Unlocking the Mystery: Understanding Freezer Door Suction

Why Understanding Freezer Door Suction Matters for Your Operation

Do commercial freezers have a suction seal on the door? This is a common question, and the direct answer is no. Commercial freezers don't contain a specific component named a "suction seal." Instead, they achieve this powerful sealing force through a combination of a high-quality door gasket—the flexible rubber or PVC lining around the door's edge—and a fundamental principle of physics. This gasket creates an airtight seal that allows a strong suction effect to occur due to air pressure differences. When you close the freezer door, the warm air that has entered cools down rapidly. As it cools, it contracts, creating a temporary vacuum inside the unit that powerfully pulls the door shut against the frame.

Quick Answer:

- The Gasket Creates the Seal: The flexible door gasket is the single most critical component for an airtight closure.

- Physics Creates the Suction: The cooling and contraction of trapped warm air creates a low-pressure zone, or partial vacuum.

- It's a Passive, Not Active, Mechanism: There is no pump, motor, or mechanical device actively creating the suction.

- All Commercial Freezers Use This Principle: Whether it's a large walk-in or a small undercounter unit, this effect is universal, facilitated by either magnetic or compression-style gaskets.

We've all experienced it. You close a walk-in or reach-in freezer door, turn to grab something, and when you try to reopen it a few seconds later, it feels stuck. That powerful pull isn't a defect or a sign of a problem; on the contrary, it's a clear indication that your freezer is working exactly as it should. The suction you feel is the result of basic thermodynamics and a properly functioning door gasket working in perfect harmony to maintain the frigid temperatures necessary to protect your valuable inventory.

For any restaurant owner or kitchen manager, a deep understanding of this phenomenon is not just trivial knowledge—it's essential for operational success. A properly sealing freezer door can be the difference between predictable, manageable energy bills and budget-breaking utility costs. It can mean the difference between serving fresh, high-quality food and discarding thousands of dollars in spoiled inventory. When you know precisely how the seal works, you can diagnose problems early, perform preventative maintenance, and fix minor issues before they escalate into expensive, business-halting emergencies.

I'm Sean Kearney from The Restaurant Warehouse, and throughout my years helping foodservice operators find the right refrigeration solutions, I've seen how a vast number of costly issues stem from a simple misunderstanding of whether commercial freezers have a suction seal on the door and how that crucial sealing function operates. My goal is to help you avoid these costly mistakes by demystifying what's happening every time you close that freezer door, empowering you to keep your equipment running efficiently for years to come.

The Science of the "Suck": How Freezer Door Suction Really Works

That familiar feeling of a freezer door being glued shut isn't a malfunction or a complex mechanical lock; it's a beautiful demonstration of physics at work in your kitchen. Grasping this process helps you appreciate why commercial freezers rely on a perfect seal to function efficiently and economically. The powerful sensation of suction isn't caused by a mechanical pump or any active device but by pure thermodynamics.

The core principle behind this phenomenon is Charles's Law, a fundamental gas law in physics. In simple terms, Charles's Law states that for a fixed amount of gas, its volume is directly proportional to its temperature. When you cool a gas, its molecules slow down, move closer together, and the gas itself contracts, or takes up less space. When warm, humid air gets trapped inside your freezer, the refrigeration system cools it rapidly. This causes the air to shrink, creating a temporary low-pressure zone—a partial vacuum. The higher atmospheric pressure outside the freezer then pushes the door firmly against the frame, creating the powerful pull you feel.

Let's walk through the step-by-step process:

Opening the Door: Your commercial kitchen air is relatively warm (75°F or higher) and contains moisture, while your freezer is maintained at a frigid 0°F or below. The moment you open the door, the laws of physics take over. The dense, cold, dry air inside the freezer is heavier than the warm air, so it spills out onto the floor. To fill this void, the warmer, moisture-laden room air rushes in to take its place. This air exchange is unavoidable and is the catalyst for the entire suction effect.

Closing the Door: You retrieve your items and shut the door, trapping this new volume of warm, humid air inside. The freezer's refrigeration system, specifically the evaporator coils and fans, immediately gets to work. These systems are engineered for rapid temperature recovery, so they begin absorbing heat from this new air almost instantly. This cooling process happens within a matter of seconds in a well-functioning commercial unit.

Creating the Vacuum: As the trapped air cools from room temperature down to 0°F, it contracts significantly. This rapid reduction in air volume creates a noticeable pressure difference between the inside and the outside of the freezer. The standard atmospheric pressure at sea level is approximately 14.7 pounds per square inch (PSI). Inside the freezer, the pressure is now lower. This external force pushes against the entire surface of the door, pressing it tightly against the door gasket and creating the strong suction effect. On a standard 30" x 78" walk-in door, this pressure differential can exert a force of over 30,000 pounds across its surface, firmly holding it in place.

This entire sequence is why you might struggle to reopen a freezer door immediately after closing it but find it opens with normal effort after waiting 15-30 seconds. During that brief pause, the pressure begins to equalize as a small amount of air inevitably seeps back in through microscopic gaps or, in some cases, a dedicated Pressure Equalization Port (PEP). A strong, immediate suction effect is one of the best indicators of a healthy freezer; it confirms your cooling system is powerful and your gasket is creating a truly airtight seal. Conversely, if you no longer feel that resistance, it's a major red flag that your gasket is likely failing and your energy bills are about to rise.

So, Do Commercial Freezers Have a Suction Seal on the Door?

While there isn't a specific part you can order from a catalog called a "suction seal," the powerful suction effect you feel is very real and is a direct result of the door gasket. This flexible rubber or PVC lining that runs along the door's perimeter is the unsung hero that creates the airtight barrier necessary for the physics of air contraction to work its magic. Without a pliable, fully intact gasket, you would never experience that satisfying pull because air would constantly leak in and out, preventing a significant pressure difference from ever forming.

The Unsung Hero: The Freezer Door Gasket

Think of the door gasket as the guardian of your freezer's internal environment. Its primary job is to compress evenly against the freezer's frame, forming a perfect, unbroken seal that locks cold air in and keeps warm, moist air out. This flawless closure is what allows the internal pressure to drop when trapped air cools, creating the vacuum effect that pulls the door tight and signals peak efficiency. When a gasket becomes brittle, torn, or flattened, air leaks develop. The suction effect vanishes, your freezer's compressor must work overtime to compensate, and your energy costs begin to climb.

Common Gasket Materials and Types in Commercial Units

Commercial freezer gaskets are engineered for extreme durability and performance. Most are made from either flexible Polyvinyl Chloride (PVC) or EPDM (ethylene propylene diene monomer) rubber. These materials are chosen for their ability to remain pliable and not crack in sub-zero temperatures. They are also formulated to resist degradation from frequent cleaning with common kitchen chemicals and sanitizers.

- Attachment Types: Gaskets attach to doors in several ways, and identifying yours is key for replacement. Push-in (or Dart) gaskets have a flexible, arrow-shaped anchor that pushes into a groove in the door. Screw-in gaskets are held in place by a metal retainer plate that is screwed onto the door. Snap-in gaskets have a rigid base that clicks securely into a channel built into the door liner.

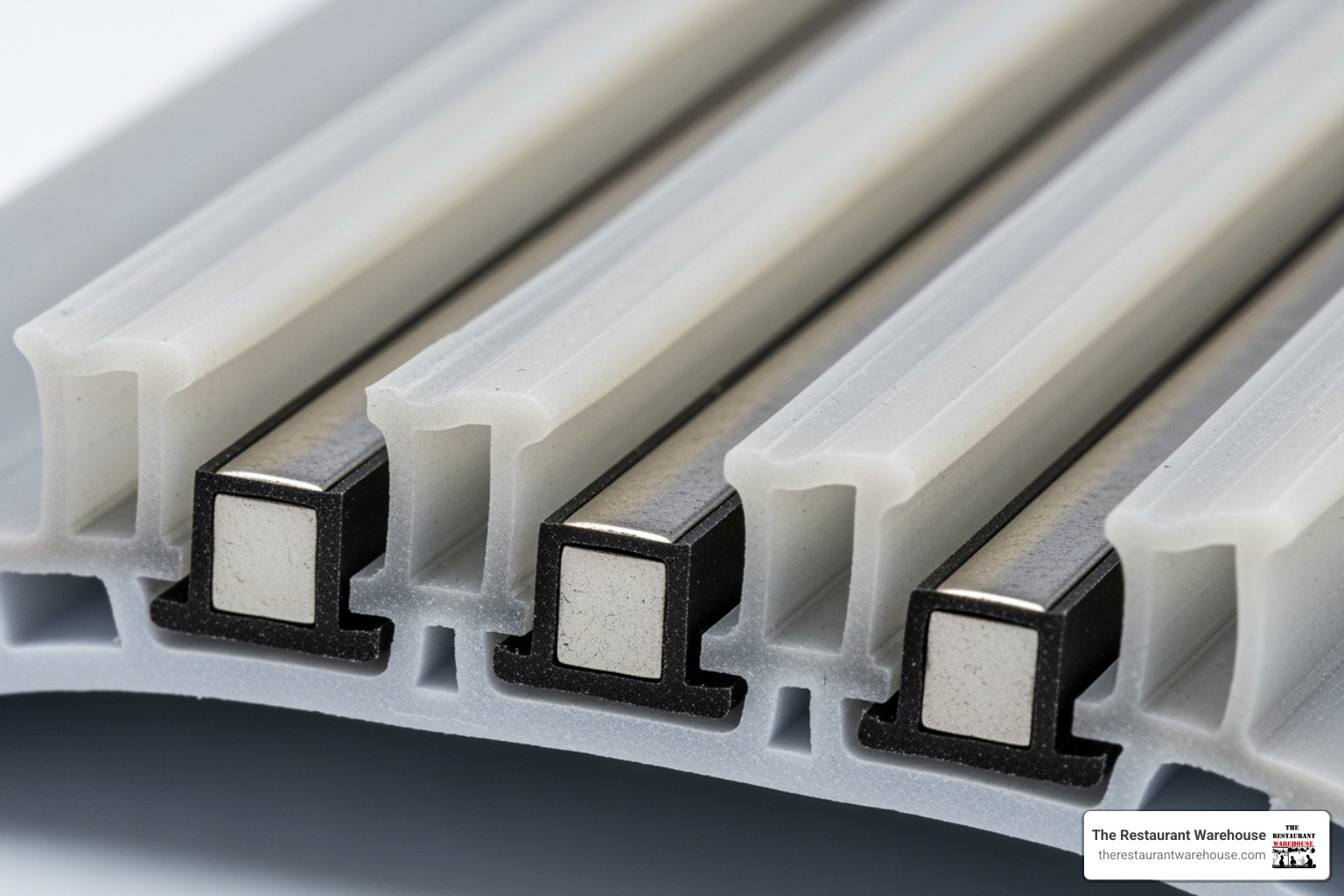

- Seal Types: To ensure a tight closure, gaskets use one of two methods. Many modern gaskets incorporate flexible magnetic strips inside the vinyl. These magnets help pull the door closed the last fraction of an inch and maintain a constant, tight seal. Other gaskets rely purely on compression, where the physical pressure of the closed door squeezes the hollow, flexible gasket material to form the seal.

If you're looking to upgrade your kitchen or need to replace an aging unit, browsing our selection of commercial freezers at The Restaurant Warehouse will show you a variety of models featuring robust, easily replaceable gaskets designed for the demands of a professional kitchen.

How Commercial Seals Differ from Residential Models

While they serve the same basic function, commercial and residential gaskets are worlds apart in design and durability. A commercial gasket is significantly thicker, more robust, and made from higher-grade materials to withstand being opened and slammed shut hundreds of times per day. A residential freezer seal might only see that much action in a month or two. Because of this intense, heavy use, commercial gaskets have a much shorter expected lifespan—typically six months to four years—and are considered a routine maintenance item designed for quick and easy replacement. The stakes are also exponentially higher. A failing residential seal is an inconvenience that might slightly raise your electric bill. A failing commercial seal can lead to thousands of dollars in spoiled inventory, soaring energy costs, and critical health inspection violations. For this reason, commercial seals are engineered for absolute reliability to maintain food-safe temperatures without fail.

Why a Perfect Seal is Non-Negotiable for Your Business

In the fast-paced, high-stakes world of the restaurant business, your commercial freezer's door seal is one of the most critical components directly affecting your profitability. When we ask if commercial freezers have a suction seal on the door, what we're really discussing is the integrity of the gasket and the powerful sealing effect it creates. A properly functioning, airtight door seal is entirely non-negotiable—it serves as the frontline defense for your inventory, your energy budget, your equipment's longevity, and your health code compliance.

The Benefits of an Airtight Freezer Seal

When your freezer door gasket is in prime condition, the benefits are tangible and immediate:

- Reduced Energy Consumption: An airtight seal prevents the constant, energy-sapping exchange of cold and warm air. This means your compressor runs less often and for shorter periods. Studies have shown that replacing a single worn-out freezer gasket can cut that unit's energy consumption by as much as 20-30%.

- Stable Internal Temperatures: A perfect seal ensures your freezer maintains its set temperature with minimal fluctuation. This stability is absolutely crucial for preserving the quality and, more importantly, the safety of your food products.

- Improved Food Quality and Safety: Consistent sub-zero temperatures are your best defense against bacterial growth. A great seal also prevents the temperature cycling that leads to freezer burn, which degrades the texture and flavor of your food, protecting your investment and your customers' dining experience.

- Less Wear and Tear on Components: By preventing the compressor and evaporator fan from running constantly, a good seal reduces the strain on your freezer's most expensive components. This translates to fewer costly repair calls and a longer overall lifespan for the unit.

The High Cost of a Faulty Seal

Conversely, when a seal fails, the negative consequences cascade quickly and can become incredibly expensive:

- Frost and Ice Formation: Leaking warm, humid air is the primary cause of excessive frost. This moisture freezes onto the evaporator coils, acting as an insulator that forces your freezer to work even harder. This ice can also block airflow, creating dangerous hot spots inside the cabinet.

- Temperature Fluctuations and Health Code Violations: An inconsistent internal temperature can allow food to enter the temperature 'danger zone' (40°F to 140°F), where bacteria multiply rapidly. This poses a serious food safety risk and can lead to immediate health code violations and failed inspections.

- Spoilage of Inventory: Premium ingredients like meat, seafood, and dairy can spoil in a matter of hours if temperatures aren't stable. A single weekend with a failed gasket could lead to thousands of dollars in lost inventory.

- Skyrocketing Electricity Bills: A freezer with a bad seal can run almost continuously as it fights a losing battle against incoming warm air. This can easily double or triple the unit's energy usage, causing a painful spike in your monthly utility bills.

- Premature Component Failure: The relentless strain on the compressor, condenser, and fan motors can cause them to fail years ahead of their expected service life, turning a simple $100 gasket replacement into a multi-thousand-dollar repair job.

If you're experiencing any of these costly issues, it's time to act. You can contact our team at The Restaurant Warehouse today to explore replacement options or discuss upgrading to a more modern, efficient unit.

Safety and Regulatory Standards You Must Know

Beyond efficiency and food safety, your freezer door seal also has important safety implications. Federal regulations, specifically the Refrigerator Safety Act enforced by organizations like the Underwriters Laboratory (UL), require that the force needed to open a refrigerator or freezer door from the inside must not exceed 15 pounds. This standard was originally created to prevent accidental entrapment, particularly of children, ensuring that anyone could push the door open from the inside. This rule highlights the critical balance required in freezer design: a door must seal tightly enough for maximum efficiency but not so tightly that it becomes a safety hazard for staff who might be inside a walk-in unit. If your door remains extremely difficult to open even after waiting a minute for the pressure to equalize, it's a red flag that needs immediate investigation. You can review the specific requirements in the Federal safety standards for refrigerator doors for more details.

A Practical Guide to Freezer Seal Maintenance and Repair

A few minutes of proactive cleaning and regular inspection can dramatically extend the life of your freezer's gasket, saving you from the significant headaches of spoiled inventory, high energy bills, and unexpected equipment failure. Following a simple but consistent maintenance routine is one of the highest-return investments of time you can make in your kitchen.

How to Test if the Suction Seal on Your Commercial Freezer Door is Working

You don't need expensive or complicated tools to check the integrity of your freezer seal. These simple, time-tested methods are highly effective for pinpointing leaks:

- The Paper Test (or Dollar Bill Test): This is the classic method. Take a sheet of paper or a dollar bill and close the freezer door on it, so half is in and half is out. Try to pull the paper out. If you feel strong resistance or it tears, the seal is good in that spot. If it slides out with little to no friction, you've found a leak. Be methodical and test multiple spots along the entire perimeter of the door—top, bottom, and both sides.

- The Visual Inspection: A healthy gasket should be soft, pliable, and uniform in shape. Carefully look over the entire gasket for any signs of damage. Are there visible cracks, tears, or missing chunks? Is the material brittle, dry, or crumbly to the touch? Look for areas that appear flattened or compressed, which won't create an effective seal. Also, check for mold or mildew buildup, which can degrade the material over time.

- The Light Test: This test is best for walk-in coolers or in a dark kitchen. Have one person go inside the freezer with a bright flashlight and close the door (ensure it's not locked). The person on the outside should look carefully around the entire edge of the door. Any pinpricks of light that escape indicate a gap in the seal.

Routine Maintenance for a Longer Lifespan

- Clean Weekly: Dirt, grease, and food debris are a gasket's worst enemy. Once a week, wipe the entire surface of the gasket with a soft cloth dampened with warm, soapy water (mild dish soap is perfect). Use a soft-bristled brush, like a toothbrush, to gently clean inside the flexible folds or bellows. Crucially, avoid harsh chemicals like ammonia, bleach, or abrasive scrubbers, as these will dry out the PVC or rubber and cause it to crack prematurely. Always dry the gasket thoroughly after cleaning.

- Condition Monthly: To keep the material supple and prevent it from drying out, apply a very thin layer of food-grade lubricant, like petroleum jelly or a specialized gasket conditioner, to the face of the gasket. This helps it maintain its flexibility and create a better seal.

- Check Door Alignment and Hinges: A sagging or misaligned door is a common cause of gasket failure. It puts uneven pressure on the gasket, creating gaps at the top or bottom. Periodically check that the door hangs straight and that all hinge screws are tight. Adjust as necessary to ensure the gasket makes even contact with the frame all the way around.

- Avoid Overloading and Obstructions: Never cram your freezer so full that boxes or containers prevent the door from closing completely. This constant pressure can permanently deform the gasket, creating a leak that remains even after the obstruction is removed.

When and How to Replace a Worn-Out Gasket

Even with perfect maintenance, gaskets are a wear item and will eventually need to be replaced. It's time for a replacement when it fails the paper test, you see visible damage, or the strong suction effect is noticeably diminished or gone completely.

- Find the Right Part: This is the most critical step. You will need your freezer's make, model, and serial number, usually found on a tag inside the unit. Identify the gasket profile: push-in, screw-in, or snap-in. Take a clear photo of the gasket's cross-section if you're unsure. Carefully measure the outside dimensions of your existing gasket to ensure you order the correct size.

- Prepare the New Gasket: When the replacement arrives, it will likely be folded or coiled from shipping. To make it pliable and easy to install, soak it in a sink or tub of warm water for 15-30 minutes. Alternatively, you can gently warm it with a hairdryer on a low setting.

- Remove the Old Gasket: For push-in gaskets, simply pull them out of the groove. For screw-in types, loosen the screws on the retainer plate and slide the old gasket out. For snap-in styles, you may need a putty knife to gently pry the old gasket out of its channel. Once removed, thoroughly clean the door channel or surface where the new gasket will sit.

- Install the New Gasket: Starting at the corners, press the new gasket firmly into place, working your way around the perimeter. For screw-in types, tighten the screws gradually in a star pattern to ensure even pressure. A new magnetic gasket may take 24-72 hours to fully magnetize and settle, creating a perfect seal. Keeping the door closed as much as possible during this time helps the process.

Replacing a gasket is a highly cost-effective repair that pays for itself in energy savings. For more detailed guidance, check out our commercial freezer guide, or contact our expert team today for help finding the right parts for your unit.

Frequently Asked Questions about Freezer Door Seals

Here are detailed answers to the most common questions restaurant owners and kitchen managers ask about their freezer door seals and the powerful suction effect.

How often should I replace my commercial freezer's door seal?

The lifespan of a commercial freezer seal typically ranges from 6 months to 4 years, but this is highly dependent on usage. In a high-volume kitchen where a reach-in door is opened dozens of times an hour, the gasket endures significant stress, compression, and temperature changes. In this environment, it may need to be replaced annually or even semi-annually. In a less busy setting, such as a storage freezer that is accessed only a few times a day, a gasket might last several years. The best practice is to not wait for visible cracks or a complete failure. Perform the paper test monthly as part of a regular maintenance schedule. Proactively replacing a gasket that is starting to fail is far cheaper than dealing with the consequences of a complete failure.

Why is my freezer door suddenly so hard to open right after I close it?

This is a good sign and means your door seal is working perfectly. The difficulty you're experiencing is caused by the vacuum effect we've discussed. When you close the door, the warm, humid air that you let in is rapidly cooled by the freezer's refrigeration system. This cooling causes the air to contract, creating a temporary low-pressure zone inside the freezer. The higher atmospheric pressure outside then pushes the door firmly shut. This powerful suction is temporary and typically lasts only 15 to 30 seconds. The solution is simple: just wait a moment before trying to open the door again. The pressure will equalize, and the door will release with normal effort.

Does ambient humidity affect my freezer's door seal?

Yes, significantly. High humidity in your kitchen means that more water vapor enters the freezer every time the door is opened. Your freezer's cooling system must then work much harder to not only cool the air but also to remove this excess moisture, which dramatically increases energy consumption. This moisture freezes onto surfaces, leading to faster and heavier frost buildup on the evaporator coils and around the door seal itself. This ice can physically push the gasket away from the frame, creating gaps and compromising the seal. It can also cause the gasket material to degrade faster. Therefore, proper kitchen ventilation and air conditioning are crucial not just for staff comfort but also for protecting your refrigeration equipment and controlling energy costs.

What is a pressure equalization port (PEP valve) and do I need one?

A Pressure Equalization Port, or PEP valve, is a small, often heated mechanical vent installed through the wall of a freezer, typically a walk-in. Its sole purpose is to mitigate the strong vacuum effect. When the pressure drops after the door is closed, the valve opens to allow a small amount of outside air to enter, equalizing the pressure much faster than it would naturally. This allows for quick re-entry without a long wait. They are most common on large walk-in freezers where the door surface area is large and the suction force can be extreme. While beneficial for high-traffic freezers, they are another component that requires maintenance and can potentially fail.

Can I repair a small tear in my gasket instead of replacing it?

For a commercial, food-service environment, the answer is almost always no. While temporary fixes using food-safe silicone or special adhesives might seem like a tempting, quick solution for a small rip or tear, these repairs rarely last. They create an uneven surface that compromises the integrity of the seal and can easily fail a health inspection. A gasket is designed to be a single, continuous, smooth barrier. Any break in that barrier, even a repaired one, is a weak point. Given the relatively low cost of a new gasket compared to the high cost of potential spoilage or energy waste, replacement is always the recommended and most professional solution.

Conclusion

So, do commercial freezers have a suction seal on the door? As we've explored, the answer is a fascinating intersection of design and physics. There is no single part called a "suction seal." Instead, the powerful pull you feel is a pressure effect—a temporary vacuum created when warm air cools and contracts inside the freezer. The true hero of this story is the door gasket, the humble but essential component that creates the airtight barrier necessary for this scientific phenomenon to occur.

The key takeaway is that the 'suction seal' is not a part you can buy, but an effect you must cultivate through proper maintenance. A well-maintained gasket is your frontline defense against energy waste, spoiled inventory, failed health inspections, and premature equipment failure. When it fails, the consequences are swift and costly, ranging from skyrocketing electricity bills to the catastrophic loss of product and the expense of emergency repairs.

The good news is that proactive maintenance is your secret weapon. This small investment of time and money in regular cleaning, inspection, and timely replacement of your gaskets pays immediate dividends in lower energy bills, protected inventory, and the peace of mind that comes from having reliable equipment. It's one of the most cost-effective procedures you can implement in your kitchen.

At The Restaurant Warehouse, we understand that the small details are what impact your bottom line. We are committed to providing affordable, high-quality commercial freezer solutions without the high retail markups common in the industry. A healthy freezer seal isn't just an operational detail—it's a cornerstone of a smarter, more efficient, and more profitable business.

Whether you are outfitting a brand-new kitchen or optimizing an existing one, we are here to help. Browse our selection of top-tier commercial freezers to find the perfect unit for your needs, or contact our expert team today for guidance on maintenance, troubleshooting, and finding the right replacement parts. We are dedicated to serving the foodservice industry with wholesale pricing and genuine expertise.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment