Essential Equipment for Restaurant Success

The essential gear in your restaurant is the engine that drives the whole operation. Generally, it all boils down to four main categories: cooking, refrigeration, preparation, and sanitation. The specific pieces you'll need really depend on your menu, but every single successful kitchen is built on a smart mix of these components working together seamlessly.

Building Your Kitchen’s High-Performance Engine

Think of your kitchen as the engine room of your entire restaurant—it’s the heart that pumps life into everything you do. Picking out the right equipment isn't just a shopping trip; it's one of the most fundamental business decisions you'll make. The choices you make here will directly impact your kitchen's speed, the quality of your food, and your bottom line.

A well-equipped kitchen just flows. A poorly planned one? It creates constant friction, bottlenecks, and headaches.

This guide goes beyond simple checklists. We're here to give you the strategic thinking you need to build a kitchen designed for success. We'll break down the core equipment categories and, more importantly, show you how each piece has to work in harmony with the others to create a cohesive, high-performance system.

The Synergy of Kitchen Components

Just like in a high-performance engine, every single part has to work together perfectly. A beast of an oven is totally useless if your refrigeration can't keep ingredients fresh enough to cook. And the fastest prep tools in the world won't do you any good if your dish pit can't keep up with the dirty pans.

The goal is to create an efficient loop. Raw ingredients should move smoothly from storage to prep, over to the cooking line, and finally to the plate.

How you arrange all this equipment is just as critical as what you buy. A logical layout shaves precious seconds off ticket times by cutting down on wasted steps for your staff during a chaotic dinner rush. If you want to dive deeper into this crucial step, our guide on creating a commercial kitchen floor plan has some fantastic insights for optimizing that workflow right from the start.

A thoughtfully equipped kitchen doesn't just produce food; it produces efficiency. By preventing operational bottlenecks, you transform your kitchen into a model of profitability and consistency from day one.

Ultimately, your menu is the blueprint for your equipment list. But the principles of workflow and synergy? Those are universal. Understanding how to choose and arrange your kitchen’s "engine parts" is the first real step toward building a restaurant that's built to last.

Choosing Your Core Cooking Equipment

This is where the magic really happens. Your core cooking line isn't just a collection of stainless steel; it's the heart of your kitchen, the engine that turns raw ingredients into the dishes that will make your reputation. Choosing the right pieces has less to do with fancy brand names and everything to do with matching the equipment’s power and function to your culinary vision.

Think of your cooking line as an orchestra. Every single piece—from the range to the fryer—has to work in perfect harmony to execute your menu, especially when you're slammed on a Saturday night. Let's walk through building a cooking line that’s a powerful, reliable foundation for your restaurant.

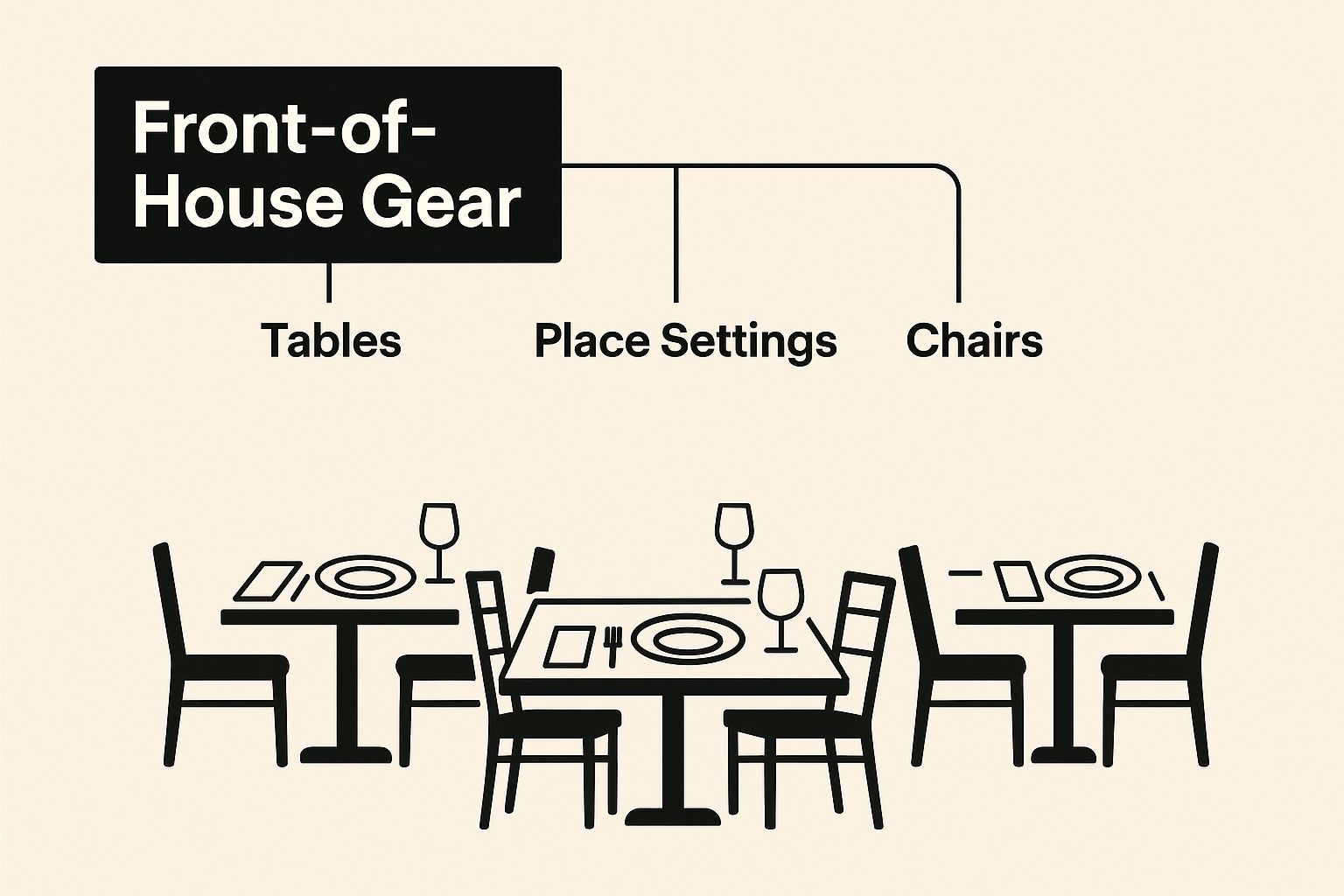

The image below breaks down all the major equipment categories you'll need to outfit your entire operation, showing you exactly how the cooking equipment fits into the bigger picture.

This gives you a great visual for understanding the central role your cooking line plays in the kitchen's workflow. It’s the star of the show.

Ranges and Ovens: The Kitchen Workhorses

The commercial range is the quintessential centerpiece of most kitchens. When you're picking one out, don't just count the burners. You need to focus on the BTU (British Thermal Unit) output. A high-BTU range is absolutely essential for getting that hard, fast sear on a steak or bringing a massive stockpot to a boil quickly. A cozy French bistro, however, might care more about lower, finely-tuned heat for delicate sauces.

Convection ovens are another non-negotiable for many spots. Unlike your standard oven, they use fans to circulate hot air, which means everything cooks faster and more evenly. This is a total game-changer for bakeries and restaurants doing a lot of roasting, cutting cook times by up to 25% and giving you a much more consistent product.

Your choice of cooking equipment is a direct reflection of your menu's ambition. A kitchen equipped for high-volume, quick-service items will look vastly different from one designed for intricate, slow-cooked cuisine. Align your hardware with your concept.

Don't underestimate how critical these decisions are. The global food service equipment market was valued at USD 39.07 billion and is expected to hit USD 58.22 billion by 2030. Kitchen equipment makes up the biggest piece of that pie at 40.6%, proving that the right gear is the foundation of a successful restaurant.

Specialized Cooking Tools: Griddles, Fryers, and Broilers

While a good range is incredibly versatile, specialized equipment is what brings real efficiency and consistency to specific dishes. A flat-top griddle, for example, is the unsung hero of diners and breakfast joints, giving you a huge, evenly heated surface for pancakes, eggs, and burgers.

For commercial fryers, the most important thing to look at is recovery time—that’s how quickly the oil gets back to the perfect cooking temperature after you drop in a basket of frozen fries. A fryer with a fast recovery time is what separates crispy, golden results from a greasy mess during a relentless dinner rush.

Charbroilers deliver that smoky flavor and those perfect grill marks that people crave on steaks and chicken. They come in different styles, from radiant and lava rock models to infrared units that provide an incredibly intense sear. Depending on your concept, you might even explore various smoker models to create those unique, deep flavors that set a menu apart.

Thinking through how each piece of equipment serves your menu is the key to building a functional and profitable kitchen. The table below breaks down the most common cooking appliances to help you match the right tool to your culinary concept.

Essential Cooking Equipment Comparison

| Equipment Type | Primary Use | Key Feature to Check | Ideal for (Menu Type) |

|---|---|---|---|

| Commercial Range | Sautéing, boiling, simmering, pan-frying | BTU Output & Temperature Control | All-purpose; essential for most concepts from fine dining to cafes. |

| Convection Oven | Baking, roasting, finishing | Air Circulation & Even Heating | Bakeries, high-volume roasting (poultry, vegetables), catering. |

| Flat-Top Griddle | Cooking multiple items on a consistent surface | Surface Area & Heat Distribution | Diners, breakfast spots, burger joints, fast-casual. |

| Commercial Fryer | Deep-frying foods quickly and consistently | Oil Recovery Time & Capacity | Quick-service, pubs, any menu with fries, wings, or battered items. |

| Charbroiler | Grilling with direct, intense heat for flavor | Heat Source (Gas, Charcoal, Infrared) | Steakhouses, BBQ joints, upscale casual with grilled proteins. |

| Smoker | Slow-cooking with smoke for deep flavor | Temperature Stability & Fuel Type | BBQ restaurants, gastropubs, concepts focusing on cured meats. |

As you can see, the "best" piece of equipment is always the one that best executes your specific dishes. Aligning your purchases with your menu from day one prevents costly mistakes and sets your kitchen team up for success.

The Gas Versus Electric Decision

Choosing between gas and electric equipment is more than just a chef’s preference; it’s a strategic decision that impacts both your budget and your daily operations.

-

Gas Equipment: Most chefs love gas for its instant heat and responsive control. It's usually cheaper to operate where natural gas prices are low, but it requires a professionally installed ventilation and fire suppression system, which adds a significant upfront cost.

-

Electric Equipment: This includes modern induction cooktops with their super-precise, efficient heating. While the utility cost can sometimes be higher, electric units are often easier to install, produce less ambient heat (making for a cooler kitchen), and are typically simpler to clean.

Your final call should be based on local utility costs, what your building can support, and the kind of cooking control your menu absolutely needs. A pastry chef would probably kill for the even, dry heat of an electric convection oven. But a high-volume stir-fry station? That would be nearly impossible to run without the raw power of a high-BTU gas wok range.

Mastering Your Cold Storage Strategy

Let's be honest, refrigeration is the silent, unsung hero of your kitchen. It’s the guardian that stands watch over your inventory, tirelessly protecting food safety and, by extension, your profits. Choosing the right equipment for a restaurant isn't just about picking a fridge; it’s about designing a smart cold storage system that preserves the quality of your ingredients from the moment they arrive until they hit the pan.

Think of this system as the backbone of your inventory management. A failure here doesn't just mean spoiled food—it means wasted money, potential health code violations, and a damaged reputation. A well-planned strategy ensures that every dollar you spend on fresh produce, meats, and dairy is a solid investment, not a gamble.

Core Components of Commercial Refrigeration

Your kitchen's cold storage will likely be a mix of several key units, each playing a distinct role in your workflow. Understanding their jobs is the first step toward building an efficient system.

-

Walk-In Coolers and Freezers: These are the titans of bulk storage. A walk-in is essential for holding large quantities of inventory, from cases of produce to sides of beef. It acts as your primary food bank, reducing the frequency of deliveries and letting you take advantage of bulk purchasing discounts.

-

Reach-In Refrigerators and Freezers: Placed strategically along your cook line, these are the workhorses for ingredients needed at a moment's notice. They give chefs immediate access to prepped items, sauces, and proteins, so no one has to leave their station during a busy service.

-

Under-Counter and Prep Table Refrigerators: These units bring refrigeration right into the prep zone. A refrigerated prep table combines a chilled storage base with a workspace up top, often with cooled wells for holding ingredients. They are indispensable for salad, sandwich, and pizza stations, keeping everything within arm's reach and at a safe temperature.

Cold storage isn't just a place to keep things cold; it's an active part of your kitchen's workflow. The right combination of walk-in, reach-in, and prep units creates a seamless "cold chain" that maintains food integrity and maximizes efficiency.

Strategic Decisions That Impact Your Bottom Line

When you're selecting the right models, you have to look beyond just size and price. A few technical details can have a massive impact on your daily operations and long-term costs.

One of the most important factors is the compressor location on your reach-in units. Top-mounted compressors are great for hot kitchen environments because they vent hot air upwards, away from the floor where dust and debris are more likely to be sucked in. Bottom-mounted compressors, on the other hand, are often easier to service and can be a better fit for cooler prep areas. Making the right choice here improves equipment lifespan and reduces maintenance headaches. For a deeper dive, our guide on choosing the right commercial refrigeration system offers detailed comparisons.

Maximizing Efficiency and Safety

Beyond the standard units, a few other pieces of equipment can elevate both your safety standards and your operational efficiency.

A blast chiller, for example, is a powerful tool that rapidly drops the temperature of hot foods. It moves them through the temperature "danger zone" (40°F to 140°F) much faster than a standard refrigerator ever could. This process not only drastically improves food safety but also preserves the texture and quality of the food.

Furthermore, always look for the ENERGY STAR rating when buying new refrigeration. These certified units are designed to be significantly more energy-efficient, often using 30-40% less energy than standard models. While the initial purchase price might be slightly higher, the savings on your monthly utility bills provide a substantial return on investment over the life of the equipment.

Equipping Your Kitchen for Peak Efficiency

Great meals begin long before the first pan hits the stove. The real secret to a smooth-running kitchen isn't just about the cooking line—it’s about the quality and organization of your prep and storage equipment. These are the tools that handle everything between receiving raw ingredients and sending a finished dish to the pass, and they have a massive impact on your speed, consistency, and ultimately, your bottom line.

Think of your prep area as mission control for your entire culinary operation. Investing in the right equipment for a restaurant here saves countless hours of labor and ensures every single ingredient is handled safely and consistently. This is where the foundation for every dish is laid, so getting it right is non-negotiable.

The Foundation of Workflow: Work Tables and Shelving

At the heart of any prep station is the humble stainless steel work table. It’s the industry standard for a reason: stainless steel is non-porous, incredibly durable, and a breeze to sanitize, making it a cornerstone of food safety. When you’re picking out tables, look for options with built-in undershelves or backsplashes to squeeze every bit of utility out of your space and keep things clean.

Smart storage is just as vital. A well-organized shelving system transforms your storeroom from a chaotic closet into a functional inventory hub. Heavy-duty wire shelving units are a popular choice because they allow for air circulation and are easy to clean. Organizing them with a FIFO (First-In, First-Out) system is a game-changer. It ensures you rotate stock properly, dramatically cutting down on food waste and spoilage.

A calm, organized kitchen is a direct result of a well-designed prep and storage strategy. When everything has a place and the workflow is logical, your team can operate with precision and speed, even during the most intense dinner rush.

This relentless focus on efficiency is driving huge growth in our industry. The global restaurant equipment market, valued at around USD 4.8 billion in 2025, is projected to more than double to USD 10.2 billion by 2035. This surge is fueled by the constant need for operational excellence, where every single piece of gear, from work tables to cooking equipment, plays a crucial role.

Labor-Saving Prep Equipment

While knives are essential, mechanical prep tools are what give your kitchen the power to handle high volume without sacrificing quality. Trust me, investing in robust, commercial-grade equipment pays for itself fast through labor savings and rock-solid consistency.

Here are a few key pieces you can't live without:

- Commercial Mixers: From countertop models for small batches to floor-standing giants that can handle 60 quarts or more, a powerful mixer is indispensable for bakeries, pizzerias, and any spot making its own bread, sauces, or batters.

- Food Processors and Blenders: A high-powered commercial food processor can chop, slice, shred, and puree in seconds. In the same way, a high-performance blender is absolutely essential for silky-smooth soups, sauces, and emulsions.

- Commercial Slicers: For delis, sandwich shops, or any operation slicing meat and cheese in-house, a commercial slicer provides a level of precision and speed that’s simply impossible to match by hand.

When you're selecting these items, always, always look for the NSF certification. This little mark ensures the equipment is designed for easy disassembly and cleaning, which is critical for preventing cross-contamination and staying on the right side of the health inspector.

Specialized Tools for Niche Operations

Your menu is what ultimately dictates your need for specialized equipment. For a detailed look at the specific items needed for a particular concept, like a coffee shop, an essential coffee shop equipment list can provide a fantastic starting point.

This same principle applies to any concept you can dream up. A steakhouse might need a commercial meat grinder for its signature burgers, while a juice bar would be lost without high-yield centrifugal or masticating juicers. Identifying these niche needs is the key to executing your menu flawlessly.

Keeping It Clean: Investing in Your Sanitation and Warewashing Systems

Let's be honest, your restaurant's reputation isn't just built on fantastic food; it’s preserved by being spotlessly clean. Sanitation and warewashing systems are the unsung heroes of a successful kitchen, working tirelessly behind the scenes to protect your customers, your brand, and your license to operate. This isn't just about cleaning up—it’s a core strategy for upholding food safety standards at every single turn.

Investing in the right equipment for a restaurant in this category is completely non-negotiable. From the simplest sink to an automated dishwasher, every piece plays a critical role in preventing foodborne illness. Plus, it ensures your front-of-house team always has pristine plates, glasses, and cutlery ready for the next guest.

The Foundation of Manual Warewashing

Before you even think about high-tech machinery, every commercial kitchen has to master the basics with a three-compartment sink. This setup isn't just a suggestion; it's a legal requirement in most places for a very good reason. It provides a systematic, effective method for washing, rinsing, and sanitizing every pot, pan, and utensil that can't just be tossed into a dishwasher.

The process is straightforward, but it has to be followed precisely every time:

- Wash: The first compartment is filled with hot, soapy water (at least 110°F) for scrubbing away all that food residue.

- Rinse: The second compartment is all about clean, warm water to get every last soap sud off.

- Sanitize: The third compartment holds either a chemical sanitizing solution mixed to the right concentration or hot water held at a blistering 171°F or higher.

This methodical approach ensures that every item isn't just visibly clean but microbiologically safe. It’s your absolute first line of defense against cross-contamination and a fundamental piece of your sanitation puzzle.

Choosing Your Commercial Dishwasher

While the three-compartment sink is essential, a commercial dishwasher is what gives your kitchen the sheer speed and efficiency it needs to handle high volumes. These powerful machines can blast through racks of dishes in mere minutes, a feat that’s simply impossible to replicate by hand. The main choice you'll have to make is between a high-temperature and a low-temperature model.

Your warewashing system is a direct reflection of your commitment to public health. The right dishwasher doesn't just clean plates; it validates the trust your customers place in you with every meal.

High-Temperature Dishwashers use powerful booster heaters to get the final rinse water up to 180°F. This intense heat is what sanitizes the dishes, no chemical agents needed. They do have a higher upfront cost and require a proper ventilation hood, but they offer faster drying times and are often preferred by operators who want to keep chemical use to a minimum.

Low-Temperature Dishwashers run at cooler temperatures (around 120°F to 140°F) and rely on chemical sanitizers in the final rinse to kill off bacteria. These units are usually more affordable to buy, use less energy, and don’t need an expensive vent hood. The trade-off, however, is the recurring cost of those sanitizing chemicals and the fact that dishes might come out wet, needing some time to air-dry.

Critical Sanitation Support Systems

Beyond the main washing stations, a few other pieces of equipment are vital for keeping your kitchen clean and compliant. A properly installed grease trap is one of the most important. It catches fats, oils, and grease from your wastewater before they can get into the sewer system, preventing disastrous plumbing blockages and hefty environmental fines.

Finally, dedicated handwashing stations are an absolute must-have, and health codes are very strict about this. These sinks must be completely separate from your food prep and warewashing sinks, always stocked with soap and paper towels, and easy for all staff to get to. Frequent and proper handwashing is one of the most effective ways to stop pathogens in their tracks, making these simple stations a cornerstone of food safety.

Making Smart Equipment Budgeting and Sourcing Decisions

Outfitting your kitchen is one of the biggest checks you'll write, and the financial choices you make here will echo for years. A smart equipment budget isn't about pinching pennies on every item; it's about investing in value. This means taking a hard, honest look at sourcing, financing, and what each piece of gear will truly cost you over its entire life in your kitchen.

Think of it like building a portfolio for your kitchen's future. You need to balance the workhorse pieces—the reliable, high-value assets—with smart, cost-saving moves elsewhere, all while keeping risk in check. Get this right, and you’re setting the stage for profitability from the moment you open your doors.

The good news is, you've got options. The foodservice equipment market is booming. It was valued at around USD 4.6 billion in 2025 and is expected to hit USD 7.3 billion by 2035. With commercial kitchen equipment making up a massive 68% of that, suppliers are getting more competitive and creative with their solutions.

Navigating the New Versus Used Debate

One of the first big forks in the road you'll hit is whether to buy new or used equipment. There are serious pros and cons to each, and the right answer depends entirely on your budget and how much risk you're willing to take on. Often, a mix-and-match approach works best.

- Buying New: New gear comes with a beautiful manufacturer's warranty, top-tier energy efficiency, and the latest tech. It’s a plug-and-play solution you can count on from day one, but it demands the most cash upfront.

- Buying Used: Pre-owned equipment can slash your initial costs by 50% or more, which is a huge relief when startup funds are tight. But that savings comes with a trade-off: no warranty, a shorter lifespan, and the looming possibility of a surprise repair bill that could wreck your week.

Here’s a strategy that works: go new for the "engine room" of your kitchen. Your primary range, oven, and refrigeration are the heart of your operation, so the peace of mind a warranty brings is worth every penny. For the less critical, supporting cast—things like stainless steel prep tables, shelving, or sinks—high-quality used pieces can be an absolute steal without adding much risk.

Exploring Leasing and Financing Options

Remember, you don't have to buy everything outright. Leasing is a powerful tool for preserving your startup capital when it's most precious. Instead of dropping a huge sum on a purchase, you make predictable monthly payments over a set period.

Leasing turns a massive capital expenditure into a manageable operating expense. This can be a game-changer for keeping your cash flow healthy during those critical first few months.

Leasing also keeps your lines of credit open for other emergencies and often includes maintenance packages, taking the headache out of unexpected repair costs. When the lease term is up, you might have the option to buy the equipment, upgrade to a newer model, or simply extend the agreement. If this sounds like a good fit, our detailed restaurant equipment financing guide can walk you through the best options for your business.

Evaluating Suppliers and Total Cost of Ownership

Choosing the right supplier is just as critical as choosing the right piece of equipment. You have to look past the sticker price and do your homework on who you're buying from. A great supplier is more than a vendor; they're a partner in your success.

When you're vetting potential suppliers, dig into these key areas:

- Warranties and Service Agreements: What exactly does the warranty cover, and for how long? Do they have a reliable service network that can get to you quickly when something breaks? Downtime is a killer.

- Customer Reviews and Reputation: What are other restaurant owners saying? A strong track record and positive reviews are solid gold indicators of quality and service you can trust.

- Total Cost of Ownership (TCO): Don't get fixated on the purchase price alone. You need to calculate the true cost over the equipment's lifespan. Factor in its long-term energy use (look for those ENERGY STAR ratings), estimated maintenance needs, and potential repair expenses. That’s the real number you should be looking at.

Common Questions About Restaurant Equipment

Stepping into the world of outfitting a commercial kitchen always kicks up a lot of questions. Getting straight, honest answers is the key to making smart decisions that actually fit your budget and how you plan to operate. Let's tackle some of the most common things I hear from aspiring restaurant owners when they're picking out equipment for a restaurant.

Think of this as a quick chat to clear up the big questions you're probably wrestling with right now.

What Is the Most Important Piece of Equipment for a New Restaurant?

While your menu is always the real boss, the two undeniable pillars of any kitchen are your commercial range/oven and your refrigeration system. The range is where all the magic happens, but your refrigerator is what makes that magic possible—and safe.

If either one of them goes down, your entire operation grinds to a halt. That’s what makes them equally critical investments for your first day and the true heart of your kitchen's engine.

How Do I Decide Between Buying New or Used Restaurant Equipment?

This really comes down to a classic trade-off: balancing your budget against how much risk you're comfortable with. New equipment gives you reliability, warranties, and top-notch energy efficiency, but it comes with a high price tag. Used gear, on the other hand, can slash your initial costs by 50-70%, but you're taking a gamble on potential repairs and a shorter lifespan.

A smart hybrid approach is usually the best way to go:

- Buy New: Invest in your "engine room" essentials—things like your main cooking range and your walk-in cooler, where you absolutely cannot afford a failure.

- Buy Used: Save some cash on less critical pieces that don't have as many moving parts, like stainless steel prep tables, storage shelves, or sinks.

What Does NSF Certified Mean and Why Is It Important?

Seeing that NSF (National Sanitation Foundation) certification is basically a seal of approval that the equipment meets some very strict standards for public health and safety. It tells you the item is designed to be cleaned easily, it's durable, and it’s made from non-toxic materials that won't harbor bacteria.

Health departments require most of the equipment in a commercial kitchen to be NSF certified. It's a non-negotiable for staying compliant and, more importantly, for showing everyone you're serious about food safety.

How Much Should I Budget for Kitchen Equipment?

There’s no magic number here, but a good rule of thumb is that your kitchen equipment will likely eat up 25-40% of your total startup costs. That figure can swing wildly depending on your restaurant concept and scale.

For instance, a small coffee shop might get by spending between $25,000 and $75,000, while a full-service restaurant could easily blow past $200,000. It all hinges on how complex your menu is, the size of your kitchen, and those big new-versus-used decisions you make. The best way to tackle this is to start with a detailed list based on your menu, then go out and get quotes from a few trusted suppliers.

Outfitting your kitchen is a huge step, and The Restaurant Warehouse is here to help you nail it. Check out our huge selection of new and used equipment and discover flexible financing options to bring your vision to life at https://therestaurantwarehouse.com.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment