Ice Cream Shop Supplies: Essentials for Launching Parlor

Launching an ice cream shop is an incredible dream. But turning that dream into a profitable reality all starts with a solid plan and stocking up on the right ice cream shop supplies. Before you even start dreaming up your signature flavors, you’ve got to get a handle on the tools of the trade—from the heavy-duty machines in the back to the tiny spoons your customers will hold.

Your Essential Ice cream Shop Supply Checklist

Think of this guide as your strategic blueprint. It's a high-level checklist that walks you through every single category of supplies you’ll need to get your doors open and keep things running smoothly. This is your master plan, designed to help you visualize the workflow and budget for every essential piece.

Getting a clear picture of what you need from day one is the best way to avoid costly surprises and operational headaches down the road. Trust me, every single item, from the big batch freezer to the smallest napkin, plays a role in your shop's efficiency and the experience you give your customers.

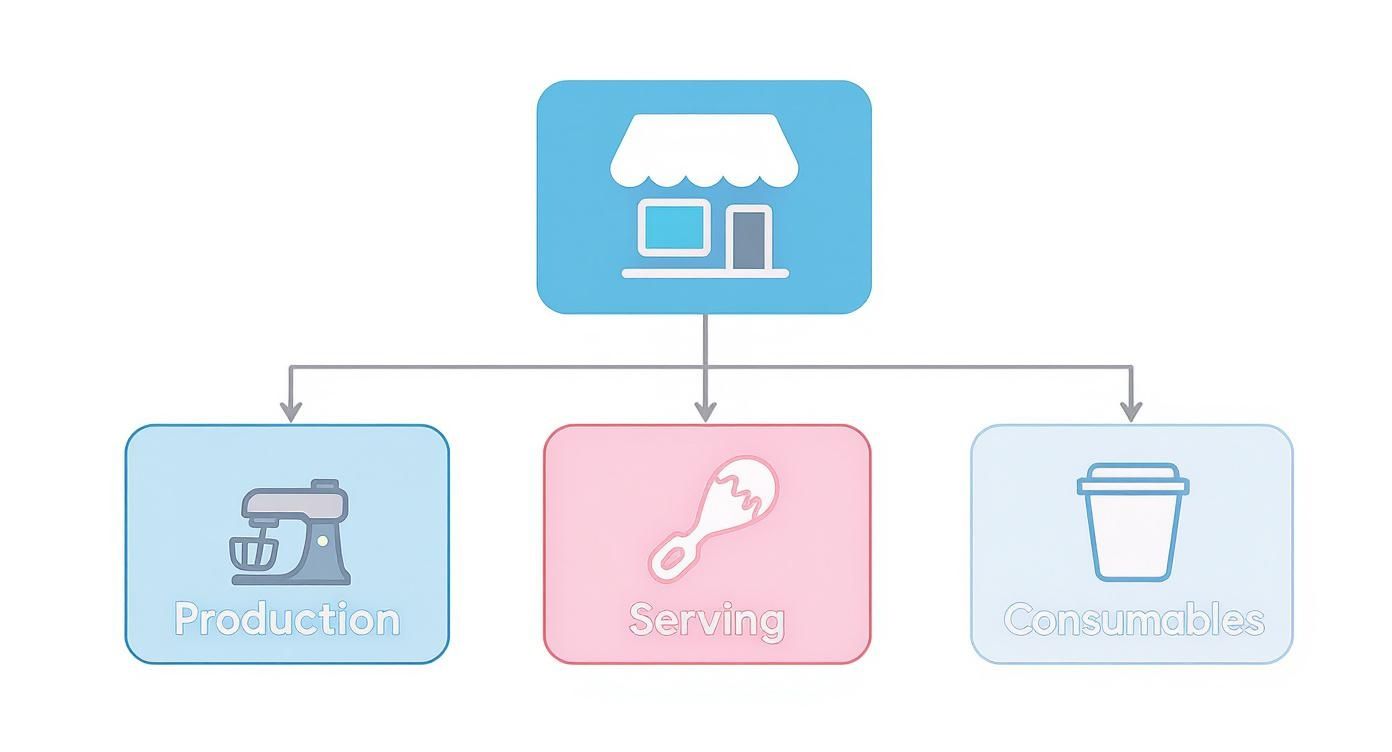

To help you see the big picture, this infographic breaks down the core supply categories into a simple visual.

As you can see, your supplies are split into three main areas that all work together. We’ll dive deep into each one throughout this guide.

To get us started, let's take a quick look at the main categories of supplies you'll be thinking about. Grouping them like this helps make sure you cover all your bases methodically, without anything falling through the cracks.

Essential Ice Cream Shop Supply Categories at a Glance

Here's a quick table to summarize the core areas we’ll be covering. It breaks down what each category is for and gives a few examples so you can start building your mental checklist.

| Supply Category | Primary Function | Key Examples |

|---|---|---|

| Production Equipment | The heart of your operation where the magic happens and ice cream is made. | Batch freezers, soft serve machines, hardening cabinets |

| Serving & Display Equipment | The front-of-house tools that showcase and serve your finished product. | Dipping cabinets, scooping tools, topping stations |

| Consumables & Disposables | Everyday items your customers interact with directly. | Cups, cones, spoons, napkins, lids |

| Pantry Ingredients | The foundational ingredients that create your unique flavors. | Dairy bases, flavorings, sugar, mix-ins, sauces, toppings |

| Cleaning & Safety Supplies | The non-negotiable items that keep your shop clean and up to health code. | Sanitizers, detergents, gloves, first-aid kits |

Each of these categories represents a critical link in the chain that takes you from raw ingredients to a happy customer holding a perfect scoop. Getting them right is fundamental to your success. Now, let's start digging into the details of each one.

The Production Powerhouse: Ice Cream Making Equipment

Let's get to the heart of your shop: the production area. This is where the magic happens, where simple ingredients are spun into the frozen masterpieces your customers will crave. The equipment you choose here is more than just an expense; it’s the core of your manufacturing line and the most critical investment you'll make in your ice cream shop supplies.

Your choice of machinery will define everything—the quality, consistency, and style of your ice cream, not to mention your daily workflow and ability to grow. Getting this right starts with understanding the main players in the game.

Batch Freezers For Artisanal Creations

A batch freezer is the quintessential tool for crafting traditional, hard-pack ice cream, gelato, or sorbet. Think of it as a powerful, fast-acting freezer and mixer all in one. It works by churning a liquid ice cream base at incredibly cold temperatures, freezing the mix while whipping in air and preventing large, crunchy ice crystals from forming.

This is the process that creates that dense, creamy, and smooth texture everyone loves in hand-scooped ice cream. Batch freezers are the perfect fit for shops that want to offer a wide, rotating menu of unique and gourmet flavors. Since you’re making the product in distinct "batches," you have the total freedom to experiment with seasonal ingredients and limited-edition recipes.

Here's what to keep an eye on when you're shopping:

- Capacity: This is measured in quarts or liters and tells you how much ice cream you can churn out in a single cycle. A small startup might do great with a 6-quart machine, but a high-volume shop will likely need a 20-quart model or even larger.

- Cooling System: Most commercial units are water-cooled, which is more efficient for back-to-back use but requires a dedicated water line and drain. Air-cooled models are more flexible in terms of placement but can kick out a lot of heat.

- Dasher Design: The dasher is the blade that scrapes and mixes the ice cream. A well-designed one is key to ensuring a smoother final product with fewer ice crystals.

Soft Serve Machines For Classic Treats

For that iconic, light, and airy swirl, you’ll need a soft serve machine. Unlike a batch freezer, which produces a finished product that needs to be hardened, a soft serve machine freezes the mix and dispenses it on demand. It incorporates more air into the product—a process called overrun—which is what gives soft serve its signature light texture.

These machines are a must-have for high-traffic shops focusing on cones, cups, and classic sundaes. They generally come in two main flavors: gravity-fed models are simpler and less expensive, using gravity to feed the mix into the freezing cylinder. Pump-fed models are a bit more complex but give you precise control over the air-to-mix ratio for a perfectly consistent product every time.

The global ice cream market was valued at approximately USD 82.19 billion in 2024 and is projected to reach USD 136.03 billion by 2032. This incredible growth shows the huge opportunity for new shops, especially those tapping into trends like plant-based options, which require versatile equipment to get right.

To help you visualize the differences and find the right fit for your shop's concept, here's a quick comparison of the main machine types.

Comparing Commercial Ice Cream Machines

| Machine Type | Best For | Typical Capacity | Key Considerations |

|---|---|---|---|

| Batch Freezer | Artisanal hard-pack ice cream, gelato, sorbet, and creating a wide variety of flavors. | 6 to 40+ quarts per batch | Requires a separate hardening cabinet. Offers maximum creative freedom for recipes. |

| Soft Serve (Gravity-Fed) | Classic soft serve cones, sundaes, and milkshakes. Ideal for lower-volume shops or startups. | 10 to 20 quarts per hour | Simpler to operate and clean. Generally lower upfront cost. Less control over overrun. |

| Soft Serve (Pump-Fed) | High-volume shops needing consistent product quality and texture for cones, sundaes, and shakes. | 20 to 50+ quarts per hour | Precise control over air-to-mix ratio (overrun). More complex and higher cost. |

Choosing between these machines really comes down to the kind of ice cream you dream of serving. Are you an artisan focused on unique, dense flavors, or are you aiming to be the go-to spot for that classic, nostalgic swirl? Your answer will point you to the right production powerhouse.

Essential Supporting Production Equipment

Making the ice cream is just step one. To get that premium, perfectly textured product your customers expect, you need the right gear to properly store and harden it.

Blast Freezers and Hardening Cabinets

When your ice cream comes out of the batch freezer, it's still relatively soft—around 15-20°F. To stop large, unappealing ice crystals from forming, you have to freeze it solid as fast as possible. This is where a blast freezer or hardening cabinet is absolutely essential.

These specialized freezers use powerful fans to circulate frigid air, dropping your ice cream’s temperature to below 0°F in just a few hours.

Skipping this step is one of the most common—and costly—mistakes new shop owners make. Tossing freshly churned ice cream into a standard freezer is way too slow; it will guarantee an icy, grainy texture. Once it's properly hardened, you can move the tubs to a dipping cabinet for serving. You can learn more about this in our complete https://therestaurantwarehouse.com/blogs/restaurant-equipment/dip-freezer-guide.

For a little extra perspective on outfitting a new food service business, take a look at an essential coffee shop equipment list. While the products are different, the core principles of planning for workflow, space, and utilities are surprisingly similar.

Creating the Perfect Customer Experience

The front of your shop is your stage. While the back-of-house is where your amazing ice cream is born, the service area is where customers fall in love with your brand. The right ice cream shop supplies up front aren't just about function; they’re about creating an efficient, appealing, and memorable experience that keeps people coming back for more.

Think of your service counter as the final, critical link in your production chain. All the effort you poured into crafting the perfect scoop can be amplified—or diminished—by how it's presented and served. This is exactly where strategic investments in your display and serving tools pay huge dividends.

Showcasing Your Flavors with Dipping Cabinets

Your dipping cabinet is so much more than a freezer; it’s your number one visual marketing tool. It’s the first thing customers lay their eyes on, drawing them in with a vibrant, colorful display of delicious-looking ice cream. A high-quality dipping cabinet is engineered to hold your product at the perfect scooping temperature—typically between 0°F and -10°F—which is warmer than a deep freezer but cold enough to maintain that perfect texture.

When you're shopping for one, keep an eye out for these key features:

- Glass Tops: A crystal-clear, anti-fog glass top is non-negotiable. It lets customers see all their options, which is fantastic for encouraging them to try new flavors.

- Frost Shields: These nifty additions prevent ice buildup around the edges of the tubs, keeping your display looking clean and professional all day long.

- LED Lighting: Bright, well-placed lighting makes your ice cream look even more vibrant and appealing, directly influencing what people decide to buy.

A dipping cabinet is a specialized piece of equipment designed for both storage and presentation. To explore similar display options for other refrigerated products, check out our guide on how to choose the right commercial display refrigerator.

Perfecting the Scoop

Believe it or not, the humble ice cream scoop is one of the most important tools in your entire shop. The right scoop does more than just serve ice cream; it controls portions, cuts down on waste, and makes your team way more efficient. Using the wrong tool can lead to over-serving (which eats into your profits) or make scooping hard ice cream a frustrating, wrist-straining task for your staff.

There are a few different types of scoops, and each has a specific job:

- Zeroll Scoops: These are often considered the industry standard, and for good reason. They contain a heat-conductive fluid in the handle that uses the warmth of the user's hand to cut through hard ice cream with ease.

- Dishers (Trigger Scoops): These are fantastic for precise portion control. They have a little mechanical sweeper that ensures a consistent, perfectly round scoop every single time.

- Spades: With a flat, wide blade, spades are perfect for scraping the last bits of ice cream from a tub, mixing in toppings, or serving dense gelato.

The ice cream store industry is a competitive field. In the United States alone, it generates around $7.9 billion in revenue across more than 30,000 businesses. In such a crowded market, operational efficiency and an excellent customer experience are what set successful shops apart. Discover more insights about the competitive ice cream industry on ibisworld.com.

Encouraging Upsells with Topping Stations

Once a customer has picked their ice cream flavor, the journey isn't over. The topping station is your golden opportunity to increase the value of every single sale. An organized, clean, and attractive display of toppings can easily turn a simple one-scoop order into a high-margin deluxe sundae.

A well-designed topping station should be both functional for your staff and tempting for your customers. Use clear containers so everyone can easily see all the colorful sprinkles, candies, nuts, and fruits. For sauces like hot fudge or caramel, a dedicated sauce warmer is absolutely essential. These units keep your toppings at a perfect, consistent temperature for a smooth pour every time, ensuring a premium finish to every dessert you serve. By making your toppings a visual centerpiece, you're not just offering additions; you're selling an experience.

Mastering Your Daily Consumables and Disposables

While your shiny new batch freezer is the heart of your operation, the daily consumables are its lifeblood. We're talking about the unsung heroes of your ice cream shop supplies—the cups, cones, spoons, and napkins that your customers interact with every single day. It's a classic rookie mistake to overlook these items, but they are a direct extension of your brand and a huge part of the customer experience.

Let's be real, choosing the right disposables is a balancing act between cost, quality, and your shop's vibe. A flimsy spoon that snaps mid-bite or a cup that gets soggy can totally ruin an otherwise perfect scoop. That's why having a smart strategy for your daily supplies is just as important as perfecting the recipes you're churning in the back.

This isn't a small corner of the market, either. The global ice cream service supplies industry is projected to balloon to USD 14.53 billion by 2035. A big part of that growth is driven by customers demanding more eco-friendly packaging, especially as rules around single-use plastics get stricter. You can learn more about the growth of the ice cream supplies market on futuremarketinsights.com.

The Foundation: Cups, Spoons, and Napkins

These are the core items you'll be ordering over and over again. They need to be reliable, fit your budget, and reflect your brand's personality.

-

Ice Cream Cups: Sturdy paper or plastic cups are non-negotiable. You'll want to offer a few different sizes to create different price points and portion options. The material really matters here—a double-poly coated paper cup will stand up to condensation and prevent a soggy mess way better than a standard one.

-

Spoons: The choice between plastic, compostable plastic (PLA), and wooden spoons says a lot about your brand. While standard plastic is often the cheapest route, today's customers are actively looking for sustainable options. Wooden spoons can also add a cool, rustic feel that pairs perfectly with an artisanal brand.

-

Napkins: Whatever you do, don't skimp on the napkins. Ice cream is messy! Providing durable, absorbent napkins shows you're thinking about the customer's entire experience, from the first lick to the last sticky finger.

Expanding Your Offerings with Cones and To-Go Containers

Beyond a simple scoop in a cup, other serving options are crucial for building a menu that gets people excited.

Classic cones are an absolute must for any ice cream shop. You'll want to stock a few different types to appeal to everyone and create easy opportunities for upselling.

- Cake Cones: The classic, flat-bottomed cone with a light, subtle flavor. A nostalgic favorite.

- Sugar Cones: Crispier and sweeter with that iconic pointed tip. A definite crowd-pleaser.

- Waffle Cones: The premium choice. That rich flavor and satisfying crunch are something many customers are more than happy to pay extra for.

On top of that, offering pints or quarts for customers to take home is a fantastic way to boost your revenue. For this, you’ll need high-quality, insulated to-go containers with lids that seal tight. These need to be tough enough to survive the trip home and protect that precious ice cream from freezer burn.

Choosing eco-friendly options isn't just about doing the right thing for the planet; it's a powerful marketing move. A 2021 study found that 78% of consumers are more likely to buy something that is clearly labeled as environmentally friendly. This simple choice can build serious brand loyalty and attract a customer base that shares your values.

Branding Your Disposables for Maximum Impact

Think about it: every single cup and napkin that walks out your door is a mini billboard. Custom branding turns a simple disposable into a walking advertisement for your business. When a customer carries a cup with your logo on it, they're spreading brand awareness with every step.

Sure, there's an upfront cost for design and printing, but the return on that investment can be huge. It makes your shop look more professional, reinforces your brand identity, and helps you stand out in a crowded market. You don't have to go all-in at once—start by branding one or two key items, like your most popular cup size, and see how it goes.

Getting your sourcing and stocking right is critical for your bottom line. To keep costs in check and your supply closet organized, check out these small business inventory management tips.

Stocking a Pantry for Irresistible Flavors

Incredible ice cream doesn’t just happen at the churn; it starts with the ingredients you have on hand. Your pantry is basically the heart of your flavor lab, and what you choose to stock it with is the real difference between making good ice cream and making unforgettable ice cream.

Think of your pantry as an artist’s palette. You absolutely need those foundational colors—the high-quality dairy, sugars, and stabilizers that form your base. But you also need the vibrant, exciting pigments—the mix-ins, toppings, and sauces—that will make your creations pop. Nailing both is how you build a menu that keeps people coming back.

Building Your Ingredient Foundation

Every single great ice cream recipe starts with a solid base. This is the canvas you'll be painting your flavors on, so its quality will define the taste and texture of everything you make.

- Dairy and Non-Dairy Bases: High-quality milk, cream, and egg yolks are the classic trio for a reason. But today, offering fantastic non-dairy options is a must. Stocking things like rich coconut cream, oat milk, or cashew milk opens your doors to a much wider crowd.

- Sugars and Sweeteners: Sugar does way more than just add sweetness; it’s a key player in controlling the freezing point and achieving that perfectly smooth texture. Beyond regular cane sugar, things like corn syrup or dextrose are great for preventing pesky ice crystals from forming.

- Stabilizers and Emulsifiers: These are the unsung heroes of creamy ice cream. Ingredients like guar gum or lecithin are your secret weapons against ice crystals and rapid melting, ensuring a smooth, stable scoop from the first bite to the last.

An ice cream’s final texture is a delicate balancing act. Too much water and you get icy crunch. The right blend of fat, sugar, and stabilizers, though? That’s where you find that signature creamy mouthfeel. Getting this balance right is the key to a premium product.

The Fun Part: Toppings and Mix-Ins

Once you've perfected your base, it's time to get creative. This is where you can really set your shop apart, turning a simple scoop into a memorable dessert experience. A well-organized and diverse selection of toppings doesn't just look great; it encourages upsells and lets customers build their dream cone.

It helps to think about your toppings in a few distinct categories so you have a balanced and appealing spread.

Classic and Crowd-Pleasing Toppings

These are the essentials, the toppings people expect and love. You've got to have a solid lineup of these favorites to satisfy classic tastes.

- Sprinkles: You need a variety here. Think classic rainbow and chocolate jimmies, but also crunchy nonpareils.

- Nuts: Chopped peanuts, toasted almonds, and pecans add that perfect savory crunch.

- Sauces: Hot fudge, warm caramel, and a bright strawberry syrup are absolute must-haves for any sundae bar.

- Candies and Cookies: Crushed cookie pieces (like Oreos), chocolate chips, and gummy candies are perfect for adding texture and a bit of fun.

Gourmet and Signature Offerings

This is your chance to really stand out from the crowd. Sourcing unique, high-quality ingredients can turn your shop into a true destination.

Maybe you could partner with a local bakery for fresh brownies to crumble on top, or find an artisanal chocolatier for shavings. Offering unique items like a drizzle of sea salt caramel, a balsamic glaze, or locally sourced fresh fruit can elevate your entire menu and justify a higher price point. Building a pantry that supports both your core menu and exciting seasonal specials is how you play the long game and succeed.

Upholding Health and Safety Standards

A pristine shop is the bedrock of customer trust and a non-negotiable legal requirement. While your fancy equipment and incredible flavors get all the glory, your cleaning and safety supplies are the silent partners working behind the scenes. They’re what protect your customers, your staff, and your hard-earned reputation.

Following health codes isn't just about passing inspections; it’s about creating a safe, welcoming environment people want to come back to. The right sanitation supplies ensure every single scoop you serve is not only delicious but completely safe.

Essential Cleaning and Sanitation Supplies

A sparkling clean shop starts with having the right tools for the job. Dairy, in particular, requires specific cleaning protocols to keep bacteria at bay, so investing in high-quality, food-grade supplies is a critical part of your operational budget.

Your core cleaning arsenal absolutely must include:

- Food-Grade Sanitizers: These are required for any surface that touches food, from your prep counters to your ice cream scoops. They’re designed to kill harmful bacteria that detergents alone can leave behind.

- Dairy-Specific Detergents: Standard soaps just won’t cut through stubborn milk fat residue. You need a specialized detergent formulated to break down dairy proteins and prevent nasty buildup in your machines and tools.

- Three-Compartment Sink: This is a health code standard for a reason. It gives you a dedicated station for a proper wash, rinse, and sanitize process for all your smallwares, every single time.

Beyond these essentials, you'll also need a solid collection of brushes, scrapers, and heavy-duty spray bottles to keep every nook and cranny of your production area absolutely spotless.

A robust food safety plan is your business's insurance policy against foodborne illness. Establishing clear protocols, like a HACCP plan, demonstrates a commitment to safety that protects both your customers and your brand's integrity.

Preventing Cross-Contamination

Cross-contamination is a huge risk in any food service spot, especially when you're dealing with common allergens like nuts, wheat, or dairy. Thankfully, some simple organizational tools can make a massive difference in keeping things separate and safe.

A color-coding system is an incredibly effective and easy strategy to implement. Just assign different colored cleaning cloths, cutting boards, and utensils to specific tasks or areas. For instance, you could use red cloths only for cleaning areas where nuts are prepped, while blue is reserved for dairy-only surfaces. This simple visual cue helps prevent accidental mixing and is super easy for your staff to follow. You can learn more about building out these kinds of protocols by understanding the principles of HACCP food safety.

Equipping Your Team for Hygiene

Your team’s hygiene is the first line of defense in food safety. Providing your staff with the right supplies from day one makes it easy for them to maintain the highest standards of cleanliness throughout their shifts.

Every shop must be equipped with:

- Handwashing Stations: These need to be fully stocked at all times with hot water, antibacterial soap, and single-use paper towels. A dedicated handwashing sink should never be used for anything else, period.

- Disposable Gloves: Staff should be using gloves whenever they handle ready-to-eat foods like cones and toppings. It’s crucial to teach them to change gloves frequently, especially after touching money or cleaning surfaces.

- Aprons and Hair Restraints: A clean apron and a hairnet or hat don't just look professional—they are critical for preventing stray hairs and other contaminants from ending up in your ice cream.

By investing in these essential health and safety supplies, you're doing more than just complying with regulations. You're building a foundation of trust that will keep customers coming back for more.

Got Questions About Ice-Cream-Shop-Supplies? We’ve Got Answers.

Stepping into the world of ice cream shop supplies can feel like a lot, especially when you're just starting out. Making the right calls from day one can save you from costly headaches down the road and really set your shop up for success. Here are some straightforward, practical answers to the questions we hear most often from new shop owners.

Should I Buy New or Used Ice Cream Equipment?

This is one of the first big decisions you'll face, and it really comes down to balancing upfront cost against long-term risk. New equipment gives you that peace of mind with brand-new reliability and a manufacturer's warranty, but it’s a serious investment. Used gear, on the other hand, can save you thousands, but it might come with hidden maintenance issues and no warranty to back you up.

A smart, balanced approach often works best. You might want to buy your most critical machinery new—like your batch freezer. If that goes down, your whole operation stops. For simpler items like stainless-steel worktables or sinks, high-quality used equipment can be an absolute steal.

Pro Tip: Never, ever buy used refrigerated or mechanical equipment without getting a qualified technician to inspect it first. A pro can spot red flags that could turn into massive repair bills later.

How Do I Find Reliable Suppliers for My Shop?

Building a solid network of suppliers is the backbone of your shop's daily operations. The best strategy is usually a mix of national distributors and local partners, giving you the best of both worlds.

- National Distributors: For your big equipment purchases and basic disposables, large restaurant supply companies offer competitive pricing and massive catalogs to choose from.

- Local Purveyors: This is where you can really build your brand's story. Partnering with a local dairy farm for your milk or a nearby grower for seasonal fruit isn't just a smart move for quality—it's a huge selling point for your customers.

- Industry Events: Get yourself to a food service trade show. It’s the perfect place to meet vendors in person, see and touch the products, and negotiate some great deals.

Before you sign on with any supplier, do your homework. Always check their references and read online reviews. You need partners who are known not just for quality products but also for dependable, on-time deliveries.

What Are the Most Commonly Forgotten Supplies?

It’s so easy to get caught up in the big-ticket items that you completely overlook the small essentials that keep your shop running smoothly every single day. So many new owners miss the practical stuff that’s critical for safety and efficiency.

Here are a few of the most commonly missed supplies:

- Anti-fatigue floor mats to save your staff’s backs during long shifts.

- "Wet floor" signs to prevent dangerous slips and falls.

- A fully stocked first-aid kit for those inevitable small cuts and burns.

- Sanitizer test strips, which are often required by the health department.

- An ice machine for customer drinks and other needs you haven't even thought of yet.

- Back-office supplies like POS receipt paper and cleaning logs.

To avoid this trap, do this simple exercise: mentally walk through an entire day, from unlocking the front door to mopping the floors at close. Make a list of every single tool and supply you would need to touch. It’s a simple trick that can reveal some surprising gaps in your initial shopping list.

Ready to equip your dream ice cream shop with reliable, high-quality supplies? At The Restaurant Warehouse, we offer everything from commercial batch freezers to dipping cabinets, all at competitive prices. Explore our extensive catalog and find the perfect equipment for your business today!

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment