A Guide to Your Food Truck Layout

Let’s get one thing straight: your food truck layout is the single most critical factor in your day-to-day success. I’m not exaggerating. A smart design directly impacts how fast you can serve, how much you make, and frankly, your overall sanity on the job. It’s the difference between a smooth, profitable service and a chaotic shift you can’t wait to end.

Why Your Food Truck Layout Is Everything

In the tight quarters of a mobile kitchen, strategic design isn't some fancy luxury—it's the very foundation of your entire business. Every single inch of your truck affects everything, from how customers see you to whether you pass that next health inspection. This is where you turn a simple vehicle into a high-performance engine for your brand.

Thinking about your space correctly means going way beyond just plopping equipment where it fits. It’s about deeply understanding your operational flow. A truly great food truck layout doesn't just happen; it's meticulously planned around your specific menu and service style.

The Power of A Strategic Design

A killer layout isn't just about looking good for an Instagram post. It’s a functional blueprint for efficiency and profitability. The benefits are real and immediate:

- Faster Service: A logical path from order to pickup means quicker ticket times. That leads to happier customers and more sales during those crucial peak hours.

- Happier Staff: An ergonomic design cuts down on physical strain and stress for your team. This means fewer mistakes and a much better work environment for everyone.

- Better Food Safety: Proper zoning for cold storage, prep, and cooking minimizes the risk of cross-contamination—a make-or-break factor for health inspectors.

- Smarter Inventory: When everything has a designated spot, it’s far easier to track what you have, reduce waste, and manage your costs effectively.

The kitchen area inside a food truck is incredibly compact, typically only 70 to 150 square feet. That tiny space demands that every single corner be used efficiently. A well-planned layout segments the truck into specific zones for cooking, prepping, storing, and serving. This zoning is what cuts down on wasted movement, which is critical when customers expect their food in 7 minutes but often end up waiting closer to 12. Digging into food truck industry statistics shows just how much that speed impacts your success.

In a food truck, every wasted step is wasted time, and wasted time is lost profit. The goal is to create a layout where your team can move fluidly and purposefully, almost like a choreographed dance.

Thinking in Zones and Workflow

The absolute best way to approach your food truck layout is to think in terms of stations or "zones." Each zone has a specific job, and how you arrange them dictates your entire workflow.

The table below breaks down these core zones. Think of it as a cheat sheet for planning your mobile kitchen.

| Core Zones in an Efficient Food Truck Layout |

| :--- | :--- | :--- |

| Zone | Primary Purpose | Key Consideration |

| Service Window | Taking orders, processing payments, and handing food to customers. | Must be separate from the main kitchen flow to avoid congestion. |

| Cooking Station | Housing the primary cooking equipment like grills, fryers, and ovens. | Needs proper ventilation and to be central to the workflow. |

| Prep Station | Chopping, mixing, and assembling ingredients before cooking. | Should be located between storage and the cooking line for efficiency. |

| Storage (Cold & Dry) | Refrigerators, freezers, and shelving for all ingredients. | Must be easily accessible but not obstruct movement paths. |

| Warewashing | The three-compartment sink and handwashing station. | Placement is often dictated by plumbing and health code requirements. |

By breaking down your truck into these functional areas, you can start to visualize how your team will move through the space. The relationship between these zones is what creates (or destroys) your operational speed. A layout that forces a cook to cross the entire truck to grab something from the fridge is fundamentally flawed and will cost you dearly during a lunch rush.

Let Your Menu Design Your Kitchen

Before you measure a single inch of counter space or start browsing for equipment, just stop. Take a good, hard look at your menu. This isn't just a list of what you sell; it's the operational blueprint for your entire kitchen.

Every decision, from the size of your griddle to where you place that low-boy refrigerator, flows directly from the dishes you plan to serve. Trying to design a kitchen without finalizing your menu first is like building a house without knowing how many people will live in it. It's a surefire recipe for inefficiency and daily frustration.

From Dish to Design: A Real-World Example

To see this principle in action, let's picture two totally different food truck concepts.

Truck A: The Artisan Pizza Truck

Here, the star of the show is a 12-inch, made-to-order Neapolitan-style pizza. This single item dictates a very clear, linear workflow.

- Dough Prep: You'll need a refrigerated spot for dough balls to proof, plus a floured surface for stretching. This has to be the first station in the line.

- Topping Station: Right after the dough station comes a long, refrigerated prep rail holding all your toppings—sauce, cheese, pepperoni, veggies.

- Oven: This is the heart of your operation. The pizza oven needs to be at the end of the prep line, with a clear, heat-resistant space for launching and retrieving pizzas.

- Cutting & Boxing: Finally, you need a dedicated counter space to slice the hot pizza and box it up for the service window.

This menu demands a straightforward, assembly-line-style layout. Each step flows logically into the next, minimizing movement and maximizing how many pizzas you can pump out.

Truck B: The Gourmet Coffee & Pastry Truck

For this truck, the game is all about speed and handling lots of small, quick transactions. The workflow is completely different.

- Espresso Station: The espresso machine is the main event. It needs its own zone with the grinder, milk steaming pitchers, and syrups all within arm's reach.

- Pastry Display: A glass case near the service window is non-negotiable for showcasing your goods and keeping them fresh.

- Cold Station: You'll need a separate area with a blender for frappes and a refrigerator for milk and cold brew.

This truck’s layout is more of a station-based or "galley" style. The barista can pivot between stations without taking more than a step or two. Efficiency here comes from compact, self-contained work zones, not a long assembly line.

Mapping Your Kitchen Workflow

Now it's your turn. Take your top three best-selling items and physically map out every single step required to make them, from raw ingredient to finished product.

And I mean be excruciatingly detailed. Ask yourself:

- Where do I grab the protein from? (Cold Storage)

- Where do I chop the vegetables? (Prep Surface)

- Which appliance do I cook it on? (Cooking Line)

- Where do I assemble the final dish? (Finishing Station)

This exercise will reveal your kitchen's natural "path." Your goal is to arrange your equipment and stations to match this path, creating a seamless flow. Modern food trucks achieve this with ergonomic designs, often setting up the kitchen in a linear or L-shape. This lets cooks move effortlessly between grills, fryers, and prep tables, with storage strategically placed for instant access. You can find more examples of these efficient designs on IBISWorld.

Your equipment should serve your workflow, not the other way around. Let the journey of your most popular dish dictate where every appliance, prep board, and storage bin goes.

Turning Your Workflow into a Physical Plan

Once you've mapped out the process, you can start identifying the specific equipment and space you'll need. The pizza truck example clearly shows the need for a large, high-temperature oven and a long refrigerated prep rail. The coffee truck, on the other hand, absolutely requires a top-tier espresso machine and blenders.

Your workflow map will expose potential bottlenecks before you spend a single dollar. If making your signature burger requires you to walk from the fridge at one end of the truck to the griddle at the other, your food truck layout is broken. By designing around your menu, you ensure your kitchen works for you, not against you, setting you up for an efficient and profitable mobile operation from day one.

Choosing and Placing Essential Equipment

Alright, let's move from the blueprint to the build-out. This is where your food truck layout stops being lines on a page and starts becoming a real, functional kitchen. Selecting and arranging your equipment is a delicate dance, a balancing act where you’re trying to squeeze maximum performance out of every single square inch.

Your mission is to create a seamless, logical path from your cold storage all the way to the service window. Think of it like choreographing a routine where every movement is efficient and has a purpose. This isn't just about Tetris-ing equipment into a tight space; it's about making it all work together beautifully when the pressure is on.

Sizing Up Your Options

In a food truck, space is the most valuable thing you have. Every appliance you choose is a huge decision that ripples through your entire workflow. You’ll find yourself weighing the pros and cons of three main categories of equipment.

- Full-Size Units: These are the heavy hitters—think a big floor-model fryer or a multi-burner range. They give you high output, which is great, but they eat up a ton of floor space and demand more from your power and ventilation systems.

- Countertop Models: These are your ultimate space-savers. We're talking countertop griddles, induction burners, or panini presses. They offer fantastic flexibility but might not have the same production power as their larger cousins.

- Multi-Use Equipment: This is where you get to be really clever. A combi oven that can bake, steam, and roast, or a refrigerated prep table that gives you both cold storage and a workspace, can be an absolute game-changer in a compact layout.

The right mix really boils down to your menu. A burger truck, for instance, will probably need a full-size griddle to keep up with the rush. A crêpe truck, on the other hand, could probably run its entire operation with a couple of countertop burners.

A classic rookie mistake is buying equipment before you've drawn a to-scale diagram of your truck. Grab some painter's tape and physically map out where every piece will go on the floor of your garage or an empty room. This simple step can save you from a five-figure purchasing error.

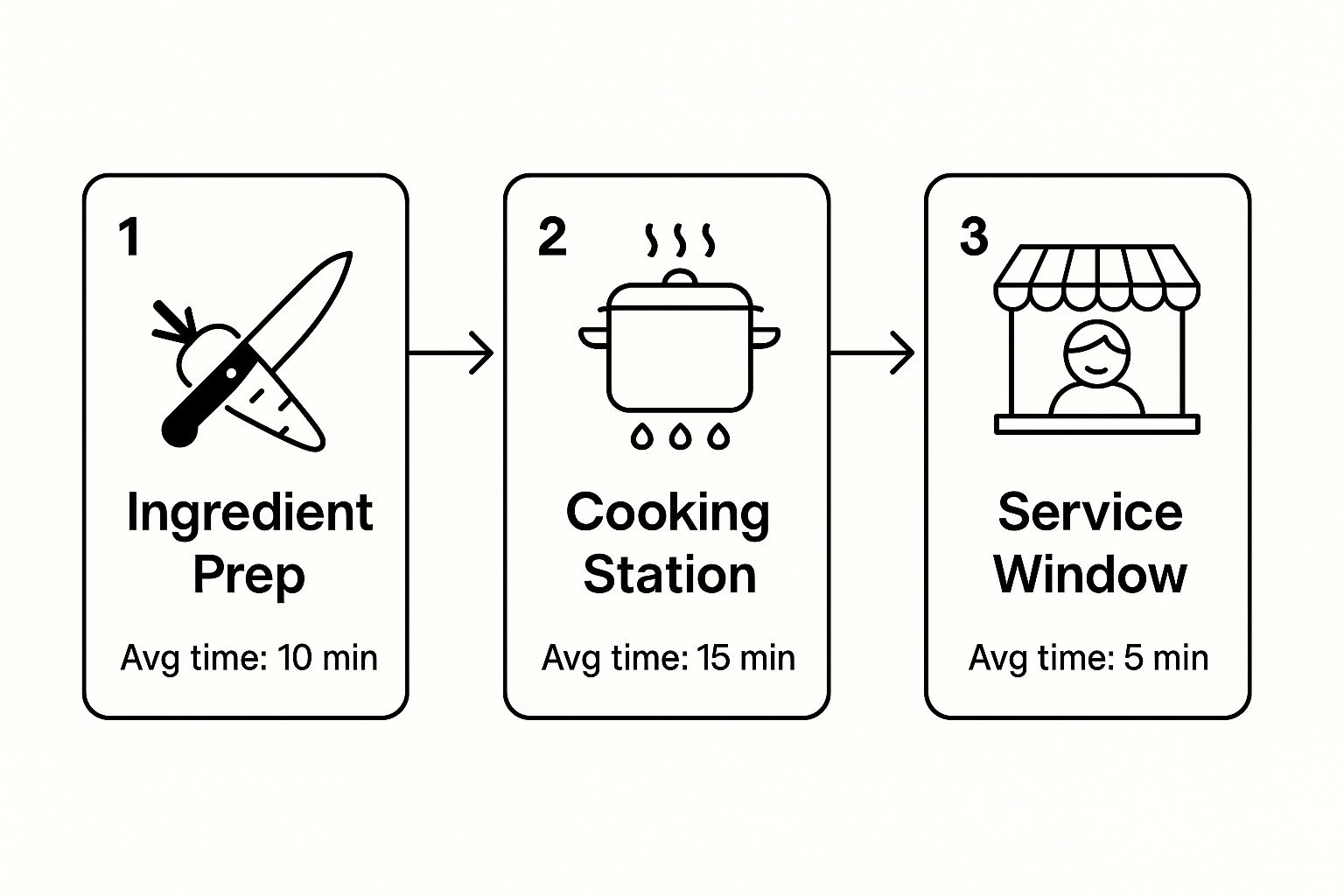

This hands-on visualization helps you feel the true flow of your kitchen. The infographic below really drives home how each station's timing adds up to affect your overall speed of service.

As you can see, shaving even a minute or two off your prep or cooking stages can have a massive impact on your total ticket time.

Strategic Placement for Peak Performance

Once you’ve picked out your gear, where you put it is just as crucial as what you bought. Placement needs to be driven by your workflow, safety, and ergonomics. This isn't about what looks good on paper; it's about what functions best when you've got ten tickets hanging and a line snaking around the block.

Cooking Appliances

Your main cooking gear—the griddle, range, and fryer—is the heart of your operation. You’ll want to group these items together right under your main ventilation hood. This creates a central "hot line," containing all the heat and grease in one manageable spot. The fryer, especially, needs a prime piece of real estate with clear access and powerful venting. Knowing the different types is key, so checking out a good commercial deep fryer guide can be a huge help in making the right choice.

Refrigeration

How you place your refrigeration directly impacts both food safety and your speed. Your main reach-in unit should be easy to get to but kept out of the main foot-traffic lane. The most critical piece, though, is usually your under-counter or refrigerated prep rail. This needs to be positioned directly next to or across from your cooking station. This setup minimizes the steps your cook has to take to grab ingredients, which is absolutely vital for shaving seconds off ticket times.

Prep Surfaces

Your primary prep area should be a clear, uncluttered stainless steel surface located between your cold storage and your cooking line. This setup follows the natural flow of work: ingredients come out of the fridge, get prepped, and then move to the hot line to be cooked. If space is really tight, a worktop refrigerator that doubles as a prep surface can be a fantastic two-for-one solution.

Sinks and Warewashing

Sink placement is often dictated by your truck’s plumbing and, more importantly, by local health codes. You'll need a three-compartment sink for washing, rinsing, and sanitizing, plus a completely separate handwashing sink. The handwashing sink should be placed near your prep and cooking areas to encourage frequent use. The three-compartment sink, however, is typically located farther from the main cooking zone to prevent splashes and any risk of cross-contamination.

Designing for Speed and Ergonomics

Once you've picked your equipment, it's time to shift your focus to the human side of your food truck layout. In a mobile kitchen, efficiency isn't just about how much food you push out—it's measured in seconds and saved steps. A design that ignores ergonomics will lead to a slow, frustrated, and exhausted team.

This is where you build a kitchen that just feels right. The goal is to cut down on physical strain and mental gymnastics, allowing your crew to hit their stride and stay there, even during a chaotic lunch rush. A few smart layout decisions can turn a stressful service into a smooth, profitable operation.

Common Layout Configurations

Most food truck layouts boil down to a few common styles. Each one has its own unique rhythm and works better for certain menus and team sizes. Getting a feel for their pros and cons is the first step to choosing the right foundation for your workflow.

Figuring out which layout style works best for your truck is one of the most important decisions you'll make. It impacts everything from how quickly you can serve customers to how comfortable your staff is during a long shift. To help you visualize the options, let's compare the most common configurations side-by-side.

Layout Style Comparison for Food Trucks

| Layout Style | Best For | Pros | Cons |

|---|---|---|---|

| Assembly Line | Step-by-step menus like tacos, pizza, or sandwiches. High-volume, repetitive tasks. | Creates a clear, logical flow that's easy to master. Extremely efficient for pumping out orders quickly. | Can create bottlenecks if one station gets backed up. Less flexible for complex or varied menus. |

| Galley | Small teams (1-2 people) and menus requiring multitasking between stations. | Very compact design minimizes steps between workstations. Highly effective for solo or duo operations. | Can feel very cramped with more than two people. Requires careful planning to avoid collisions. |

Each of these layouts has its place, but the "best" one is completely dependent on your menu and how many people you'll have working. An assembly line is fantastic for churning out tacos, but it would be a nightmare for a one-person gourmet burger concept. Be realistic about your operation before you commit.

Building for Human Comfort and Safety

Ergonomics in a food truck is all about making the workspace fit the worker—not the other way around. Every repetitive motion, from bending down to grab ingredients to reaching for a spatula, adds up. Over an eight-hour shift, a bad setup leads to physical pain, costly mistakes, and burnout.

Think about the classic "work triangle." Your main stations—cold storage (fridge), prep surface, and cooking station—should form a tight, efficient triangle. A cook should be able to pivot between these three points with just a step or two. This simple principle cuts down on wasted movement and saves energy for where it counts: the food.

A well-designed food truck layout allows a cook to reach for 90% of what they need for their primary tasks without taking more than one step. If your team is constantly walking back and forth, your layout has a fundamental flaw.

Here are a few ways to make your space more ergonomic and safer:

- Reach and Access: Keep your most-used tools and ingredients between hip and shoulder height. Heavy items go on lower shelves, light items go up high.

- Aisle Space: This is non-negotiable. You need at least 36 inches of clear aisle space. This lets one person safely pass behind another, which is critical for preventing accidents with hot pans or knives.

- Flooring: Don’t forget what’s underfoot. Invest in high-quality anti-fatigue mats. They make a huge difference in reducing back and leg strain during long shifts.

The equipment you choose can also make a big difference. For example, you can learn more about why high-efficiency fryers are the secret sauce for food truck success, as modern units often have better designs that are easier and safer to use.

Finally, think about your end-of-day cleanup. Placing trash bins and cleaning supply stations strategically can shave a ton of time off your closing duties. A bin near the prep station and another by the service window keeps the workflow clear and makes teardown a much quicker process.

Passing Inspection with a Compliant Layout

A brilliant, efficient food truck layout means absolutely nothing if it can't pass your local health inspection. I've seen too many new owners get sidelined by this, and it's frustrating. Navigating the maze of safety regulations can feel like a nightmare, but getting it right from the very beginning will save you from expensive retrofits and soul-crushing delays.

This isn’t just about checking off boxes for an inspector. It’s about building a fundamentally safe operation that protects your customers, your reputation, and your business. Many aspiring owners get so caught up in the fun stuff—the grill, the smoker, the menu—that they completely overlook the non-negotiable elements that inspectors are trained to spot first. A mistake here can shut you down before you serve a single taco.

The Non-Negotiables of Health and Safety

Every health department has its own quirks and specific rules, but there are a few core requirements that are pretty much universal across the country. Think of these as the absolute foundation of any compliant food truck layout. Get these right, and you're well on your way.

- Sinks, Sinks, and More Sinks: This is the big one, and it's not flexible. You are required to have a three-compartment sink for washing, rinsing, and sanitizing all your dishes and utensils. On top of that, you need a completely separate handwashing station, with its own hot and cold running water, soap, and paper towels. This handwashing sink must be easy to get to from your food prep and cooking areas.

- Water Systems: Your truck needs separate, distinct tanks for fresh (potable) water and for used "grey" water. The required size for these tanks varies by location, but it's often calculated based on your sink capacity and how much water you'll use. A solid rule of thumb is to make sure your grey water tank is at least 15% larger than your freshwater tank to prevent any nasty overflows.

- Ventilation and Fire Suppression: Any piece of equipment that produces grease-laden vapors—I'm talking about your fryer, griddle, or charbroiler—must be installed under a commercial-grade ventilation hood. This system is non-negotiable for air quality and fire safety. You'll also need an integrated fire suppression system with nozzles aimed right at these high-risk appliances, plus accessible Class K fire extinguishers.

These systems are the structural backbone of a safe mobile kitchen. For a more detailed look at all the gear you'll need to consider, our complete food truck equipment list is a great resource to have open as you plan.

Surfaces and Materials That Pass the Test

The materials you build your truck with are just as critical as the equipment you install. Health inspectors are trained to look for surfaces that are smooth, non-porous, durable, and—most importantly—incredibly easy to clean and sanitize.

This is exactly why stainless steel is the undisputed king of food truck interiors. It's tough as nails, it resists corrosion, and it doesn't have any tiny cracks or pores where bacteria can set up shop. All of your food contact surfaces, from prep counters to backsplashes, should be stainless steel. For flooring, you need something just as durable, non-slip, and grease-resistant, like commercial-grade vinyl or diamond plate aluminum.

Inspectors can spot red flags in an instant. Things like wooden cutting boards, cracked grout on a tiled surface, or any material that isn't smooth and easily wipeable will immediately draw their attention—and not in a good way.

The logic is simple: if a surface can't be cleaned effectively, it can't be considered food-safe. It's also worth noting that your layout has to accommodate more than just health codes. Your business will need multiple permits, with many trucks requiring at least six different licenses and having to follow strict zoning rules in over 70% of major U.S. cities.

Beyond the Basics: Pest Control and Cleanliness

A compliant layout isn't just about the big stuff; it also has to account for keeping things clean and pest-free. This means having properly sealed storage for all your dry goods, tight-fitting doors and windows, and absolutely no gaps in your walls or floors where critters could sneak in.

Ensuring your truck passes inspection means you have to be proactive about pest control. This involves adopting comprehensive fly control strategies for food service to protect public health and your hard-earned reputation. Proper waste management is also a huge part of this, so make sure you have lidded, leak-proof trash cans that are emptied regularly. After all, a clean truck isn't just good for inspections—it's just plain good for business.

Your Food Truck Layout Questions Answered

Even with the best plan on paper, questions are bound to pop up when theory meets the hard reality of a metal box. Designing a food truck layout is really a balancing act, a series of critical trade-offs between what you can afford, the space you have, and how your kitchen needs to function.

Let's dig into some of the most common questions I hear from aspiring owners. Getting these right can save you from seriously costly mistakes and put your business on the right track from day one. This is where we shift from general ideas to specific, practical advice you can use right now.

What Is the Most Common Mistake in a Food Truck Layout?

The single biggest—and most frequent—error is designing the layout before the menu is set in stone. It happens all the time. New owners get excited, buy a pre-built truck, or start placing equipment based on what "looks right" without truly thinking through the step-by-step dance of making their food.

This rookie mistake creates a fundamentally broken workflow. It leads to situations where a cook has to constantly cross the entire truck, wasting precious seconds during a chaotic lunch rush. For example, if your main fridge is far from the prep station, every single order starts with an inefficient trip. It’s a recipe for disaster.

Takeaway: Always map out your menu’s workflow first. Let the journey of your signature dish, from raw ingredient to finished plate, dictate where every single piece of equipment goes. The physical space has to serve the culinary process, not the other way around.

How Can I Design a Flexible Layout for a Changing Menu?

In the food truck world, flexibility isn't just a bonus—it's a survival skill. To build a kitchen that can evolve, you need to think in terms of modularity and multi-purpose equipment. This approach ensures you can jump on new trends, cater special events, or experiment with your menu without a wallet-draining overhaul.

Here are a few strategies I've seen work wonders for creating a more adaptable food truck:

- Go Countertop: Choose countertop cooking gear like induction burners, portable griddles, or sous vide machines. These can be swapped out in minutes, offering far more flexibility than large, permanently installed ranges.

- Put It on Wheels: Use rolling stainless steel carts for prep stations or storage. Under-counter refrigerators with casters are also fantastic because you can reconfigure your entire workflow on the fly.

- Invest in More Cold Storage: It might seem backward, but buying a slightly larger, higher-quality refrigeration unit than you think you need is a brilliant move. It gives you the capacity to handle different ingredients as your menu evolves over the seasons.

This kind of adaptability is becoming more important every year. The global food truck market, valued at $5.22 billion in 2025 and projected to soar to $8.78 billion by 2033, is growing at a 6.7% CAGR. This boom is driven by customers hungry for diverse and healthier street food, pushing savvy owners toward these flexible, modular layouts. You can find more insights on the evolving food truck market from Straits Research.

What Is the Ideal Amount of Aisle Space Inside a Food Truck?

Every inch inside a food truck is prime real estate, but skimping on aisle space is a massive safety and efficiency blunder. The ideal width really depends on one thing: how many people will be working in the truck at the same time.

For a two-person team, you should aim for a minimum of 36 inches of clear, unobstructed walkway. This allows one person to safely and comfortably move behind another without causing a collision or a major service disruption.

If you plan on having three or more people crammed in there during peak hours, pushing that aisle to 42 to 48 inches is strongly recommended. That extra bit of room dramatically cuts down the risk of accidents and creates a much less stressful, more productive environment for your crew.

Here's a crucial pro tip: Always, always measure this space with your equipment doors—like your oven and low-boy fridges—fully open. An aisle that seems wide enough can become an impassable deathtrap when a refrigerator door is swung open.

How Much Does a Custom Food Truck Layout Cost?

The cost of a food truck layout can swing wildly, so it’s vital to understand what drives the price. It all comes down to the level of customization you need, the grade of equipment you choose, and the overall complexity of your build.

Here's a general breakdown of what you can probably expect:

- Used Truck with a Basic Layout: For a pre-owned truck that comes with a standard, pre-existing kitchen setup, you could spend somewhere in the ballpark of $40,000 to $50,000. This is a budget-friendly way to get started, but you'll almost certainly have to make some compromises on your ideal workflow.

- New Truck with a Custom Layout: A brand-new truck with a layout designed from the ground up for your specific menu and workflow will typically run from $90,000 to over $150,000.

The main cost drivers in a custom build are the specialized cooking equipment, the amount of stainless steel fabrication needed, and how intricate the plumbing and electrical systems have to be to support your unique design.

Equipping your truck with the right gear is the final, critical piece of the puzzle. At The Restaurant Warehouse, we offer a huge selection of commercial-grade equipment perfect for any food truck layout, from compact countertop fryers to durable stainless steel worktables. With our competitive pricing and flexible financing options, you can build your dream kitchen without breaking the bank. Explore our full catalog and start building your mobile kitchen today.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment