Choosing the Right Mop Sink Size for Your Business

Choosing the right mop sink isn't just about picking a basin that fits; it's about optimizing your entire cleaning process. The size of your mop sink directly impacts how efficiently your team can work, so it's a decision worth getting right.

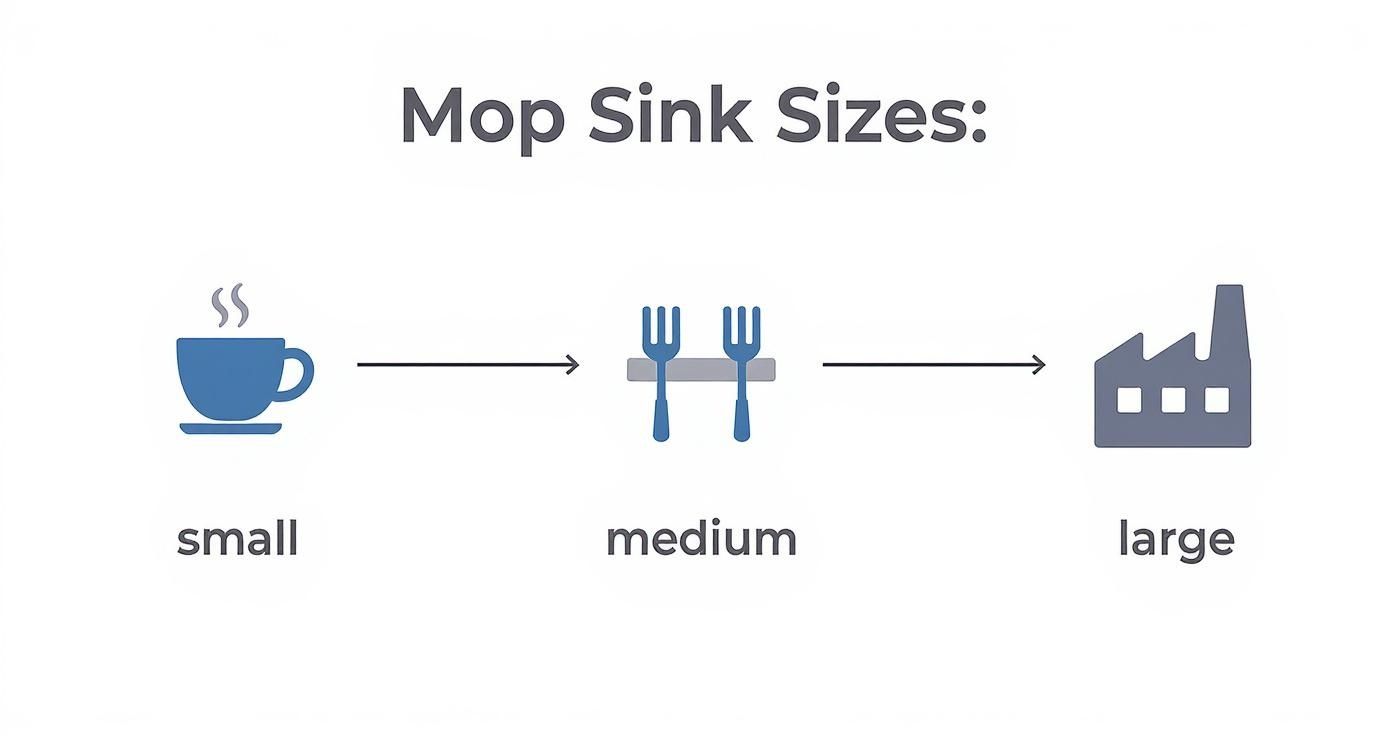

Think of it this way: a small sink is like a compact car, perfect for navigating tight spaces. A medium sink is the reliable workhorse sedan that suits most businesses, while a large sink is a heavy-duty truck built for the toughest industrial cleaning jobs. This simple analogy can help you quickly match a mop sink size to your facility's real-world demands.

How to Quickly Find Your Mop Sink Size

The first step in picking the perfect mop sink is understanding the three main categories: small, medium, and large. Each one is engineered for a different level of use, ensuring you don't waste precious floor space with an oversized unit or frustrate your staff with one that’s just too small.

A small mop sink, which is typically around 24x24 inches, is the ideal choice for low-volume spots like a small café or a retail stockroom. It gets the basic cleaning done without eating up a large footprint. On the other end of the spectrum, a large sink, often 36x36 inches or even bigger, is built for high-traffic facilities like hospitals and warehouses where heavy-duty cleaning is a constant.

This quick decision-tree infographic gives you a visual guide to which mop sink size category aligns best with different commercial environments.

As you can see, the sweet spot for many businesses falls right in the middle. The global mop sink market reflects this trend, with a projected value of approximately $716 million by 2025. Medium-sized mop sinks (15-30 gallons) are the most widely adopted for a reason—they offer the perfect balance of capacity and footprint for restaurants, hospitals, and schools.

Quick Guide to Mop Sink Sizes

To make things even easier, here's a quick reference table that breaks down the standard sizes and their most common applications.

| Size Category | Common Dimensions (Inches) | Typical Capacity (Gallons) | Best For |

|---|---|---|---|

| Small | 24 x 24 or smaller | 10 - 15 | Small cafes, retail backrooms, office buildings |

| Medium | 24 x 28 to 32 x 32 | 15 - 30 | Restaurants, schools, small hospitals |

| Large | 36 x 36 or larger | 30+ | Warehouses, large hospitals, industrial plants |

By identifying your daily cleaning volume and the space you have available, you can confidently select a mop sink that makes your entire operation safer and more efficient.

For a deeper dive into selecting the right model specifically for a commercial kitchen, be sure to check out our comprehensive restaurant mop sink guide for more detailed recommendations.

Getting a Handle on Standard Mop Sink Dimensions

Alright, now that you've got the general categories down, let's get into the nitty-gritty of mop sink size. The specific dimensions of a mop sink—its width, length, and depth—are what will make or break its daily usefulness. Getting these three measurements right ensures your cleaning routine is smooth, not a sloppy, frustrating mess.

For most commercial kitchens, a standard 24x24 inch floor sink is the sweet spot. It gives you plenty of room to fill and empty a big mop bucket without turning the surrounding floor into a hazardous splash zone. That common size is great for keeping floors dry and preventing slip-and-fall accidents.

On the flip side, a more compact 20x16 inch model can be a smart, space-saving solution if you're working with a cramped utility closet or run a business with fairly light cleaning needs.

Why Basin Depth Is So Important

While the width and length determine the sink's footprint, it's the depth of the basin that really keeps messes contained. A shallow basin is basically an open invitation for dirty water to splash all over clean floors and walls, completely defeating the purpose of the task at hand.

A mop sink that is 10 to 12 inches deep is the key to containing the splash-back when a full, heavy bucket gets dumped out. This small detail makes the whole process cleaner, faster, and way more efficient for your staff.

Ultimately, the perfect dimensions boil down to your available space and the sheer scale of your cleaning operations. To help you visualize it, here are a few common scenarios:

- Small Coffee Shop: A compact 24x24x10 inch model fits neatly into a back-of-house closet and can easily handle a standard mop bucket.

- Busy Restaurant: A slightly larger 36x24x12 inch basin offers more versatility for frequent, heavy-duty cleaning and bigger pieces of equipment.

- Large Facility (School/Hospital): An expansive, deep sink, maybe 48x36x14 inches, becomes necessary to manage high-volume cleaning demands and meet those strict hygiene standards.

Thinking through these standard sizes helps you move from a vague idea to a specific mop sink that will feel like it was custom-made for your workspace.

Matching Your Sink to Commercial Demands

Your business isn't a cookie-cutter operation, and your mop sink shouldn't be either. The right mop sink size really comes down to the specific cleaning challenges your industry throws at you. When you pick a sink that lines up with your daily operational grind, it stops being just a utility and becomes a critical tool for keeping things efficient and hygienic.

Take a high-volume restaurant kitchen, for example. It’s a constant battle against spills, grease, and grime, demanding relentless cleaning. A medium-to-large sink, something like a 24x24 inch or 36x24 inch model, is pretty much non-negotiable here. This gives your crew plenty of room for big mop buckets and allows for quick, effective cleanups during a chaotic service, preventing bottlenecks in the workflow.

On the flip side, a small retail shop or a cozy café has a completely different set of priorities. In these spots, every square foot of floor space is prime real estate. A compact, space-saving corner unit or a smaller 24x24 inch basin is often the smartest choice, giving you the function you need without sacrificing valuable room.

Specialized Environments and Materials

For some industries, the demands go way beyond just size. If you're outfitting a school or a hospital, hygiene is the absolute top priority, and the sink's material becomes just as important as its dimensions. These facilities need extremely durable, non-porous surfaces to meet the strictest sanitation standards.

In healthcare and educational settings, a robust stainless steel or terrazzo mop sink is essential. These materials are built to withstand harsh cleaning chemicals and resist bacterial growth, which is key for complying with health codes and protecting vulnerable people.

For businesses taking on major renovations or building out a new commercial space, understanding how specialized fixtures fit into the bigger picture is crucial. These larger efforts, often called tenant finish projects, demand careful planning from the get-go to make sure all the plumbing and fixtures meet both your operational needs and the building codes.

Choosing the right sink is about more than just measuring a space; it’s about having a clear understanding of your industry’s unique workflow. If you want to dive deeper into the various options built for heavy use, you can learn more about the different industrial sink types available for commercial kitchens. By matching the mop sink's size and material to your specific demands, you ensure your new fixture becomes a true asset, not an obstacle.

Making Sure Your Mop Sink Plays by the Rules

Putting in a new mop sink is a bit more involved than just picking a corner and hooking it up. You’ve got to navigate some critical plumbing and health codes. Think of these rules as the essential safety net for your building's water system—they’re there to prevent contamination, ensure proper drainage, and keep everyone safe. Skipping over them can lead to some serious headaches, like failed inspections, hefty fines, and genuinely unsafe conditions for your staff and customers.

One of the first things any inspector will look at is the drain. Getting the mop sink size for the drain right is crucial for preventing nasty clogs and backups filled with dirty water, mop strings, and other gunk. Most local plumbing codes are very clear on this: the drain needs to be at least 2 inches in diameter. For kitchens that see a lot of action, I usually recommend stepping up to a 3-inch drain to handle the heavy-duty waste more effectively.

The Must-Have Plumbing Parts

Beyond the drain itself, a few other components are absolutely non-negotiable for a compliant setup. These pieces work together as a team to protect both your internal plumbing and the public water supply from contamination.

- P-Trap: This is the U-shaped pipe you see under sinks. Its simple job is incredibly important: it holds a small amount of water to create a seal that blocks foul—and potentially hazardous—sewer gases from creeping back into your facility.

- Backflow Prevention: A backflow preventer is a one-way gate for your water. It stops contaminated water from the sink from being siphoned back into your clean water lines, which is a massive health risk you can't afford to take.

- Proper Venting: Good venting is what allows your drainage system to "breathe." It ensures water flows smoothly down the drain and prevents pressure changes that could suck the water right out of the P-trap, rendering it useless.

Health and safety codes aren't just friendly suggestions; they are legally binding requirements designed to protect public health. A single mistake, like failing to install a backflow preventer, could contaminate an entire building's water supply.

Finally, don’t forget about accessibility. The Americans with Disabilities Act (ADA) has specific guidelines for utility sinks to make sure they’re usable by every employee. This covers things like the design of faucet controls and ensuring there’s enough clear floor space around the sink. Ticking these boxes from the get-go makes your facility not just compliant, but also safe and inclusive for everyone on your team.

Smart Installation and Placement Strategies

Where you decide to put your mop sink is just as critical as the size you choose. The final steps—smart placement and a smooth installation—are what turn a simple basin into a cleaning station that’s safe, efficient, and fully compliant. Think of it as designing the perfect parking spot for your cleaning crew’s most important tool.

One of the first calls you'll make is whether to go with a floor-mounted or a drop-in model. Floor-mounted sinks sit right on the ground, which makes dumping heavy, sloshing mop buckets incredibly easy—no lifting required. On the flip side, drop-in or wall-mounted sinks are elevated. This can be more ergonomic for filling buckets but definitely requires more muscle to empty them.

Key Placement Considerations

Strategic placement is everything. It has a real impact on your kitchen’s workflow, overall safety, and even how your space is perceived by staff. A well-thought-out location is a cornerstone of an effective commercial kitchen floor plan, ensuring janitorial tasks don’t get in the way of other operations.

Before you lock in the spot, run through this quick checklist:

- Proximity to Utilities: Is it close to existing hot and cold water hookups and a suitable drain line? Moving plumbing is an expense you want to avoid.

- Away from Traffic: Will it be clear of high-traffic zones for both staff and customers? You need to prevent trip-and-fall accidents.

- Near Janitorial Storage: Is it conveniently located right next to where you store your mops, buckets, and cleaning chemicals?

- Proper Floor Slope: For floor-mounted sinks, the surrounding floor absolutely must slope gently toward the drain. This prevents standing water, which is a major slip hazard and a guaranteed health code violation.

One of the most common installation mistakes I see is neglecting the floor slope. Without proper drainage, you’ll end up with a permanent puddle of dirty water—a breeding ground for bacteria and a constant safety risk.

By carefully thinking through these factors, you ensure your mop sink is a long-term asset, not a daily headache.

Answering Your Final Questions About Mop Sinks

Even after you’ve compared models and measured your space, a few nagging questions can pop up right before you make a final decision. Getting these last details ironed out is what gives you the confidence that you’re choosing a mop sink that’s practical, compliant, and built to last. Let's tackle some of the most common questions we hear from business owners.

One of the biggest questions is always about the plumbing. What is the standard drain size for a commercial mop sink? For most commercial kitchens and facilities, a 2-inch diameter drain is the bare minimum. But if you're running a high-volume spot like a busy restaurant, do yourself a favor and upgrade to a 3-inch drain. It's a smart move to prevent clogs from all the gunk—mop strings, dirt, and other debris—that inevitably goes down that drain.

Then there’s the faucet. Do I need a dedicated faucet for my mop sink? The short answer is yes, absolutely. A dedicated, wall-mounted faucet with a long hose is the standard setup for a reason. It keeps the faucet clear when you're dumping heavy buckets and gives you the flexibility you need to rinse out the basin and fill buckets without a struggle.

Health Codes and Material Choices

Of course, compliance is always top of mind. Is a mop sink actually required by the health department? In just about every commercial food service or healthcare setting, the answer is a firm yes. Health codes are very clear about this: you need a separate, dedicated utility sink just for disposing of mop water. This prevents cross-contamination with any sinks used for food prep or hand-washing, and not having one is a surefire way to fail a health inspection.

Think of a mop sink as non-negotiable insurance for your facility's hygiene. It’s a foundational element of sanitation that inspectors look for first, and its absence is a major red flag indicating poor cleaning protocols.

Finally, what should the sink itself be made of? What is the best material for a mop sink? The right choice really comes down to the demands of your environment.

- Stainless Steel: This is the top choice for a reason. It's incredibly durable, hygienic, and stands up to harsh chemicals and corrosion, making it perfect for hospitals and kitchens.

- Terrazzo: A heavy-duty composite material that is extremely durable. It's built to last, which is why you'll often see it in high-traffic places like schools and industrial facilities.

- Fiberglass/Molded Stone: This is a more budget-friendly option that works well for lower-traffic areas. Think small offices or the stockrooms of retail shops.

Getting clear on these final questions helps ensure you select and install the perfect mop sink, setting up a cleaning station that is efficient, safe, and fully compliant from day one.

At The Restaurant Warehouse, we provide the durable, code-compliant mop sinks and accessories your business needs to maintain a pristine and safe environment. Equip your facility with the right tools by exploring our selection at therestaurantwarehouse.com.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment