Commercial Kitchen Ventilation Requirements: Essential Guide

Your commercial kitchen ventilation system isn't just a piece of equipment; it's the lungs of your entire operation. It has the critical job of breathing out all the dangerous heat, smoke, and grease-filled air while pulling in fresh, clean air for your team. Getting this system right isn't about comfort—it's a non-negotiable part of keeping your staff safe, staying legally compliant, and preventing catastrophic fires.

Why Kitchen Ventilation Is Your First Line of Defense

A poorly designed or maintained ventilation system can lead to a host of problems, from miserable working conditions caused by poor air quality to the kind of grease fire that can devastate a business in minutes. That buildup of grease in your exhaust ducts is a huge fire hazard. Codes like NFPA 96 are in place for a very good reason: to stop those disasters before they happen.

This guide will walk you through the essentials of commercial kitchen ventilation requirements. We're going to break down what you actually need to know to avoid the risks and build a system that works.

The Foundation of a Safe Kitchen

Navigating the web of regulations can feel a bit overwhelming at first, but it gets a lot clearer once you understand the main goal. You're trying to create a negative pressure zone right under the hood to capture all the nasty stuff at the source before it has a chance to escape into the kitchen.

Several key components work together to make this happen:

- Exhaust Hoods: These are the frontline soldiers, positioned right above your cooking equipment to grab smoke and grease.

- Ductwork: This is the network of channels that safely carries all those hazardous vapors out of your building.

- Exhaust Fans: These are the powerful motors that act as the engine, pulling all that contaminated air through the entire system.

- Makeup Air Units: This is the crucial other half of the equation, replacing the air that's been exhausted to keep the whole system in balance.

A properly engineered ventilation system is the single most important factor in preventing restaurant fires. It actively removes the fuel source—grease—from the cooking area, dramatically reducing risk.

We’ll get into everything, from decoding complex standards like NFPA 96 to figuring out the right type of exhaust hood for your specific appliances. We'll also dive deep into the critical, and often misunderstood, role of makeup air. Think of this as your roadmap to designing a system that’s not just compliant, but a true cornerstone of a safe, efficient, and successful kitchen.

Decoding Key Ventilation Codes and Standards

Trying to make sense of kitchen ventilation rules can feel like deciphering a foreign language. But once you cut through the technical jargon, you’ll find it all boils down to one critical goal: safety. Getting a handle on the "why" behind these codes is the first step to building a kitchen that’s not just compliant, but genuinely secure.

The entire framework for commercial kitchen ventilation requirements is built on two major pillars. These are the foundational documents that guide almost every decision in your system's design, installation, and upkeep.

The Two Pillars of Ventilation Safety

Think of these codes as the essential rulebooks for your kitchen's lungs. They often overlap, but each has a specific job in keeping your operation safe and functional.

-

The International Mechanical Code (IMC): This is the broad engineering playbook for all mechanical systems, ventilation included. It lays down the baseline for things like how your ducts are built, required airflow rates, and the overall structural integrity of the system.

-

NFPA 96: Published by the National Fire Protection Association, this standard is laser-focused on one thing—fire safety. It gives you the nitty-gritty details on preventing fires in commercial kitchens, covering everything from where you place your hood to how often you need to clean it.

So, what’s the difference? The IMC tells you how to build a mechanically sound system, while NFPA 96 tells you how to build a fire-safe one. Your local city or county will almost certainly adopt a version of both, which makes them the law.

From National Standards to Local Enforcement

Those national codes like the IMC and NFPA 96 aren't just friendly suggestions; they form the basis of local law. Your local authorities—like the fire marshal and the health department—are the ones who adopt these standards and make sure you’re following them. This is a crucial point to understand.

Your fire marshal isn't just running through a checklist of parts. They're making sure your entire setup actively reduces fire risk according to NFPA 96.

For example, NFPA 96 requires a specific clearance distance between your hot ductwork and any combustible materials like wood framing. That isn’t just some random number; it’s a scientifically-backed gap needed to prevent the intense heat inside the duct from setting the building around it on fire.

The same logic applies to fire suppression systems. The rule for an automated system right over your cooking appliances is a direct response to the high risk of grease flare-ups. The system is designed to kill a fire at its source before it can spread into the ductwork, which could otherwise act like a fuse in a grease fire.

Having a solid grasp of these principles is incredibly valuable. It helps you ask the right questions and ensures your contractors are installing a system that will pass inspection the first time. For a closer look at the different components that make up these setups, you can learn more about various commercial kitchen ventilation systems and how they all work together.

Ultimately, compliance isn't about memorizing code numbers—it’s about respecting the principles of fire prevention and air quality that keep your staff, customers, and business safe.

Choosing the Right Exhaust Hood for Your Kitchen

The exhaust hood is easily the most visible piece of your kitchen's ventilation system, and it’s also the most critical. Think of it as the first responder, capturing heat, smoke, and grease right at the source before they can escape into your kitchen. Picking the wrong one isn't just inefficient—it's a direct violation of safety codes and a serious fire risk.

Your most important decision comes down to two very different types of hoods, each built for a specific job. The kind of cooking equipment you use will dictate which type you are legally required to have.

Type I Hoods for Grease and Smoke

Type I hoods, often called grease hoods, are the heavy-hitters of kitchen ventilation. They are 100% mandatory over any appliance that produces grease-laden vapors. That means equipment like:

- Grills and charbroilers

- Fryers

- Griddles

- Ranges and woks

These hoods are serious business. They're built with integrated fire suppression systems and special baffles designed to capture tiny grease particles, stopping them before they can get into the ductwork where they could easily fuel a dangerous fire. Installing anything less over this kind of equipment is a critical compliance failure, plain and simple.

Type II Hoods for Heat and Steam

On the flip side, Type II hoods (also known as condensate or heat hoods) are designed for a much lighter task. Their job is to manage the removal of steam, heat, and odors from appliances that do not produce any grease.

You'll typically find them installed over equipment such as:

- Convection or deck ovens

- Commercial dishwashers

- Steamers

Because they aren’t dealing with flammable grease, Type II hoods don't need the same tough fire suppression and filtration systems as their Type I cousins. A common mistake is thinking a Type II hood is good enough for a low-volume cooking line; if there's any grease involved, you absolutely need a Type I.

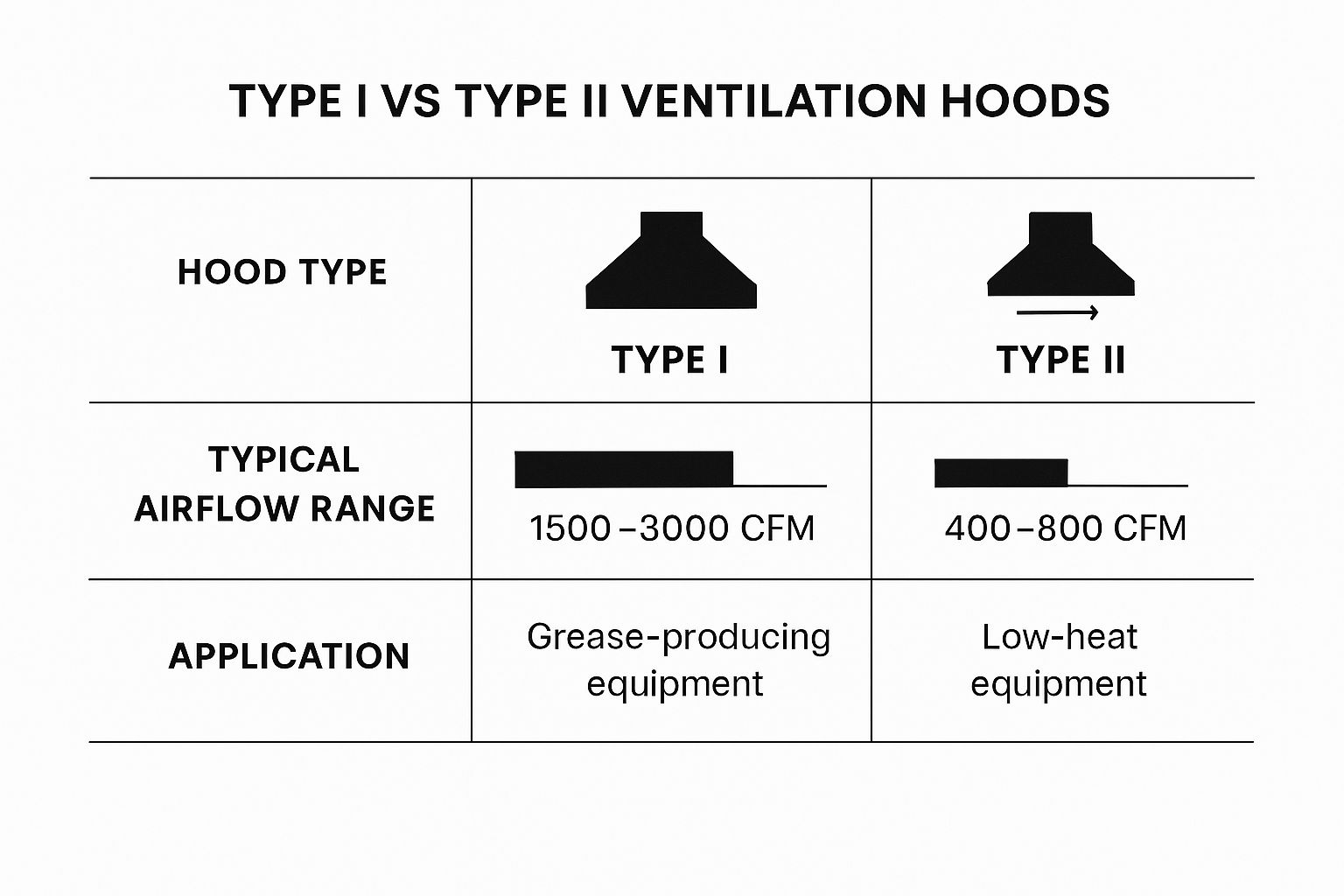

Type I vs Type II Exhaust Hoods at a Glance

To make it even clearer, let's break down the core differences. This table should help you quickly see which hood your kitchen needs based on what you're cooking.

| Feature | Type I Hood (Grease Hood) | Type II Hood (Condensate/Heat Hood) |

|---|---|---|

| Primary Use | Captures grease, smoke, and combustion byproducts | Removes heat, steam, moisture, and odors |

| Required Over | Grills, fryers, ranges, charbroilers, woks, griddles | Ovens, steamers, commercial dishwashers |

| Fire Suppression System | Required. Integrated system is mandatory. | Not Required. Does not handle flammable vapors. |

| Filtration System | Baffle filters designed to trap grease particles. | Simple mesh filters or no filters. |

| Construction | Heavy-duty, fully welded stainless steel. | Lighter-gauge construction. |

| Typical Airflow (CFM) | High (e.g., 150-400 CFM per linear foot) | Low (e.g., 50-75 CFM per linear foot) |

| Code Compliance Focus | Fire safety and grease containment (NFPA 96, IMC). | General ventilation and comfort. |

Ultimately, the choice isn't really a choice—it's a requirement. If your equipment produces grease, you must have a Type I hood.

The following infographic gives a great visual of how these two hoods differ in what they're built to handle.

As you can see, Type I hoods are engineered for much higher airflow to deal with the intense output from grease-producing equipment, while Type II hoods operate at lower capacities just for heat and moisture.

The rule is simple: if it fries, grills, or sizzles with grease, it must be under a Type I hood. This isn't just a best practice; it is a core commercial kitchen ventilation requirement that fire marshals will check without fail.

Your kitchen's physical layout also plays a huge role. Wall-mounted canopy hoods are common, but if you have a central cooking station, you'll need an island canopy hood that can capture vapors from all sides. For a deeper dive into different styles and how they fit your space, check out this detailed commercial kitchen hood guide. Matching the hood type and style to your specific appliances and layout is the key to an effective and compliant system.

The Critical Role of Makeup Air Systems

Have you ever tried using a powerful vacuum in a small, perfectly sealed room? It works great for a few seconds, but the suction quickly dies as it runs out of air to pull in. Your kitchen’s exhaust system is basically a giant, powerful vacuum designed to suck out all the smoke, grease, and heat. It works on the exact same principle.

For every single cubic foot of air your exhaust fan aggressively rips out of the kitchen, you absolutely have to bring in another cubic foot of fresh, clean air to replace it. This replacement air has a name: makeup air. It’s not an optional upgrade—it’s a non-negotiable part of a balanced, safe, and code-compliant kitchen ventilation system.

The Dangers of Negative Air Pressure

When you’re exhausting more air than you’re bringing in, you create a state of negative air pressure. This imbalance literally starves your exhaust fan for air, choking its performance and drastically cutting its ability to capture smoke and grease. But a weak hood is just the beginning; the problems spiral into some truly hazardous conditions throughout your kitchen.

Without enough makeup air, your kitchen can experience some serious issues:

- Poor Exhaust Performance: The first thing you'll notice is the hood failing to do its job. Smoke and grease will start spilling out into the kitchen, creating a nasty, uncomfortable, and unsafe place for your team to work.

- Dangerous Back-Drafting: This one is serious. Gas-burning appliances like your ovens and water heaters need a steady supply of oxygen to work safely. Negative pressure can actually reverse their airflow, pulling lethal carbon monoxide and other toxic fumes back into the kitchen instead of venting them safely outside.

- Mysterious Drafts and Door Issues: A classic sign of negative pressure is an exterior door that's nearly impossible to pull open or one that slams shut with incredible force. The entire building is desperately trying to suck in air through any crack or crevice it can find.

A makeup air unit isn't just about blowing fresh air inside; it's about maintaining a neutral, balanced atmospheric pressure. This balance is what allows all of your equipment—from the exhaust hood to the gas range—to operate exactly the way it was designed to: safely and efficiently.

Why Makeup Air Is a Code Requirement

Because of these very real safety risks, providing adequate makeup air is a core pillar of commercial kitchen ventilation requirements under both the IMC and NFPA 96. A system that creates significant negative pressure is a guaranteed failed inspection.

Modern makeup air systems are wired to be interlocked with the exhaust fan, meaning they turn on and off together to ensure the kitchen stays perfectly balanced at all times. They also frequently include heating and cooling components to "temper" the incoming air. This prevents you from blasting your cooks with freezing winter air or suffocating them with hot, humid summer air, keeping the kitchen climate stable.

For a complete overview of how makeup air units integrate with various hoods, you can explore this detailed commercial kitchen exhaust hood guide. When it comes down to it, investing in a properly sized makeup air system isn't negotiable. It's about protecting your staff, passing inspections, and making sure your entire ventilation system actually works.

Innovations in Sustainable Kitchen Ventilation

Let's be honest, meeting commercial kitchen ventilation requirements used to be about one thing: passing the inspection. But times have changed. Modern systems are so much more than just a box to tick—they’re powerful tools for slashing operating costs and boosting efficiency.

Instead of running at full blast all day long, newer technologies can actually adapt to your kitchen’s real-time needs. Think about it: a system that works smarter, not harder, is going to save a significant amount of energy.

This push toward sustainability isn’t just a passing trend; it's being written directly into the rulebook. In Europe, for instance, the EN 16282 standard has set a new bar for both safety and efficiency, covering everything from hood design to air purification. It’s even tied to an Ecodesign Directive that requires a minimum thermal efficiency of 73% for certain heat recovery units. You can dig deeper into these evolving global ventilation standards and regulations to see how the industry is shifting worldwide.

This forward-thinking approach has cleared the way for some exciting tech that delivers a serious return on your investment.

Demand Control Kitchen Ventilation

One of the biggest game-changers out there is Demand Control Kitchen Ventilation (DCKV). The easiest way to think of it is like a smart thermostat for your entire exhaust system. A standard, old-school ventilation system is like leaving your air conditioning on high all day, even when nobody's home—it works, sure, but it's incredibly wasteful.

A DCKV system is much smarter. It uses advanced sensors to detect what’s actually happening on the cookline. These sensors are constantly monitoring for heat and smoke, automatically adjusting the fan speed up or down based on the cooking volume at any given moment.

The impact on your bottom line is massive:

- During peak hours, when the grill is fired up and the fryers are bubbling, the system runs at full power to keep everyone safe and comfortable.

- During slow periods, like that lull between lunch and dinner, the fans ramp down, sometimes by as much as 50% or more. That's a huge cut in energy consumption.

By running fans only as much as needed, DCKV systems don't just reduce electricity costs for the fans themselves; they also slash the expense of heating or cooling all that replacement air.

Capturing Wasted Energy with Heat Recovery

Another brilliant innovation is the use of heat recovery units. In a typical kitchen, all that hot air pulled from the cookline is just vented straight outside. It's a tremendous waste of thermal energy, especially if you're operating in a colder climate.

A heat recovery system acts like an energy exchanger. It cleverly captures the heat from the outgoing exhaust air and uses it to pre-warm the fresh makeup air being pulled into the kitchen. This means your HVAC system doesn't have to work nearly as hard to keep the space comfortable.

While it isn't the perfect solution for every single kitchen—especially those with extremely high grease loads—it's a powerful tool for cutting down those utility bills. Investing in these smarter, more sustainable technologies is one of the best ways to future-proof your operation against rising energy costs.

Keeping Your System Compliant for the Long Haul

Passing that initial inspection feels great, but it’s really just the starting line. When it comes to your kitchen’s ventilation system, true compliance isn't a one-and-done deal—it's an ongoing commitment. This means having a rock-solid, documented maintenance plan focused on tackling the single biggest hazard in any commercial kitchen: grease buildup.

Think of the grease coating the inside of your ductwork as a fuse, just waiting for a spark to set it off. This isn't an exaggeration; it's a serious fire risk. That’s why the National Fire Protection Association (NFPA) takes it so seriously in their NFPA 96 standard, which provides a clear roadmap for managing this risk with regular, professional cleaning. It’s not a friendly suggestion—it’s a core safety requirement that both fire marshals and your insurance company expect you to follow to the letter.

How Often Does NFPA 96 Say You Need to Clean?

The cleaning schedule for your system isn't a one-size-fits-all rule. It’s directly tied to what you’re cooking and how much you’re cooking. Getting this wrong can lead to immediate violations, and more importantly, it dramatically increases the risk of a devastating fire.

Here’s how the standard cleaning intervals break down:

- Monthly: This is for systems dealing with solid fuel cooking. Think wood-fired pizza ovens or anything using charcoal charbroilers.

- Quarterly: The common schedule for most high-volume operations. This includes 24-hour diners, busy fast-food chains, and restaurants that do a lot of charbroiling.

- Semi-Annually: This applies to kitchens with more moderate cooking volumes, like your typical sit-down restaurant or the average hotel kitchen.

- Annually: Reserved for low-volume kitchens, such as those you’d find in day camps, churches, or other seasonal businesses.

Keeping a detailed logbook of every professional cleaning isn't just good housekeeping—it’s your proof of due diligence. When a fire marshal shows up for a surprise inspection, that log, complete with service dates and a certificate from your cleaning company, is the first thing they'll want to see.

This documentation is also your best friend when it comes to your insurance policy. If a fire does happen, being able to prove you’ve kept up with certified maintenance can be the deciding factor in whether your claim gets approved. Ultimately, being proactive about maintenance is the best way to protect your investment, keep your staff safe, and ensure your kitchen stays open for business.

Common Questions About Kitchen Ventilation

Even with a solid plan in place, a few specific questions always seem to pop up when we're talking about commercial kitchen ventilation. Let's tackle some of the most common ones I hear from restaurant owners, clearing up the confusion so you can move forward with confidence.

How Often Should My Hood System Be Cleaned?

This is a big one, and the answer comes straight from the NFPA 96 fire code: it all depends on what you’re cooking and how much of it.

- For high-volume kitchens, especially those using solid fuel or charbroilers, that grease builds up fast. You'll need a professional cleaning every single month.

- Most restaurants with a moderate daily volume fall into the quarterly service category.

- Operations with very low volume, like a church kitchen or a seasonal camp, can typically get by with an annual cleaning.

When in doubt, always bring in a certified professional. They can assess your specific operation and set a cleaning schedule that keeps you safe and compliant.

Can I Use a Second-Hand Ventilation Hood?

While you might see a used hood for sale and think it's a great deal, I usually advise caution. It's technically possible, but it’s often a risky and impractical path.

Any pre-owned hood still has to be UL listed, sized perfectly for your cook line, and meet all current local codes. The catch is that those codes might have been updated since the hood was first made. The costs for a proper inspection, transportation, and any custom retrofitting needed to make it compliant can quickly add up—often costing you more than a brand-new system that comes with a warranty.

What Is an Upblast Exhaust Fan?

The difference here is all about the direction the air flows, and it's a critical detail for fire safety.

Upblast fans are mandatory for kitchen exhaust systems because they shoot greasy air straight up and away from the building. This is hugely important because it prevents that flammable grease from coating your roof, which is a major fire hazard.

Downblast fans, on the other hand, push air downward. They’re perfectly fine for general building ventilation or restrooms, but they should never be used to exhaust grease-laden air.

From exhaust fans to complete hood packages, The Restaurant Warehouse has the code-compliant equipment you need to build a safe and efficient kitchen. Find the right ventilation solutions for your business today at https://therestaurantwarehouse.com.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment