doors, which consist of two panels that slide open in opposite directions, are designed for extra-wide openings to accommodate oversized loads or high-volume traffic.

Decision tip: sketch the approach, swing or slide paths, and high-traffic times of day. Map the actual cart and pallet routes. Then match door type to the reality of your space and workflow, not just the opening size.

Your door choice should be driven by your specific operational needs. Ready to discuss which door type fits your operation? Contact us today and let's figure out the perfect solution together.

The Anatomy of a High-Performance Walk in Freezer Door

A high-performance walk in freezer door is an engineered system designed to combat extreme temperature differentials and constant use. Its effectiveness depends on four critical elements: insulation, sealing, hardware, and safety features.

Insulation and R-Value: The Core of Cold Retention

The heart of a freezer door is its insulation, typically foamed-in-place rigid polyurethane. This dense material creates a continuous thermal barrier. The effectiveness of insulation is measured by its R-value; a higher number indicates better resistance to heat flow. For a walk in freezer door, a minimum of 4 inches of polyurethane insulation is essential to maintain temperatures at or below 0°F. In many cases, 4 inches of quality polyurethane yields an approximate whole-door R-value in the high 20s to low 30s. Skimping on insulation thickness forces your refrigeration system to run constantly, wasting energy and money, while also increasing defrost frequency and shortening component life.

Insulation quality is not just thickness—uniform foam density, complete cavity fill, and robust thermal breaks at the frame all contribute to performance. Look for doors with factory-injected foam and continuous bonds between skins and core to minimize thermal bridging and warping.

Sealing the Deal: Gaskets and Sealing Technology

An airtight seal is non-negotiable. This is achieved with gaskets lining the door's perimeter.

- Magnetic gaskets create a strong, continuous seal that pulls the door shut.

- Compression gaskets squeeze against the frame to form a barrier.

- Sweeper gaskets seal the gap at the floor.

Over time, seals harden, tear, or take a set. Degraded seals lead to frost and ice buildup, creating slip hazards and forcing your compressor to work overtime. Plan to inspect gaskets weekly and clean with mild soap and water. Depending on traffic and environment, many operations replace perimeter gaskets every 12–24 months to maintain peak efficiency. Always verify the door is closing evenly across the full gasket length—if you see shiny wear spots or frost lines, the seal is compromised.

Essential Features for Your Walk in Freezer Door

Several features distinguish a high-performance door:

- Heated Frames (Perimeter Heaters): These 115-volt heating cables run around the door frame to prevent condensation and ice from forming, which could otherwise freeze the door shut or damage gaskets. The draw is modest compared to the energy wasted by frozen jambs and repeated forced entry.

- Pressure Relief Ports: These small vents equalize air pressure when the door is closed, preventing a vacuum effect that can make the door difficult to reopen. They also reduce stress on door hardware.

- View Windows: Allow staff to check inventory without opening the door, saving energy and improving safety by preventing collisions. For freezer applications, heated, multi-pane windows help prevent fogging and frost.

- Kick Plates: Diamond-patterned metal plates at the bottom protect the door from damage from carts and pallet jacks, keeping the panel square and the seal intact.

- Heavy-Duty Hardware: Durable hinges and self-closing mechanisms are critical for high-use doors, ensuring they close properly every time. Stainless or corrosion-resistant finishes endure the moisture and cleaning common to freezer entries.

- Interior Safety Release: A crucial safety feature that allows anyone accidentally locked inside to exit. Test it regularly and train staff on its location and use.

Cooler vs. Freezer Door: What's the Difference?

Using a cooler door on a freezer is a costly mistake. The two are engineered for vastly different temperature requirements.

- Insulation: Freezer doors require 4 inches of insulation, while cooler doors typically use 2-3 inches.

- Heated Components: Freezer doors must have heated frames and jambs to prevent ice buildup. Cooler doors, operating above freezing, do not need this feature. For more on cooler operation, see our guide on Walk-In Cooler Temperature.

- Pressure Equalization: More critical for freezers due to the larger temperature differential.

- Hardware: Freezer door hardware is built to be more robust and corrosion-resistant to withstand harsher conditions.

Installing the wrong door leads to costly system breakdowns, massive energy waste, and spoiled inventory. The up-front savings vanish quickly if coils ice up, thresholds freeze, or seals fail. Ready to make sure you've got the right door for your application? Contact us today and let our team help you find the perfect solution.

Sizing, Installation, and Maintenance: A Practical Guide

Once you've chosen the right type of walk in freezer door, the next steps are ensuring it's sized correctly, installed professionally, and maintained properly. These practical details are what make your investment pay off.

Getting the Right Fit: Standard vs. Custom Sizing

Getting the dimensions wrong can cause air leaks and installation delays. Most operations can use standard door dimensions like 36" x 78" or 48" x 78", which refer to the clear opening size. These are designed to fit standard walk-in panel systems, making replacement straightforward.

For a replacement, you must measure the exact width and height of the rough opening—the space in the wall itself. Measure in multiple places (top, middle, bottom; left, center, right) and use the smallest measurement to account for any out-of-square conditions. Note panel thickness, wall construction, and whether you have an offset door or a flush mount. If standard sizes don't work for your building, custom sizing is available, but be prepared for longer lead times. The door frame must also integrate perfectly with your walk-in panels. For more on planning, our 8x10x7 Walk-In Guide offers helpful insights.

If you routinely move pallets or large carts, confirm the clear opening after door hardware is installed, not just the panel cutout. Also consider the threshold height and whether a ramp or recessed threshold is necessary to meet accessibility and workflow goals.

Installation Best Practices for Your Walk in Freezer Door

A door that is even slightly misaligned will be a constant source of energy loss and frost buildup. While most walk in freezer doors come pre-hung on a frame to simplify the process, professional installation is worth every penny.

An experienced technician ensures the frame is perfectly level and plumb, creating the crucial airtight seal. They will also handle the electrical connections for the 115-volt heated frame safely and correctly, which is non-negotiable for freezer applications and often required for the warranty to be valid. They will verify thermal breaks, apply sealant correctly at panel joints, and ensure no shims create thermal bridges. A DIY installation can easily void your warranty and lead to costly energy waste that negates any upfront savings. Professional installation isn't an expense—it's insurance for your investment.

Commissioning checklist recommendations:

- Verify frame is square, plumb, and anchored per manufacturer specification.

- Confirm gasket compression is uniform around the perimeter.

- Test closer and latch to ensure the door consistently self-closes and latches.

- Energize perimeter heaters; confirm warmth at the jamb after several minutes.

- Inspect pressure relief ports for proper operation and clear pathways.

- Document voltages, amperages for heaters, and any controller parameters.

Keeping it Functional: Routine Maintenance and Troubleshooting

Consistent maintenance is the key to a long-lasting door. A simple weekly or monthly checklist can prevent thousands of dollars in emergency repairs and energy waste.

- Gasket Inspection: Weekly, check gaskets for tears, cracks, or hardening. A damaged gasket is a primary source of energy loss. Clean them with mild soap and water and replace them immediately if damage is found. Keep spares on hand to minimize downtime.

- Hardware Lubrication: Periodically lubricate hinges, latches, and sliding door tracks with a food-grade lubricant to ensure smooth operation.

- Heated Frame Check: Weekly, feel the door jamb to ensure it's slightly warm. If it's cold, the heater is not working, and ice will soon accumulate. Verify circuit breakers and connections if heat is absent.

- Clear Pressure Relief Ports: Regularly check that these small vents are not clogged with ice or debris, as a blockage can make the door difficult to open.

- Check Door Alignment: Monthly, watch the door close to ensure it shuts evenly. A sagging door may indicate that the hinges need adjustment.

- Threshold and Floor Care: Keep thresholds clean and dry. Ice accumulation here signals gasket or heat issues upstream.

Common issues like torn seals, excessive ice, or a door that sticks are often signs that maintenance is overdue. Catching them early prevents product loss and system strain. For more tips, see our guide on Walk-In Cooler Maintenance. If you need help sourcing replacement gaskets or hardware, reach out—our team can match parts to your make and model at wholesale pricing.

The Business Case: Maximizing ROI and Efficiency

A walk in freezer door is an investment that either pays you back or quietly drains your profits. The real cost of a door isn't just the sticker price; it's the total cost of ownership, which is heavily influenced by its energy efficiency.

Calculating the Savings: Energy Efficiency and ROI

A staggering 80% of the refrigeration load on a freezer comes from door opening events. Every time the door opens, your compressor works overtime. A high-performance door with superior sealing and auto-closing mechanisms can dramatically reduce this energy waste.

For example, high-speed roll-up doors can reduce open times by 75%, delivering an ROI in as little as 6 months. This can translate to annual savings of around $2,000 for a single freezer door. According to EnergyStar, every dollar saved on energy in a grocery store is equivalent to generating $59 in new sales. Investing in a door with a high R-value, magnetic gaskets, and heated frames is a strategic financial move. As the U.S. Department of Energy commercial refrigeration guide notes, proper door selection and maintenance play an outsized role in reducing overall energy consumption.

A simple way to estimate savings:

- Estimate average door open time per cycle (seconds) and cycles per hour.

- Compare existing open time to projected open time with a better door (e.g., auto-closer or high-speed roll-up).

- Convert reduced open time to fewer defrosts and reduced compressor runtime.

- Multiply reduced runtime by your kWh rate to estimate savings. Even conservative estimates often justify premium doors within months, not years.

Beyond energy, a consistent seal reduces ice-related downtime, slip hazards, and wear on evaporator coils. These soft savings add up in fewer service calls and longer component life.

Choosing a Supplier and Understanding Warranties

The lowest price doesn't always mean the best value. A knowledgeable supplier who understands your business and stands behind their products is essential. At The Restaurant Warehouse, our wholesale pricing model means you get quality products at honest prices without high retail overhead.

When evaluating suppliers, also look closely at the warranty. A strong warranty is a sign of the manufacturer's confidence in their product. Some heavy-duty doors come with 10-year warranties, but you must read the fine print. Understand what is covered (panels, hardware, heaters) and what might void the warranty, such as improper installation. Ask whether professional installation is required and what documentation you’ll need for future claims.

Ready to talk specifics? Contact us today to discuss your cold storage needs and get a quote custom to your operation. We can help you compare door options side by side and estimate the payback period based on your traffic patterns and utility rates.

Finding the Right Door for Your Budget

Walk-in freezer door prices vary based on type, size, and features.

- Standard Swinging Doors: Typically range from $1,600 to $2,850. They are a reliable and cost-effective choice for most restaurants.

- Sliding Doors: Range from $5,450 to $5,700. The premium price reflects the space-saving design and more complex track system.

- Roll-Up Fabric Doors: These are the most expensive but offer the highest energy efficiency and are often the smartest long-term investment for high-traffic operations.

Features like heated frames, view windows, and kick plates add to the cost but also add value by extending the door's lifespan and improving performance. The best approach is to buy the door that matches your actual operational requirements, balancing upfront cost with long-term performance. Explore our selection of affordable walk-in cooler solutions to find a walk-in cooler that fits your budget.

Bonus tip: many utilities offer incentives for energy-efficient upgrades. Pairing a high-performance door with smart controls and staff training can qualify you for rebates and lower your total cost of ownership even further.

Frequently Asked Questions about Walk-In Freezer Doors

When investing in a walk in freezer door, many questions arise. Here are answers to some of the most common ones.

How often should I replace my walk-in freezer door?

There is no set timeline; replacement depends on condition, not age. Look for these warning signs:

- Damaged Seals: Torn, cracked, or hardened gaskets are a major red flag, causing energy loss and ice buildup.

- Poor Insulation: If the exterior of the door feels cold to the touch (away from the heated frame), the insulation is failing.

- Physical Damage: Significant dents, warping, or corrosion compromise the door's structure and seal.

- Operational Issues: If the door sticks, is hard to open, or won't close properly, it's a safety and efficiency problem.

If repairs become frequent or a single repair costs more than 30-40% of a new door's price, it's time to upgrade. A new, efficient door often pays for itself in energy savings. Also consider lifecycle: if your door requires multiple major repairs (heaters, hinges, latches) within a short window, the cumulative cost and downtime may outweigh replacement.

Can I install a walk-in freezer door myself?

We strongly advise against it. Installing a walk in freezer door is a precision job. An improper installation will create immediate energy leaks, costing you far more in the long run than professional installation. The frame must be perfectly level and plumb to ensure an airtight seal.

Furthermore, freezer doors require a 115-volt heated frame to be wired correctly to prevent ice buildup. Improper electrical work is a safety hazard. Most importantly, most manufacturers require professional installation to honor the warranty. A DIY attempt could void a 10-year warranty to save a few hundred dollars.

What is the most energy-efficient type of freezer door?

The most efficient door depends on your traffic volume.

- For high-traffic environments, high-speed roll-up fabric doors are best. By cutting open times by up to 75%, they drastically reduce energy loss from air exchange.

- For standard, moderate traffic, a well-insulated swinging or sliding door is highly efficient. Key features for efficiency are at least 4 inches of high R-value insulation, airtight magnetic gaskets, and a self-closing mechanism.

For any door, a heated frame is essential for freezer applications to maintain the integrity of the seal. User behavior also plays a huge role; train staff to minimize open times and never prop doors open.

How do I prevent ice buildup around the door?

Start with the fundamentals: ensure the door is aligned, gaskets are soft and continuous, and perimeter heaters are functioning. Keep thresholds dry and clean, and verify pressure relief ports are clear. Avoid propping the door open, especially during high humidity events (deliveries, dishroom runoff nearby). If ice persists, inspect for air leaks with a flashlight test at night—light leaks often track exactly with frost patterns.

Do I need a threshold or ramp?

Thresholds protect the bottom seal and reduce air exchange at the floor. If you use carts or pallet jacks, consider a low-profile or recessed threshold paired with a ramp for smooth access. The right approach height reduces impacts on the bottom of the door and improves long-term sealing performance.

What electrical requirements should I plan for?

Most freezer door perimeter heaters operate on 115 volts and require a dedicated circuit sized per manufacturer specs. During installation, confirm voltage at the frame, verify current draw, and label the circuit for easy maintenance. If your door includes accessories (auto-closers, sensors), coordinate additional power and control wiring during the initial install to avoid rework later.

Ready to find the perfect balance of efficiency and affordability? Explore our selection of walk-in freezer doors at The Restaurant Warehouse, where wholesale pricing meets commercial-grade quality.

Conclusion: Secure Your Investment with the Right Door

Your walk in freezer door is a critical investment that impacts your inventory, energy costs, and operational workflow. Choosing the right door—whether it's a reliable swinging door, a space-saving sliding door, or a high-efficiency roll-up model—is fundamental to your business's success.

The key is to look beyond the initial price and consider the anatomy of a high-performance door: thick insulation, airtight seals, and essential features like heated frames. These components are the difference between a door that lasts a decade and one that wastes money daily. Remember the critical distinction between cooler and freezer doors; using the wrong type is a recipe for failure.

Proper sizing, professional installation, and routine maintenance protect your investment and ensure years of reliable service and energy savings. The business case is clear: with over 80% of a freezer's refrigeration load coming from door openings, the right door can pay for itself in a surprisingly short time.

At The Restaurant Warehouse, we provide quality doors at wholesale prices, helping you find the right balance of upfront cost and long-term value. The right door secures your food safety, your efficiency, and your profitability.

Want custom advice and pricing? Connect with our team for a quick needs assessment and same-day quotes—contact us today. Prefer to research first? Dive into our Commercial Freezer Guide for more expert insights, or reach out to compare options side by side for your footprint, budget, and traffic profile.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment