Your Guide to Commercial Kitchen Ventilation Systems

Commercial kitchen ventilation systems are easily the single most important safety feature in any foodservice operation. They're more than just a fan in the ceiling; they are complex, engineered solutions designed to yank dangerous heat, smoke, and grease-filled air out of your kitchen while bringing in fresh, clean air. The goal? To maintain a safe and comfortable place for your team to work.

Why Ventilation Is The Heart Of Your Kitchen

Think of your kitchen as a living, breathing thing. While the flashy ovens and sizzling grills might seem like the star players, the real heart of the operation is the ventilation system. It’s the unsung hero working tirelessly in the background, performing a job that is absolutely non-negotiable for safety, compliance, and your staff's well-being.

Without a high-performance system, a busy cookline would quickly become an unbearable and hazardous space. The primary job of commercial kitchen ventilation systems is to capture and exhaust all the intense byproducts of cooking.

This includes:

- Excessive Heat: Pulling intense heat away from your cooking equipment is crucial. It protects your staff from heat stress and keeps the kitchen's temperature from becoming completely overwhelming.

- Smoke and Odors: A good system removes the smoke that can cloud vision and the strong odors that would otherwise seep into your dining room and cling to everything.

- Grease-Laden Vapor: Most importantly, it extracts airborne grease particles. These tiny droplets are highly flammable and are the leading cause of devastating kitchen fires.

More Than Just A Safety Mandate

Beyond preventing fires, a well-designed system is fundamental to running a great kitchen. An environment with poor air quality directly torpedoes employee health and comfort, which often leads to lower productivity and higher staff turnover. Lingering smoke and grease can also damage your equipment and building surfaces over time, leading to expensive repairs you didn't budget for.

On top of all that, a powerful and balanced ventilation system ensures your kitchen operates in full compliance with strict fire, building, and health codes. Authorities like the National Fire Protection Association (NFPA) set crystal-clear standards for ventilation to protect both your employees and the public.

A properly functioning ventilation system isn't an expense—it's an investment in the safety of your people, the longevity of your equipment, and the very viability of your business. It's the invisible force that lets your culinary team create their magic.

The Foundation Of A Functional Space

Ultimately, the placement and power of your ventilation system are deeply tied to the overall workflow of your kitchen. You can't just stick it anywhere. An effective system must be considered from the very beginning of the design process.

To get a better handle on how ventilation integrates into a high-functioning workspace, you can explore our detailed guide on commercial kitchen layout and design. This guide will serve as your roadmap to understanding, choosing, and maintaining this critical asset for your foodservice establishment.

Understanding Your Ventilation System's Core Components

To really get a feel for how a commercial kitchen ventilation system works, it’s helpful to stop thinking of it as one big machine. Instead, picture it as a highly coordinated team where each member has a critical job to do. I often use the analogy of the human respiratory system—each part is essential, and if one falters, the whole system suffers.

Let's break down this mechanical "breathing" process, piece by piece. Understanding how these components work together is fundamental, especially when you're considering new or replacement equipment. For a wider look at how everything in your kitchen fits together, our complete commercial kitchen equipment guide provides some great context.

The Exhaust Hood: Your Front Line of Defense

The first thing you’ll notice is the exhaust hood, the big metal canopy hanging directly over your cookline. Think of the hood as the system's mouth and nose; its main job is to "inhale" all the gunk produced during cooking.

This canopy creates a capture zone, pulling in heat, smoke, steam, and hazardous, grease-filled vapor before it has a chance to escape. It's the first and most vital step in clearing the air. Without a good hood, those byproducts would spill into the kitchen, creating a dangerous and frankly miserable environment for your staff.

Ductwork: The Critical Airway

Once the hood captures that dirty air, it needs a clear path to get outside. That's the job of the ductwork. These metal channels are the windpipe of your ventilation system, funneling the captured air from the hood straight up through the building and out the roof.

You can't overstate how important a well-designed duct system is. It needs to be perfectly sealed and routed to handle incredibly high temperatures and keep grease from building up to dangerous levels. A poorly designed duct system is not only inefficient but also a serious fire hazard.

The Exhaust Fan: The Powerful Lungs

If the ducts are the airways, then the exhaust fan is the powerful set of lungs that drives the entire process. Usually sitting on the roof, this fan is a high-powered motor that creates the suction—the sheer force—needed to pull air from the cookline, through the hood, and up the ducts.

It's the engine of the whole operation. The fan's power is measured in Cubic Feet per Minute (CFM), and it must be perfectly matched to your hood's size and the type of cooking you do. An undersized fan just can't keep up, while an oversized one will be an energy-sucking monster that costs you a fortune to run.

The harmony between the hood, ducts, and fan is what makes a ventilation system work. Each piece must be correctly sized and installed to create a balanced system that effectively removes contaminants without creating other problems.

Makeup Air Unit: Bringing in the Fresh Air

Here's a part of the system many people forget: for every single cubic foot of air your exhaust fan blasts out of the kitchen, another cubic foot of fresh air has to come back in. This crucial job belongs to the Makeup Air (MUA) unit, which "exhales" fresh, clean, and often conditioned air back into the kitchen.

Without a proper MUA unit, your powerful exhaust fan creates what’s called negative air pressure. This vacuum effect can cause all sorts of problems:

- Doors become surprisingly hard to open.

- The flames on your gas appliances can flicker or even go out.

- Worst of all, you can get dangerous back-drafting that pulls carbon monoxide into your kitchen.

Fire Suppression: The Ultimate Safety Net

Finally, tucked right into the hood itself is the fire suppression system. This is your kitchen's ultimate safety net, no questions asked. It consists of nozzles aimed directly at your cooking surfaces, all connected to a tank of fire-suppressing chemicals.

If a fire ever ignites on your cookline, this system can be triggered automatically or pulled manually to snuff it out in seconds. It’s the one component you hope you never have to use, but it could be the one thing that saves your business from a catastrophe.

Choosing The Right Type Of Ventilation System

Picking the right commercial kitchen ventilation system isn’t like choosing a new toaster off the shelf. It’s a critical decision that comes down to one simple thing: what are you cooking? Just like a race car needs different tires than a delivery truck, your ventilation hood has to be perfectly matched to the job to keep your kitchen safe, clean, and compliant.

The world of kitchen ventilation is split into two main camps, each designed to pull specific things out of the air. Understanding this difference is the absolute first step. Getting this wrong isn't just inefficient—it’s a direct violation of fire codes and one of the most dangerous mistakes you can make.

H3: Type I Hoods: The Grease Wranglers

If your kitchen has any equipment that kicks up grease or smoke, a Type I hood isn’t just a good idea; it’s the law. This is your heavy-duty specialist, built for the toughest jobs in the kitchen.

You'll find these hoods stationed over appliances like:

- Grills and charbroilers

- Fryers

- Ranges and griddles

- Woks and salamanders

Often called "grease hoods," Type I systems are serious business. They're engineered with special baffle filters and must have an integrated fire suppression system. Their entire mission is to capture flammable, grease-filled vapor before it can build up in your ductwork, where it could easily spark a devastating fire. Without one over these appliances, you’re creating a major fire risk.

There are a couple of common designs for Type I hoods, and your kitchen’s layout will dictate which one you need.

A wall-mounted canopy hood is what you see most often. It’s installed against a wall, right over a line of cooking equipment. This design works incredibly well because it uses the wall as a natural barrier to help funnel all that smoke and heat directly into the hood.

An island or center-canopy hood hangs from the ceiling over a block of equipment in the middle of a room. Since it’s open on all four sides, it has to be larger than the cooking surface below and needs a more powerful exhaust fan to pull in air effectively from every direction.

H3: Type II Hoods: The Steam and Heat Managers

On the other hand, Type II hoods have a much simpler, but still important, job. They handle the heat, steam, and condensation coming off appliances that do not produce any grease. Think of them as the light-duty workhorses for the less messy side of your kitchen.

These are also known as "condensate hoods," and you’ll typically see them over equipment like:

- High-temperature dishwashers

- Pasta cookers and steamers

- Most commercial ovens (like pizza or convection ovens)

Since they aren’t dealing with flammable grease, Type II hoods don’t need the heavy-duty filters or fire suppression systems that their Type I cousins do. Their main purpose is to improve air quality and comfort by pulling excess moisture and heat out of the air, keeping your kitchen from turning into a swampy, uncomfortable sauna. Putting a Type II hood over a fryer would be a serious and dangerous code violation.

H3: Comparing Type I vs Type II Ventilation Hoods

Making the right choice between a Type I and a Type II hood is absolutely critical for safety and compliance. It all boils down to what your cooking equipment produces. This table offers a quick side-by-side comparison to help you determine which hood type you need.

| Feature | Type I Hood (For Grease) | Type II Hood (For Condensate & Heat) |

|---|---|---|

| Primary Function | Removes grease, smoke, and combustion byproducts | Removes steam, heat, and moisture |

| Required Over | Fryers, grills, ranges, charbroilers, woks | Dishwashers, steamers, pasta cookers, most ovens |

| Fire Suppression | Mandatory integrated system required | Not Required |

| Filters | Baffle or cartridge-style grease filters | Simple mesh filters or no filters |

| Construction | Heavy-duty, fully welded stainless steel | Lighter-duty construction |

| Primary Goal | Fire prevention and safety | Air quality and employee comfort |

The rule is simple and absolute: if it creates grease, it demands a Type I hood. If it only puts out heat and steam, a Type II hood is all you need. Mixing this up is one of the costliest and most hazardous mistakes a restaurant owner can make.

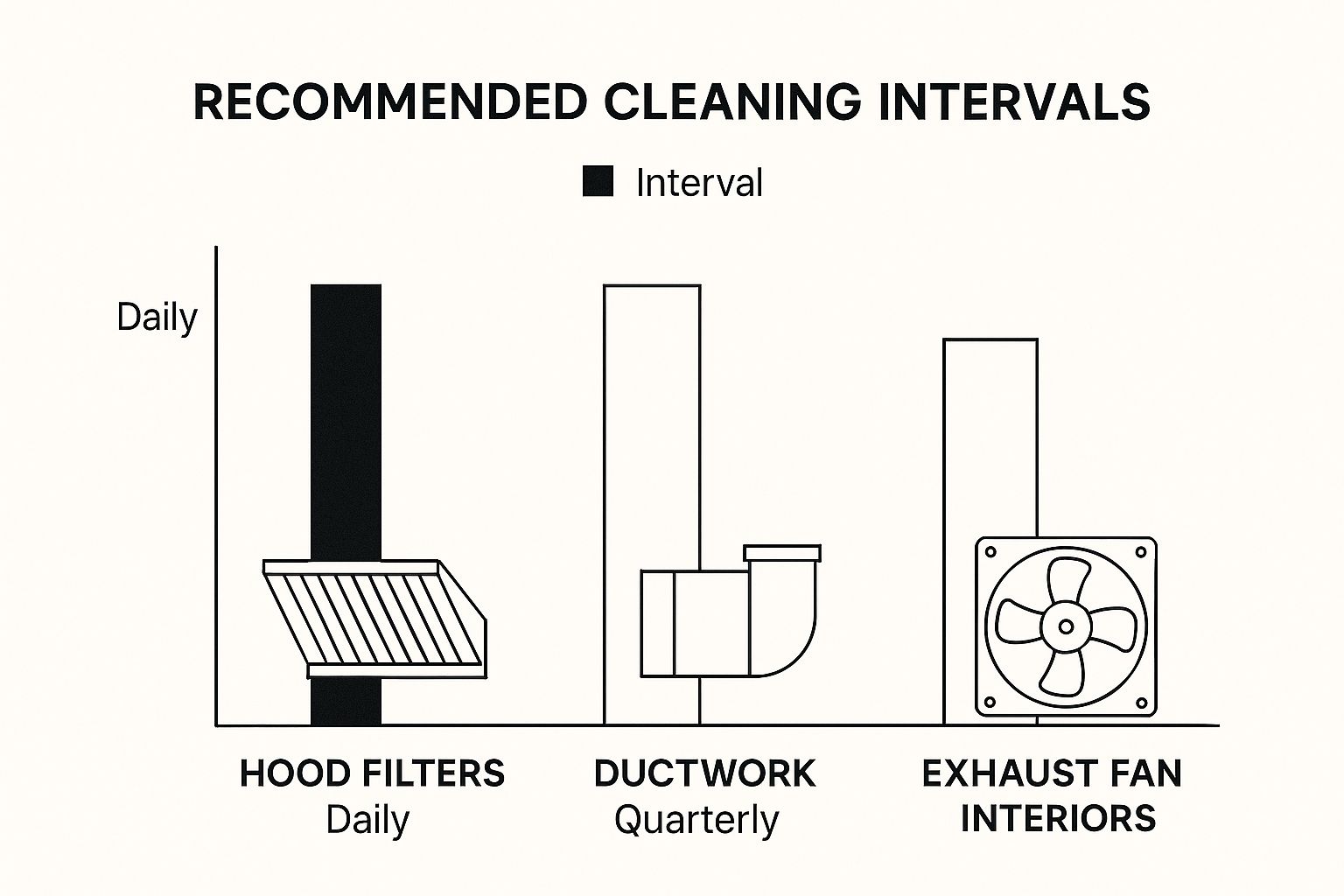

The image below gives you a better sense of how maintenance schedules are tied directly to the type of cooking you do—and therefore, the type of hood you must have.

As you can see, kitchens with high-grease cooking require far more frequent cleaning and maintenance, which really drives home how important it is to get the system right from day one.

Choosing between a wall-mounted or island hood usually comes down to your kitchen’s floor plan. A wall-mounted setup is generally more efficient and budget-friendly if your layout works for it. For open-concept kitchens or large operations with cooking islands, however, the island hood is the necessary solution, even though it often comes with a higher price tag for both the hood and the powerful fan needed to make it work.

Critical Design And Installation Factors

A commercial kitchen ventilation system that actually works is never an accident. It’s the direct result of careful planning, precise calculations, and an installation done by a true expert. Simply hanging a hood over your cookline isn't going to cut it; the entire system has to be engineered to work in harmony with your specific kitchen, your equipment, and your building's structure.

This is where the engineering blueprint translates into real-world safety and performance. Getting the design right from the very beginning saves you from a world of headaches—like costly fixes, failed inspections, and dangerous working conditions down the road. Let's break down the factors that you absolutely cannot afford to get wrong.

Calculating Your Airflow Needs

The single most important number in ventilation design is your airflow, measured in Cubic Feet per Minute (CFM). This figure represents the sheer volume of air your exhaust fan needs to pull out of the kitchen every single minute to effectively capture all the heat, smoke, and grease.

Think of it like trying to bail out a flooding basement with the right size water pump. If the pump is too small, it won’t keep up with the incoming water, and the basement will flood anyway. In the same way, an undersized fan with a low CFM rating will let smoke and hazardous fumes spill out from the hood, completely defeating the purpose of the system.

Figuring out the correct CFM is a complex process that depends on a few key things:

- The type and intensity of your cooking equipment (a charbroiler needs a lot more CFM than a steamer).

- The size and style of your exhaust hood (an island hood requires more CFM than one mounted against a wall).

- The specific requirements laid out by your local building and fire codes.

For a deeper dive into how hoods are designed to handle different cooking loads, our comprehensive commercial kitchen hood guide offers some fantastic insights.

The Importance Of Balanced Makeup Air

Here's a rule you can't break: for every bit of air your powerful exhaust fan blasts out of the building, an equal amount of fresh air has to be brought back in. This critical balancing act is handled by the Makeup Air (MUA) unit. An unbalanced system, where more air is exhausted than supplied, creates a nasty condition called negative pressure.

Ever tried to suck the last bit of juice out of a juice box without letting any air in? The box collapses on itself. A kitchen with negative pressure experiences a similar, and much more dangerous, effect.

Negative pressure can cause poor exhaust performance, miserable drafts, and doors that are surprisingly hard to open. Most dangerously, it can cause back-drafting from gas appliance flues, pulling deadly carbon monoxide gas right back into your kitchen. A 1:1 ratio of exhausted air to makeup air is the gold standard for safety and efficiency.

Proper Ductwork Design And Routing

The ductwork acts as the superhighway that carries all that hazardous, grease-filled air from your hood safely outside. Its design and installation are governed by very strict fire safety codes, mainly NFPA 96. The ducts must be built from continuously welded steel to prevent any grease from leaking out, which could easily start a fire inside your walls or ceiling.

On top of that, the path the ductwork takes is crucial. It should follow the shortest, most direct route to the roof with as few bends as possible. Every single turn creates resistance that slows down the airflow and creates another spot where flammable grease can build up. Maintaining proper clearance from any combustible materials is another non-negotiable code requirement.

Why You Must Hire Certified Professionals

Let me be perfectly clear: designing and installing a commercial kitchen ventilation system is not a DIY project. This is a job that should only be handled by certified and licensed professionals who specialize in this exact field. These experts understand the complex dance between airflow dynamics, fire safety, and strict code compliance.

Trying to cut corners by hiring an unqualified installer almost always leads to a disaster, including:

- Failed Inspections: The system won't meet local fire and building codes, forcing you to pay for expensive and frustrating rework.

- Serious Fire Hazards: An improperly welded seam or incorrect clearance from combustibles can create a life-threatening fire risk for everyone in the building.

- Poor Performance: An incorrectly designed system will fail to clear the smoke and heat from your kitchen, hurting staff health, morale, and productivity.

Investing in a professional, certified installer isn't just a strong suggestion; it's an absolute necessity to protect your staff, your customers, and your entire business.

Navigating Ventilation Codes And Regulations

Let's be honest, nobody gets excited about reading codes and regulations. But when it comes to your kitchen’s ventilation system, these rules are everything. This isn't just about red tape or passing inspections; it's about the fundamental safety of your kitchen, your staff, and your customers. An improperly designed or maintained ventilation system is one of the single biggest fire hazards in any restaurant.

Think of these codes as the official playbook for preventing disaster. They’ve been written and refined over decades by safety experts who have seen what happens when things go wrong. Ignoring them isn't just a gamble—it's a direct route to failed inspections, forced shutdowns, and potentially catastrophic fires. Getting a handle on these rules is the first, most critical step in protecting your entire business.

The industry is taking this more seriously than ever. In fact, the global market for commercial kitchen ventilation systems is expected to balloon to around $2.44 billion by 2031. This isn't just because of new restaurants opening; it's driven by stricter regulations on fire safety and air quality worldwide. You can learn more by checking out this report on the global market growth for ventilation systems.

The Key Authorities And Their Standards

When you're figuring out what's required, you'll hear two names come up again and again. While your local fire marshal has the final say, their rulebook is almost always built on the foundation of these two industry-wide standards.

-

NFPA 96: The National Fire Protection Association's Standard 96 is the undisputed bible of commercial kitchen ventilation. Officially titled the "Standard for Ventilation Control and Fire Protection of Commercial Cooking Operations," it lays out everything—from how your hood must be designed and your ducts built to how your fire suppression system must be integrated.

-

International Mechanical Code (IMC): This is a broader model code that covers all the mechanical systems in a building, including your HVAC. Chapter 5 is what you care about, as it specifically details the requirements for kitchen exhaust systems, and it works hand-in-hand with NFPA 96.

Getting familiar with these two documents isn't optional; it's essential for any operator.

Think of NFPA 96 and the IMC as your kitchen's building instructions. You wouldn't build a house without a blueprint, and you shouldn't run a kitchen without understanding the safety blueprint that these codes provide.

Core Requirements You Must Know

The full codes are incredibly detailed, but fire marshals and health inspectors tend to focus on a few non-negotiable areas. If you fail on any of these, you're guaranteed to fail your inspection.

Clearances From Combustibles

This is a big one. NFPA 96 requires very specific distances between your hot ventilation components (like the hood and ducts) and anything that can burn, like wood framing or drywall. This clearance creates a life-saving buffer zone, preventing the intense heat from your system from igniting a fire inside your walls or ceiling. The standard requirement is an 18-inch clearance from combustible materials, unless a specially rated protective barrier is installed.

Fire Suppression Integration

Your ventilation and fire suppression systems can't be two separate things; they have to operate as a single, coordinated unit. This means:

- Your fire suppression system has to be designed specifically for the cooking equipment it's protecting.

- When triggered, it must automatically cut the fuel or power to all the cooking appliances underneath the hood.

- It also must automatically shut down the makeup air unit to stop it from fanning a fire with fresh air.

Mandatory Cleaning Schedules

Grease buildup is a massive red flag for any inspector. NFPA 96 is very clear about how often your system needs to be professionally cleaned, and it all depends on what you're cooking.

- Monthly: For kitchens cooking with solid fuel, like wood-fired ovens or charcoal grills.

- Quarterly: For high-volume operations, like 24-hour diners or restaurants that do a lot of charbroiling.

- Semi-Annually: For most typical, moderate-volume restaurants.

- Annually: For low-volume kitchens, such as those in churches, day camps, or seasonal businesses.

Following these cleaning schedules isn't just about passing an inspection—it's one of the most effective fire prevention tasks you can perform.

Essential Maintenance And Cleaning Practices

A brand-new, perfectly designed commercial kitchen ventilation system will quickly become a dangerous liability without a consistent maintenance and cleaning schedule. It’s a bit like a high-performance car; you can’t just drive it off the lot and expect it to run flawlessly forever. Its performance, safety, and longevity depend entirely on proactive upkeep.

Protecting your investment, your staff, and your business means creating a routine to keep every component in peak condition. The single most critical task? Managing the constant buildup of flammable grease. Even a thin layer of grease inside the hood and ducts creates a significant fire hazard, just waiting for a single stray spark to ignite.

A Proactive Cleaning Schedule

A structured cleaning plan is your best defense against problems. This isn't something to leave to chance; it should involve both daily tasks for your kitchen staff and periodic deep cleaning by certified professionals. Creating a simple checklist can keep everyone on the same page and the system running as it should.

Here’s a practical breakdown of tasks you can implement right away:

- Daily: Your staff should clean the hood filters at the very end of every shift. Soaking them in a degreasing solution and rinsing them clean removes the day's grease accumulation before it gets a chance to bake on and become a much bigger problem.

- Weekly: Take a few minutes to inspect and empty all grease traps and collection cups. This is also a good time to give the interior and exterior surfaces of the exhaust hood a thorough wipe-down.

- Monthly: Check the exhaust fan belt for any signs of fraying, cracking, or excessive wear. A snapped belt means your fan stops working instantly, bringing your entire cookline to a grinding halt.

For any business, getting the fundamentals of upkeep right is crucial. A great resource that covers broader system care is a guide to commercial HVAC preventative maintenance, which offers valuable insights that help ensure operational continuity.

The Importance Of Professional Servicing

While daily cleaning by your team is absolutely essential, it’s only one piece of the puzzle. You must schedule regular, deep cleaning and inspection by certified professionals. These technicians have the specialized tools and expertise to clean the parts you simply can't see or reach, like the internal ductwork and the exhaust fan on the roof.

Strict regulatory frameworks mandate specific standards for managing contaminants in commercial kitchens. This has spurred market growth, with one analysis valuing it at USD 4.30 billion and projecting it to reach USD 6.82 billion by 2032. This trend underscores the industry's focus on safer, healthier workplaces. Discover more insights about these market trends on fortunebusinessinsights.com.

Warning Signs Of A Failing System

Your ventilation system will almost always give you warning signs before a complete failure. Learning to spot these red flags allows you to act before you’re facing a kitchen shutdown, an emergency repair bill, or a potential disaster.

Keep an eye—and an ear—out for these common symptoms:

- Smoke Spillage: If smoke and heat are visibly escaping the hood and spilling into the kitchen, your system isn't pulling enough air.

- Lingering Odors: Strong cooking smells that hang in the air long after service are a clear indicator of poor exhaust performance.

- Loud or Strange Noises: Rattling, squealing, or grinding sounds from the exhaust fan often point to a failing motor or a damaged belt.

- Grease Dripping: If you see grease dripping from the hood, it's a sign of a severe buildup that needs immediate professional attention.

Ignoring these signs is a recipe for trouble. The moment you notice a problem, call a certified technician to diagnose and fix the issue.

Got Questions About Kitchen Ventilation? We’ve Got Answers.

Even after you’ve got a handle on all the components and codes, the real-world questions always start to pop up. As a restaurant owner or manager, you’re juggling a million things every day, and when it comes to your commercial kitchen ventilation system, you need clear, straightforward answers. This is where we tackle the most common questions we hear from people in the trenches, helping you solve problems and make smarter decisions for your kitchen.

And it's no surprise these questions are coming up more often. The global market for these systems, currently valued at a hefty USD 11.73 billion, is on track to hit USD 17.43 billion by 2031. That’s a 4.5% annual growth rate, driven by a global push for better air quality and tighter food safety rules. You can dig into more of the numbers in this commercial kitchen ventilation market analysis.

How Often Should I Get My Hood Professionally Cleaned?

This is probably the number one question we get, and the short answer is: it all depends on how much cooking you do. The National Fire Protection Association (NFPA 96) lays out some pretty clear guidelines to follow:

- Quarterly: This is for the real heavy-hitters—kitchens running 24/7 or using charbroilers and other high-grease equipment where buildup is fast and constant.

- Semi-Annually: This is the sweet spot for most restaurants. If you're running a moderate-volume kitchen with standard lunch and dinner services, twice a year is the standard.

- Annually: If your kitchen sees lighter use—think churches, day camps, or seasonal businesses—once a year should be enough to keep things safe.

One last thing on this: always, always check with your local fire marshal. They have the final word and might have stricter rules for your area.

What Is Negative Air Pressure and Why Is It a Problem?

Negative air pressure sounds technical, but it’s a simple (and very common) problem. It happens when your exhaust fan is pulling more air out of your kitchen than your Makeup Air (MUA) unit is pushing in. This imbalance basically turns your kitchen into a giant vacuum.

So, what’s the big deal? You'll start to see a few tell-tale signs. Smoke might hang in the air instead of getting sucked up the hood. You might even find that your front door is suddenly hard to open. The most dangerous issue, though, is the risk of back-drafting from your gas appliances, which can pull deadly carbon monoxide right back into your kitchen. A balanced system isn't just about comfort—it's absolutely critical for safety.

Can I Just Install My Own Ventilation System?

In a word: no. This is one job you absolutely have to leave to certified professionals. A commercial kitchen ventilation system is a complex web of ductwork and fans that must be installed to meet very strict fire and building codes. A DIY installation is a huge fire hazard, is guaranteed to fail an inspection, and will cost you way more in fines and rework than you'd ever save. Don’t risk it.

What Are the Warning Signs My System Needs Service?

Your system will almost always give you a heads-up before it completely gives out. Paying attention to these clues can save you from a major headache and an emergency shutdown. Keep an eye (and an ear) out for these red flags:

- Smoke and heat are spilling out from under the hood instead of being captured.

- You hear strange rattling or grinding noises coming from your exhaust fan.

- There's visible grease dripping from the hood or other parts of the system.

- Cooking smells seem to stick around in the dining room long after you've closed.

If you notice any of these, don't put it off. Get a professional out to take a look right away.

At The Restaurant Warehouse, we understand that the right equipment is the foundation of a successful kitchen. From high-performance ventilation hoods to the cooking equipment they protect, we provide top-tier brands and flexible financing to help you build a safe and efficient operation. Find everything you need for your kitchen at https://therestaurantwarehouse.com.

About The Author

Sean Kearney

Sean Kearney is the Founder of The Restaurant Warehouse, with 15 years of experience in the restaurant equipment industry and more than 30 years in ecommerce, beginning with Amazon.com. As an equipment distributor and supplier, Sean helps restaurant owners make confident purchasing decisions through clear pricing, practical guidance, and a more transparent online buying experience.

Connect with Sean on LinkedIn, Instagram, YouTube, or Facebook.

Leave a comment