Your Guide to Walk In Refrigerator Systems

A walk-in refrigerator is the heart of a professional kitchen. Far more than just a big cold box, it’s the operational core where you protect thousands of dollars in perishable goods, directly influencing everything from your daily prep flow to your overall profitability.

Choosing the right walk-in allows your business to buy ingredients in larger, more cost-effective quantities, slash food waste, and deliver the consistent quality your customers expect. It’s not an appliance; it’s a strategic asset.

Your Guide to Walk-In Refrigerators

Think of a walk-in cooler not as a simple piece of equipment, but as the central hub of your entire inventory system. The right unit streamlines daily operations, safeguards your product, and ensures you nail those strict health and safety standards without breaking a sweat. This guide is here to demystify this complex machine and make it a manageable part of your business.

We're going to move past the basic definitions and get into the critical decisions you’ll face. This is your roadmap to choosing, installing, and managing a system that fits your kitchen like a glove, whether you're building a new restaurant from the ground up or upgrading your current setup.

These systems are absolutely essential, and their market size proves it. The global walk-in refrigerator market was recently valued at around $10.9 billion and is expected to grow significantly, which tells you just how vital they are to the modern foodservice industry.

What You'll Learn

This guide will give you the practical know-how to handle every aspect of owning a walk-in cooler. Here’s what we’ll cover:

- System Types and Selection: We'll break down the real-world differences between self-contained and remote refrigeration systems so you can pick the best fit for your kitchen's heat and noise levels.

- Sizing and Layout: Learn how to calculate the right cubic footage for your needs and design an interior layout that makes sense for your daily workflow.

- Installation and Compliance: Get a handle on the complexities of site prep, health codes, and why a professional installation is non-negotiable.

- Energy and Maintenance: Discover simple, actionable strategies to keep your operating costs down and extend the life of your investment. For a bigger-picture view on managing all your kitchen assets, looking into broader topics like facility management best practices can offer some valuable insights.

- Costs and Financing: We'll give you a transparent look at the total cost of ownership and explore different ways to finance the purchase to make it manageable for your business.

Choosing Your Walk In Refrigerator System

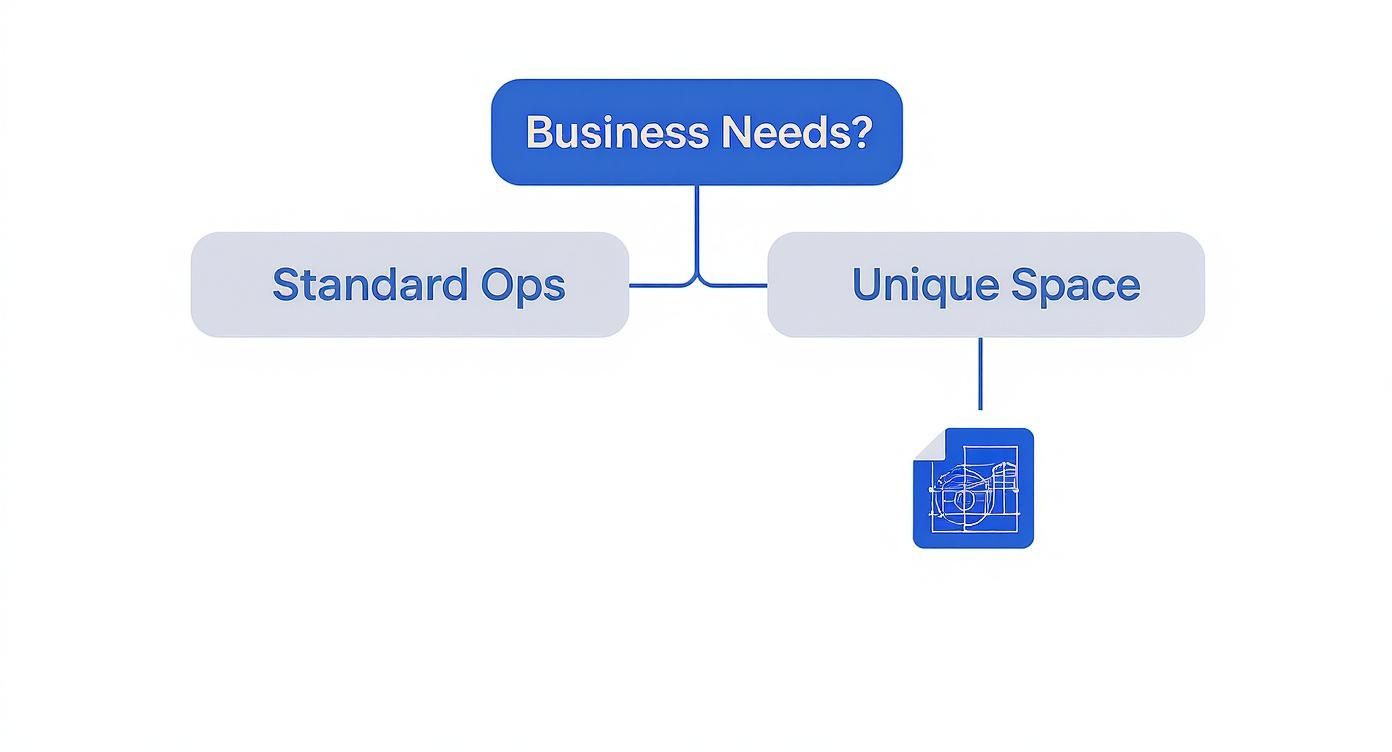

Picking the right walk-in refrigerator system is one of those foundational decisions that will shape your kitchen's workflow and efficiency for years to come. It’s not just about keeping food cold; it’s about choosing a technology that fits seamlessly into your space, budget, and daily grind. You really have two main paths to go down: prefabricated modular units or a fully custom-built solution.

Think of prefabricated walk-in coolers like high-quality, ready-to-assemble kits. They’re made in standard sizes with panels that lock together quickly right on site. This approach is often the faster and more wallet-friendly option, making it a fantastic choice for businesses with pretty standard layouts and a need to get up and running quickly.

On the other hand, a custom-built walk in refrigerator is crafted to fit your unique space like a glove. If you're wrestling with an oddly shaped room, low ceilings, or pesky support columns, a custom build lets you squeeze every last square inch of value out of your floor plan. While this gives you ultimate flexibility, it usually means a longer design and construction timeline and a bigger initial investment.

This quick visual guide can help you figure out which path makes the most sense for your operation.

As you can see, the choice is pretty clear. If your needs are straightforward, a prefab unit is often the most practical way to go. But if your building throws you a curveball, a custom design is your best bet.

Self-Contained vs. Remote Refrigeration

Beyond the type of box, you have to pick the "engine" that powers it. This choice comes down to two main types of refrigeration systems: self-contained and remote. Each one has a huge impact on your kitchen’s environment and your budget.

A self-contained system is basically an all-in-one package. Imagine a window air conditioner—all the important parts, like the compressor and condenser, are bundled together in a single unit that sits right on top of or on the side of the walk-in. The big win here is that installation is simpler and usually more affordable upfront.

A remote system works more like your home's central AC. The noisy, heat-generating components (the condenser and compressor) are installed "remotely"—usually outside or on the roof of your building. This completely changes the vibe in your kitchen.

By moving the heat-generating components outside, a remote system significantly reduces ambient kitchen temperatures and noise levels. This creates a more comfortable and productive working environment for your staff.

The choice directly impacts your kitchen's atmosphere. A self-contained unit will pump heat and noise into your kitchen, which can be a real headache in smaller, busy spaces. A remote system gets rid of those problems but requires a more complex installation with refrigerant lines running through walls or ceilings.

For a side-by-side look, this table breaks down the key differences to help you decide.

Comparing Self-Contained vs. Remote Refrigeration Systems

| Feature | Self-Contained System | Remote System |

|---|---|---|

| Installation | Simpler and faster; all components are in one unit. | More complex; requires running refrigerant lines. |

| Upfront Cost | Generally lower. | Typically higher due to complex installation. |

| Kitchen Environment | Adds heat and noise to the immediate area. | Keeps kitchen cooler and quieter. |

| Space Impact | Requires ventilation clearance around the unit inside. | Frees up interior space; requires outdoor/roof space. |

| Maintenance | Components are easily accessible for service. | May require roof or outdoor access for service. |

| Best For | Smaller operations, budget-conscious setups, simple layouts. | High-volume kitchens, noise-sensitive areas, new constructions. |

Ultimately, the best system depends on your priorities—whether that's upfront cost and simplicity or long-term kitchen comfort and efficiency. For a deeper dive, our guide on choosing the right commercial refrigeration system offers even more valuable insights.

Considering Combo Cooler and Freezer Units

Got a diverse inventory but not a lot of floor space? A combination walk-in cooler and freezer unit is a smart, efficient solution. These units use a single walk-in box divided by an insulated interior wall, creating two separate temperature zones—one for chilling and one for freezing.

This setup offers some serious advantages:

- Space Optimization: You get two temperature-controlled zones in a single footprint, which is a lifesaver for saving valuable kitchen real estate.

- Cost Efficiency: It's almost always cheaper to install one combo unit than it is to buy and install two separate walk-in systems.

- Streamlined Operations: Having your refrigerated and frozen goods in one central spot can simplify inventory checks and cut down on the time your staff spends running between different storage areas.

A combo unit is perfect for restaurants, cafes, and small grocery operations that need to store everything from fresh produce to frozen proteins without dedicating the space and budget to two separate, full-size walk-ins.

How to Size Your Unit and Plan Your Layout

Getting the size of your walk-in right is one of the most important calls you'll make, and it’s a decision that will echo in your daily workflow and budget for years. Go too small, and you're setting yourself up for cramped, chaotic conditions, damaged inventory, and a seriously inefficient kitchen. But swing too far the other way with an oversized unit, and you’re just throwing money away on wasted kitchen real estate and sky-high utility bills.

The sweet spot is a unit that’s big enough to comfortably hold your inventory between deliveries but not so big that it’s an energy hog. This isn’t just about square footage; it’s about really understanding the rhythm and needs of your specific operation.

Calculating Your Ideal Cubic Footage

Think of sizing your walk-in less like buying a bookshelf and more like designing a custom workspace. The real metric you need to focus on is cubic footage, not just the footprint on the floor. A small cafe that gets fresh produce delivered daily has completely different needs than a large catering company that buys ingredients in bulk for massive weekly events.

To nail down a realistic number, you need to think about these real-world factors:

- Inventory Volume: How much product do you truly need to hold at your absolute peak? Don’t just plan for today—think about where your business will be in a few years.

- Delivery Frequency: If you’re getting shipments multiple times a week, you can probably get by with a smaller unit. But if those deliveries only come once a week, you’ll need much more space to hold that bigger load.

- Menu Complexity: A diverse menu with a ton of unique ingredients means you need more organizational breathing room to keep things separated and prevent cross-contamination.

- Product Packaging: Think about the actual shape of your inventory. Bulky boxes of lettuce, big pails of sauce, and kegs all eat up space very differently than neatly stacked Cambros.

For a deeper dive into the numbers, our guide on determining commercial refrigerator and freezer space can help you get your calculations just right.

A good rule of thumb to start with is allocating about one cubic foot of storage for every 25-30 pounds of food. But always, always adjust this based on your menu, your delivery schedule, and how bulky your products are.

Designing a Layout for Maximum Efficiency

Once you've landed on a size, it’s time to plan the inside. A smart layout isn't just about cramming everything in; it's about creating a system that boosts speed, safety, and smart inventory management. A well-organized walk-in saves your staff from wasting time hunting for ingredients, cuts down on the risk of accidents, and makes stock rotation second nature.

This is especially critical in competitive markets. For example, North America is a huge player in the global walk-in refrigerator market, accounting for a massive 33-49.2% of the market share. That dominance comes from the sheer number of restaurants and supermarkets that depend on these systems to function, making an efficient layout a true competitive edge.

Strategic Shelving and Organization

The right shelving is the absolute backbone of a functional layout. Your choice should be all about what you’re storing and how your team needs to get to it.

Here’s a quick rundown of your best options:

- Wire Shelving: This is the most popular choice for a very good reason. The open-wire design is fantastic for air circulation, which is critical for keeping temperatures even and your products fresh. It's perfect for produce boxes, individual containers, and prepped ingredients.

- Dunnage Racks: These are your heavy lifters. They're low, heavy-duty racks designed to keep bulky items safely off the floor. Use them for big bags of flour or sugar, kegs, or large buckets of sauce. Remember, health codes demand everything be stored at least six inches off the floor, and dunnage racks make that a breeze.

- Wall-Mounted Shelves: To squeeze every last bit of utility out of your space, think vertically. Wall-mounted shelves installed above your main racks are perfect for stashing less-frequently used items, keeping them organized but out of the way of daily traffic.

Ultimately, your layout should be built to support the First-In, First-Out (FIFO) method of stock rotation. Always place new inventory behind the older stuff. This ensures products get used in the right order, which is the single best way to slash food waste and guarantee freshness. And don't forget to leave clear, wide pathways to prevent trips and falls, and label everything clearly to help your team work faster and smarter.

Navigating Installation and Compliance

Getting a new walk-in cooler installed is a whole lot more than just slotting a few panels together. You should treat it like a pre-flight checklist for one of your kitchen's most critical assets. Getting this stage right from the get-go ensures your unit runs efficiently, keeps you on the right side of the law, and is safe for your team from day one.

Honestly, the real work starts long before the delivery truck even pulls up. Proper site preparation is the foundation for a reliable, long-lasting walk-in. Taking the time to prep your space will help you sidestep common headaches that can lead to expensive delays, performance problems, and major operational disruptions down the road.

Preparing Your Site for Installation

First things first, you need to make sure the location is physically ready. A walk-in cooler is incredibly heavy, and the floor has to be perfectly level and strong enough to support the weight of the unit plus thousands of pounds of inventory. If the floor is even slightly uneven, it can throw off the whole structure, leading to misaligned panels and air leaks that absolutely kill your energy efficiency.

Once the floor is sorted, you'll need to confirm the site has the right infrastructure in place. This includes a few non-negotiables:

- Sufficient Electrical Supply: A walk-in is a power-hungry machine and needs its own dedicated circuit. You'll need a qualified electrician to make sure your panel can handle the load without risking overloads or creating a fire hazard.

- Proper Drainage: Condensation is a normal part of any refrigeration system. You absolutely must have a floor drain ready to handle this moisture, preventing puddles that create nasty slip hazards and sanitation nightmares.

- Adequate Ventilation: The refrigeration system produces a lot of heat and needs room to breathe. Make sure there’s enough clearance around the entire unit, especially for self-contained systems, to allow for good airflow and stop the motor from overheating.

Hiring a certified professional for the installation isn't just a friendly suggestion—it's essential. Most manufacturer warranties are immediately voided if the unit isn't installed by a qualified technician. Think of the cost of professional installation as an investment in safety, compliance, and protecting your equipment's lifespan.

Understanding Health and Building Codes

With your site prepped and ready, it's time to turn your attention to the legal stuff. Health and building codes aren't just bureaucratic red tape; they're there to ensure food safety and protect your employees. Failing an inspection can shut your whole operation down, so it's crucial to get this right.

These regulations dictate very specific requirements for your walk-in cooler. While the exact codes can vary depending on where you're located, they almost always cover several key areas that you need to be aware of before the first panel is ever moved into place.

Key Compliance Requirements

To make sure you sail through your inspection without a hitch, you’ll want to focus on these critical compliance points. A good professional installer will know the local requirements like the back of their hand, but as the operator, it’s vital for you to understand them, too.

Here are some of the most common regulations you're likely to run into:

- Approved Floor Materials: The flooring inside and just outside your walk-in has to be non-porous, durable, and easy to sanitize. Materials like sealed concrete or commercial-grade tile are often required to stop bacteria from finding a place to grow.

- Emergency Door Release: This is a non-negotiable safety feature. Every walk-in door must have a safety release mechanism on the inside to prevent accidental entrapment. It allows anyone inside to open the door easily, even if it’s been locked from the outside.

- Proper Interior Lighting: Good lighting is mandatory. The light fixture must be shatter-proof or have a protective cover to prevent glass from contaminating your food if it breaks. An external light that shows when the interior light is on is also a common requirement.

- NSF and UL Certifications: Always make sure your walk-in and all its components are certified by recognized organizations like the National Sanitation Foundation (NSF) and Underwriters Laboratories (UL). These certifications are proof that the unit meets strict public health and safety standards—something inspectors will look for right away.

Boosting Efficiency And Mastering Maintenance

Your walk-in refrigerator is one of the hardest-working pieces of equipment in your entire operation, running 24/7 to protect thousands of dollars in valuable inventory. But that constant performance doesn't have to come with an outrageous energy bill. With a smart approach to both purchasing and daily upkeep, you can get a handle on operating costs and keep your walk-in running at peak efficiency.

The journey to an energy-efficient unit actually begins before it's even installed. When you're in the buying phase, keep an eye out for specific features designed to minimize energy waste. These small details really do add up to significant long-term savings on your utility bills.

Key Energy-Saving Features

Think of your walk-in's energy consumption like a bucket with a few small holes—every little leak adds up over time. Plugging these holes with the right features is the key to keeping your operating costs down.

- High R-Value Insulation: The R-value is just a measure of how well the insulation panels resist heat transfer. A higher R-value means less cold air escapes and less warm air gets in, forcing your refrigeration system to work less to maintain temperature.

- Automatic Door Closers: A door left ajar, even for just a few extra seconds, is a massive source of energy loss. Automatic closers and heavy-duty strip curtains ensure the door seals shut promptly every time, trapping the cold air right where it belongs.

- LED Lighting: Modern LED lights are a no-brainer. They use way less energy and produce far less heat than old-school fluorescent or incandescent bulbs, which reduces the overall cooling load on your system.

- Motion-Activated Lights: This feature takes LED efficiency a step further. It ensures the lights are only on when someone is actually inside the unit, cutting down on unnecessary energy use and heat generation.

Getting a general sense of appliance energy efficiency ratings can be really helpful here. It gives you a great framework for understanding how these individual features contribute to the bigger picture of savings.

Building A Proactive Maintenance Routine

Once your walk-in refrigerator is up and running, a consistent, proactive maintenance schedule is your single best tool for preventing costly breakdowns and keeping it efficient. Don't wait for a problem to pop up; a little bit of regular attention goes a very long way.

A great maintenance plan is broken down into simple daily, weekly, and annual tasks. This approach makes the workload manageable and ensures nothing important gets missed.

Proactive maintenance isn't a cost—it's an investment. A well-maintained unit can use up to 10-15% less energy than a neglected one, directly impacting your bottom line and extending the equipment's lifespan by years.

Your Essential Maintenance Checklist

Use this schedule as a starting point and feel free to adapt it to your kitchen's specific needs. The goal here is consistency.

Daily Tasks (5 Minutes)

- Check and Log Temperatures: This is the most crucial daily habit. Use an independent thermometer to verify the unit is holding its target temperature. Keeping a simple log helps you spot gradual cooling issues long before they cause spoilage. For more details on what to aim for, our guide on proper walk in cooler temperature has you covered.

- Quick Visual Sweep: Just take a quick look inside for any spills, debris, or blocked airflow around the fans. A clean interior is absolutely essential for good air circulation and food safety.

Weekly Tasks (15-20 Minutes)

- Inspect Door Seals and Gaskets: Run your hand along the door gasket to feel for any cold air leaks. A tight seal is critical for efficiency. Clean the gaskets with a damp cloth to remove any grime that could prevent a proper seal.

- Clean Condenser Coils: If your condenser is easily accessible (this is common on self-contained units), gently brush away any dust or grease buildup. Clogged coils force the system to work much harder to release heat.

- Check for Ice Buildup: A thin layer of frost is normal, but excessive ice piling up on the evaporator coils can block airflow and signals a problem with the defrost cycle.

Annual Professional Service

At least once a year, you need to bring in a certified refrigeration technician. They have the tools and expertise to perform a deep-dive inspection that your in-house team simply can't.

This professional service typically includes:

- Checking refrigerant levels and looking for leaks.

- Testing all electrical components and connections.

- Performing a deep cleaning of evaporator and condenser coils.

- Calibrating thermostats and defrost timers.

Think of this annual check-up as your best insurance policy against an unexpected and catastrophic system failure. It keeps your walk-in running at peak performance, extends its lifespan, and provides invaluable peace of mind.

Figuring Out Costs and Financing

When you're looking to add a new walk in refrigerator to your kitchen, it’s easy to get fixated on the price tag. But that initial number is just the beginning of the story. To get a real handle on what you'll actually spend, you need to think in terms of Total Cost of Ownership (TCO). This gives you a much clearer picture of what the unit will cost over its entire working life.

This bigger number includes the unit itself, of course, but also delivery fees, professional installation, and the ongoing costs of electricity and regular maintenance. A walk-in that looks like a bargain upfront could easily end up costing you more down the road if it’s an energy hog or needs constant repairs.

Breaking Down the Initial Investment

The upfront cost for a walk-in cooler can swing pretty widely depending on what you need. A smaller, standard 6’x6’ prefabricated unit might start in the $6,000 to $8,000 range. If you need something larger or a custom-built layout, the price can easily climb past $20,000.

But the base price isn't the final number. You'll need to budget for a few other critical expenses to get your unit up and running:

- Delivery and Shipping: These things are big and heavy, and they don't ship for free. Expect to add several hundred to a few thousand dollars for freight, depending on the size and your location.

- Professional Installation: This is absolutely not a DIY job. Proper installation is critical for the unit to work correctly and for your warranty to be valid. This typically runs between $2,000 and $4,000, and could be more if your site needs significant electrical or plumbing prep.

When you add it all up, a complete, professionally installed walk-in can range from around $10,000 for a basic setup to over $30,000 for a large, custom solution with a remote refrigeration system.

Exploring Your Financing and Leasing Options

That upfront cost can be a tough pill to swallow, especially for a new or growing business. The good news is, there are several ways to get this essential piece of equipment without completely draining your cash reserves.

Traditional equipment loans from a bank or credit union are a common path. They let you own the asset outright while spreading the cost over a few years. However, companies that specialize in equipment financing often have more flexible terms and a quicker approval process geared specifically for the foodservice industry.

Leasing is a powerful alternative to buying. It lets you get a brand-new, efficient walk-in refrigerator with a much lower initial cash outlay. This keeps your working capital free for other critical needs, like inventory or marketing.

Buying vs. Leasing a Walk In Refrigerator

Deciding whether to buy or lease your walk-in is a big strategic choice. It really depends on your business's cash flow, your long-term plans, and how you handle your taxes. Each path has its own clear advantages for different types of operations.

Here’s a straightforward comparison to help you weigh the options:

| Consideration | Buying (Outright Purchase or Loan) | Leasing (Lease-to-Own) |

|---|---|---|

| Upfront Cost | High initial cash outlay is required. | Low to no down payment; preserves cash flow. |

| Ownership | You own the equipment at the end of the term. | You have the option to buy it at the end of the lease. |

| Monthly Payments | Typically higher than lease payments. | Generally lower, more manageable monthly payments. |

| Tax Implications | Allows for depreciation deductions. | Lease payments are often fully tax-deductible as an operating expense. |

| Technology | You are responsible for upgrades or replacement. | Easier to upgrade to newer, more efficient models at the end of the term. |

Ultimately, buying is a great long-term investment if you have the capital and plan to use the unit for its full lifespan. Leasing, on the other hand, offers more financial flexibility and makes it easier to keep up with the latest energy-efficient technology. That makes it an excellent choice for businesses that need to watch their cash flow and stay adaptable.

Your Top Questions Answered

When you're running a busy kitchen, questions about your walk-in are bound to come up. Here are some quick, no-nonsense answers to the things operators ask us most.

How Often Should I Get My Walk-In Professionally Serviced?

Even with your daily and weekly checks, you absolutely need to get a professional service at least once a year. Think of it as a deep check-up that goes way beyond your regular cleaning.

A certified tech will do things your team can't, like checking refrigerant levels, testing sensitive electrical parts, and deep cleaning the evaporator coils. This one visit is your best defense against small problems turning into a catastrophic, business-stopping failure. It keeps your unit running efficiently and can add years to its life.

What’s the Perfect Temperature for My Walk-In Cooler?

The sweet spot for a general-purpose walk-in cooler is between 35°F and 38°F (1.6°C to 3.3°C). This temperature range is ideal for slowing down the growth of most foodborne bacteria, keeping your fresh ingredients safe and extending their shelf life.

It's absolutely critical to stay below the 40°F (4°C) mark. Anything warmer is the start of the food safety "danger zone," where bacteria can multiply like crazy.

A quick pro tip: Always double-check your walk-in's temperature with a separate, calibrated thermometer you place inside. Never rely only on the external display, which can be inaccurate. This simple habit is a cornerstone of solid food safety.

Can I Just Install a Walk-In Myself?

I'm going to be direct here: please don't. We strongly advise against any DIY installation for a few huge reasons. First off, most manufacturer warranties are instantly voided if the unit isn't installed by a certified professional. That alone makes it a massive financial gamble.

Beyond the warranty, you're dealing with high-voltage electricity and pressurized refrigerant lines. Without the right training and tools, it's a serious safety risk for you and your staff. An improper installation is a surefire recipe for poor performance, sky-high energy bills, and a system that dies an early death. The cost of a professional installer is a non-negotiable investment in the safety, compliance, and lifespan of your walk-in.

At The Restaurant Warehouse, we know that your walk-in is the heart of your kitchen's inventory management. We offer a huge selection of high-quality units and flexible financing to help you get the right equipment for your operation. Come see what we have to offer at The Restaurant Warehouse and let's get your kitchen set up for success.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment