A Buyer's Guide to Used Commercial Dishwashing Machines

Sinking a ton of cash into brand-new kitchen equipment can feel like a punch to the gut for your budget. But here's a smart move more and more operators are making: a used commercial dishwasher can be a powerful, budget-friendly workhorse. Think of it like a certified pre-owned car. When you know what to look for, 'used' means incredible value and proven reliability, not a risky gamble.

Why a Used Commercial Dishwasher Is a Smart Investment

For any food service spot, from a packed-out cafe to a massive cafeteria, the speed of your dish pit is directly tied to your profits. A slow-moving wash cycle means fewer tables turning over, and sanitation slip-ups can bring on the health inspector—and nobody wants that. A commercial dishwasher is the engine that drives your whole sanitation process, but a shiny new one often carries a five-figure price tag that can put a serious strain on your finances.

This is where buying a used commercial dishwasher can be a total game-changer. By choosing a pre-owned model, you can often get your hands on a high-quality, seriously durable machine for 30-60% less than the sticker price. That’s a huge chunk of change you can pour back into other parts of your business, like marketing that actually brings people in the door, hiring another line cook, or stocking up on inventory.

Balancing Cost Savings with Operational Needs

The trick is to go into it with a plan. A lower price is always nice, but the real win is finding a machine that can handle your kitchen's daily grind without skipping a beat. The biggest benefits of going with a used model really boil down to this:

- Immediate ROI: When you save that much money upfront, the machine pays for itself way faster than a brand-new one.

- Access to Premium Brands: Your budget for a new machine might only get you an entry-level model. That same budget in the used market could land you a top-tier dishwasher from a brand known for being an absolute tank.

- Proven Reliability: A new model is an unknown. A used machine, on the other hand, often has a history. With a good inspection, you're buying a piece of equipment that's already proven it can survive in a real kitchen.

There's a common myth that "used" just means "unreliable." Honestly, a well-maintained commercial dishwasher from a solid brand is built to take a beating for years. Finding the right used machine isn't a shot in the dark; it's a calculated investment.

At the end of the day, a used commercial dishwasher closes the gap between what your budget allows and what your operation truly needs. It gives you the powerful sanitation required by health codes and the speed you need for smooth service, all while keeping your business financially healthy and ready to grow.

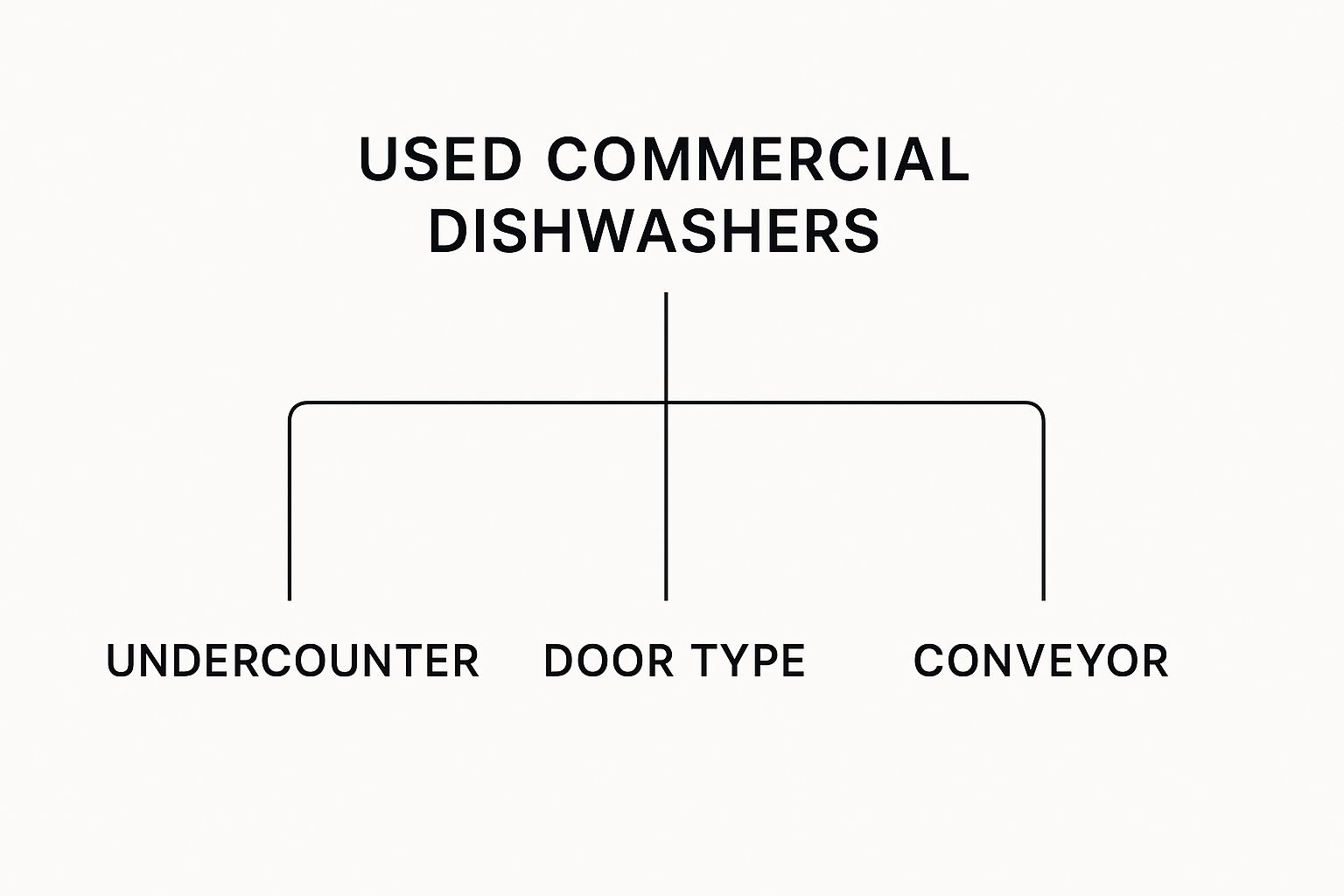

Choosing the Right Type of Commercial Dishwasher

Stepping into the market for a used commercial dishwasher can feel a bit like car shopping. You wouldn't buy a tiny sedan for a construction crew, and you wouldn't get a massive truck for a simple city commute. The same exact logic applies here—matching the machine to the job is the most critical first step you'll take.

Before you even start hunting for deals, you need to get familiar with the three main workhorses of the commercial kitchen. Getting this right from the start keeps you from overspending on a unit with power you'll never actually use. Even worse, it prevents you from underpowering your kitchen and creating a huge sanitation bottleneck right in the middle of your busiest hours.

This breakdown gives you a clear sense of the hierarchy. Each of these machines serves a totally different operational scale and workflow, from a small neighborhood cafe to a sprawling university kitchen.

To make it even easier to see how they stack up, here’s a quick comparison of the most common types. This should help you quickly identify the best fit for your business's volume and the space you have to work with.

Commercial Dishwasher Types at a Glance

| Dishwasher Type | Best For | Typical Capacity (Racks/Hour) | Space Requirement |

|---|---|---|---|

| Undercounter | Small cafes, bars, low-volume spots | 20-40 | Compact, fits under a standard counter |

| Door/Hood Type | Most mid-sized restaurants, steady service | 50-150 | Moderate, freestanding unit |

| Conveyor | High-volume institutions, cafeterias, hotels | 200-1000+ | Large, requires significant floor space |

As you can see, the jump in capacity is pretty significant between types. Let's dig into what that means for your daily operations.

Undercounter Dishwashers

Think of an undercounter model as the compact specialist. These machines look a lot like the dishwasher you have at home but are built with the speed and durability needed for a commercial setting. They're the perfect fit for tight spaces like coffee shops, bars, or small cafes where staff are mostly washing glassware and a limited number of dishes.

- Capacity: Typically handle 20-40 racks per hour.

- Best For: Low-volume operations with limited space.

- Key Consideration: These are manually operated, meaning an employee has to load, start, and unload every single cycle.

Door Type or Hood Type Machines

This is pretty much the industry standard for most mid-sized restaurants. Door type machines, often called hood type models, are freestanding units where a staff member slides a rack of dishes inside, pulls a large hood down over it, and starts the cycle. They strike a fantastic balance between footprint and power.

These machines offer a major step up in capacity from undercounter models, making them the ideal choice for restaurants with a steady, consistent service. They're a huge part of why the commercial dishwasher market is booming—restaurants everywhere need this kind of efficient, reliable cleaning power.

Conveyor Dishwashers

When you need sheer, unadulterated power and volume, you bring in a conveyor dishwasher. These are the absolute giants of the dish pit, designed for the most demanding high-volume environments like hospitals, university cafeterias, and huge catering operations.

Dishes get loaded onto a conveyor belt that automatically pulls the racks through separate wash, rinse, and sanitizing chambers.

Conveyor systems are all about creating a continuous, uninterrupted workflow. They can process hundreds of racks an hour, completely eliminating the stop-and-go process of smaller machines and easily keeping pace with the busiest kitchens.

Their size and utility requirements are massive, there's no doubt about it. But for a large-scale operation, their efficiency is simply unmatched. As you consider any of these options, taking some time to understand the nuances of buying used restaurant equipment can give you a serious advantage in finding a reliable machine that won't let you down.

Your Essential Pre-Purchase Inspection Checklist

Buying a used commercial dishwasher isn't just about snagging a good price; it's about making sure you're not inheriting someone else's expensive headache. A thorough, hands-on inspection is absolutely non-negotiable. Think of yourself as a detective on the hunt for clues. This checklist will give you the confidence to assess a machine like a seasoned pro, turning a potentially risky buy into a smart, calculated decision.

We'll break this down into three simple, manageable areas. By zeroing in on these key components, you can spot the red flags that scream "future repair bills." Let's dive in.

Mechanical and Structural Integrity

First things first, let's look at the heart and skeleton of the machine. These parts are almost always the most expensive to fix, so you'll want to pay extra close attention here.

Start with the wash pump and motor. If you can, have them fire it up. Listen carefully for any grinding, whining, or unusually loud noises while it's running. Those sounds are often the tell-tale signs of worn bearings or internal damage—a repair that can easily climb into the hundreds of dollars.

Next, give the machine's body a good once-over for structural problems. Check every corner, seam, and panel for:

- Rust and Corrosion: Be on the lookout for significant rust, especially around the base and the door seals. A little surface rust might be manageable, but deep corrosion is a deal-breaker. It compromises the whole unit.

- Leaks: Get down and look underneath the machine and around all the fittings. Do you see any water stains or, worse, active drips? A persistent leak could point to a cracked tank or failing seals, and those are major-league problems.

- Door and Hood Operation: Open and close the door or hood multiple times. It should feel smooth, not like it's sticking or catching. A wonky, misaligned door leads to leaks and heat loss, which kills efficiency.

These machines are the backbone of hygiene in places like hotels and hospitals. It's no surprise the global commercial dishwasher market is growing where cleanliness is everything. Making sure the unit is structurally solid is your first step to proper sanitation.

Plumbing and Water Systems

Alright, now let's follow the water. The plumbing system is what does all the heavy lifting for cleaning and sanitizing. Clogs, buildup, and wear in this area can tank a machine's performance.

Start by examining the spray arms. If you can, pop them off and check the little nozzles for limescale buildup or bits of old food. Clogged jets mean spotty cleaning and sanitizing. They should also spin freely when you give them a gentle push.

Pro Tip: A machine that came from an area with hard water is a prime suspect for hidden limescale buildup inside pumps and heating elements. Don't be shy—ask the seller about the water quality where the machine was last used.

While you're at it, inspect every visible hose and connection. You're looking for cracks, brittleness, or any signs of leaking. Old, hardened rubber is a super common failure point. It’s easy to spot but can cause a world of water damage if you ignore it.

Electrical Components and Controls

Finally, it's time to check the brains of the operation. A faulty electrical system isn't just expensive to fix; it can be downright dangerous.

The best-case scenario is seeing the machine run a full cycle. Keep your eyes on the control panel and any gauges.

- Verify Cycle Times: Does the machine actually run through its wash and rinse cycles in the time the manufacturer says it should? If the timing is all over the place, you could be looking at a faulty timer or control board.

- Check Temperature Gauges: For high-temp models, this is critical. Make sure the wash and final rinse temps hit their sanitation targets. You're generally looking for 150-160°F for the wash and a blistering 180°F for the final rinse.

- Test All Buttons and Switches: Push every single button. Does it respond like it should? A dead switch might seem like a small thing, but it could be a symptom of a much deeper issue with the main control board.

A careful look at these three areas will give you a solid picture of the machine's true condition. It's how you walk away confident that you've bought a used dishwasher that will be a workhorse, not a liability.

Calculating the True Cost and Return on Investment

That sticker price on a used commercial dishwasher can look pretty tempting, but it’s only the first chapter of the financial story. To really know if a pre-owned machine is a smart buy, you have to look beyond the initial savings and figure out its Total Cost of Ownership (TCO). This gives you the real-world picture of what that machine will cost you over its entire life in your kitchen.

Think of it like buying a cheap car. The low price is great upfront, but if it’s constantly in the shop for expensive repairs and guzzles gas like there’s no tomorrow, it’s not much of a bargain, is it? The exact same principle applies here. A lower initial cost is a great starting point, but a true cost analysis ensures your investment actually helps your bottom line for years to come.

This bigger-picture financial view is more important than ever as the demand for efficient sanitation equipment keeps growing. The global dishwasher market was valued at a whopping USD 35.57 billion and is expected to expand big time, thanks to the booming foodservice industry. Savvy operators know that long-term value always beats a low initial price. You can dig into more data on this market trend over at Renub Research.

Factoring in the Hidden Costs

To get an accurate TCO, you’ve got to account for all the expenses that aren't on the price tag. These "hidden" costs can chew through your initial savings in a hurry if you're not ready for them.

Here are the key variables to build into your calculation:

- Potential Repairs: Always set aside a budget for unexpected fixes. Even a well-inspected used machine can throw you a curveball. A good rule of thumb is to budget 10-15% of the purchase price for first-year repairs.

- Utility Consumption: Let's be honest, older models are often less efficient. Do a little homework on the specific model's water and energy stats. Estimate how much more it might add to your monthly utility bills compared to a new, energy-efficient model.

- Remaining Lifespan: Be realistic about how many years of solid service you can expect. Divide your total projected cost by its estimated remaining lifespan to get the true annual cost of owning that machine.

Projecting Your Return on Investment

Once you have a handle on the TCO, you can calculate your Return on Investment (ROI). This is where you see how the money you spent translates into real dollars back in your pocket. Your ROI isn't just about the cash you saved upfront; it's about the operational efficiencies you unlock.

The real value of a commercial dishwasher isn't just clean plates. It's the accelerated workflow that generates revenue—faster table turnover, higher customer capacity, and more efficient labor allocation.

Think about these powerful financial benefits:

- Saved Labor Hours: Figure out how many hours your staff currently spends stuck at the sink washing dishes by hand. A commercial machine can slash this time by over 80%, freeing up your team for revenue-generating tasks like food prep or taking care of customers.

- Increased Table Turnover: A fast, reliable dishwasher means a constant, ready supply of clean plates, glasses, and silverware. This directly translates to seating more guests during your busiest hours, which is a straight boost to your daily revenue.

- Improved Sanitation Compliance: Dodging health code violations saves you from hefty fines and, just as importantly, protects your reputation. Consistent, high-temperature sanitation is a financial safeguard that a dependable machine delivers, cycle after cycle.

How to Maintain Your Used Dishwasher for a Longer Life

So, you've made the smart move and invested in a used commercial dishwasher. Now comes the most important part: protecting that investment. The truth is, how long any pre-owned machine lasts comes down almost entirely to a solid, consistent maintenance routine. Skipping simple daily care is a lot like never changing the oil in your car—sooner or later, you're going to face bigger, more expensive problems.

A practical, easy-to-follow schedule will do wonders for extending the life of your dishwasher and helping you dodge those dreaded middle-of-the-rush repair calls. By making a few quick checks part of your kitchen's closing routine, you ensure that used machine stays the reliable, efficient workhorse you bought it to be.

This isn’t about needing a mechanic on-site. We're talking about simple, repeatable tasks that any staff member can easily handle. A few minutes of effort each day is far more powerful than a massive repair job once a year.

Your Daily Maintenance Checklist

At the end of every single shift, just a few key actions can head off the most common headaches like clogs, funky smells, and dishes that just aren't getting clean.

- Drain and Clean the Interior: Always drain the machine completely and give the inside walls a good wipe-down. This simple step is your best defense against mildew and grime buildup.

- Remove and Clean Filters: Pull out all the scrap trays and filters. Give them a thorough rinse to get rid of any food bits that could clog up your pumps and spray arms.

- Inspect and Wipe Spray Arms: Take a quick look at the nozzles on the spray arms for any blockages. Wiping them down ensures they can spin freely and shoot water everywhere it needs to go.

This little five-minute routine is probably the single most important thing you can do to keep your used commercial dishwashing machines running like a charm.

A common myth is that modern dishwashers don't require pre-scraping. While they are powerful, removing large food debris before washing is still essential for proper sanitization and preventing mechanical failures.

Weekly and Monthly Preventative Care

Once you've got the daily habits down, a couple of slightly more involved tasks will tackle the slower-moving problems like hard water buildup and general wear and tear.

Once a week, you've got to de-lime the machine. Hard water deposits, or scale, are the silent killer of heating elements and pumps. Running a de-liming cycle with a proper commercial-grade solution keeps these vital parts working efficiently.

Then, on a monthly basis, take a few extra minutes to:

- Inspect Door Seals and Gaskets: Look for any cracks, brittleness, or signs that water is escaping. A bad seal wastes a ton of energy and can cause water damage around the machine.

- Calibrate Temperatures and Chemical Dispensers: Use test strips to make sure your sanitizer levels are spot-on. You'll also want a thermometer to check that the final rinse is hitting the required 180°F for proper sanitation.

For a deeper dive into how all these steps contribute to a truly effective dishwashing operation, our complete commercial dishwashing machine guide covers everything from sanitation standards to cycle efficiency. Sticking to a structured plan like this will turn your used dishwasher from just another purchase into a lasting, profitable asset for your kitchen.

Alright, you've done your homework and know exactly what to look for in a used commercial dishwasher. That’s a huge step. But the next big question is just as important: where do you actually find one?

Navigating the second-hand market takes a bit of strategy if you want to avoid ending up with a lemon. Your best bet is to stick with sources that offer some level of transparency and accountability. Reputable restaurant supply dealers and certified refurbishers are usually the safest routes. These folks professionally inspect, service, and sometimes even offer a limited warranty on their used commercial dishwashing machines. Sure, the price might be a little higher than a private sale, but you’re really paying for peace of mind. Online marketplaces can have some great deals, but they require a lot more diligence on your part, as you're often buying "as-is" with little recourse if things go south.

Exploring Financing and Leasing Options

Let's be real—for many startups or even established spots managing a tight budget, dropping a chunk of cash on equipment upfront just isn't in the cards. This is where getting smart about how you acquire your gear becomes incredibly valuable, letting you get the machine you need without draining your capital.

Think of financing or leasing as a tool to manage your cash flow. It allows you to put your capital toward revenue-generating activities like marketing or inventory, while the equipment pays for itself over time.

Here’s a quick look at the most common paths you can take:

- Equipment Financing: This is a pretty straightforward loan. You make regular payments over a set term, and at the end of it, you own the machine outright. It's an excellent option if you want to build equity in your assets.

- Lease-to-Own: This gives you the flexibility of a lease with the option to buy the dishwasher when the contract is up, often for a price you agree on from the start. It’s ideal if you’re not ready to commit fully but want the option to own it later on.

These options make getting essential equipment much more accessible, even if your initial funds are limited. To see how these plans can fit into your business strategy, our detailed restaurant equipment financing guide breaks down the entire process, helping you choose the best path for your financial situation.

Common Questions About Used Commercial Dishwashers

Stepping into the world of used kitchen equipment always brings up a few questions. That's completely normal. Getting solid, straight answers is the best way to feel confident about your purchase, so let's dig into some of the most common things buyers wonder about when looking at a used commercial dishwasher.

Lifespan and Reliability

What's the real lifespan of a used commercial dishwasher?

While a shiny new machine might give you 10-15 years, a well-cared-for used model from a trusted brand can still easily provide 5-8 years of solid service. The final number really boils down to its age, how well it was maintained before, and the brand's reputation for building things to last. Always ask the seller if they have any service records you can look at.

Is a refurbished machine better than just a standard "used" one?

In most cases, yes. A refurbished machine is typically the safer bet. It means a professional technician has already gone through it, inspecting, repairing, and testing everything. They often even come with a short warranty. An "as-is" machine is cheaper upfront, but you're taking on all the risk. For most restaurant owners, that little bit of extra cost for a certified unit buys a whole lot of peace of mind.

It's worth remembering that "sanitized" and "sterilized" are two very different things. Commercial dishwashers are built to sanitize—killing enough germs to meet health code standards. They aren't designed for sterilization, which is a much more intense process you'd see in a hospital.

Do older models use a lot more energy and water?

It's very likely they'll use more than a brand-new, ENERGY STAR-rated unit, and that's something to be aware of. When you're calculating your total cost of ownership, it’s smart to factor in slightly higher utility bills. But honestly, the huge upfront savings you get from buying used usually more than make up for this small increase in running costs, especially for kitchens that aren't running the machine nonstop all day.

At The Restaurant Warehouse, we stock high-quality, reliable used and new equipment to fit any kitchen and any budget. Find the perfect dishwasher to power your kitchen's success by exploring our current inventory.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment