Top Tips for Choosing the Best Ice Maker for Hotel Success

Choosing the best ice maker for hotel operations is about more than just buying equipment. It's about selecting a reliable workhorse that boosts the guest experience and protects your bottom line. A dependable supply of quality ice is a non-negotiable amenity, and it directly impacts everything from the cocktails at your bar to guest satisfaction on every floor.

The Strategic Role of Ice in Modern Hospitality

A steady ice supply is so much more than a simple convenience; it’s a critical piece of your hotel’s operational success and brand identity. When you start viewing the purchase of an ice machine as a strategic investment instead of just another equipment buy, the whole decision-making process changes. The right machine will bolster your reputation, while the wrong one can create some serious headaches.

Let’s walk through a real-world scenario. It’s the middle of summer, and your hotel is hosting a sold-out conference. Demand for ice is at its peak as guests flood the hallways. At the same time, your restaurant is slammed, and the bartenders need hundreds of pounds of ice for cocktails and soft drinks. A properly sized, reliable ice maker sails through this challenge, making sure every single guest gets what they need.

But what happens if that machine is undersized or malfunctioning? It quickly turns into a logistical nightmare. Your staff might be forced into emergency runs to buy bags of ice—a costly and inefficient fix. Worse, guests find empty dispensers, which leads to frustration and, almost inevitably, negative online reviews. One bad experience over a seemingly small detail can tarnish their entire stay.

Beyond the Bucket: The Business Impact of Ice

The choice of an ice maker for a hotel has a direct ripple effect across several key areas of your business, extending far beyond the guest floors.

- Revenue Generation: Your bar and restaurant rely on a consistent supply of clean, quality ice. Without it, beverage service grinds to a halt, directly hitting your most profitable revenue streams.

- Guest Satisfaction: From filling a personal cooler to making a drink in their room, guests simply expect ice to be available. A working machine is an unspoken promise; a broken one is a loud disappointment.

- Operational Efficiency: A dependable machine minimizes staff intervention and prevents costly emergency repairs. Smart selection avoids those frantic "what do we do now?" moments that disrupt workflow and pull employees away from guest-facing duties.

- Brand Integrity: Every single touchpoint contributes to your brand's perception. Providing clean, sanitary ice from a well-maintained machine shows a real commitment to quality and guest well-being.

The decision to invest in a specific ice machine is a commitment to your brand's promise. It signals to guests and staff that you prioritize quality, reliability, and safety in every aspect of your operation.

The global market absolutely reflects this importance. The ice maker market was valued at around USD 5.78 billion in 2024 and is projected to keep growing, with the hospitality sector being a major driver. This growth highlights the rising demand for cold beverages and an all-around better customer experience. You can explore more data about the growing ice maker market and its drivers to see the trends. This really underscores that choosing the right machine isn't just about keeping up—it's about leading in guest service.

Accurately Calculating Your Hotel's Daily Ice Needs

Choosing the right size ice maker for your hotel is a balancing act, and a misstep can be surprisingly costly. I’ve seen it happen time and again. An undersized machine means frustrating shortages and unhappy guests during peak season, while an oversized unit is a constant drain on capital, space, and energy. The secret is to go beyond a simple per-room guess and do a real audit of every single spot in your property that uses ice.

The most common mistake I see managers make is basing their calculation solely on the number of rooms. That approach just doesn't work because it ignores the unique demands of your hotel. A 150-room business hotel has a completely different ice footprint than a 150-room resort with two pools, a big conference center, and a hopping nightclub.

To get a number you can actually trust, you have to map out where and how ice is used across your entire operation. It's the only way to make a smart, data-driven decision that guarantees a steady supply without overspending.

Auditing Your Hotel's Ice Consumption Points

Your first move is to conduct a thorough audit. Seriously, grab a notepad and walk your property. List every single area that needs ice, from the most obvious to the easily overlooked. Think beyond what guests see and consider all your back-of-house needs, too.

Your audit list should include places like:

- Guest Floor Dispensers: These are your most visible touchpoints. How many do you have? Where are they located?

- Bar and Restaurant Operations: This is often your biggest ice consumer. You need to account for ice in cocktails, soft drinks, water service, and even kitchen prep lines.

- Room Service: How many orders a day include iced drinks or requests for a bucket of ice? Don't guess—look at your data.

- Catering and Events: Do you host weddings, conferences, or banquets? A single event can chew through hundreds of pounds of ice in a few hours.

- Amenities: Don't forget other spots like a poolside bar, spa facilities, or an executive lounge. Each has its own unique demand.

Once you have your complete list, you can start putting some numbers to it. Industry averages are a great place to start, and you can then tweak them based on what you know about your own hotel's rhythm.

Estimating Daily Ice Production Needs

With your audit complete, you can start translating it into a concrete production number. A standard business hotel might pencil in 5 lbs of ice per guest per day just for room use. But if you’re running a luxury resort in a hot climate, you should probably be budgeting closer to 8-10 lbs per guest. This is where knowing your property's specific character is so important.

A critical takeaway is that forecasting ice demand is not a one-time calculation. You should revisit it seasonally and adjust for special events. This ensures your equipment can handle both average days and peak demand without a hitch.

This careful approach is more important than ever. The hotel ice dispenser market is growing fast as guests increasingly look for sanitary, self-service options. Projections show the market expanding from USD 4.22 billion in 2025 to USD 7.85 billion by 2035, a clear sign that guest expectations are rising. You can read the full analysis on hotel ice dispenser market trends to see how things are shifting.

To help you visualize this, I’ve put together a quick chart to estimate daily ice needs.

Hotel Ice Consumption Estimation Chart

This table gives you a basic framework for calculating the total daily ice your hotel might need. We'll use a sample 150-room hotel at full occupancy to make it concrete. (Assuming 1.5 guests per room, or 225 total guests).

| Usage Point | Estimated Ice Per Person/Day | Example Calculation (150-Room Hotel) |

|---|---|---|

| Guest Rooms (Self-Serve) | 5 lbs per guest | 225 guests x 5 lbs = 1,125 lbs |

| Restaurant & Bar | 3 lbs per seat | 100 seats x 3 lbs = 300 lbs |

| Room Service | 10 lbs per bucket | 25 daily requests x 10 lbs = 250 lbs |

| Catering (Small Event) | 2 lbs per attendee | 50 attendees x 2 lbs = 100 lbs |

| Total Estimated Need | — | 1,125 + 300 + 250 + 100 = 1,775 lbs/day |

As you can see, our 150-room hotel could easily need a machine capable of producing over 1,700 lbs of ice per day. By breaking down your consumption this way, you can confidently select an ice maker for your hotel that truly fits your needs, ensuring you’re prepared for any level of demand.

Matching the Ice Maker Type to Hotel Operations

Selecting the right ice maker for a hotel is about more than just crunching numbers on daily volume. It's about playing matchmaker—pairing a machine's specific design and function to the unique operational zones within your property. The high-capacity workhorse you need for a bustling hotel kitchen is a completely different beast than the quiet, user-friendly unit required for a guest hallway.

Get this match right, and you’re looking at enhanced efficiency, happier guests, and a much smoother workflow for your team. But a mismatch? That’s where the headaches start. Imagine the noise complaints from putting a loud, air-cooled modular unit next to your premier suites. Or the service bottlenecks from trying to supply a busy bar with a small undercounter model that can't keep up. By understanding the main types of commercial ice machines, you can place the perfect unit exactly where it's needed.

High-Volume Modular Ice Makers

For the demanding heart of your hotel—the kitchen or a central ice supply hub—a modular ice maker is almost always the answer. These are the heavy lifters of the ice world. A modular unit is a two-part system: a separate ice-making "head" that sits right on top of a storage bin.

This design gives you incredible flexibility. You can mix and match components to create a system that’s just right for your needs. If your ice demand grows down the line, you can often upgrade just the ice maker head to a model with a higher capacity, without having to replace the entire storage bin. That’s a significant capital saving. These machines are built for high-volume production, some churning out 500 to over 2,000 lbs of ice per day. They are the engine that keeps your restaurant, bar, and catering operations running at full steam.

Space-Saving Undercounter Ice Makers

Now, picture the tight quarters of a hotel bar, a small café, or a poolside service station. A big modular unit just wouldn't work. This is where undercounter ice makers really shine. These self-contained machines combine the ice maker and storage bin into one compact unit, designed to slide neatly under a standard 34-inch-high counter.

Their production capacity is lower, typically ranging from 50 to 350 lbs per day, but their true value is in their small footprint and point-of-use convenience. Placing an undercounter unit right where it's needed empowers your bartenders and servers with immediate access to fresh ice. This speeds up drink service and means they don’t have to leave their station to haul ice from a central location.

Guest-Facing Ice Dispensers

Finally, we have the most visible ice machine in any hotel: the guest-facing ice dispenser. These units are specifically engineered for self-service in public areas like hallways and lounges. For these machines, hygiene, safety, and ease of use are far more important than raw production power.

Modern dispensers usually feature push-button or lever activation. This is a critical design choice that prevents guests from scooping ice with their hands (or worse, a used glass), which is a major step in preventing cross-contamination. Many models now also include antimicrobial surfaces to stop bacteria and mold growth—a key selling point for today's health-conscious travelers.

A guest's experience with the ice machine directly reflects your hotel's commitment to hygiene. A clean, modern, and perfectly working dispenser builds trust. A dirty or broken one can instantly sour their impression of your entire property's cleanliness standards.

Comparison of Hotel Ice Maker Types

Choosing the right ice machine is a critical decision that impacts both your staff's workflow and your guests' experience. To help you visualize how different types fit into a hotel setting, we've put together a comparison of the most common options, from the back-of-house workhorses to the quiet, guest-facing units.

| Ice Maker Type | Best For | Capacity Range | Pros | Cons |

|---|---|---|---|---|

| Modular Ice Makers | High-volume areas like kitchens, central supply hubs, and large banquet facilities. | 500 - 2,000+ lbs/day | Highly customizable; can upgrade head/bin separately; maximum production. | Larger footprint; can be noisy; requires separate bin purchase. |

| Undercounter Ice Makers | Point-of-use locations with limited space, such as hotel bars, cafes, and poolside service stations. | 50 - 350 lbs/day | Compact, all-in-one design; improves workflow by providing ice where needed. | Lower production capacity; not suitable for high-demand areas. |

| Guest Ice Dispensers | Self-service guest areas like hallways, lounges, and fitness centers. | 100 - 500 lbs/day | Hygienic dispensing; easy for guests to use; often features antimicrobial surfaces. | Lower production; focused on safety and ease-of-use over volume. |

Each type serves a distinct purpose. By strategically placing the right machine in the right location, you create a more efficient and guest-friendly operation across your entire property.

The Right Ice for the Right Drink

The machine is only half of the story; the type of ice it makes is just as crucial. The shape and size of the ice cube directly affect beverage quality, presentation, and even your bottom line.

- Full-Cube Ice: This is the classic, slow-melting cube. It's perfect for general use in soft drinks or standard cocktails because it chills drinks effectively without watering them down too quickly.

- Half-Cube Ice: A more versatile choice, half-cubes pack more tightly into a glass, which can create the illusion of a fuller drink. They are great for blended beverages and are dispensed more easily than full cubes.

- Nugget Ice: Often called "chewable ice," this soft, porous ice has become incredibly popular. It soaks up the flavor of the drink and is seen as a premium choice for specialty sodas, smoothies, and high-end cocktails.

- Flake Ice: This soft, moldable ice isn't typically used in drinks but is essential for food presentation. You'll see it on seafood displays, in salad bars, or for therapeutic applications in a hotel spa.

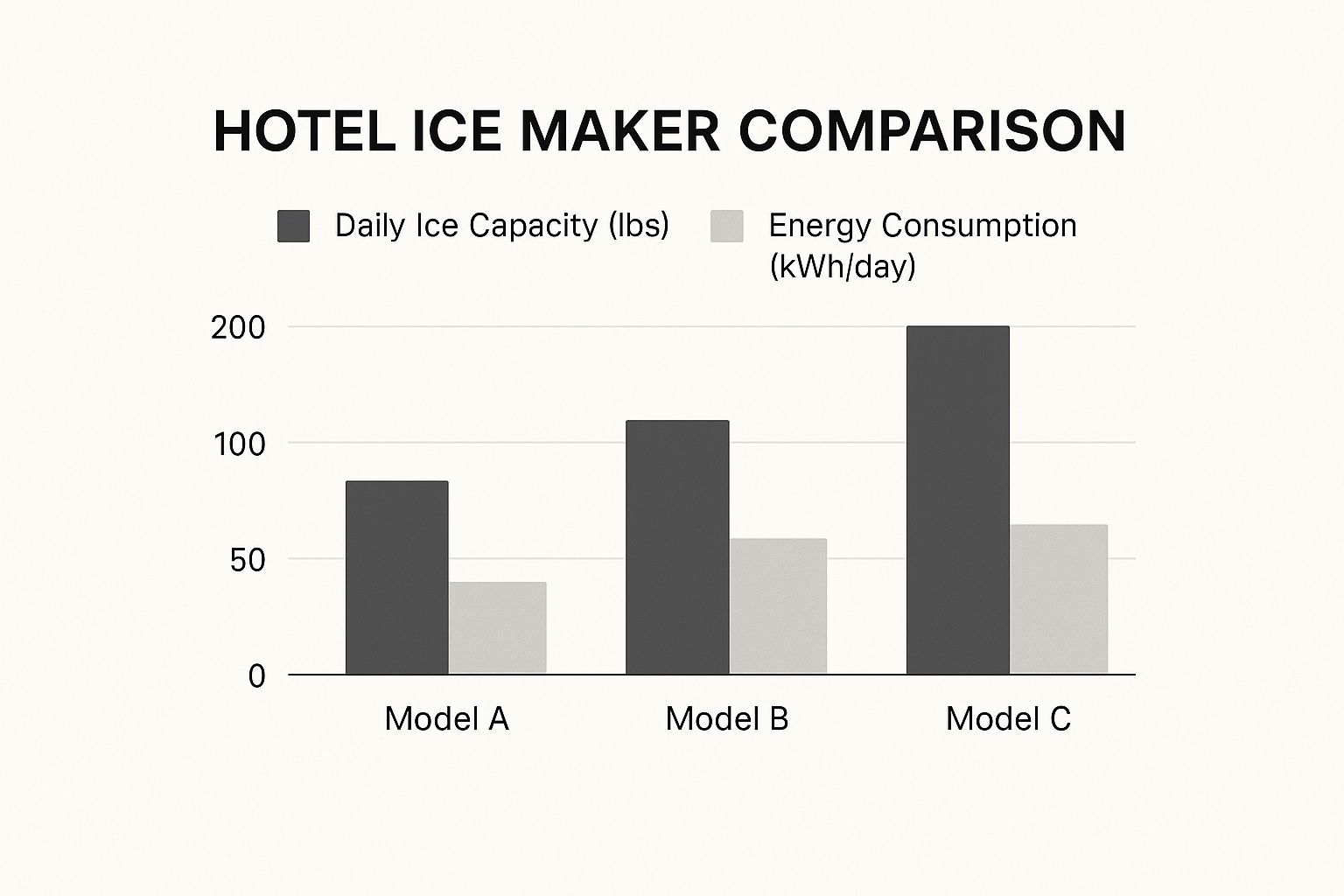

The chart below shows a few common ice maker models, comparing their daily output to their energy use. It gives you a quick snapshot of how these specs can differ.

As you can see, higher ice production almost always means greater energy consumption. This really drives home the importance of sizing your machine accurately to avoid waste. By carefully selecting not just the machine type but also the ice it produces, you can fine-tune every part of your beverage service, from operational efficiency to the guest's final, satisfying sip.

Essential Features for Hotel Ice Machines

Once you’ve settled on the general size and type of ice maker for a hotel, the real work begins. Diving into the specification sheets can feel overwhelming, but this is where you separate a true operational asset from a future headache. Certain features directly impact your daily running costs, staff workload, and, most importantly, guest safety.

Understanding these details is the key to making a smart, long-term investment. It’s not just about how much ice the machine makes, but how efficiently and safely it does so. Let’s break down the critical features you absolutely need to look for.

Energy and Water Efficiency

Your ice machine will be running 24/7, making it a constant consumer of both electricity and water. These costs add up significantly over the life of the unit. Prioritizing efficiency isn't just an eco-friendly choice; it's a direct boost to your bottom line.

The simplest way to gauge efficiency is to look for the ENERGY STAR® certification. Machines with this label are, on average, 10-15% more energy-efficient and 20-30% more water-efficient than standard models. This translates into hundreds, or even thousands, of dollars in savings each year, depending on the machine’s size and your local utility rates.

These efficiency goals are becoming a global standard. Regionally, the ice maker market shows different priorities. North America currently dominates with over 37.8% of the market share, largely driven by demand for convenient and energy-efficient units. In contrast, the European market heavily emphasizes sustainability, pushing for innovations in eco-friendly refrigerants and reduced resource consumption to meet strict environmental regulations. You can discover more insights about regional ice maker market trends on metastatinsight.com to understand these global shifts.

Condenser Types and Your Climate

The condenser is the component that removes heat from the refrigerant, and how it does this is a crucial decision based on your hotel's environment.

- Air-Cooled: These are the most common and generally most affordable option. They use a fan to blow ambient air over the condenser coils. Their main drawback is that they vent hot air into the surrounding space, which can raise the room temperature and put extra strain on your HVAC system.

- Water-Cooled: These units use a continuous flow of water to cool the condenser. They are more energy-efficient than air-cooled models and operate silently, making them ideal for hot kitchens or areas near guests. However, they use a significant amount of water and have a higher upfront cost.

- Remote Condensers: This system places the noisy, heat-producing condenser unit outside or on the roof, away from the ice machine itself. It’s the best solution for keeping guest areas and workspaces cool and quiet, but it involves a more complex and expensive installation.

For a deeper dive into how these components function, you might be interested in our commercial ice machine guide, which covers the mechanics in greater detail.

Sanitation and Guest Safety Features

In the hospitality industry, hygiene is non-negotiable. A dirty ice machine is a serious health hazard and a reputational disaster waiting to happen. Modern machines now come with advanced features designed to make sanitation easier and more effective.

Prioritize models with built-in antimicrobial protection. This often involves a silver-based compound infused into the plastic components of the food zone, which actively inhibits the growth of bacteria, mold, and mildew between cleanings.

Additionally, look for machines with automated cleaning cycles. While these do not replace the need for manual deep cleaning and sanitizing, they simplify the process for your staff, ensuring it gets done correctly and on schedule. These features are vital for keeping guests safe, acing health inspections, and minimizing the labor hours spent on maintenance. A clean machine delivers clear, odorless ice—a small detail that speaks volumes about your hotel's commitment to quality.

Installation and Proactive Maintenance Strategies

The moment your new ice maker arrives is just the beginning. Its long-term performance and lifespan don’t just depend on the factory warranty—they’re almost entirely in your hands, hinging on a perfect installation and a disciplined maintenance routine.

A poorly installed machine will never operate at its best, and skipping regular care is the fastest way to invite disruptive breakdowns and expensive emergency service calls. Let's make sure that doesn't happen.

Getting the installation right is the foundation of a reliable ice maker for a hotel. It goes way beyond just plugging it in and connecting a water line. One of the most common—and costly—mistakes I see facility managers make is failing to provide enough ventilation.

Air-cooled units, the most popular choice for hotels, need room to breathe. We’re talking at least 6-12 inches of clearance on all vented sides. Without it, the machine can't push out hot air effectively. This forces the compressor to work overtime, guzzling energy and leading to a much shorter lifespan.

Critical Installation Requirements

Before the installer even shows up, a little prep work goes a long way. Making sure the designated spot is ready prevents delays and ensures your machine starts its life under ideal conditions. The right setup involves more than just physical space; it means thinking about power and water quality from the very start.

Here are the essential environmental factors to get right:

- A Dedicated Electrical Circuit: Ice machines draw a serious amount of power, especially when they kick on. They absolutely need their own dedicated circuit to prevent tripping breakers, which can halt ice production at the worst possible times.

- Proper Drainage: Your unit needs a floor drain. Make sure it's conveniently located and has a good downward slope. This prevents water from backing up into the machine, which is a major sanitation risk.

- Water Filtration System: This is non-negotiable. Connecting an ice machine without a high-quality water filter is like driving a new car and never changing the oil. A good filter removes minerals and sediment that cause scale buildup—the number one enemy of ice makers.

Ensuring a stable and correct power source is vital for any major piece of hotel equipment. While the specifics can be complex, the principle is universal. For broader insights, you can review guides on power supplies for various business equipment, as many of the core concepts of electrical stability apply.

Building a Proactive Maintenance Schedule

Once your machine is installed and running, a consistent maintenance schedule is your best defense against unexpected failures. Don’t wait for problems to pop up. A proactive approach keeps your machine running efficiently and guarantees the ice you serve is always clean and safe for your guests.

A regular cleaning schedule does more than just protect your investment. It protects your guests. An uncleaned machine can harbor mold, slime, and bacteria, turning a guest amenity into a significant health liability.

A simple yet effective maintenance plan can be broken down into daily, weekly, and semi-annual tasks. You can learn more about the specifics for certain models in our detailed Atosa ice machine maintenance guide, but these general principles apply to most commercial units.

Preventative Maintenance Checklist:

- Daily Checks: A quick visual inspection is all it takes. Check that the machine is producing ice properly and listen for any unusual noises like grinding or excessive vibration. Make sure the area around the unit is clean and clear.

- Weekly Tasks: Wipe down all exterior surfaces. If the machine has a removable air filter, clean it according to the manufacturer's instructions. A clogged air filter is a classic rookie mistake that restricts airflow and strains the compressor.

- Semi-Annual Deep Clean: This is the big one. At least twice a year, the entire machine needs to be shut down, emptied, and thoroughly descaled and sanitized by a trained technician. This process nukes mineral buildup from internal components and eliminates any potential biofilm or mold growth in the food zone.

This structured approach transforms maintenance from a reactive chore into a strategic practice, safeguarding your investment, ensuring guest safety, and keeping your hotel operations running smoothly.

Common Questions About Hotel Ice Makers

Even after you think you’ve got it all figured out, a few nagging questions can stand between you and clicking "buy." Choosing an ice maker for a hotel is a big deal, and it’s completely normal to want to get the details right—especially when those details impact your budget, daily operations, and guest safety.

We hear the same great questions from hotel owners and facility managers all the time. Getting these answers sorted will help you lock in your choice and feel confident that the machine you pick is a perfect fit for your property.

What Is the Real Difference Between Air-Cooled and Water-Cooled?

This is one of the most frequent—and important—questions we get. The choice between an air-cooled and a water-cooled ice maker has a direct line to your installation options and your long-term operating costs.

An air-cooled ice maker is the go-to for most hotels. It’s the industry standard for a reason. These units use fans to pull in the surrounding air and blow it across condenser coils to cool the system. They’re generally cheaper upfront and much simpler to install. The catch? They push warm air back into the room, which can raise the temperature and put a little extra strain on your HVAC, especially if the machine is in a small, enclosed space.

A water-cooled unit takes a different approach, using a continuous stream of water to cool the condenser. This makes them incredibly energy-efficient and almost silent—a massive plus if the machine has to be near guest rooms. The trade-off is a much higher initial cost and, more importantly, a hefty water bill. Unless you're dealing with major ventilation challenges or extreme heat, an air-cooled model is almost always the more practical and budget-friendly choice.

Should I Buy or Lease a Commercial Ice Maker?

The "buy vs. lease" debate really boils down to your hotel's capital budget and how you feel about managing maintenance. There’s no single right answer here, but understanding what each path looks like will make the best choice for your financial strategy pretty clear.

Buying an ice maker for a hotel outright means you’ll spend less money over the machine's entire lifespan. You own the asset, plain and simple. The downside is the big upfront cost and the fact that you're on the hook for all maintenance, service calls, and repairs after the warranty runs out.

Leasing flips that script. It’s a low-to-no-money-down option with a predictable, fixed monthly payment. The biggest perk is that most lease agreements bundle in comprehensive service, covering everything from regular professional cleanings to all repair costs. This is a great fit for hotels wanting to hold onto their capital and avoid the stress of surprise repair bills. A good way to decide is to calculate the total cost of each option over a five-to-seven-year period.

How Important Is a Water Filter?

Let me be clear: a high-quality water filter isn't just an optional accessory. It is an absolutely essential part of your ice machine system. Installing a commercial ice maker without one is one of the costliest mistakes you can make.

A filter's main job is protecting your machine from itself. It pulls out minerals like calcium and magnesium from the water, stopping scale from building up on the internal parts. Scale is the number one cause of breakdowns and inefficiency, forcing the machine to work way harder until it eventually gives out.

But it’s not just about the machine. A filter is critical for your guests. It's the difference between serving ice that is crystal clear, odorless, and tasteless, and ice that makes a guest question the hygiene of your entire hotel. The cost of a good filtration system is a tiny fraction of the repair bills and bad reviews you'll face without one.

How Often Do I Really Need to Professionally Clean My Machines?

This is a critical question for both guest safety and health code compliance. The absolute minimum for a professional deep cleaning and sanitization is every six months. This isn't just a friendly suggestion; it's the standard recommended by manufacturers and required by most local health departments.

Some environments, however, require more frequent cleanings. If an ice machine is near a kitchen where baking happens, airborne yeast can get into the machine, and you should bump that schedule up to every three or four months.

Regular cleaning is the only way to prevent slime, mold, and harmful bacteria like E. coli or Listeria from growing inside the machine. I once heard a food safety expert describe finding a "slimy" film inside a hotel ice bucket, which made him question the hotel's entire hygiene protocol. That’s exactly the impression you need to avoid. A clean machine is non-negotiable for passing health inspections and, more importantly, protecting your guests. For a more detailed look at this, check out our comprehensive guide on choosing the right hotel ice maker.

Ready to equip your hotel with a reliable, high-performance ice maker? Explore our extensive collection at The Restaurant Warehouse. We offer top brands, expert advice, and flexible financing to help you find the perfect solution for your property. Upgrade your guest experience and streamline your operations today. Visit us at https://therestaurantwarehouse.com.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment