Maxx Cold to Avantco: The Best 2-Door Pizza Prep Fridges Reviewed

Why a 2-Door Pizza Prep Table is Essential for Your Pizzeria's Success

A 2 door pizza prep table combines refrigerated ingredient storage with a dedicated workspace, making it the backbone of efficient pizza operations. These units keep your toppings at safe temperatures while providing easy access during busy service periods.

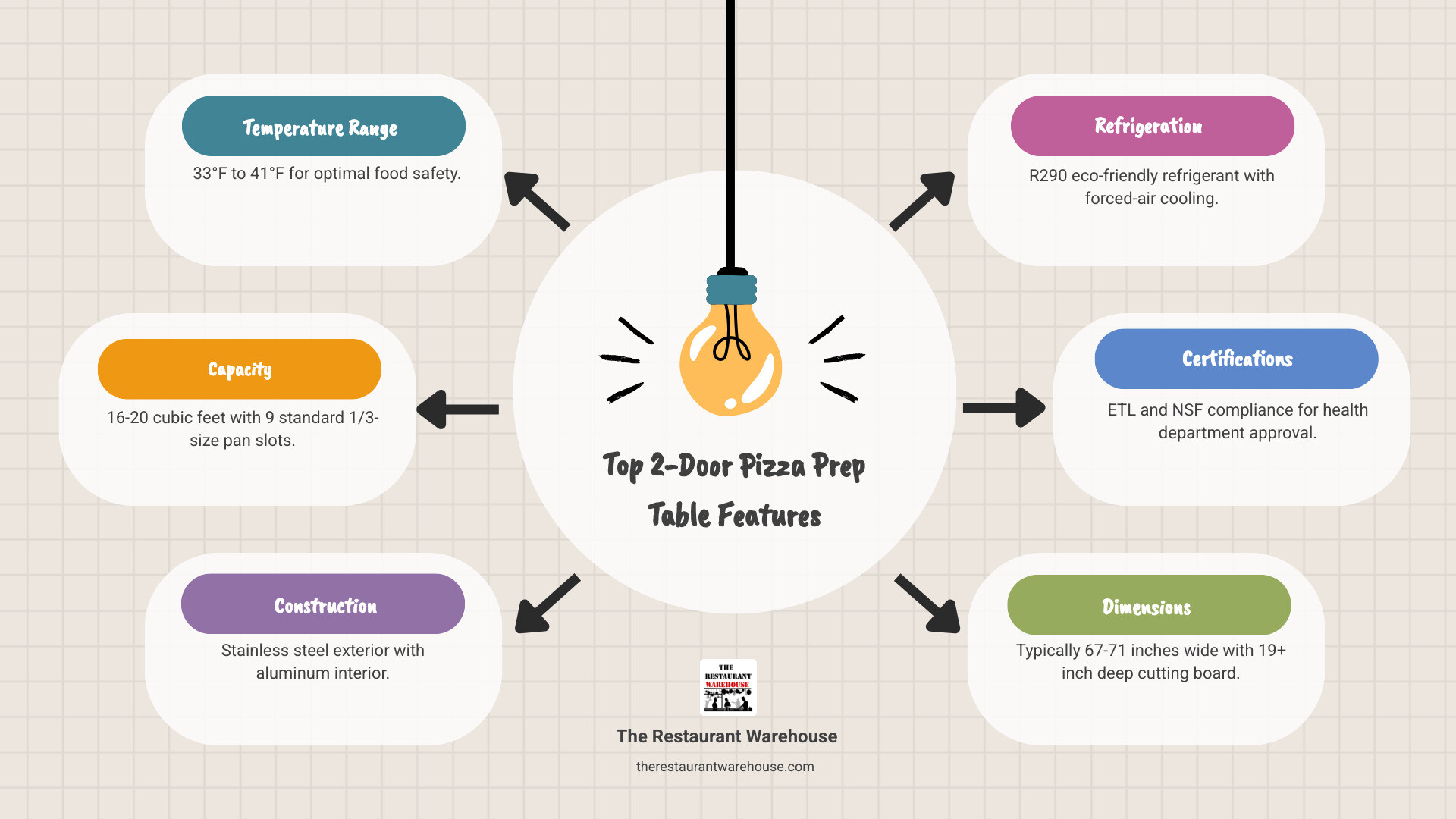

Top 2-Door Pizza Prep Table Features to Look For:

- Temperature Range: 33°F to 41°F for optimal food safety

- Capacity: 16-20 cubic feet with 9 standard 1/3-size pan slots

- Construction: Stainless steel exterior with aluminum interior

- Refrigeration: R290 eco-friendly refrigerant with forced-air cooling

- Certifications: ETL and NSF compliance for health department approval

- Dimensions: Typically 67-71 inches wide with 19+ inch deep cutting board

Running a pizzeria means juggling speed, quality, and food safety all at once. The right prep table transforms chaotic pizza assembly into a smooth operation where everything you need stays within arm's reach.

Traditional refrigeration setups force your staff to constantly move between different storage areas, slowing down service and increasing the risk of temperature abuse. A quality 2-door unit eliminates this inefficiency by consolidating your most-used ingredients in one ergonomic workspace.

Research shows that modern, high-capacity units can offer over 28 cubic feet of storage space while maintaining precise temperature control through digital controllers. Meanwhile, eco-friendly models using R290 refrigerant can save up to 40% on energy costs compared to older systems.

Whether you're launching a new pizzeria or upgrading existing equipment, understanding the key features and specifications will help you make the right investment for your operation's long-term success.

Why a 2-Door Pizza Prep Table is a Game-Changer for Your Kitchen

Think of a 2 door pizza prep table not just as a piece of equipment, but as a true game-changer for your kitchen. It's an investment that transforms how you create delicious pizzas, making your entire operation smoother and more successful. Whether you run a cozy local pizzeria or a high-volume kitchen, you'll be amazed at how these units can revolutionize your workflow. They don't just store ingredients; they streamline everything from staff efficiency and reduced prep time to ensuring top-notch food safety standards and consistent product quality. You'll see optimal space utilization, an ergonomic design that supports your team, and a significant food safety improvement by keeping ingredients at safe temperatures and reducing cross-contamination risk.

The Efficiency Boost

Ever dream of a kitchen where every single movement is just right? Where ingredients magically appear exactly when and where they're needed? That's the magic of an efficiently designed 2 door pizza prep table! It creates a fantastic, organized station that lets your team work like a well-oiled machine. By keeping all your delicious toppings perfectly chilled and literally within arm's reach in the refrigerated pan rail, you dramatically reduce staff movement. No more dashing back and forth to a separate fridge! This super accessibility means faster pizza assembly and a huge boost in increased output during peak hours, which is absolutely vital when the orders are flying in. You'll see improved team productivity and a truly streamlined workflow. Plus, the deep, full-length cutting board gives you plenty of space for stretching dough and prepping ingredients right there. This smart, ergonomic design means your team can work comfortably and quickly, making more amazing pizzas in less time. It's all about making the most of your space and your team's energy!

Upholding Food Safety and Quality

But wait, there's more! Beyond just making things faster, a top-notch 2 door pizza prep table is a true champion when it comes to food safety. This is super important for any place serving food, right? These tables are specially designed to keep your ingredients in tip-top shape and incredibly fresh, ensuring fresh ingredients every time. They excel at maintaining optimal temperature, usually between 33°F and 41°F. This isn't just a number; it means your perishable ingredients stay safe and fresh much longer, preventing those pesky bacteria from growing and preventing spoilage. This precise temperature control is absolutely key for meeting health code standards. You'll love features like the insulated lids on the pan rail and the consistent cooling that spreads evenly throughout the unit. These work together to protect your ingredients, even when your kitchen is buzzing and those lids are popping open frequently. By keeping everything perfectly chilled and neatly organized, you significantly reduce the risk of cross-contamination. This means every pizza you make starts with the freshest, safest components possible. This dedication to food safety not only keeps your customers happy and healthy but also builds a fantastic reputation for your quality and care. Want to dive deeper into how a pizza prep table can seriously improve your kitchen's operations and boost your food safety game? You can always check out our resources right here: More info about pizza prep tables.

Essential Features to Look for in a 2-Door Pizza Prep Table

When considering a 2 door pizza prep table, it’s not just about finding any unit; it’s about investing in one that offers durability, performance, and long-term value. We believe that understanding the key components and their impact on your operation is crucial for making an informed decision.

Construction and Materials: The Foundation of Durability

The longevity and hygiene of your 2 door pizza prep table largely depend on its construction and the materials used. We always recommend units built with high-quality stainless steel for both the exterior and interior. While 430-grade stainless steel offers good corrosion resistance, many premium models use 304-gauge stainless steel for superior durability and longevity, especially in demanding kitchen environments. This material is not only robust against dents and wear but also incredibly easy to clean, which is vital for maintaining sanitation standards.

Inside, you'll often find corrosion-resistant aluminum liners, providing a lightweight yet durable storage environment. The cutting board is another critical component; a deep cutting board, typically 19 inches or more, made from high-density polyethylene, offers ample space for preparing large pizza doughs and can be easily removed for cleaning. Some specialized units even feature granite tops, which are excellent for maintaining lower temperatures on the work surface, optimizing dough handling and ingredient management.

For mobility and stability, heavy-duty casters are a must, allowing you to move the unit for cleaning or repositioning. Lastly, don't overlook the importance of magnetic door gaskets. These provide a positive seal, ensuring cold air stays in and warm air stays out, which contributes to energy efficiency and consistent internal temperatures.

Refrigeration System: The Heart of Freshness

The refrigeration system is arguably the most critical component of your 2 door pizza prep table, as it directly impacts food freshness and safety. We advocate for units equipped with forced-air refrigeration, which ensures uniform cold temperatures throughout the cabinet's interior and, crucially, under the pan rail where your ingredients are stored.

You’ll encounter different compressor configurations: side-mount compressors are praised for their efficient operation and easier integration into existing kitchen layouts, as they often allow for front breathing. Others may have rear-mount or bottom-mount systems. Regardless of the mounting, the type of refrigerant used is a significant consideration. Many modern, eco-friendly models use R290 refrigerant. This natural refrigerant has zero ozone depletion potential (ODP) and a very low global warming potential (GWP), making it a responsible choice for the environment. Beyond its eco-credentials, R290 can also contribute to significant energy savings, with some units boasting up to 40% energy efficiency improvements.

Advanced features such as a self-cleaning condenser, found in some high-end units, can dramatically reduce maintenance needs and ensure optimal performance over time. Additionally, an anti-corrosion coated evaporator helps extend the lifespan of the system by protecting against wear and tear in humid kitchen environments.

Temperature Control, Insulation, and Certifications

Precise temperature control is non-negotiable for food safety. A 2 door pizza prep table should feature a digital temperature controller, allowing for easy and accurate adjustments to maintain the ideal temperature range, typically between 33°F and 41°F. These digital displays provide clear read-outs, so you can always be confident that your ingredients are stored at safe temperatures.

High-density polyurethane insulation is essential for effective temperature maintenance and energy efficiency. We always look for CFC-free insulation, which demonstrates a commitment to environmental responsibility. This insulation helps keep the cold air inside, reducing the workload on the compressor and lowering energy consumption.

Finally, certifications are your assurance of quality and compliance. We highly recommend units that are ETL Certified for electrical safety and ETL Sanitation Certified, conforming to NSF standards. These certifications verify that the equipment meets North American product safety and sanitation standards, which is often a requirement for passing health inspections. Choosing a certified unit provides peace of mind and ensures your operation adheres to critical health department compliance. To learn more about the importance of these standards, you can visit Learn about NSF standards for food equipment.

Sizing, Capacity, and Power: Matching the Table to Your Space

Getting the right 2 door pizza prep table for your kitchen is like finding the perfect puzzle piece - it needs to fit your space, match your workflow, and handle your daily production volume without breaking a sweat. We've seen too many operators fall in love with a unit's features only to find it won't actually fit through their kitchen door or leaves their staff bumping into each other during the dinner rush.

The key is thinking beyond just the unit itself. You need to consider how it integrates with your existing layout, where your electrical connections are, and how much storage capacity you actually need during your busiest periods.

Dimensions and Capacity

When we talk about 2 door pizza prep table dimensions, most units fall into a fairly standard range that works well for professional kitchens. Typical widths run from 67 to 71 inches, though you'll find larger models stretching up to 93 inches for high-volume operations that need extra workspace and storage.

The unit depth is equally important - most models measure around 31 to 33 inches deep. This might not sound like much, but in a busy kitchen where every inch counts, you need to ensure there's enough clearance for staff to move comfortably behind the unit while doors are open.

Here's where pizza prep tables really shine: that cutting board depth of 19 inches or more gives you the generous workspace needed for stretching large pizza doughs. Compare that to sandwich prep tables with their narrower boards, and you'll immediately understand why this extra depth matters when you're handling 16-inch pizza bases during a Friday night rush.

Interior capacity typically ranges from 16 to 20 cubic feet, with some larger models offering up to 28.4 cubic feet of refrigerated storage space. The refrigerated pan rail accommodates 9 standard 1/3-size food pans up to 6 inches deep, keeping your most popular toppings at the perfect temperature and within easy reach.

The real beauty lies in the adjustable shelving below. This flexibility lets you customize the storage to fit your specific needs - whether that's stackable dough trays, bulk ingredient containers, or backup supplies for your busiest shifts. The ability to reconfigure shelf heights means your storage can evolve as your menu and operations change.

Power and Electrical Requirements

Understanding the electrical needs of your 2 door pizza prep table prevents those frustrating installation delays that can keep your new equipment sitting unused while you wait for an electrician. Most professional-grade units operate on standard 115V/60/1-phase power, which is the same voltage your other small kitchen appliances likely use.

Amperage draw varies between 3 and 9 Amps depending on the compressor size and additional features. While this might seem modest, we always recommend connecting these units to a dedicated circuit. This prevents potential issues during peak operation when multiple pieces of equipment are running simultaneously.

You'll find most units come with a NEMA 5-15P plug - that's the standard three-prong grounded plug you're familiar with. The cord length typically runs 8 to 9.5 feet, giving you some flexibility in positioning without needing extension cords, which many health departments frown upon in professional kitchens.

Compressor horsepower ranges from 1/5 HP up to 2/3 HP for heavy-duty models. Higher horsepower doesn't just mean more cooling power - it also indicates the unit's ability to recover quickly after frequent door openings and maintain consistent temperatures during busy periods.

Before making your final decision, double-check these specifications against your kitchen's electrical capacity. The last thing you want is to find your electrical panel can't handle the new equipment after it's already delivered.

Making the Right Choice: Price, Warranty, and Maintenance

Choosing a 2 door pizza prep table is a big step for your business. It's more than just buying a piece of equipment; it's an investment in your kitchen's future. We want you to think beyond the initial price tag. Consider the total cost of ownership. This includes things like how much energy it uses, how easy it is to maintain, and what kind of warranty it comes with. Protecting your purchase and making sure it lasts a long time are key to getting the best return on your investment.

Understanding the Price Range and Cost Factors for a 2-Door Pizza Prep Table

The cost of a 2 door pizza prep table can vary quite a bit. You'll typically see prices from around $2,500 to $5,500. Some very fancy or extra-large models might even go higher. Why such a range? Well, a few things play a big part.

Brand reputation often influences the price. Well-known brands usually cost more because they've built a name for reliability and great customer service. The material quality also matters a lot. If a table uses higher-grade stainless steel (like 304-gauge) or special worktops like granite, it will naturally be pricier. Think of it as buying a car – a luxury model costs more for a reason!

The compressor type makes a difference too. More advanced compressors, especially those using eco-friendly R290 refrigerant or with self-cleaning features, might raise the initial price. But, they often save you money in the long run on energy bills and maintenance. Advanced features like precise digital temperature controls, special anti-corrosion coatings, bright LED lighting, or super-efficient insulation also add to the cost. However, these features usually mean better performance and more convenience for your team. Lastly, a longer and more comprehensive warranty length can sometimes mean a slightly higher upfront cost, but it offers greater peace of mind.

It’s easy to just pick the cheapest option. But we really encourage you to look at the big picture. Investing a little more upfront in a well-built, energy-efficient 2 door pizza prep table can save you a lot of money on operational costs down the road. Plus, you’ll have fewer headaches from unexpected breakdowns. It’s about value over time, not just the price today.

Warranty, Support, and Long-Term Maintenance for Your 2-Door Pizza Prep Table

A strong warranty is a sign that a manufacturer truly believes in their product. For a 2 door pizza prep table, you can usually expect a standard warranty of 1 to 3 years on parts and labor. The compressor, which is like the heart of the refrigeration system, often comes with an even longer warranty, frequently 5 years or more. It's always a good idea to double-check the warranty details, especially if you plan to use the table in a food truck or trailer, as terms might be different for those setups.

Beyond the warranty, consider the support you'll get after your purchase. At The Restaurant Warehouse, we're proud to offer fantastic support to all our customers. We make sure you can get technical help and replacement parts whenever you need them. Our goal is to provide affordable, wholesale pricing without ever cutting corners on quality or support.

Keeping your 2 door pizza prep table running smoothly for years really comes down to routine maintenance. These simple tasks make a huge difference:

- Routine Cleaning: Regularly wipe down all inside and outside surfaces with a mild soap and water solution. This keeps things sparkling clean and hygienic.

- Condenser Coil Maintenance: Don't forget to periodically clean the condenser coil. Dust and debris can build up, making the compressor work harder and use more energy. Many modern units have easy-to-reach or even self-cleaning condensers, which makes this job much simpler.

- Gasket Inspection: Check the magnetic door gaskets often for any tears or gaps. If they're damaged, cold air can escape, and warm air can get in, costing you energy. Luckily, many gaskets are tool-less for easy removal and cleaning.

- Sanitization Procedures: Always follow proper cleaning rules for any surfaces that touch food, like the cutting board and pan rail. This prevents germs from growing and keeps your ingredients safe and fresh.

By following these simple maintenance tips and knowing you have reliable support from us, your 2 door pizza prep table will be a hardworking part of your pizzeria for many years. Ready to find the perfect unit for your kitchen? You can always Contact Us for purchasing options.

Frequently Asked Questions about 2-Door Pizza Prep Tables

When you're shopping for a 2 door pizza prep table, we know you probably have questions. After helping hundreds of pizzeria owners find the perfect prep table, we've noticed the same concerns come up time and again. Let's tackle the most common questions we hear, so you can make your decision with confidence.

What is the main difference between a pizza prep table and a sandwich prep table?

Here's the thing that catches most people off guard: it's all about the cutting board depth. A 2 door pizza prep table comes with a much deeper cutting board, typically 19 inches or more, because you need that extra space to stretch out pizza dough without bumping into the refrigerated pan rail.

Think about it this way – when you're making a 16-inch pizza, you need room to work. A sandwich prep table's narrow cutting board might give you just enough space for a sub roll, but it'll leave you struggling when you're trying to toss dough or spread sauce on a large pizza base.

The pan configurations are different too. Pizza prep tables are designed to hold the variety of toppings that make pizzas special – multiple cheeses, various meats, fresh vegetables, and specialty ingredients. The refrigerated rail layout reflects this need for diverse ingredient storage, while sandwich tables focus more on the basics like lettuce, tomatoes, and cold cuts.

How important is an NSF certification for a professional prep table?

We can't stress this enough – NSF certification isn't just nice to have, it's absolutely essential for your 2 door pizza prep table. This certification from NSF International means your equipment has been put through rigorous testing to ensure it meets strict food safety and sanitation standards.

Here's why this matters for your daily operations: NSF certification verifies that the materials used are safe for food contact, the design promotes proper cleaning and prevents bacterial growth, and the construction can withstand the demands of a busy food service environment. When the health inspector visits your pizzeria, seeing that NSF certification mark gives them confidence that you're serious about food safety.

Without NSF certification, you might face challenges during health inspections, and some local health departments actually require it for food service equipment. It's one of those things that seems like a small detail until you realize it can make or break your ability to pass inspection and keep your doors open.

Can I use different sizes of food pans in the refrigerated rail?

Most 2 door pizza prep table units are specifically designed for standard 1/3-size food pans that are up to 6 inches deep. These pans fit perfectly into the refrigerated rail, creating a tight seal that keeps your ingredients at the right temperature even during busy periods.

Now, here's where it gets interesting – some models do offer flexibility with adapter bars or specialized inserts that let you use different pan configurations. You might be able to fit 1/6-size pans for smaller portions of specialty toppings, or 1/9-size pans for expensive ingredients like truffle oil or specialty cheeses.

But here's our advice: always check the manufacturer's specifications before you start experimenting with different pan sizes. Using pans that don't fit properly can create gaps that let cold air escape, which means your ingredients won't stay at safe temperatures. That's not just bad for food quality – it's a food safety risk that could get you in trouble with health inspectors.

The key is making sure whatever pans you use create that proper seal in the rail. When in doubt, stick with the recommended 1/3-size pans – they're the standard for a reason, and they'll give you the most reliable performance from your prep table.

Conclusion

So, we've walked through quite a journey, haven't we? It's clear by now that a 2 door pizza prep table isn't just another piece of equipment for your pizzeria; it's truly a cornerstone, a central hub that transforms how your kitchen runs. We've seen how this smart investment can completely change your daily operations, bringing a wonderfully streamlined workflow, precise temperature control, and a significant boost in productivity.

Think about it: from the moment you choose a unit with its durable stainless steel construction – especially that high-grade 304-gauge steel – you're setting yourself up for success. And let's not forget the eco-friendly R290 refrigerant, which isn't just kind to the planet but also helps you save big on energy bills. Every thoughtful feature, like the precise digital controls that keep your ingredients perfectly chilled, and those crucial NSF and ETL certifications that prove you meet all health and safety standards, adds immense long-term value. It's all about making your life easier and your business better.

So, when it comes time to pick out your perfect 2 door pizza prep table, remember it's more than just the price tag. You'll want to think about its capacity for all those delicious toppings, its power requirements to fit seamlessly into your kitchen, and the excellent support you'll get for its maintenance. When you invest in a quality unit from The Restaurant Warehouse, you're not just getting a piece of equipment. You're building a strong foundation for amazing operational efficiency, rock-solid food safety compliance, and that consistent product quality your customers will rave about. This is how you set your pizzeria up for success, not just for today, but for many, many years down the road. Ready to chat about what your kitchen needs? We'd love to help! Feel free to Book a Strategy Call to discuss your needs.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment