How to Boil Out a Deep Fryer: A Complete Guide

That stubborn, caked-on gunk in your commercial fryer isn't just an eyesore—it's ruining your food and costing you money. Old oil residue and carbonized bits can make even the best fries taste off. The solution is a proper boil out fryer procedure. This isn't your average scrub-down. It's a deep clean that uses a specialized solution and boiling water to dissolve the toughest grease and grime. Think of it as a reset button for your fryer, restoring its performance and protecting your investment.

Getting this done right is critical for food quality, kitchen safety, and keeping your expensive equipment running for the long haul.

The Real Reasons You Need to Boil Out Your Fryer

Thinking of a fryer boil out as just another annoying chore is a common—and costly—mistake in a lot of kitchens. This task isn't about making the fryer look pretty. It’s a fundamental process that directly protects your food's taste, the lifespan of your equipment, and your business's hard-earned reputation. Pushing this job off has real consequences that go way beyond a dirty-looking vat.

The first thing to suffer is the taste of your food. Old, broken-down oil is full of free fatty acids and carbon deposits, and they will absolutely impart a rancid, burnt flavor to everything you cook. That perfectly seasoned fried chicken or those golden fries? They'll just taste off, no matter how skilled you are in the kitchen. This slow decline in quality is often the first thing a customer notices, even if they can't quite put their finger on why.

More Than Just Clean: Safety and Longevity

Beyond just flavor, regular boil outs are a big deal for safety and operational efficiency. When a thick layer of carbonized grease builds up, it acts like an insulator, forcing the fryer's heating elements to work much harder just to maintain the right oil temperature.

This struggle leads to a few problems you'll definitely notice:

- Higher energy bills: Your utility costs will slowly creep up as the fryer fights to keep the oil hot enough.

- Slower recovery times: The oil will take much longer to get back up to temperature after you drop in a basket of frozen food. The result? Greasy, undercooked products and longer ticket times.

- A shorter equipment lifespan: Components that are constantly overworked are far more likely to fail, leading to expensive repairs and frustrating downtime right in the middle of a dinner rush.

And let's not forget the most serious risk: that heavy grease buildup is a major fire hazard. Grease fires are notoriously difficult to put out and can be absolutely catastrophic for a restaurant. Regular boil outs dramatically reduce this risk by removing the very fuel that a fire would feed on.

A clean fryer is an efficient, safe, and profitable fryer. Neglecting this task to save a little time in the short term almost always leads to bigger expenses and headaches down the line, from failed health inspections to complete equipment breakdowns.

Good Food Starts with a Clean Fryer

The demand for high-performance frying equipment isn't slowing down. In fact, the commercial deep fryer market is projected to grow from USD 583.92 million in 2024 to about USD 798.24 million by 2032.

This growth reflects how popular fried foods are in fast-service restaurants, where consistency and quality are everything. You can learn more about the future of commercial deep fryers and their market trends. As these machines get more advanced, proper maintenance like a boil out becomes even more crucial to protect what is a significant capital investment. A proactive approach is what keeps your kitchen running smoothly and your customers happy.

Your Boil Out Prep Kit: Safety Gear and Tools

Before you even think about draining that old oil, let's talk about the most important step in any fryer boil out: getting your gear together. This isn't just about being organized. It's about setting up a safe zone to handle boiling water and some pretty potent cleaning chemicals. Trying to wing it or rush the prep is a common mistake, and frankly, it's a dangerous one.

Let me be clear: this process demands respect. The risk of getting a severe burn from a splash of hot water or a chemical rash is no joke. That means gearing up with the right Personal Protective Equipment (PPE) is mandatory, every single time. No exceptions.

Before you start, you'll need a few essential items to keep you safe. We've put together a quick checklist to make it easy to remember what you need and why it's so important.

Your Non-Negotiable Safety Checklist

| Item Category | Specific Equipment | Primary Purpose |

|---|---|---|

| Hand & Arm Protection | Heat-Resistant, Gauntlet-Style Gloves | Protects hands and forearms from hot water and chemical splashes. |

| Eye Protection | Splash-Proof Safety Goggles | Shields eyes from boiling water splatters and chemical fumes. |

| Body & Clothing Protection | Heavy-Duty, Waterproof Apron | Creates a barrier between your body and the hot, chemical solution. |

Think of this table as your pre-flight check. A quick glance ensures you're ready to tackle the job safely and effectively.

Triple-Check the Drain Valve

This might sound overly cautious, but trust me, it’s a lesson you only want to learn once. Before a single drop of water or cleaning solution goes into that vat, you need to be absolutely certain the drain valve is completely closed. Forgetting this step is one of the most common—and messiest—mistakes in the kitchen. A good rule of thumb is to check it three separate times. This simple habit can save you from the nightmare of dumping gallons of boiling, chemical-filled water all over your kitchen floor, creating a dangerous, slippery disaster that brings the entire line to a halt.

Never Leave the Fryer Unattended

Once the water and cleaning solution are in and the heat is on, your job is to stay put. Never, ever walk away from a fryer during a boil out. The chemical reaction from the cleaner, combined with the boiling water, creates a lot of foam and bubbles that can rise incredibly fast. It can easily boil over the sides of the vat in a matter of seconds if you’re not watching it. This isn't a "set it and forget it" task. You need to be right there to monitor the process and manage the heat, ready to turn it down if the foam starts to climb too high.

Consider Turning Off the Pilot Light

There's some debate in kitchens about whether to turn off the pilot light during a boil out, and the right answer often depends on the situation. For a full, deep clean where the fryer will be empty for an extended period, turning off the pilot light is the safest move. It eliminates any risk associated with having an open gas line near water and cleaning chemicals. However, if you're just doing a quick rinse and refill, some chefs might leave it on for convenience. When in doubt, always refer to the manufacturer's guidelines for your specific deep fryer model and prioritize safety.

What Cleaning Tools Do You Need?

Once you're suited up, it's time to assemble your cleaning arsenal. Having everything you need within arm's reach is crucial because stepping away mid-process is when accidents tend to happen. You're going to need more than just a sponge to tackle the baked-on gunk you're about to face.

A successful boil out is 90% preparation and 10% execution. Taking ten minutes to gather everything you need will save you from making a dangerous mistake later.

Your toolkit should have a long-handled, stiff-bristled brush to scrub the fryer walls and heating elements without getting your hands too close to the heat. You’ll also want a sturdy scraper—preferably one that won't scratch up the stainless steel—to break loose any stubborn carbon buildup. Finally, make sure you have a designated, heat-proof container ready and waiting for the old oil. Looking at a list of essential cleaning materials can give you a good sense of how having the right tools makes any tough cleaning job easier.

How to Pick the Right Boil Out Solution

Now for the most critical item on your list: the cleaning agent. Whatever you do, do not use generic degreasers, dish soap, or any caustic chemical not specifically made for a fryer boil out. Using the wrong product can seriously damage your equipment, leave behind nasty residues, or even create a dangerous chemical reaction.

Always go with a manufacturer-approved, food-safe boil out solution. These products are specifically formulated to break down that stubborn, polymerized grease without harming the fryer's components. More importantly, they won't pose a risk to food safety after you’re done. Check your fryer’s manual for recommended brands or pick up a trusted commercial-grade solution. This single choice is what makes the entire process both safe and effective.

How to Boil Out Your Fryer, Step-by-Step

Alright, you’ve got your safety gear on and your tools are ready to go. Now for the satisfying part: transforming that greasy, carbon-caked fryer back into a pristine piece of equipment. Let's walk through this together, step by step, focusing on doing it right—and doing it safely.

First things first: the old cooking oil. You absolutely have to make sure the fryer is completely turned off and the oil has cooled down to a safe temperature. I always aim for below 150°F. Trying to drain scorching hot oil is, without a doubt, one of the fastest ways to get a severe burn in a commercial kitchen. It's just not worth the risk.

Once it's cool enough to handle, slowly open up the drain valve. Let the oil flow steadily into your designated, heat-proof container. Whether you're planning to filter it for another use or dispose of it completely, take your time. Rushing this step is a recipe for a dangerous, messy spill.

First: Get Rid of the Gunk

After all the oil is drained, you'll be face-to-face with the worst of it—a sludgy layer of carbonized food bits and that thick, almost plastic-like polymerized grease. Before you even think about adding water, grab your scraper and a long-handled brush.

The goal here is pretty simple: physically remove as much of that loose gunk as you can. Really get in there and focus on the fryer walls, the heating elements, and especially the corners where everything seems to collect. Scraping this stuff out now means the cleaning solution can attack the really stubborn grime, making the whole boil out way more effective. Don't stress about getting it spotless; just clear out the major buildup.

When you're done scraping, make sure you close that drain valve and secure it tightly. The last thing you want is a vat full of boiling water suddenly leaking all over the kitchen floor.

Clear Debris Before Draining

Before you even touch that drain valve, there’s a quick but crucial step that will save you a major headache. Take a long-handled crumb scoop and fish out any large food particles and sediment sitting at the bottom of the vat. Think of it as pre-cleaning; getting the big stuff out of the way now prevents it from clogging your drain pipe, which is a messy problem you don't want to deal with. This also allows the boil out solution to work directly on the tough, polymerized grease stuck to the fryer walls, making the entire process much more effective. Once you’ve scooped out the debris, it’s a smart move to quickly run a cleanout rod through the drain pipe to ensure the path is completely clear. Taking a minute to do this prep work is one of the most important practices for maintaining your kitchen equipment and ensuring a smooth, efficient cleaning process.

Next: Mix Your Solution and Bring to a Boil

Now you're ready to fill the fryer vat with cold water. A good rule of thumb is to leave about three to four inches of space from the top. This headspace is super important because it gives the solution room to foam up as it heats without boiling over and creating a hazardous mess.

Next, it's time to add your commercial boil out cleaning solution. You have to follow the manufacturer's instructions on the label for the correct ratio of cleaner to water. A common mix is about one part cleaner to twenty parts water, but always, always go by what the product says. Adding too much can create a foam volcano, while using too little just won't cut through the grease.

With the water and cleaner in, you can turn the fryer back on. Set the thermostat to a low simmer. You're aiming for a temperature somewhere between 190°F and 200°F.

Crucial Safety Tip: Whatever you do, never bring the solution to a rapid, rolling boil. A gentle simmer is all you need for the chemicals to work their magic and break down the grease. A hard boil doesn't clean any better, but it creates a massive splash and steam hazard.

Let the solution simmer away for about 20 to 30 minutes. This gives it enough time to penetrate and loosen all that remaining, baked-on grime.

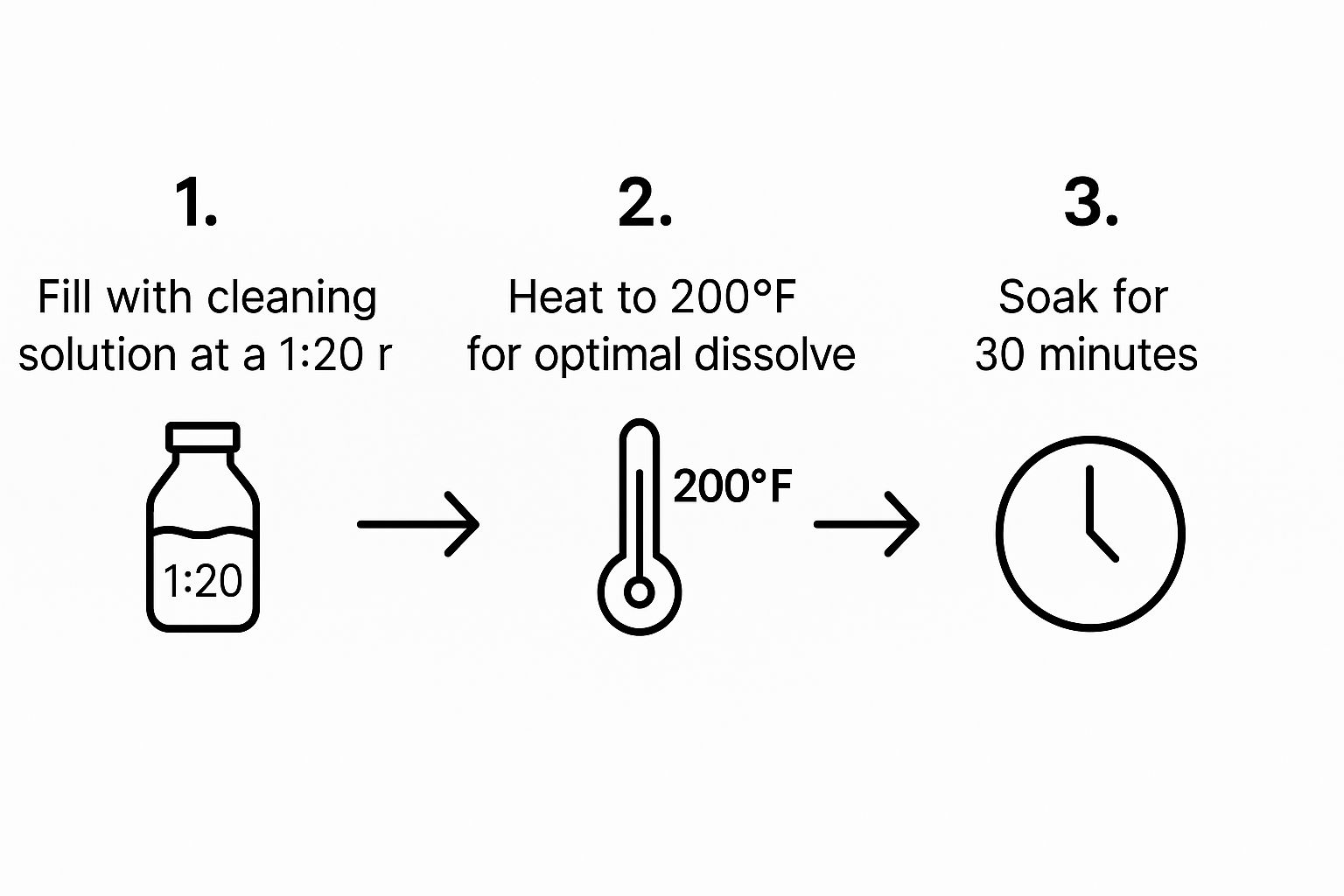

The infographic below really visualizes the core stages of this process.

As you can see, it's that perfect combination of the right solution ratio, the right temperature, and the right amount of time that makes this whole thing work so well.

Once the simmering time is up, turn the fryer off completely and let the hot solution sit for a few more minutes to cool down just a bit. While the water is still hot, grab your long-handled brush and give the interior one last good scrub. This will help dislodge any final bits of stubborn carbon. If you want a more detailed look at each stage, this guide on the deep fryer boil out process has some great additional tips.

Finally, very carefully drain the hot cleaning solution. Use a heat-proof container or a designated floor drain, and make sure no one is standing nearby. That water is still dangerously hot, so proceed with extreme caution. The next step is just as important: rinsing away every trace of chemical residue to get the fryer ready for fresh, clean oil.

Special Considerations for Electric Fryers

Electric fryers are fantastic, but they have a few quirks you need to know about when it's time for a boil out. The basic steps we've covered—draining, scraping, simmering, and rinsing—are exactly the same. However, the way electric models heat the oil and regulate temperature means there are a couple of extra details to pay attention to. These aren't complicated things, but getting them right ensures you're cleaning the machine effectively without causing any damage to the sensitive heating elements or controls. Think of it as fine-tuning the process specifically for your equipment.

Use the "Boil Mode" if Available

Many modern electric deep fryers come with a feature that makes this whole process much simpler: a dedicated "boil mode." If your fryer has this setting, you should absolutely use it. This mode is specifically calibrated to heat the water and cleaning solution to the perfect simmering temperature—and keep it there—without the risk of a violent, rolling boil. It takes all the guesswork out of managing the thermostat. This gentle, consistent heat is exactly what you need to dissolve that tough, burnt-on carbon from the heating elements without creating a safety hazard. Just fill the vat, add your solution, and let the boil mode do the heavy lifting.

Don't Forget the Temperature Probe

Inside your electric fryer, there's a small but critical component called the temperature probe. This little sensor is the brain of the operation, telling the heating elements when to kick on and off to maintain a precise temperature. During a boil out, it's easy to overlook, but it needs a good cleaning just like everything else. If the probe gets coated in grease and carbon, it can't get an accurate reading of the water temperature. This can lead to an ineffective boil out or, during regular service, cause major issues with food quality. A dirty probe is often the culprit behind inconsistent cooking and oil that breaks down too quickly. So, when you're scrubbing the vat, give the temperature probe a gentle but thorough cleaning with your brush. This simple step ensures your fryer cooks accurately and efficiently.

Finishing the Job: Rinsing and Neutralizing

Draining out that murky, greasy water feels like a victory, but the job isn't quite done. This next stage—the rinse and neutralization—is where a lot of kitchens try to cut corners. It’s a mistake I’ve seen happen, and it directly tanks your food quality. Skip a proper rinse, and you’re leaving behind a chemical residue that contaminates fresh oil, giving your food a nasty, soapy flavor nobody wants.

First things first, you need to flush the vat with a series of hot water rinses. After draining the cleaning solution, fill the fryer back up with clean, hot water. Bring it to a simmer for about five to ten minutes, then carefully drain it out again. This isn't a one-and-done deal. You need to repeat this hot water rinse at least twice to make sure every last trace of the alkaline cleaning agent is gone.

How to Perform the Neutralizing Rinse

After the hot water has done its job, it’s time for the final, most crucial step: the neutralizing rinse. Those powerful boil-out cleaners are highly alkaline (or basic), and any residue left behind will degrade new cooking oil in a heartbeat. To counteract this, you need a mild acid.

This is where a simple, cheap kitchen staple comes to the rescue: plain white vinegar. A quick vinegar rinse will effectively neutralize any lingering alkaline film, leaving you with a perfectly balanced surface that protects the life and flavor of your next batch of oil.

Here’s all you have to do:

- Fill the fryer vat about halfway with clean, cool water.

- Add white vinegar using a ratio of roughly one cup of vinegar for every gallon of water.

- Use your long-handled brush to swish the solution around, making sure you coat every interior surface.

- Let it sit for about 10 minutes, then drain the fryer completely.

This final step is your insurance policy against off-flavors transferring to your food. For more tips on keeping your kitchen spotless and food-safe, our detailed guide on cleaning restaurant equipment has you covered.

You'll know the fryer is truly clean and neutralized when you can wipe the interior with a clean, white cloth and it comes away spotless—no greasy film, no chalky residue. That's your green light to start drying.

Drying and Prepping for New Oil

Ensure the Fryer is Completely Dry

You’ve scrubbed, rinsed, and neutralized, and that stainless steel is finally gleaming. It's tempting to call it a day and immediately start filling it with fresh oil, but this last step is non-negotiable. Any water left hiding in the vat is the number one enemy of new cooking oil. When you heat that oil, leftover water will turn to steam, causing violent, dangerous splattering. Even worse, that moisture will immediately start to break down the oil, drastically shortening its lifespan and making your food taste greasy. Taking a few extra minutes to dry the fryer properly protects your staff, your food quality, and your bottom line.

After the final drain, grab a stack of clean, dry, lint-free cloths and thoroughly wipe down the entire interior. Pay special attention to the corners, welds, and the areas around the heating elements where water loves to pool. Once you think it's dry, go over it one more time. For absolute certainty, you can turn the fryer on to a very low temperature—just enough to warm the metal—for about five to ten minutes. This will evaporate any final, invisible traces of moisture. This simple trick is the best way to protect the longevity of high-performance commercial deep fryers and ensure you get the most out of your investment in clean oil.

Why Modern Fryers Need That Final Rinse

Proper maintenance is more critical than ever. The deep fryer market is projected to grow from USD 733.6 million to USD 1,085.9 million between 2025 and 2035, driven by the demand for high-capacity, ultra-efficient machines. These modern fryers rely on pristine surfaces and precise temperature controls to work correctly.

Following every step of the boil-out process, especially the final rinse and neutralization, is how you protect that significant investment and ensure your kitchen is putting out consistently great food.

Pro Tips for Efficiency and Oil Management

A fryer boil out is the perfect time to reset your entire frying operation. It’s not just about getting the machine clean; it’s an opportunity to implement smarter habits that save you time, cut down on costs, and seriously improve the quality of your food. Managing your cooking oil is one of the most impactful things you can do for your kitchen's bottom line. Good oil management means your fried chicken is crispier, your fries are golden, and you aren't literally pouring money down the drain. By building a few key practices into your routine, you can make the most of the boil out process itself, extend the life of your expensive cooking oil, and handle disposal in a way that’s both safe and smart.

Making the Most of Your Boil Out

Think of the boil out as a multitasking opportunity. While that powerful cleaning solution is working its magic inside the fryer vat, it can be doing double duty elsewhere. This is all about working smarter, not harder. With a little planning, you can use the time and resources dedicated to cleaning your deep fryers to tackle other greasy jobs in the kitchen. This approach streamlines your cleaning schedule and makes one of the kitchen's least favorite chores feel a lot more productive. It’s a simple shift in perspective that turns a maintenance task into a full-blown efficiency win.

Clean Multiple Items at Once

While the cleaning solution is simmering in the fryer, don't let that potent degreasing power go to waste. You can carefully place other greasy, hard-to-clean items directly into the vat to get them sparkling clean at the same time. Things like fryer baskets, vent hood filters, and even small stainless steel pots can benefit from a soak in the hot solution. This simple trick saves an incredible amount of time and elbow grease later on. Just be sure the items are fully submerged and won't damage the fryer's interior, and always remove them carefully with tongs before you drain the solution.

Let the Hot Water Clear Your Drains

After you’ve drained the cleaning solution and are in the rinsing stage, you have another opportunity for some preventative maintenance. That hot rinse water is perfect for helping to clear out your floor drains. As you carefully drain the hot water from the fryer, it will help dissolve and flush away any grease buildup that has started to accumulate in the pipes. This can prevent slow drains and costly plumbing calls down the road. It’s a free, easy step that leverages a process you’re already doing to keep another part of your kitchen running smoothly.

Extending the Life of Your Cooking Oil

Cooking oil is one of the biggest recurring expenses in any kitchen that does a lot of frying. Getting the most out of every drop is crucial for managing your food costs. The key isn't just to use it until it's smoking and dark; it's to actively maintain its quality from the very first batch of fries. Simple, consistent habits can dramatically slow down the natural breakdown of oil, allowing you to use it longer without sacrificing the flavor or texture of your food. This means better products for your customers and real, measurable savings for your business.

Filter Your Oil Daily

This is the single most important thing you can do to preserve your oil. Throughout the day, tiny food particles and breading break off and float around in the hot oil. If left there, they burn, turn into carbon, and rapidly accelerate the breakdown of the oil, creating off-flavors. You need to filter that oil at the end of every single day. Whether you have a fryer with a built-in filtration system or use a separate filtering machine, making this a non-negotiable part of your closing routine will keep your oil cleaner, extend its life, and ensure your fried foods taste fresh and delicious.

Consider a Cascading Oil System

For kitchens with multiple fryers, a cascading system is a brilliant strategy for maximizing oil life. The concept is simple: you move oil from one fryer to another based on what you cook in it. For example, oil from a fryer used only for french fries (which is relatively gentle on oil) can be filtered and moved to a fryer used for breaded chicken (which is much harder on oil). This ensures you get the maximum utility from your oil before it's discarded. It takes a bit of organization, but it’s a professional technique that can lead to significant cost savings in high-volume operations.

Use Oil Stabilizers

Think of oil stabilizers as a supplement for your fryer oil. These are typically powders or pads that you add to the oil to slow down the chemical processes, like oxidation, that cause it to break down. Using an oil stabilizer can help maintain the oil's quality, reduce foaming, and prevent it from darkening as quickly. It’s a proactive measure that helps you maintain a high-quality product while stretching your oil budget a little further. When you’re already investing in quality equipment, taking this extra step helps protect your investment in the consumables that go with it.

Smart Disposal Methods

Once your oil has reached the end of its useful life, you can't just pour it down the drain. Not only is that terrible for your plumbing and the local sewer system, but it can also lead to hefty fines. Handling oil disposal needs to be done safely and responsibly. Many areas have specific regulations for disposing of used cooking oil, so it's important to have a clear and consistent process in place. Setting up a smart disposal system protects your kitchen, your community, and your business from unnecessary problems.

Properly Dispose of Old Oil

The safest way to handle used oil is to let it cool completely. Once it's at a safe temperature, pour it into a sturdy, leak-proof container with a secure lid. An empty plastic jug or a dedicated oil disposal caddy works perfectly. Make sure you label the container clearly as "Used Cooking Oil." Many restaurants contract with a rendering or recycling service that will pick up used oil for free, as it can be converted into biodiesel. Check for services in your area; it’s an easy, environmentally friendly solution that solves the disposal problem for you.

Save Money on Boil Out Water Disposal

While you can't save the boil out water itself, you can save money by making the process protect your infrastructure. The biggest hidden cost of improper fryer maintenance is plumbing emergencies. When you perform the hot water rinse step correctly, that large volume of hot water helps flush grease from your floor drains, as mentioned earlier. This preventative action can save you hundreds, if not thousands, of dollars on emergency plumbing calls to clear grease clogs. Think of the final rinse as a way to protect your pipes, ensuring the money you save on oil isn't just spent on a plumber later.

Did Something Go Wrong? A Troubleshooting Guide

Even with the best plan, a boil out can sometimes go sideways. I’ve seen just about everything in my time in different kitchens, but the good news is most common hiccups are easy to fix without damaging your equipment or creating a safety hazard.

One of the most common things to watch for is the solution foaming up and threatening to boil over. If you see this start to happen, kill the heat immediately. An overflow isn't just a pain to clean up; it creates a serious slip hazard on the kitchen floor. This usually happens for one of two reasons: you used too much cleaning chemical or you simply overfilled the vat with water.

Another classic frustration is finding those stubborn, baked-on carbon spots that refuse to budge, even after a full boil out. Whatever you do, don't grab a steel wool pad—you'll scratch the heck out of the fryer's surface. A little targeted effort is a much better approach.

- First, drain the fryer. Then, make a thick paste using your boil out powder and a tiny bit of water.

- Apply that paste directly onto the stubborn spot and just let it sit for 15-20 minutes. This gives it time to really penetrate the gunk.

- Finally, use a non-abrasive scrub pad or a stiff nylon brush to gently work the spot loose.

This method concentrates the cleaning power right where you need it, without putting your fryer at risk.

Help! My Fryer Still Isn't Clean

Have you ever finished the boil out process, only to discover a chalky, white film coating the inside of the vat? That's a textbook sign of improper rinsing. That film is leftover alkaline residue from your cleaning solution, and it will absolutely destroy the flavor of your food and shorten the life of your next batch of oil.

The fix is simple but absolutely non-negotiable: you need another rinse cycle. Fill the vat with a 10:1 water-to-vinegar solution and let it sit for about 15 minutes to neutralize all that residue. Drain it, then give it one last, thorough hot water rinse. The inside of your fryer should be perfectly clean after that.

The worst-case scenario is when someone accidentally grabs the wrong chemical. If this happens, do not heat the fryer. Immediately drain the chemical and consult the Safety Data Sheet (SDS) for proper handling and disposal. Follow up with multiple, thorough hot water rinses and a neutralizing vinegar pass before even thinking about using the fryer again.

The demand for fried foods has exploded, leading to a huge expansion in the deep fryer market. Valued at USD 592.1 million in 2025, it’s projected to hit USD 758.5 million by 2032. Protecting these valuable assets starts with doing the maintenance right and knowing how to fix problems when they pop up. For a broader overview, check out our commercial deep fryer guide for more expert tips.

Got Questions About Fryer Boil Outs? We’ve Got Answers.

Even with the best training, a few questions always come up when it’s time to boil out the fryer. It’s a big job, and getting the details right is crucial for safety and for protecting your equipment.

Think of this as your quick-reference guide for those common "what if" moments. We’ll clear up the most frequent points of confusion so your team can tackle the task with total confidence.

How Often Should I Really Be Boiling Out My Fryer?

There’s no single right answer here—it really comes down to how hard you work your fryer and what you’re cooking in it. For a high-volume kitchen that’s cranking out heavily breaded items all day, a boil out might be a weekly necessity. On the other hand, a spot with lighter fryer use could easily get by with a bi-weekly or even monthly schedule.

The best approach? Let the fryer tell you what it needs. Take a look at the oil and the vat every day. If you see that oil smoking way too much, looking dark and murky, or giving off a funky, rancid smell, it’s past time for a boil out. Don’t just wait for the next scheduled cleaning day; get it done right away.

Can I Just Use Vinegar Instead of a Commercial Cleaner?

While vinegar is a fantastic tool for the final rinse, it’s not nearly strong enough to do the heavy lifting of the main cleaning. Commercial boil out cleaners are formulated with powerful alkaline ingredients specifically designed to break down and dissolve the stubborn, caked-on grease and carbonized crud that builds up in a fryer.

Using only vinegar for a boil out would be like trying to scrub a greasy, baked-on pan with just hot water. It simply doesn’t have the chemical muscle to cut through that kind of grime. Stick with a dedicated, food-safe commercial cleaner for the boil out itself, and save the vinegar for that all-important neutralizing rinse at the end.

What’s the Big Deal If I Skip the Neutralizing Rinse?

Skipping that final vinegar rinse is a classic rookie mistake, and it’s a costly one. Any alkaline residue left behind from the cleaning solution will immediately start to break down your fresh, expensive cooking oil. This absolutely torches the lifespan of your oil, forcing you to change it out way more often than you should.

It also wrecks your food quality. Anything you cook in that compromised oil will taste off—sometimes soapy or chemical-like—and it will absorb way more grease. That quick vinegar and water rinse is a tiny step with a massive impact. It protects your oil, ensures your fried food tastes clean and crispy, and ultimately, protects your restaurant’s reputation.

At The Restaurant Warehouse, we know that great equipment is only the beginning. Proper maintenance is what protects your investment and keeps your kitchen running like a well-oiled machine. You can find the perfect commercial fryer and all the supplies you need to keep it in prime condition at The Restaurant Warehouse.

Key Takeaways

- Preparation Prevents Problems: Before starting, gather your heat-resistant gloves, safety goggles, and a commercial-grade boil out solution. A few minutes of prep work is the best way to prevent burns, chemical splashes, and other dangerous kitchen accidents.

- The Final Rinse is Non-Negotiable: Draining the cleaner isn't the last step. You must perform multiple hot water rinses and a final neutralizing rinse with vinegar and water to remove all chemical residue, which protects your oil's lifespan and your food's flavor.

- Daily Filtering Saves Money: A boil out is a deep clean, but filtering your oil at the end of every shift is the most effective habit for extending its life. This simple daily task maintains food quality and directly reduces your recurring oil costs.

Related Articles

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment