From Compact to Colossal: Pizza Prep Tables for Every Space

Why a 119 pizza prep table Is the Game-Changer Your Pizzeria Needs

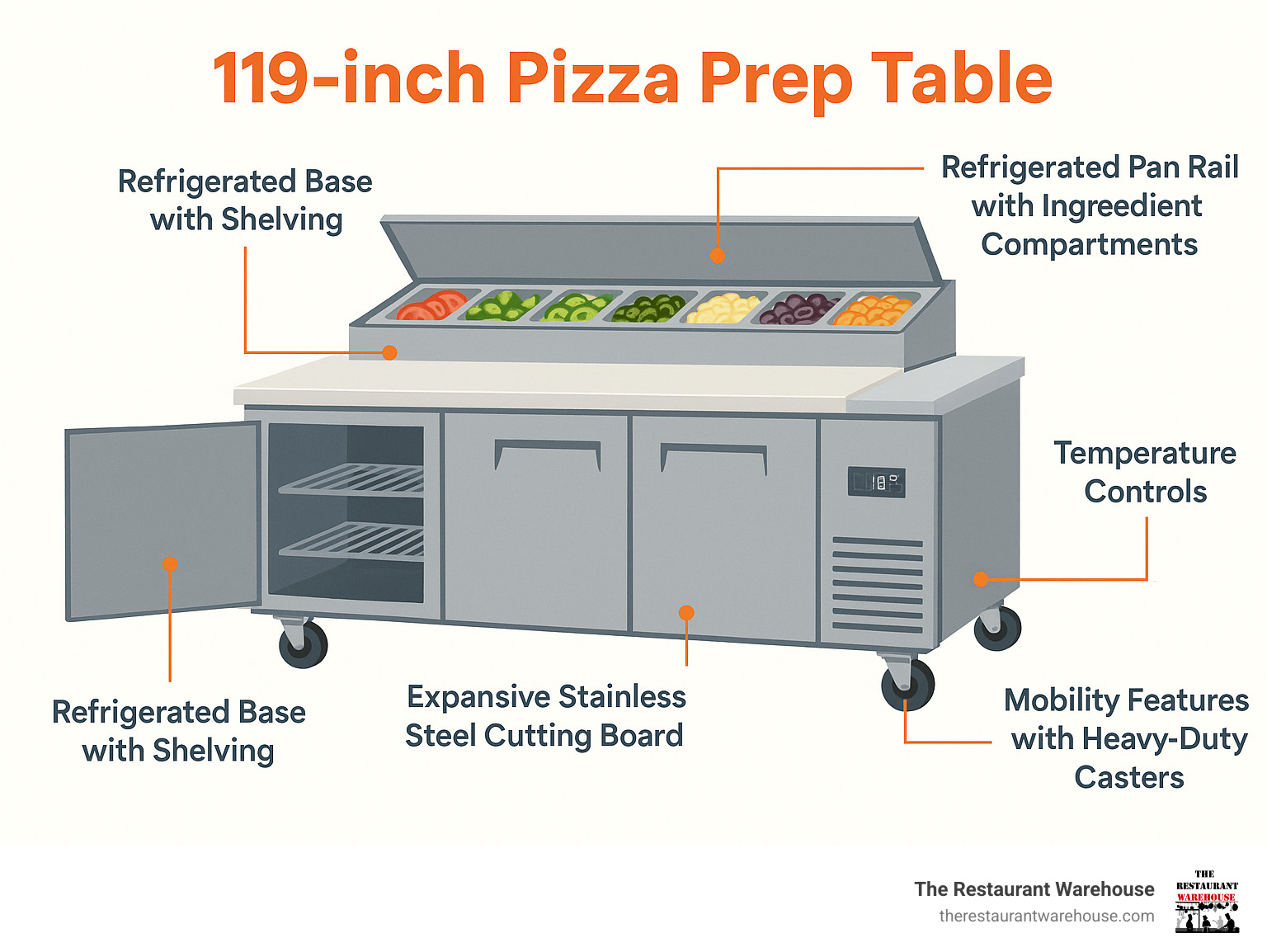

A 119 pizza prep table is the ultimate solution for high-volume pizzerias, offering massive workspace, extensive ingredient storage, and professional-grade refrigeration in one unit.

Top 119-Inch Pizza Prep Table Models:

- True TPP-AT-119-HC: 15 pan capacity, 19.5" cutting board, 975 lbs

- Victory VPPD119HC-3: 42.2 cu. ft. storage, 6 shelves, side-mounted refrigeration

- Beverage-Air DP119HC: 42.2 cu. ft. capacity, 8 shelves, 725 lbs

Key Specifications:

- Dimensions: ~119" W x 33-38" D x 38-54" H

- Pan Capacity: 15 (1/3-size) pans typical

- Temperature Range: 33°F to 41°F (0.5°C to 5°C)

- Power: 115V/60Hz/1PH, 7.1 Amps standard

- Refrigerant: R290 (eco-friendly hydrocarbon)

During peak hours, every second counts. The right prep equipment can be the difference between smooth operations and chaos. A 119-inch pizza prep table transforms your kitchen into a high-efficiency production line by solving three critical problems: workspace limitations, ingredient accessibility, and temperature control. With nearly 10 feet of prep space, multiple staff can work simultaneously. The refrigerated pan rail keeps toppings at food-safe temperatures, and the deep cutting board accommodates the largest pizza bases.

The investment is sound, as a single 119-inch table can replace multiple smaller units, reducing equipment costs and maximizing your kitchen's footprint. Features like NSF/ANSI Standard 7 compliance and R290 refrigerant provide commercial-grade reliability and environmental responsibility.

The Main Event: A Deep Dive into the 119 Pizza Prep Table

For a busy pizzeria, the 119 pizza prep table is the command center of the operation. These massive workstations stretch nearly 10 feet, turning kitchen chaos into choreographed efficiency. They are the ultimate solution for serious pizza operations.

Core Features and Specifications

The scale of a 119 pizza prep table is evident in its pan capacity. They hold 15 full-size 1/3 pans in the refrigerated rail, keeping toppings at perfect temperatures. This eliminates trips to the walk-in cooler during a dinner rush, as everything is within reach.

The smart design includes a 19.5-inch deep cutting board, giving pizza makers ample room to work. This space accommodates stretching a 20-inch specialty pizza or prepping multiple orders side-by-side without feeling cramped. The board is made from high-density, NSF-compliant polyethylene, making it durable and easy to sanitize.

Below the work surface is a refrigerated base with 42.2 cubic feet of storage, enough for backup ingredients, dough, and other bulk items. The interior is organized with adjustable, PVC-coated shelves (typically 6 to 8) that handle heavy weight and resist corrosion.

Storage access is available in various configurations. Some models mix doors and drawers; drawers are ideal for frequently used items and can hold up to 275 pounds each. Doors often have a stay-open feature at 120 degrees for hands-free access during peak hours.

For a complete breakdown of how these features work together to streamline your operations, check out our Pizza Prep Table Guide.

Built to Last: Construction and Materials

The quality of materials separates a good prep table from a great one. A well-built 119 pizza prep table will serve your kitchen for years under demanding conditions.

The stainless steel exterior provides a professional look and handles splashes, spills, and daily wear. It resists corrosion and wipes clean easily, which is crucial for maintaining health standards during busy service.

The interior is typically aluminum with coved corners to prevent food particles from getting trapped, simplifying end-of-day cleaning. Some models feature clear-coated aluminum liners for extra protection against wear.

These units are NSF/ANSI Standard 7 compliant, meaning they are tested and approved for storing open food products safely. This certification provides confidence during health inspections.

The removable polyethylene cutting board withstands thousands of cuts without harboring bacteria. A galvanized steel back provides structural support, while heavy-duty casters with locking mechanisms allow for mobility and stability.

Want to learn more about the benefits of stainless steel construction? Our Stainless Steel Prep Table Guide has all the details.

Keeping Cool: Refrigeration, Safety, and Efficiency

Temperature control is critical when dealing with fresh ingredients. A 119 pizza prep table maintains the essential 33°F to 41°F range to keep toppings fresh and safe.

The refrigeration system uses forced-air circulation for consistent cooling throughout the storage space, eliminating hot spots and temperature fluctuations.

Modern units use R290 refrigerant, a hydrocarbon with zero ozone depletion potential and a low global warming potential. Critically for your budget, R290 is highly energy efficient, leading to lower electricity bills.

The electrical requirements are reasonable, with most 119 pizza prep tables running on standard 115v/7.1 Amp service. This makes installation straightforward, as they typically come with an 11-foot cord and a standard NEMA plug.

Some advanced models include adaptive defrost systems that only run when needed, further reducing energy consumption and justifying the investment in a premium unit.

For detailed technical specifications and refrigerant information, take a look at this Refrigerant Spec Sheet to see exactly what you're getting.

Sizing Up Your Options: From Compact Stations to the 119-Inch Powerhouse

Selecting the right pizza prep table size is critical, as it directly impacts kitchen workflow, team efficiency, and profitability. While the 119 pizza prep table is a powerful option, it's important to understand how it compares to other sizes to find the best fit for your volume and space.

Small Footprints: 27-48 Inch Prep Tables

For establishments with limited square footage, such as small cafes, delis, or restaurants where pizza is a secondary menu item, compact prep tables from 27 to 48 inches are an ideal solution.

These space-saving units provide essential functionality in a small footprint. A typical 44-inch model accommodates around 6 (1/3-size) pans, which is adequate for crafting artisanal pizzas one at a time rather than handling a high-volume rush. Their main benefit is providing dedicated refrigerated storage and workspace without overwhelming a compact kitchen.

If you're exploring options for tighter spaces, our guides on the Best 27 Inch Prep Tables and 48 Inch Sandwich Prep Refrigerators provide excellent insights into maximizing efficiency in minimal space.

The Mid-Range Workhorses: 60-93 Inch Models

Units ranging from 60 to 93 inches are the sweet spot for many pizzerias. They offer a balance of capacity and practicality, making them popular for medium-volume operations that need serious functionality.

These mid-range models provide significantly more prep space and ingredient storage. A 67-inch or 93-inch table gives pizza makers more elbow room and access to a wider variety of ingredients, helping them handle busy dinner rushes without feeling cramped.

These sizes are ideal for pizzerias that are expanding, adding menu items, or seeing steady growth. They offer increased pan capacity, extended cutting board space, and improved storage without requiring a complete kitchen redesign.

Why Go Big? The Case for a 119 Pizza Prep Table

A 119 pizza prep table is a strategic investment in operational excellence for high-volume pizzerias. During peak hours, when orders are streaming in, the sheer size of a 119-inch table becomes essential.

With nearly 10 feet of workspace, you create multiple workstations that can operate simultaneously. Two, three, or even four pizza makers can work side-by-side without interference. This creates a pizza assembly line: one person stretches dough, another sauces, a third adds toppings, and a fourth handles finishing touches.

The benefits extend beyond accommodating more staff. A 119 pizza prep table facilitates menu expansion and diversification. With 15 or more pan slots, you can offer seasonal specialties, gourmet toppings, and unique ingredients that set your pizzeria apart. This variety can increase average ticket sizes and build customer loyalty.

During peak hours, smaller tables create bottlenecks. A 119-inch table eliminates these friction points, as each team member has dedicated space and easy access to ingredients. This reduces bottlenecks and improves workflow, ensuring steady output even during the busiest periods. This consistency leads to higher customer satisfaction and revenue.

For pizzerias serious about scaling, a 119 pizza prep table is a game-changer. To understand how the right prep table can revolutionize your entire restaurant operation, explore our comprehensive Restaurant Prep Table Guide.

Optimizing Your Pizzeria's Workflow

A 119 pizza prep table is the command center of your pizza operation. Using its full potential transforms it from a simple prep station into the heart of an efficient kitchen.

Designing for Speed: Cutting Boards and Pan Layouts

Speed in a pizzeria comes from smart, efficient movement. The design of a 119 pizza prep table is engineered for this purpose.

The extra-deep cutting boards, at 19 to 19.5 inches, are strategic. They give pizza makers the space to stretch dough and assemble pizzas with confidence and without feeling cramped.

Excellent ingredient accessibility is key. With up to 15 chilled pans within arm's reach, there's no need to run to a walk-in cooler. This setup enables a smooth, efficient workflow, turning raw ingredients into finished pizzas quickly.

This layout naturally creates an assembly line flow. One person can stretch dough, another can add sauce and cheese, and a third can handle toppings, with the table acting as a highway for production.

Reducing cross-contamination is simplified with proper pan organization. Individual compartments keep ingredients separate, while the refrigerated environment maintains food safety. Covered pans protect against airborne contaminants, and easy-to-clean surfaces make sanitization simple. A clean, organized station also builds customer confidence.

For insights into creating efficient workflows, our guide on how to Choose Sandwich Prep Station offers valuable principles that apply to any prep operation.

Customization and Accessories for Your 119 Pizza Prep Table

Every pizzeria operates differently, and 119 pizza prep tables can be customized to match a unique workflow.

- Overshelves: Mounted above the prep table, they provide prime real estate for tools like pizza peels, cutters, and portion scoops, keeping the main work surface clear.

- Garnish racks: These are practical for keeping fresh basil, specialty cheeses, or other delicate garnishes organized and accessible for final touches.

- Drawers vs. Doors: The choice affects workflow. Doors offer large, open access, while drawers provide organized compartments for easier inventory management. Models like the True TPP-AT-119D-4-HC offer a combination. Heavy-duty drawers can hold up to 275 pounds.

- Caster options: The right wheels for your flooring type are crucial for mobility during deep cleaning or kitchen rearrangements. Locking mechanisms ensure the table remains stable during service.

- Field-reversible doors: This feature allows you to reverse the door swing on-site, providing flexibility if your kitchen layout changes.

Installation, Maintenance, and Warranty Considerations

Proper care of your 119 pizza prep table ensures years of reliable service.

- Proper placement: These units require adequate ventilation, especially around the condensing unit, for optimal performance and energy efficiency. Most are designed for front-access service, but airflow space is still necessary.

- Routine cleaning: Daily cleaning and sanitizing of the removable cutting board and other food contact surfaces are essential. Magnetic, tool-free door gaskets simplify deep cleaning. Stainless steel surfaces are durable and easy to wipe down.

- Compressor maintenance: While professional service is recommended, some units like the Victory VPPD119HC-3 feature front-serviceable refrigeration systems, reducing downtime and service costs. Regularly cleaning dust from coils prevents overheating.

- Warranty terms: Understanding the warranty provides peace of mind. Victory and Beverage-Air offer impressive 7-year warranties on parts, labor, and the compressor. True offers 7 years on the compressor and 3 years on parts and labor. This represents significant protection for your investment.

For detailed maintenance tips, our Sandwich Prep Table Maintenance guide offers practical advice for all refrigerated prep equipment.

Frequently Asked Questions about Pizza Prep Tables

Here are answers to the most common questions about 119 pizza prep tables.

What's the difference between a pizza prep table and a sandwich prep table?

While they look similar, pizza and sandwich prep tables are designed for different workflows. The two main differences are the cutting board depth and food pan configuration.

A 119 pizza prep table features a much deeper cutting board, typically 19 inches or more. This depth is necessary to provide adequate space for stretching large pizza doughs and arranging toppings without mess or difficulty. A shallow sandwich prep board is simply not practical for making pizza.

The second difference is the food pan configuration. Pizza prep tables use larger 1/3-size pans to hold ingredients like cheese and pepperoni, which are used in high volumes. Sandwich prep tables use smaller 1/6-size pans to accommodate a wider variety of ingredients used in smaller quantities. In short, pizza prep tables are built for volume and workspace, while sandwich prep tables are for variety and precision.

Why is R290 refrigerant a key feature to look for?

R290 refrigerant is a critical feature for both environmental and financial reasons.

Environmentally, R290 is a hydrocarbon with zero ozone depletion potential and a very low global warming potential of 3. Choosing a unit with R290 is a responsible environmental choice compared to older refrigerants with much higher GWP.

Financially, R290 is highly energy-efficient. Its thermodynamic properties allow the compressor to maintain temperature with less work, which translates to lower electricity bills. Over the lifespan of a prep table that runs 24/7, these energy savings can be significant. It also helps future-proof your business against stricter environmental regulations.

How do I ensure my prep table meets health codes?

Ensuring your 119 pizza prep table meets health codes involves choosing the right equipment and maintaining it properly.

The most important certification to look for is NSF/ANSI Standard 7 compliance. This seal from NSF International confirms the equipment is designed and built for safe commercial food storage, covering materials and ease of cleaning. This is essential for passing health inspections.

Temperature control is the other critical factor. Health codes require perishable foods to be kept at 41°F or below. Our 119 pizza prep tables are engineered to maintain a range of 33°F to 41°F, safely within this requirement.

Proper maintenance is also key. This includes daily cleaning and sanitization of all food contact surfaces, especially the removable cutting board. Door gaskets must be cleaned to maintain a proper seal, and temperatures should be logged regularly to demonstrate compliance. Modern prep tables are designed with features like removable boards and gaskets to make these tasks easier.

Conclusion

Choosing the right pizza prep table is a critical decision that comes down to matching your pizzeria's needs with the right equipment. From compact 27-inch units to the colossal 119 pizza prep table, the right choice can transform your kitchen into a high-efficiency powerhouse.

Your prep table is the command center of your operation, influencing service speed, product consistency, and food safety. For high-volume establishments, the 119 pizza prep table is essential for handling peak demand. With nearly 10 feet of prep space, capacity for 15 ingredient pans, and massive refrigerated storage, these units help you exceed customer expectations.

The right prep table can turn a chaotic rush into a smooth, efficient workflow. Multiple team members can work simultaneously, ingredients stay chilled and organized, and orders flow out of the kitchen with speed.

The investment pays for itself through improved productivity, reduced food waste, and the ability to handle higher volumes. Features like R290 refrigerant for energy efficiency and NSF compliance for food safety make it a smart investment in your pizzeria's long-term success.

At The Restaurant Warehouse, we provide top-quality commercial equipment at prices that make sense for your bottom line. By avoiding middleman markups and retail overhead, we offer professional-grade 119 pizza prep tables at wholesale prices. Whether you're opening a new location or upgrading an existing kitchen, we are here to help you make smart equipment choices that support your goals.

Explore Our Full Range of Pizza Prep Tables

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment