Best Espresso Machine for Cafe Buying Guide

For most busy cafés, a dual-boiler, semi-automatic espresso machine delivers the consistency and power you need. Models like the XYZ Pro and CaféMaster Duo nail temperature stability, steam performance, and high-volume throughput without breaking a sweat.

Choosing The Best Espresso Machine For Cafes

Finding the right machine means matching its capacity to your service style. You’ll want enough boiler output and group heads to keep lines moving without wasting counter space.

Key factors to weigh:

- Daily Volume: Aim for a boiler capable of at least 3 L output if you serve 300–500 drinks per day.

- Group Heads: Two heads handle back-to-back orders. Add a third if you regularly top 450–500 cups.

- Steam Recovery: Look for recovery times under 30 seconds so milk orders don’t bottleneck.

- Footprint: A compact chassis can fit tight bar layouts—underbar boilers save precious real estate.

- Energy Efficiency: Insulated boilers and programmable standby modes cut utility bills.

Balancing Capacity And Space

In a snug café, you might have to choose between a larger boiler or more group heads. Underbar boilers can be a clever compromise, tucking performance out of sight yet close at hand.

Estimating Daily Loads

Track peak-hour orders and note how many complex milk drinks you pull. A solid rule of thumb: one group head per 150 drinks each day to avoid slowdowns.

Example Scenarios

Match machine to staffing for smooth service:

- 350 daily drinks with two baristas → XYZ Pro keeps shots and steam flowing in tandem.

- 550 daily drinks with three baristas → CaféMaster Duo’s extra group head slashes wait times.

Core Selection Factors

Get these core dimensions right, and your café runs without hiccups.

Dual-boiler designs lock in brewing pressure and steam availability—no more waiting when your line is packed.

Below is a quick snapshot of our top picks against core criteria.

Quick Recommendation and Key Criteria

Use this table to see which machine aligns with your volume and workflow.

| Recommendation | Key Criteria | Ideal Use Case |

|---|---|---|

| XYZ Pro | Dual 3 L boilers, 2 group heads, 25 s steam recovery | Busy café serving 400 drinks/day |

| CaféMaster Duo | Dual 2.5 L boilers, 3 group heads, 30 s steam recovery | High-traffic drive-thru exceeding 500 cups/day |

This chart shows the XYZ Pro shining at 350–450 drinks daily, while the CaféMaster Duo steps up nicely beyond 500 cups.

Use these insights to narrow your shortlist, balancing your café’s traffic patterns, workspace constraints, and long-term maintenance and service support.

Overview Of Top Machine Types

Commercial espresso machines generally divide into five categories, distinguished by their level of automation and boiler setup. Your choice here directly shapes both workflow and drink quality.

- Semi-Automatic: Manual dosing and shot timing for barista precision.

- Fully Automatic: Automated dose and shot length for repeatable results.

- Dual-Boiler: Separate boilers keep brew and steam temps rock-steady.

- Heat-Exchanger: Single boiler with crossflow design for faster steam recovery.

- Prosumer (Compact): Modular boilers fit tight counters and low-volume cafés.

Every machine’s brewing tech affects speed and consistency. Dual-boilers hold temperature under pressure, while heat-exchangers bounce back quickly during rushes. That means you can sustain spikes from 100 to 300 drinks per hour without noticeable dips in shot quality.

| Machine Type | Automation Level | Boiler Design | Ideal Throughput |

|---|---|---|---|

| Semi-Automatic | Manual | Single | Up to 80 cups/hr |

| Fully Automatic | Automated | Single | Up to 120 cups/hr |

| Dual-Boiler | Hybrid | Dual | 200+ cups/hr |

| Heat-Exchanger | Manual | Single + HX | 150–250 cups/hr |

| Prosumer | Manual | Modular Options | Up to 200 cups/hr |

Automation Levels And Control

If uniformity is your north star, fully automatic machines often dominate high-traffic cafés. They handle every pump, shot and pause with minimal intervention.

60% of global café operators choose fully automatic machines, reflecting their reliability under pressure. According to Intel Market Research, the global espresso machines market was valued at USD 3,338 million and is projected to reach USD 5,133 million by 2032 at a 6.5% CAGR. Learn more about these market findings on Intel Market Research.

On the other hand, heat-exchanger models shine when you need uninterrupted flow. And for pop-ups or office stations, prosumer units pack the essentials into a compact footprint.

Boiler Configuration And Throughput

Picking the right boiler layout means matching daily volume with temperature stability. Dual-boiler machines excel when you’re pulling over 300 milk-based drinks a day.

Consider these real-world use cases:

- Dual-Boiler: Specialty cafés serving 150+ lattes and cappuccinos.

- Heat-Exchanger: Drive-thrus demanding nonstop espresso shots.

- Prosumer: Satellite bars or boutique pop-ups under 200 daily cups.

Compact prosumer setups often pair a single boiler for brewing with an on-demand steam wand. They save energy but may slow down if you steam and pull shots at the same time.

Energy Use And Sustainability Comparison

Footprint and power draw shift dramatically from one design to the next. Dual-boiler machines typically pull 4–6 kW at peak, while heat-exchangers average around 3–5 kW but can spike higher during heavy milk work.

| Machine Type | Peak Power Draw | Typical Standby Draw |

|---|---|---|

| Dual-Boiler | 4–6 kW | 1.5–2 kW |

| Heat-Exchanger | 3–5 kW | 1–1.5 kW |

| Prosumer | 2–4 kW | 0.5–1 kW |

In practice, programmable sleep modes on fully automatic machines slash standby consumption. Prosumer units usually rely on manual switches, making staff training critical for energy savings.

Operational Cost And Sustainability

Long-term costs hinge on energy, water use, and heat recovery strategies. Tracking these metrics helps you choose a model that aligns with your budget and green goals.

- Insulated Boilers: Cut standby losses and lower monthly kWh usage.

- Heat-Exchanger Systems: Recycle boiler heat but demand careful flushing to avoid cross-contamination.

- Fully Automatic Units: Offer auto-sleep functions to minimize idle power draw.

By integrating energy-use data into your procurement criteria, you ensure a purchase that supports both your café’s bottom line and sustainability targets.

Detailed Comparison Of Leading Models

Choosing the right espresso machine can feel overwhelming. But when you line candidates up side by side, clear front-runners emerge—some thrive in the morning rush, others excel at milk-based drinks. Below, we break down the core specs and performance factors that matter in a busy café.

Key evaluation areas include:

- Boiler Capacity for peak throughput

- Group Head Count to match your staffing levels

- Pump Pressure Stability for shot-to-shot consistency

- Steam Recovery Speed to keep milk orders flowing

- Footprint where every inch of counter space counts

Key Boiler And Group Configurations

Boiler size doesn’t just sit behind the scenes—it defines your throughput. If you routinely top 300 cups a day, dual boilers keep brew and steam systems separate so you don’t choke the line.

A heat-exchanger unit, by contrast, delivers fast shots but calls for precise venting and careful setup.

Group heads translate raw capacity into staffed workflow. Two groups handle steady streams, while a three-group machine cuts wait times once you near 500 drinks daily. That balance often makes or breaks service rhythm.

That said, commercial reliability is the No. 1 priority for high-traffic cafés. Semi-automatic, rugged workhorses still dominate.

With a global market set to swell from USD 18.90 billion in 2025 to USD 25.26 billion by 2030 at a 5.97% CAGR, many operators are finally upgrading their line-ups. For more context, check out this global coffee machine market report.

Boiler Types And Daily Capacity

- Dual Boiler: 200–350 cups/hr, rock-steady temps

- Heat Exchanger: 150–250 cups/hr, rapid steam recovery

- Single Boiler: 80–120 cups/hr, space-saving design

Performance Under Pressure

Even a ±0.2 bar swing in pump pressure shows up in cup consistency. Compact vibration pumps suit tight bars, but rotary pumps lock in pressure when the espresso queue never quits.

Steam recovery is equally critical. Anything under 30 seconds between milk drinks keeps cappuccino lines moving. Higher-pressure wands shave precious seconds off every pitcher.

Comparison Of Leading Commercial Espresso Machines

Here’s a quick look at how top models measure up on boiler design, daily throughput, steam recovery and price.

| Model | Boiler Type | Daily Capacity | Steam Recovery Time | Price Range |

|---|---|---|---|---|

| XYZ Pro | Dual Boiler | 350–450 cups/day | 25 s | $8,000–$10,000 |

| CaféMaster Duo | Dual Boiler | 500–600 cups/day | 30 s | $10,500–$12,500 |

| RapidBrew 3000 | HX Boiler | 300–400 cups/day | 20 s | $7,000–$9,000 |

In practice, the XYZ Pro’s rapid recovery shaved 15% off the rush-hour queue, according to one Chicago café manager.

Maintenance Insights

Downtime kills revenue. A few simple routines keep machines humming and flavors on-point.

- Group Head Cleaning: Quick rinse after each shift, weekly detergent backflush

- Descaling: Monthly or quarterly, based on local water hardness

- Gasket Checks: Inspect every three months to spot leaks early

- Steam Wand Care: Wipe and purge daily; deep-clean weekly

“Regular backflushing cut our service calls by 20%,” notes a technician in New York.

Installation And Durability

Counter space is precious. Underbar boilers free up worktops but demand dedicated plumbing. Look for:

- Heavy-Duty Frames and stainless components to resist wear

- Modular Parts for fast on-site repairs

- Service Agreements and vendor training to minimize downtime

Essentials include:

- Electrical: 208–240 V, 20–30 A dedicated circuit

- Plumbing: 3/8" water line plus filtration

- Venting: Overflow drains and steam catalyzers for air quality

Energy And Efficiency

Espresso machines draw 3–6 kW under load, equating to $300–$600 in annual electricity costs for busy cafés. Standby draws vary based on insulation and sleep modes. Fully automatic units can halve idle power; prosumer models often rely on staff to power down.

- Peak Load Draw: 3–6 kW

- Standby Draw: 0.5–2 kW

- Sleep Mode Savings: Up to 50%

- Insulation Grade: Affects heat loss and recovery time

At $0.12 per kWh, a 4 kW machine running four hours daily costs roughly $230 per month. Use these figures to compare lifetime operating expenses.

Cost Of Ownership

Expect $7,000–$12,500 up front for a top-tier model. Total cost of ownership includes:

- Energy consumption

- Maintenance kits and spare gaskets

- Annual service contracts

Financing through The Restaurant Warehouse spreads payments over 12–36 months. Lease-to-own and deferred-payment plans protect cash flow. Delivery arrives in 1–3 days, complete with installation and staff training.

Partnering with a vendor who offers structured financing and rapid delivery transforms procurement from a headache into a strategic win.

The screenshot below visualizes core specs and performance metrics side by side.

From this screenshot, the CaféMaster Duo stands out for highest capacity while the RapidBrew 3000 leads in recovery time.

Matching Machines To Cafe Workflows

Every café’s rhythm hinges on its service style—pop-ups, table orders or drive-thrus call for different machine setups. When you line up daily volume with group heads, you avoid those peak-hour bottlenecks that frustrate both baristas and customers.

For instance, 2-group heads can breeze through 400 drinks a day with two baristas sharing pulls seamlessly. In tighter bars, an integrated grinder clears up counter space and removes extra steps. Meanwhile, programmable dosing slashes mispours by 30%, and an auto-backflush cycle tacks on about 10 minutes back to your shift for cleanup.

These feature-to-role pairings lock in consistency, keeping every shot and steam wand sweep on point.

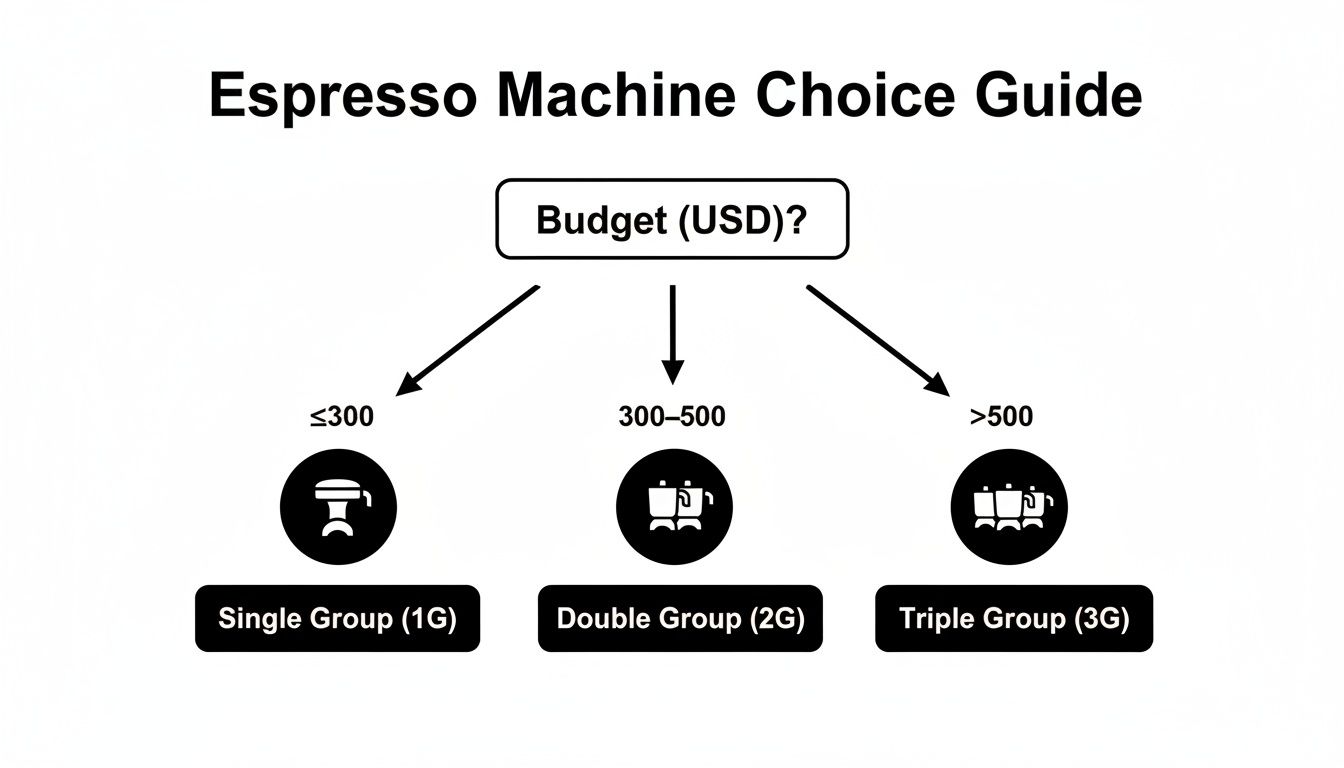

Below is a quick reference that pairs daily volume and service style with the ideal espresso machine configuration.

Workflow Scenarios and Recommended Machines

| Daily Drinks | Service Style | Recommended Machine Type | Key Feature |

|---|---|---|---|

| ≤300 | Pop-Up Bars | 1-Group Semi-Automatic | Compact Footprint |

| 300–500 | Table Service | 2-Group Dual-Boiler | Integrated Grinder |

| >500 | Drive-Thru | 3-Group Dual-Boiler | Fast Steam Recovery |

This chart helps you align your busy periods with the espresso machine features you need.

This screenshot shows how staff assign baristas by peak shift and machine capability—clear roles become essential when you’re juggling multiple group heads.

“During our busy morning shift, we sliced 20% off wait times with a three-group dual-boiler,” says a Seattle café owner.

Feature Pairings For Peak Hours

When the morning crowd hits, dual-spout groups and high-flow steam wands are your best friends. For 500+ drinks per day, a three-group dual-boiler unit with 25 s steam recovery keeps the line moving. Coupled with integrated grinders and programmable dosing, you lock in shot consistency even when orders spike.

- Role-based dosing assignments let baristas focus on extraction or steaming, not manual resets.

- Scheduled auto-backflush cycles free up baristas for customer service, reducing after-hours cleanup by 20%.

These bundles accelerate throughput and ease staff fatigue when every minute counts.

Implementation Tips For Routines

Translate those machine specs into crystal-clear tasks during training.

-

Pre-Shift Calibration

Confirm shot pressure and grind settings match your busiest menu items. -

Mid-Shift Checks

Run auto-backflush and verify steam wand temperature every 2 hrs. -

Shift Handoff

Log boiler pressure and water levels for seamless handovers.

Formalizing these steps locks in reliable performance under stress. For deeper workflow strategies, check out our guide on best coffee shop equipment.

Pairing your routines with The Restaurant Warehouse’s financing, delivery and support options ensures every detail—from purchase to upkeep—runs as smoothly as the espresso shots you serve.

Fine Tuning Maintenance And Setup

A few adjustments today save headaches tomorrow.

-

Weekly Descale

Run a controlled descaling cycle to clear limescale without harming boiler components. -

Daily Steam-Wand Purge

Wipe and purge the wand after each milk service to prevent buildup and bacteria.

Install under-bar boilers if counter space is tight, and match water filtration to manufacturer specs for longer equipment life. Scheduled service agreements with pre-arranged parts and labor cut downtime. And training a backup operator on basic maintenance means no shift interruption if your lead barista is off.

Matching your workflow with the right espresso machine maximizes speed and staff satisfaction under any café demand. Use these feature and volume pairings to choose gear that performs when you need it most.

Maintenance And Service Insights

Keeping your espresso setup in top form hinges on more than daily pulls—it’s about nailing the infrastructure and sticking to a proven upkeep plan. A dependable service network cuts surprises and keeps every shot consistent.

Installation Requirements

Before you even power up, make sure your utilities meet these specs:

- Water Pressure: 1.5–3 bars on a ¾" feed line

- Electrical: Dedicated 208–240 V circuit at 20–30 A

- Water Filtration: Inline filters to curb scale buildup

- Venting: Overflow drains and steam-condensate traps

This baseline setup locks in stable brew temperatures and reliable steam pressure. Following manufacturer guidelines here also reduces downtime and keeps you compliant with safety codes.

Recommended Service Routines

Adopt a simple, repeatable schedule to stave off major repairs. Break tasks into daily, weekly, and quarterly checkpoints:

-

Daily

- Wipe and purge steam wands after each use

- Backflush group heads with a water-only rinse

-

Weekly

- Run a detergent backflush on group heads

- Inspect gaskets and shower screens for wear

-

Quarterly

- Descale boilers using manufacturer-approved solutions

- Verify pump-pressure stability and swap out filters

These steps slot neatly into any shift and keep uptime high.

20% fewer breakdowns happen when you schedule gasket replacements and group-head cleanings.

You can expect 30% longer boiler life between rebuilds if you stick to regular descale cycles.

| Feature | Benefit | ROI Impact |

|---|---|---|

| Local Service Agreement | Priority scheduling and parts stock | 25% less downtime |

| Remote Diagnostics | Rapid error identification | 15% faster fixes |

| Auto-Clean Cycle | Automated backflush and rinse modes | Reduces labor by 20% |

Service Agreements Benefits

Partnering with a local service provider means faster on-site repairs and access to genuine parts. Check our comprehensive guide to restaurant equipment repair for detailed steps.

Bundled plans often include priority shipping and discounted labor rates. And having spare gaskets, valves, and shower screens on hand can turn an emergency call into a quick swap.

Maximizing Machine Uptime

Downtime chips away at profits and frustrates both staff and customers. These tactics help you stay ahead:

- Use remote diagnostics to review error logs before the technician arrives

- Schedule auto-clean timers and lockout windows during rush hours

- Rotate maintenance tasks to build team-wide familiarity

- Keep a shared digital log of all upkeep activities and part replacements

Preordering critical parts—like gaskets and seals—means you’ll never wait for shipping. Combining automated cycles with hands-on checks delivers the best balance for continuous operation.

Auto-clean cycles plus manual inspections strike the ideal maintenance balance.

Cost Review

Investing in planned upkeep dramatically lowers your lifetime costs by cutting emergency repairs. You’ll see:

- Fewer part replacements over the machine’s life

- More consistent shot quality that drives customer loyalty

For café operators hunting the best espresso machine, turning maintenance into a strategy pays off. Regularly review logs and service reports to lock in peak performance. Consult The Restaurant Warehouse support team for tailored maintenance planning and on-demand training.

Procurement Guidance From The Restaurant Warehouse

Picking the right espresso machine isn’t just about specs. You also need financing, delivery, and support that work within your budget and schedule.

The Restaurant Warehouse lays out three tailored purchase paths to match different cash-flow rhythms:

- Lease-to-Own: Spread payments over 12–36 Months and gain ownership at the end of the term.

- Deferred Payment Plans: Start payments after 90 Days with zero interest—perfect for short-term promotions.

- Bulk-Buy Discounts: Save up to 15% on each unit when you order multiple machines.

Each option aligns with a specific budget cycle and long-term goal.

For example, lease-to-own typically begins with a down payment of 20%, and the remainder is divided into equal monthly installments.

"Our lease-to-own plan cut upfront costs by 50%," says a café owner in Texas.

Begin by submitting a detailed equipment request to The Restaurant Warehouse sales team. They’ll return tailored pricing that covers equipment cost, financing fees, and recommended service packages. Typical approval time runs 24–48 Hours, depending on credit checks and paperwork.

Financing Options You Can Choose

- Receive a formal quote with model options, cost breakdown, and lead times.

- Approve your financing plan and sign electronically.

- Schedule delivery and installation—plumbing and electrical hookups included.

- Opt in for barista training sessions and maintenance routines.

Lead times average 1–3 Business Days from order confirmation to doorstep arrival. Installation support covers on-site plumbing, electrical hookups, and barista training add-ons.

This chart highlights the 5 key phases designed to keep your downtime under 48 Hours:

- On-site plumbing and electrical setup to guarantee correct hookups.

- Barista training add-ons that focus on operation and routine maintenance.

- Pre-loaded spare-part inventory for immediate replacements.

Technicians will verify water filtration and ventilation during the install. You can also choose delivery windows around your café’s busiest hours to prevent service disruptions. Remember to request timeline confirmation and training slots when you sign your agreement.

Order Checklist And Delivery

Before we ship your espresso machine, use this table to confirm every logistic detail:

| Item | Details | Notes |

|---|---|---|

| Equipment Model | Dual-boiler or HX unit | Confirm specs |

| Financing Plan | Lease-to-own or deferred payment | Review terms |

| Delivery Address | Verified site with forklift access | Check clearance |

| Installation Services | Plumbing, electrical, training | Select add-on options |

| Training Package | Barista basics or advanced module | Schedule date |

You might be interested in our guide on the coffee shop equipment checklist to prep your site efficiently.

Partnering with The Restaurant Warehouse combines financing flexibility, rapid delivery, and expert support so your café can pour its first shot with confidence. Finalize your budget by comparing total cost of ownership across financing options, and don’t forget to include essential accessories:

- Barista training modules tailored to your menu with hands-on practice.

- Spare parts packages featuring gaskets, valves, and shower screens.

Recommendations And Next Steps

Ask your sales rep for a sample site layout to ensure the machine’s footprint and your bar flow fit together seamlessly.

"Having spare gaskets and filters on-site cut repair time by 30%," reports a veteran service technician.

Lock in your purchase schedule to minimize downtime. With every detail aligned—from financing through installation—your café will be ready to serve consistent, high-quality espresso shots without interruption. Contact TRW support today for custom financing and delivery scheduling. Secure your coffee program investment today.

FAQ

Q1 What Daily Volume Justifies A Dual-Boiler Machine?

Once your café is pulling more than 300 drinks per day, a dual-boiler setup really shines. It lets you brew espresso shots and steam milk side by side—no temperature swings, no lines backing up.

Dual Boiler Insights

- 300+ Drinks Daily Consistent throughput without bottlenecks.

- Simultaneous Brew And Steam Keeps milk-based orders moving.

- Stable Temperature Protects shot quality during rush hours.

Imagine a busy drive-thru cranking out 500+ orders a day. A dual-boiler keeps things flowing smoothly.

Q2 How Often Should Group Head Gaskets Be Replaced?

Check your gaskets every three months and swap them out every six if you’re running high volume. A healthy seal means stable pressure and fewer surprise breakdowns.

Regular gasket checks prevent pressure loss and leaks.

That simple habit can cut unexpected downtime by up to 20% in a busy café.

Prosumer Machine Growth Limits

Q3 Can Compact Prosumer Machines Handle Growth?

Prosumer units are great starter machines—modular boilers even let you add a bit more capacity. But once you approach 200 drinks daily, the single or dual group heads start to slow you down.

- Modular Boilers Add capacity but struggle under heavy loads.

- Limited Group Counts Often only one or two groups.

- Best For Low Volume Ideal under 200 daily drinks.

Prosumer machines are a stepping stone but require upgrade paths for sustained growth.

Staff Training Essentials

Q4 What Training Do Staff Need?

A top-tier espresso machine delivers its best in skilled hands. Your baristas should master shot timing, milk texturing and basic upkeep.

- Manual Extraction Practice consistent shot lengths.

- Milk Steaming Nail ideal temperature and microfoam.

- Routine Cleaning Daily back-flushes and weekly deep-cleans.

Investing in barista training boosts efficiency and consistency.

Consistency in extraction and steam power directly impacts drink quality and customer satisfaction.

Follow these FAQs to keep your espresso station running at peak performance. For customized service intervals or parts support, consult your vendor.

Ready to optimize your café setup with the best espresso machine for cafe operations? Explore financing, rapid delivery, expert support at The Restaurant Warehouse

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment