Maximize Your Space: Top 72-Inch Pizza Prep Tables

Why 72-Inch Pizza Prep Tables Are Essential for High-Volume Operations

A 72 inch pizza prep table offers the perfect balance of workspace and storage for busy kitchens that need to maximize efficiency. These units provide 16.9 to 23 cubic feet of refrigerated storage while maintaining optimal ingredient temperatures between 33°F and 41°F. They solve a critical workflow problem: keeping frequently used ingredients at arm's length while providing ample workspace for consistent pizza preparation. Instead of constant trips to walk-in coolers, everything stays organized and accessible in one central station.

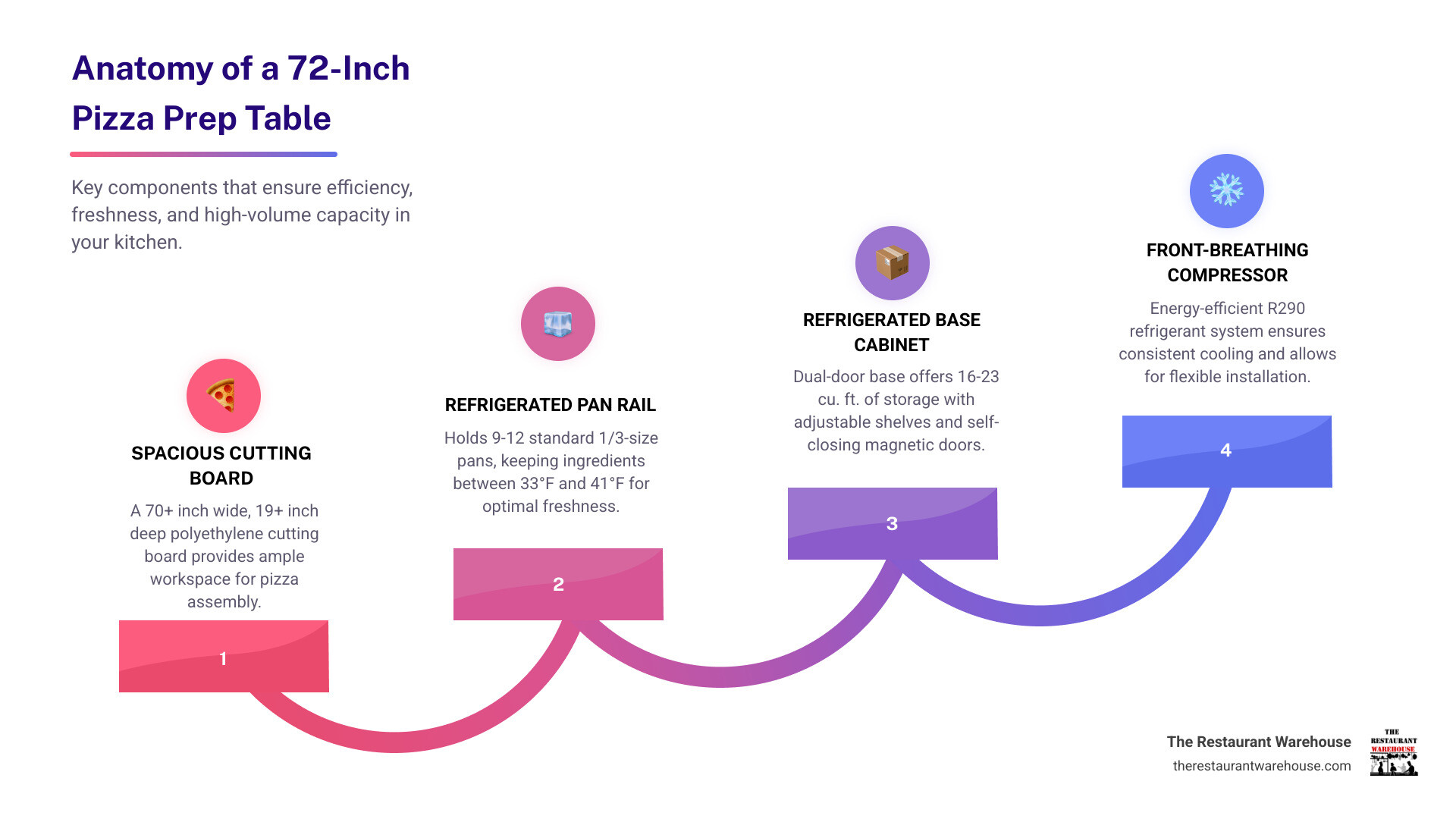

Top 72-inch pizza prep tables typically feature:

- Spacious cutting boards - 70+ inches wide with 19+ inch depth

- Large pan capacity - Hold 9-12 standard 1/3-size pans

- Dual-door refrigerated base - 16-23 cu. ft. storage capacity

- Temperature range - 33°F to 41°F for food safety compliance

- Durable construction - Stainless steel exterior with aluminum interior

- Energy-efficient refrigeration - R290 refrigerant systems

- Professional features - Self-closing doors, adjustable shelves, magnetic gaskets

The combination of refrigerated storage below and ingredient pans above creates ideal prep-line efficiency, where speed meets food safety standards without compromise. A well-chosen 72 inch pizza prep table can transform how your team operates, ensuring ingredients are fresh, organized, and always within reach. This impacts overall kitchen workflow, food safety, and your bottom line. The generous workspace minimizes bottlenecks and keeps the production line moving smoothly, even when orders are flying in.

For a deeper dive into how these units can revolutionize your workflow, we invite you to explore our comprehensive Pizza Prep Table Guide.

The Ideal User for a 72-Inch Unit

Who stands to gain the most from investing in a 72 inch pizza prep table? These units are particularly beneficial for:

- High-volume pizzerias: Allows multiple pizza makers to work side-by-side, ensuring orders are fulfilled quickly during peak times.

- Large restaurants with diverse menus: The large refrigerated workspace can be leveraged for prepping salads, sandwiches, and other items.

- Catering businesses: A mobile, self-contained prep station with heavy-duty casters is a game-changer for off-site events.

- Ghost kitchens: Provides a compact yet comprehensive solution for ingredient storage and preparation in a streamlined, delivery-focused environment.

- Any establishment prioritizing speed and consistency: From busy delis to cafeterias, the benefits are immediately apparent for any operation relying on quick assembly.

Sizing Up the Benefits

The advantages of a 72 inch pizza prep table fundamentally improve operational dynamics.

- Streamlined assembly line: Centralizing ingredients and workspace creates an intuitive flow that significantly reduces preparation time per item.

- Reduced staff movement: With everything at hand, your team spends less time walking to storage areas, boosting productivity and reducing fatigue.

- Centralized prep station: Consolidates refrigerated storage, a cutting surface, and ingredient pans into one footprint, simplifying inventory management.

- Improved food quality: Consistent temperature maintenance (as low as 33°F) means ingredients remain fresher for longer, resulting in a higher quality product.

- Meeting peak demand: The capacity to hold large volumes of ingredients and accommodate multiple users means you can handle sudden surges in orders.

For more insights into how these stations can lift your kitchen, check out our guide on Pizza Prep Stations.

How a 72-Inch Prep Table Improves Ticket Times

A longer, deeper board and a full-width rail mean two staff can work simultaneously—one stretching dough and saucing, the other topping and finishing. Even a modest 15–20 seconds saved per pie adds up fast. At 100 pizzas per peak shift, that’s 25–33 minutes of production time reclaimed. Over a week, the time savings can translate into an extra service turn, reduced overtime, or the ability to absorb delivery surges without compromising quality.

- Faster mise en place resets between orders thanks to organized pan layout

- Fewer ingredient hand-offs between stations as everything is within reach

- More consistent portioning due to stable, visible pan positions and clear sightlines

Space Planning and Installation Considerations

Before you buy, measure the intended space carefully and plan for:

- Door swings and clearance: Ensure doors can open fully (and benefit from 90° stay-open features) without blocking aisles.

- Power availability: Confirm voltage and amperage requirements, and dedicate a circuit if needed to avoid nuisance trips.

- Ventilation path: Front-breathing models can sit flush to the wall, but always follow the manufacturer’s clearance recommendations for optimal airflow.

- Workflow adjacency: Place your 72-inch table between the dough station and finishing/boxing area to minimize backtracking.

Food Safety, Quality, and Compliance

Maintaining 33°F–41°F is about more than regulations—it’s about taste and texture. Cold toppings resist wilting and bleeding, shredded cheese holds better, and proteins stay within safe limits during busy, frequent lid openings. With proper lids and disciplined rail use, you’ll extend holding life and reduce shrink.

- Use dedicated utensils per pan to minimize cross-contact

- Rotate pans FIFO, pulling fresh refills from the base as the rail depletes

- Keep a simple temperature log at open, mid-shift, and close to catch issues early

Real-World Capacity Planning

A 72-inch rail that holds 9–12 1/3 pans lets you dedicate high-demand ingredients to larger pans and split lower-volume items without overcrowding. In the base, adjustable shelves can be configured for dough boxes, sauce tubs, cheese totes, and backup pans. Map your top 12 toppings to the rail, then stage the next-most-used items at chest height in the base to support quick swaps during rushes.

ROI You Can See

- Labor: Less walking, fewer trips to the walk-in, and fewer interruptions per ticket.

- Waste: Better cold retention reduces topping breakdown and spoilage.

- Throughput: A wider, dedicated board and rail increases line capacity without enlarging your kitchen footprint.

For teams expanding from a 48- or 60-inch station, upgrading to a 72-inch unit often feels like opening a second make-line—without the added staffing or square footage.

Key Features to Look for in a 72 Inch Pizza Prep Table

When investing in a 72 inch pizza prep table, understanding the key features is crucial for your daily operations. The difference between a good unit and a great one lies in the details of its refrigeration system, construction, and workspace design.

Refrigeration System: The Heart of Freshness

A reliable refrigeration system is the most critical component. The best systems consistently maintain the food-safe temperature range of 33°F to 41°F, even during the busiest service hours.

- NSF-7 Compliance: This certification ensures the unit can hold product temperatures at 41°F or below, a critical standard for commercial kitchens.

- Cooling Methods: Forced-air cooling circulates cold air throughout the pan rail and base, while cold-wall cooling builds coils into the rail walls, creating a "blanket of cold." Some advanced cold-wall systems allow the rail to be shut off independently to save energy (up to 60%) overnight, provided toppings are moved to the refrigerated base.

- Energy Efficiency: The industry standard is now environmentally friendly R290 refrigerant. This propane-based coolant is not only better for the environment but is also energy-efficient compared to legacy refrigerants, helping lower utility bills.

- Practical Design: A front-breathing design allows the unit to be placed flush against a wall and provides easy access to the compressor for maintenance.

- Advanced Controls: Digital thermostats and Dixell controllers offer precise temperature management and monitoring. Adaptive defrost systems are a smart feature, running defrost cycles only when ice buildup is detected, which saves energy and prevents unnecessary warming of ingredients.

Best practices to support the refrigeration system:

- Pre-chill clean, empty pans before loading toppings into the rail

- Keep insulated lids closed during lulls to retain cold and reduce frost

- Wipe gaskets daily and inspect for tears to maintain a tight seal

- Clean condensers monthly or more frequently in greasy, dusty environments

For tips on keeping your refrigeration system running smoothly, our Sandwich Prep Table Maintenance guide offers practical advice.

Construction and Durability: Built to Last

The quality of construction determines the longevity of your 72 inch pizza prep table.

- Materials: Type 304 stainless steel is the gold standard for food service applications due to its excellent resistance to corrosion and acids. Look for a lower gauge thickness (e.g., 18-gauge or 14-gauge), as this indicates thicker, more durable steel that can withstand daily abuse. Interiors are often made of corrosion-resistant aluminum, while back panels may use durable galvanized steel.

- Hygiene and Sanitation: Design details like rounded interior corners prevent bacteria buildup and make cleaning easier. Magnetic gaskets that are removable without tools are essential for maintaining a tight seal and proper sanitation. Ease of cleaning should be a priority, with smooth, accessible surfaces that reduce cleanup time.

- Insulation: High-density polyurethane foam-in-place insulation helps stabilize temperatures, resist heat infiltration, and supports structural rigidity without adding unnecessary weight.

- Hardware: Heavy-duty hinges, door stays, and full-length handles contribute to longevity and reduce service calls.

- Serviceability: Front-access service panels and slide-out condensing units make maintenance tasks faster and less disruptive to operations.

Our Stainless Steel Prep Table Guide dives deeper into why material choices are so important.

Workspace and Ergonomics: Designing for Efficiency

The workspace design directly impacts your team's speed and comfort.

- Cutting Board: A key feature of a pizza prep table is its deep cutting board, typically 14 to 19 inches or more. This extra depth is necessary for working with large pizza crusts. Polyethylene cutting boards are the standard as they are durable, easy on knives, and simple to remove for cleaning.

- Refrigerated Rail: The raised, angled refrigerated rail makes these tables highly efficient, keeping ingredient pans visible and within easy reach. This ergonomic design reduces strain on staff during long shifts.

- Pan Capacity: A 72-inch unit typically holds 9 to 12 standard 1/3-size pans, allowing you to keep a full range of toppings ready without constant restocking.

- Insulated Lids: This feature is crucial for locking in cold air, maintaining consistent temperatures, and improving energy efficiency, especially during slower periods or overnight.

- Board Height and Reach: Standard working heights support neutral wrist posture, while the angled rail reduces overreaching. If staff are different heights, consider anti-fatigue mats to keep ergonomics optimal during long shifts.

- Organization: Label pan positions and standardize a left-to-right build sequence (sauce, cheese, primary toppings, finish) to cut decision time and make training faster.

For more insights on optimizing your kitchen workflow, our Prep Table Kitchen Guide offers practical advice.

Comparing Configurations: Doors, Drawers, and Custom Setups

Doors vs. Drawers: What's Best for Your Workflow?

Both doors and drawers offer distinct advantages, and the best choice depends on your operational needs.

-

Doors for bulk storage:

- Pros: Offer larger, open storage compartments ideal for bulk ingredients like cheese blocks, sauce containers, or dough boxes. They generally provide more total cubic footage.

- Cons: Accessing items at the back can require bending and reaching.

-

Drawers for pan rotation:

- Pros: Excellent for organizing and rotating pans of ingredients. They simplify swapping empty pans from the rail with fresh ones from below and offer ergonomic, quick access.

- Cons: May offer slightly less overall bulk storage capacity than door compartments.

- Combination units: Many 72 inch pizza prep table models offer a mix of doors and drawers, providing a versatile solution for both bulk storage and quick pan access.

High-volume operations with frequent pan changes often prefer drawers for their speed, while kitchens needing to store diverse bulk ingredients may find doors more practical.

| Feature | Doors | Drawers |

|---|---|---|

| Storage Capacity | Generally higher cubic footage | Often slightly less bulk capacity |

| Accessibility | Good for large, bulky items | Excellent for organized, quick pan access |

| Organization | Requires internal shelving/bins | Self-organizing with pan inserts |

| Ideal Use Case | Bulk ingredient storage, backup supplies | Rapid pan rotation, specific item access |

Customizing Your 72 Inch Pizza Prep Table Setup

Beyond doors and drawers, several features allow you to optimize your 72 inch pizza prep table.

- Number of sections: A 72-inch unit is commonly a two-section (two-door) design, but three-door configurations are also available for more segmented storage.

- Adjustable shelves: Heavy-duty, PVC-coated adjustable shelves are a must-have for customizing the base storage to fit various container sizes. Look for high load capacities (some support up to 155 lbs) to handle heavy ingredients.

- Casters for mobility: Most commercial units come with pre-installed casters, making them easy to move for cleaning. Locking casters are essential for stability during use.

- Door Features: Self-closing doors help maintain internal temperatures and save energy. A 90-degree stay-open feature is a convenient addition that allows for easy loading and unloading with both hands.

- Magnetic gaskets: These ensure a tight seal to prevent cold air from escaping. Look for gaskets that are removable without tools for easy cleaning and replacement.

Additional configuration tips:

- If your menu relies on frequent pan swaps (e.g., multiple cheese blends or seasonal vegetables), prioritize a drawer bank directly beneath the rail positions that turn fastest.

- For New York–style pizzas with larger dough boxes (18"x26"), confirm door-compartment clearances and shelf spacing to fit trays without tilting.

- Consider dedicating one section to sauces and par-baked components; group like items to reduce open time per door or drawer.

- Choose rail pan layouts you’ll actually use daily; a neat 9-pan layout you stick to is better than a 12-pan layout that becomes chaotic mid-rush.

Understanding these features is the key to selecting a table that is perfectly optimized for your kitchen’s unique operational demands.

Frequently Asked Questions about 72-Inch Pizza Prep Tables

Here are answers to the most common questions about purchasing and maintaining a 72 inch pizza prep table.

What is the difference between a pizza prep table and a sandwich prep table?

While they look similar, these tables are designed for different workflows. The key distinctions are:

- Cutting Board Depth: A 72 inch pizza prep table features a deep, 14 to 19-inch cutting board, providing essential space for stretching dough and assembling large pizzas. Sandwich prep tables typically have a much shallower board (8-9 inches).

- Rail Design: Pizza prep tables use a raised, angled refrigerated rail. This ergonomic design lifts ingredient pans up and tilts them toward the user for easy access while building a pizza.

- Pan Compatibility: Pizza prep tables are designed for larger 1/3-size food pans to hold high volumes of common toppings like cheese and pepperoni. Sandwich tables typically use smaller 1/6-size pans for a wider variety of ingredients in smaller quantities.

The entire ergonomic flow of a pizza prep table is optimized for the specific motions of pizza making. To help decide which style is right for you, see our guide on how to Choose Sandwich Prep Station.

How do I maintain my 72 inch pizza prep table for longevity?

Proper care will ensure your investment serves your kitchen for years. Follow a consistent maintenance schedule:

- Daily Cleaning: Thoroughly clean all food contact surfaces (cutting board, pan rail, stainless steel) with mild soap and water, followed by a sanitizing solution. This prevents residue buildup and ensures food safety.

- Gasket Care: Daily, inspect the door gaskets for tears or damage. A proper seal is crucial for energy efficiency and temperature control. Many modern units feature tool-free gasket removal for easy cleaning and replacement.

- Condenser Coil Cleaning: Monthly, clean the condenser coil to remove grease and dust buildup. A clogged coil forces the compressor to work harder, increasing energy consumption and risking equipment failure. Front-breathing designs make this task easier.

- Temperature Monitoring: Regularly log internal temperatures to ensure they remain consistently between 33°F and 41°F. This helps you spot potential issues before they become critical problems.

- Annual Professional Servicing: Have a qualified technician inspect your unit annually to check refrigerant levels, electrical components, and perform deep maintenance to keep it running efficiently.

Our Sandwich Prep Table Maintenance guide offers more detailed tips applicable to all refrigerated prep equipment.

What are the typical price ranges for these units?

The price of a 72 inch pizza prep table varies based on features, materials, and construction.

- Entry-level models ($2,500 - $4,000): These units provide reliable refrigeration and solid construction, making them a great choice for new businesses or lower-volume operations.

- Mid-range models ($4,000 - $6,000): In this range, you'll find more energy-efficient features like R290 refrigerant, more robust compressors, better insulation, and conveniences like self-closing doors. The energy savings can often justify the higher initial cost.

- Premium units ($6,000+): Built for the most demanding kitchens, these tables feature thicker gauge stainless steel, advanced refrigeration technologies (like cold-wall cooling), sophisticated electronic controls, and hybrid door/drawer configurations.

Key factors influencing price include material quality (Type 304 stainless steel vs. others), refrigeration technology, and additional features. When making your decision, focus on long-term value over initial cost. An energy-efficient, well-built unit will save money on utilities and repairs, reducing your total cost of ownership. At The Restaurant Warehouse, we provide wholesale pricing by cutting out middleman markups, ensuring you get better value at every price point.

What electrical and installation requirements should I plan for?

- Power: Verify the unit’s voltage and amperage and supply a dedicated circuit if recommended. Avoid extension cords.

- Clearance: Even with front-breathing designs, follow the manufacturer’s minimum clearance for airflow and service access.

- Leveling: Use the adjustable feet or casters to level the unit; an unlevel cabinet can cause door alignment issues and drainage problems.

- Ambient Conditions: Most units are rated to hold temperature in typical kitchen ambient conditions. Avoid placing the table in direct sunlight or right beside high-heat equipment that could stress the refrigeration system.

How should I set up pan layouts for speed and consistency?

- Map toppings left to right in build order: dough/sauce, cheese, core proteins, vegetables, finishers.

- Place highest-velocity items closest to your dominant hand.

- Dedicate larger pans for high-volume toppings and split lower-volume items into shared wells.

- Maintain laminated planograms at eye level for training and consistency.

Can I shut off the rail at night to save energy?

If your unit supports an independently switchable cold-wall rail, you can shut it off overnight—after transferring toppings to the refrigerated base and sealing pans with lids or wraps. This can significantly reduce overnight energy usage without compromising food safety. Always verify your specific model’s capabilities and follow the manufacturer’s guidance.

How do I care for the cutting board?

- Remove and wash with warm, soapy water; sanitize and air-dry thoroughly before reinstalling.

- Avoid harsh abrasives that can create deep grooves; resurface or replace boards that develop excessive cuts.

- Keep the board free of open flame or extreme heat sources; maintain a dry underside to discourage microbial growth.

What’s the best way to reduce frost and ice around the rail?

- Keep insulated lids closed when not actively building pies.

- Minimize time pans spend out of the rail; swap quickly and keep backups in the base.

- Wipe condensation and spills promptly; moisture accelerates frost formation.

- Ensure door gaskets are intact; warm air leaks drive ice buildup.

How do drawers compare to doors for sanitation and speed during rushes?

Drawers excel when you need rapid, frequent swaps of pre-staged pans. They reduce bending and can be easier to organize by product type. Doors are ideal for large containers and bulk. Sanitation is achievable with either; drawers have more rails and slides to wipe, while door cavities have more open space but may require deeper reaches to clean. Choose based on which pattern best fits your menu and staffing.

What warranty and service considerations matter most?

- Look for clear parts-and-labor coverage on the cabinet and separate coverage on the compressor.

- Confirm availability of common wear parts (gaskets, hinges, handles) and tool-free replacement where possible.

- Favor units with easy-access service panels and front-breathing condensers to minimize downtime during maintenance.

Any tips to reduce food waste with a 72-inch station?

- Portion toppings using consistent scoops or scales to prevent overuse.

- Keep a par list for rail and base; refill just-in-time rather than overloading the rail.

- Store backups sealed and labeled in the base; rotate FIFO and check timestamps at shift change.

- Use insulated lids diligently to extend holding quality and reduce drying or oxidation.

Conclusion: Making the Right Investment for Your Pizzeria

Choosing the right 72 inch pizza prep table is a strategic investment in your kitchen's future efficiency and profitability. These units are genuine game-changers for busy operations, designed to streamline workflow and improve product quality.

The value lies in how a 72 inch pizza prep table transforms your daily process. By centralizing ingredients and workspace, it creates an organized, efficient hub for food production. This translates directly to your bottom line through faster service, reduced food waste, and a more productive staff.

Key features like durable stainless steel construction, energy-saving self-closing doors, and flexible storage with adjustable shelves ensure your investment withstands the rigors of a commercial kitchen. Whether you choose doors for bulk storage or drawers for quick pan rotation, the right configuration will align perfectly with your kitchen's unique demands.

At The Restaurant Warehouse, we understand the challenges of the foodservice industry. That's why we are committed to offering affordable, wholesale pricing on essential equipment. We eliminate the high commissions and retail overhead that inflate prices elsewhere, passing those savings directly on to you.

Your 72 inch pizza prep table is the command center for consistent quality and service. The investment you make today in quality equipment will pay dividends for years through lower energy bills, fewer repairs, and a workflow that can handle peak demand without stress.

Before you finalize your purchase, use this quick checklist:

- Confirm rail capacity and pan layout match your top 12 toppings

- Verify door/drawer configuration aligns with your bulk vs. pan-swap needs

- Measure clearances for door swing, aisle width, and service access

- Check electrical requirements and plan for a dedicated circuit if needed

- Review insulation, gasket design, and serviceability for long-term durability

- Standardize a cleaning and coil-maintenance schedule from day one

For complete guidance on selecting the perfect unit, we invite you to Explore our complete guide to choosing the perfect pizza prep table. We're here to help you make the right choice for your kitchen's success.

When you’re ready, our team can help you compare models, map your ideal pan planogram, and choose the configuration that fits your space and menu. With wholesale pricing and knowledgeable support, you’ll get the right 72-inch station, set up for speed, consistency, and long-term value.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment