Troubleshooting Tips for a Commercial Ice Machine Not Making Ice

Why Your Commercial Ice Machine Not Making Ice Costs More Than You Think

When your commercial ice machine not making ice, every minute of downtime hits your bottom line hard. Restaurant operations grind to a halt, customers leave unhappy, and food safety becomes a real concern.

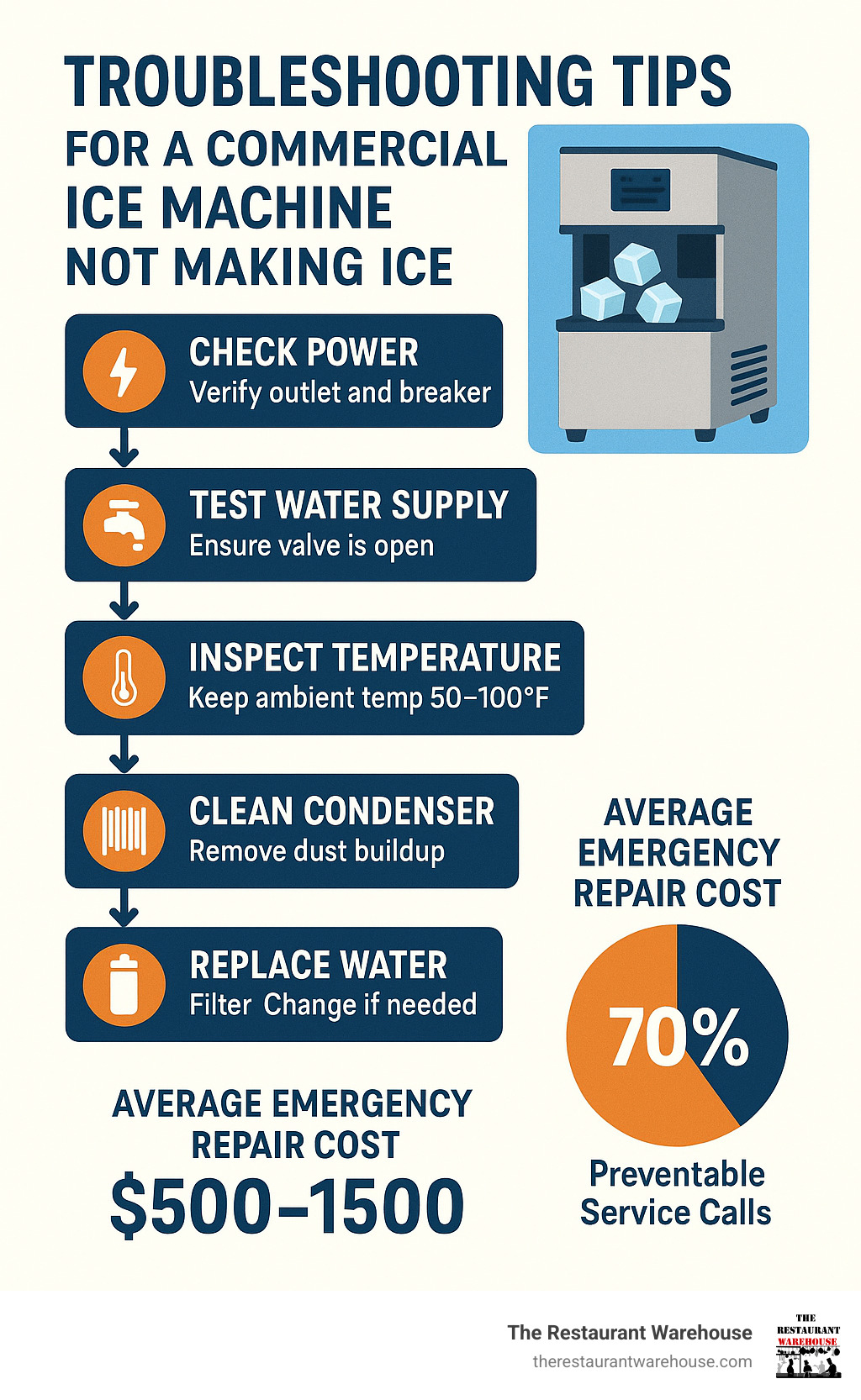

Quick Fix Checklist for Ice Machine Not Making Ice:

- Check power - Verify outlet works and breaker hasn't tripped

- Test water supply - Ensure valve is open and filter isn't clogged

- Inspect temperature - Keep ambient temp between 50-100°F

- Clean condenser coils - Remove dust buildup blocking airflow

- Reset the machine - Power off, wait 10 seconds, restart

- Replace water filter - Change every 6 months minimum

The research shows that up to 70% of commercial ice machine service calls could have been prevented with regular cleaning and maintenance. Even worse, a clogged water filter alone accounts for about 60% of ice production failures - a simple $20 fix that restaurants often overlook.

Your ice machine works harder than most kitchen equipment. It runs 24/7, processes gallons of water daily, and operates in hot, humid conditions. When it fails, you're looking at emergency repair costs that can hit $500-1,500, plus lost revenue from unhappy customers.

The good news? Most ice machine problems have simple solutions you can handle yourself. This guide walks you through systematic troubleshooting steps that will get your ice flowing again - often without calling an expensive technician.

How a Commercial Ice Machine Works: The Basics

Think of your commercial ice machine as a hardworking refrigerator that's been trained to make perfect ice cubes around the clock. Understanding how it operates will save you time and money when troubleshooting problems.

The heart of your ice machine is the evaporator, where water meets freezing-cold metal plates or tubes. This is where the actual ice formation happens - water flows over these super-chilled surfaces and gradually builds up into solid ice cubes.

Your compressor acts like the engine of the whole operation. It pumps refrigerant through the system, creating the pressure changes that make cooling possible. Without a functioning compressor, your commercial ice machine not making ice becomes inevitable.

The condenser coils work as the heat dump for your system. They release all that unwanted heat from the refrigerant back into your kitchen air. Here's the catch - when these coils get clogged with grease and dust (which happens fast in busy kitchens), your entire machine has to work overtime.

Temperature control happens through thermostat sensors placed throughout the system. These little sensors constantly monitor conditions and tell other components when to start or stop working. The expansion valve acts as a traffic cop for refrigerant flow, controlling exactly how much cooling power reaches the evaporator.

Now here's where ice machines get interesting. The harvest cycle is what actually gets your finished ice into the storage bin. During harvest, hot refrigerant flows through the evaporator, warming it just enough to release the ice cubes. It's like a controlled mini-defrost that happens dozens of times per day.

Your water inlet valve controls the fresh water supply, while the float switch prevents messy overflows. The bin control system knows when your storage bin is full and stops production automatically - pretty smart for a machine that just makes frozen water.

The tricky part about ice machines is that they juggle the refrigerant loop, water management, temperature monitoring, and mechanical ice harvesting all at once. When any single component in this complex dance fails, you'll quickly find why preventive maintenance beats emergency repairs every time.

Quick Diagnostics: Commercial Ice Machine Not Making Ice

When your commercial ice machine not making ice, don't panic - most problems have surprisingly simple causes. We've found that about 80% of ice machine failures come down to basic maintenance issues that you can spot and fix yourself.

Let's start with the fundamentals. Your machine needs proper airflow clearance - at least 6 inches around air-cooled units. I can't tell you how many times we've seen restaurants cram ice machines into tight corners, only to wonder why ice production drops by 30% or more. Heat needs somewhere to go.

Incoming water pressure is another culprit that catches people off guard. Here's a quick test: disconnect your supply line and run water into a bucket for one minute. You should get at least 5 gallons at 20-80 psi pressure. If you're getting less, you'll end up with hollow cubes or no ice at all.

Your kitchen's ambient temperature matters more than most people realize. Ice machines work best between 50-100°F, but once you hit above 70°F, maximum output starts dropping. Those blazing hot summer days when your kitchen feels like a sauna? That's when your ice machine struggles most.

Don't overlook the basics like power supply and breaker issues. We've seen expensive service calls that ended with someone simply plugging the machine back in properly. Test your outlet with a voltage meter or just plug in your phone charger to make sure you're getting power.

Here's the big one: clogged water filters cause about 60% of ice production failures. It's a $20 fix that restaurants often ignore until their machine stops working entirely. Change filters every 6 months - more often if you have hard water.

Dirty condenser coils act like a blanket wrapped around your machine, trapping heat and reducing ice production by 30% or more. A simple brushing or blast with compressed air can work wonders.

| Symptom | Most Likely Cause | Quick Fix |

|---|---|---|

| No ice production | Clogged water filter | Replace filter |

| Slow ice production | Dirty condenser coils | Clean with brush/compressed air |

| Hollow ice cubes | High water temperature (>90°F) | Check water supply temperature |

| Machine won't start | Tripped breaker or blown fuse | Reset breaker, replace fuse |

| Ice melts quickly | Poor ventilation/high ambient temp | Improve airflow, reduce room temperature |

| Water leaking | Clogged drain line | Clear blockage, check connections |

What to Check First When Your Commercial Ice Machine Not Making Ice

Start with the embarrassingly simple stuff first. You'd be amazed how often the problem is something basic that makes you want to facepalm.

Outlet voltage is your first stop. Test the electrical outlet with a multimeter, or just plug in another device to see if it works. We've heard stories of expensive service calls that ended with the technician simply plugging the machine back in properly.

Look for the selector switch and make sure it's set to "ICE" mode. Many machines have wash/off/ice switches, and it's surprisingly easy for someone to accidentally bump it to the wrong setting during cleaning.

Check that your water valve is fully open. Building maintenance sometimes shuts off water for repairs without telling kitchen staff, leaving everyone scratching their heads about why the ice stopped.

Most ice machines have tripped safety limits that shut everything down when something goes wrong - high temperature, high pressure, or other fault conditions. Look for reset buttons on your control panel and don't be afraid to press them.

Try the reset sequence that works for most machines: turn the power switch off, wait for all evaporator ice to melt completely (this part is crucial), then unplug for at least 10 seconds before restarting. Watch for indicator lights that confirm the reset worked.

Environmental Factors That Leave Your Commercial Ice Machine Not Making Ice

Your kitchen environment plays a huge role in ice production. In fact, over 80% of ice machine breakdowns connect to environmental factors like poor ventilation, bad installation spots, or excessive heat.

Think about your kitchen heat load. Those fryers, grills, and ovens pump out serious heat that forces your ice machine to work overtime. If possible, position machines away from major heat sources - your ice maker will thank you.

Poor ventilation kills ice production faster than almost anything else. Ice machines need constant airflow to remove heat from condenser coils. Block those vents or skimp on ventilation, and efficiency drops dramatically.

Hot incoming water above 90°F leads to thin, slushy ice or complete production failure. Ideal incoming water temperature sits around 50°F - if your water comes in hot, you'll need to address that supply issue.

Make sure your machine sits level. An unlevel machine causes uneven water distribution during the freeze cycle, leading to incomplete ice formation or harvest problems that'll drive you crazy.

Humidity buildup creates its own set of headaches. Excessive moisture promotes mold growth and can mess with sensors. Maintain proper ventilation and consider dehumidification if you're dealing with problem areas.

More info about Atosa Refrigerator and Freezer Cleaning the Condenser

Deep-Dive Troubleshooting & DIY Fixes

When your basic troubleshooting doesn't fix your commercial ice machine not making ice, it's time to roll up your sleeves and dig deeper. Don't worry - most of these problems are more intimidating than they are difficult.

Water supply problems top the list of culprits. Everyone checks the filter, but what about that kinked supply line hiding behind the machine? Or the water inlet valve that's partially closed from last week's plumbing work?

When you replace that water filter (and yes, every 6 months is the absolute minimum), take a good look at what comes out. If it's brown, slimy, or has chunks of scale, you've found your problem. That $20 filter just saved you a $300 service call.

Here's a pro tip: flush the inlet line while you're at it. Disconnect the water supply and let it run into a bucket for a few minutes. You'd be amazed what comes out - rust flakes, mineral deposits, and sometimes things you don't want to think about.

The float mechanism in your water reservoir is like the toilet float in your bathroom - when it gets stuck, nothing works right. A stuck float means your machine either overflows or runs bone dry. Both scenarios leave you with no ice and potentially expensive repairs.

Electrical issues sound scary, but many are straightforward if you're comfortable with basic electrical work. Always turn off power at the breaker before poking around with wires.

Testing with a multimeter isn't rocket science. Those thermostats should show continuity when they're supposed to be closed, and infinite resistance when open. If you're getting weird readings, you've likely found your problem.

Sometimes the control board just needs a reset - kind of like rebooting your computer when it gets cranky. The key is following the exact sequence: power off, wait for complete ice melt (this part is crucial), unplug for at least 10 seconds, then restart.

Mechanical failures can be trickier, but some are surprisingly manageable. A failed compressor start relay sounds complicated, but it's often just a $30-50 plug-in component that clicks but doesn't start the compressor.

Fan motor problems usually announce themselves with grinding noises or complete silence where you should hear a fan running. Check for proper voltage at the motor terminals - if you've got power but no movement, the motor's likely seized.

The hot-gas solenoid has one job: release the ice when it's ready. When this valve fails, your machine makes perfect ice but never drops it into the bin. You'll see a thick slab of ice stuck to the evaporator that never harvests.

When all else fails, try a complete defrost and reboot. Turn everything off, let the ice melt completely, then restart following your manufacturer's procedures. Sometimes the simplest solutions work best.

Spotting Water & Filter Problems

Water problems are like that friend who always causes drama - they're responsible for most of your headaches, but they're usually the easiest to deal with once you know what to look for.

Slow fill times tell you everything you need to know about water flow. Time your machine's fill cycle - it should complete in 2-3 minutes for most units. If it's taking longer, you've got a restriction somewhere in the system.

Hollow cubes are your machine's way of saying "this water is too hot" or "I'm not getting enough water." Check that incoming water temperature first - anything above 90°F will give you disappointing ice that melts faster than you can use it.

Scale buildup looks like someone sprinkled chalk dust all over your machine's water-contact surfaces. This mineral accumulation from hard water doesn't just look bad - it insulates surfaces and restricts water flow, making your machine work harder for less ice.

The replace every 6 months rule is a minimum, not a suggestion. If you're in a hard water area, you might need monthly changes. Keep spare filters in stock because waiting for delivery when your machine fails costs way more than having extras on hand.

More info about Crystal Clear Ice Awaits

Handling Power & Control Board Errors

Modern ice machines are basically computers that happen to make ice. They're smart enough to diagnose their own problems, but sometimes that intelligence creates new ways to break down.

Blown fuses are like circuit breakers for your ice machine - they sacrifice themselves to protect more expensive components. Test them with a multimeter for continuity. If a fuse is blown, always replace it with the exact same amperage rating. Using a higher-rated fuse is like removing a safety net.

LED error codes are your machine's way of talking to you. Most manufacturers use different colored lights or blinking patterns to communicate specific problems. Red lights typically mean "call for help," while blue or green usually indicate normal operation.

Safe-mode operation kicks in when your machine detects a problem but can still limp along. For example, some machines will average recent cycles when their ice thickness sensor acts up, maintaining production while letting you know something needs attention.

The hard reset sequence is different for every manufacturer, but the basic idea is the same: give the machine a fresh start. Turn the power switch off, wait for all evaporator ice to melt completely, unplug for at least 10 seconds, then restart. Look for the right indicator lights to confirm the reset worked.

Surge protection is like insurance for your control board. If your area has frequent power fluctuations, invest in a surge protector rated for your machine's electrical load. It's cheaper than replacing a fried control board.

Mechanical Red Flags Requiring a Technician

Some problems are like changing your car's transmission - theoretically possible, but you really don't want to try it yourself. These mechanical issues need professional attention for safety, warranty, and sanity reasons.

Refrigerant leaks require EPA-certified technicians to handle legally. You'll hear hissing sounds, see oil stains around fittings, or notice ice forming on only part of the evaporator. Don't mess with refrigerant - the environmental regulations alone will give you a headache.

Restricted capillary tubes or expansion valve problems affect the delicate pressure and temperature relationships throughout your refrigeration system. These components require specialized tools and training to diagnose properly.

Compressor failure is the ice machine equivalent of a blown engine. If your compressor isn't building pressure, you're looking at $780-1,150 plus labor for replacement. On older machines, this often means it's time to shop for a replacement.

Seized pumps prevent water circulation during the ice-making cycle. Water pumps are mechanical workhorses that eventually wear out, especially in hard water areas where mineral buildup accelerates wear.

Belt noises from fan motors or other components suggest bearing wear or tension problems. While belts themselves are replaceable, proper tension adjustment requires experience to avoid premature failure.

Scientific research on condenser fouling

Preventive Maintenance, Costs & Pro Tips

Think of ice machine maintenance like changing your car's oil - skip it, and you'll pay dearly later. The numbers don't lie: restaurants that follow proper maintenance schedules cut their emergency repair costs in half and keep their machines running 2+ years longer.

Here's the reality check most restaurant owners need to hear: that $200 annual maintenance investment prevents those heart-stopping $400+ emergency repair bills when your commercial ice machine not making ice during your busiest weekend.

Your daily wipe-down routine should become as automatic as cleaning your prep tables. Grease, dust, and food particles love to accumulate on ice machine surfaces, creating perfect breeding grounds for bacteria while interfering with proper operation. A simple damp cloth takes two minutes and prevents major headaches.

Weekly sanitizing keeps your operation food-safe and your health inspector happy. Use only approved sanitizers on ice contact surfaces - never grab household cleaners that leave residues. Your customers trust that ice is clean, and weekly sanitizing maintains that trust.

The biannual deep clean is where you tackle the mineral deposits that slowly strangle your machine's efficiency. Schedule these descaling sessions during slower periods, and use only manufacturer-approved solutions. This isn't the time to experiment with generic cleaners.

Condenser brushing monthly keeps your machine breathing properly. Clean condenser coils can boost ice production by 30% while slashing energy costs. In dusty kitchens, you might need to brush them every two weeks. It's a small price for big savings.

Your water filter schedule should be sacred. Every 6 months minimum, but hard water areas need monthly changes. That $20 filter replacement can extend your machine's lifespan by up to 2 years. Do the math - it's the best investment you'll make.

Keep a logbook tracking maintenance dates, problems, and repairs. This simple habit helps you spot patterns before they become expensive surprises. Plus, warranty claims often require proof of proper maintenance.

Here's what repairs actually cost when prevention fails: Water filter replacement runs $15-30, while a start relay replacement hits $280-420. Solenoid valve replacement jumps to $450-650, and compressor replacement can cost $780-1,150. Complete system restriction repairs average $450-550.

Maintenance saves 50% on emergencies according to industry research. Those restaurants that stick to proper maintenance schedules rarely face the panic of a dead ice machine during rush periods.

More info about Atosa Ice Machine Maintenance

Frequently Asked Questions about Commercial Ice Machine Failures

Why does my new machine already have low ice output?

Here's the frustrating truth: most "defective" new ice machines aren't actually broken. They're just installed in conditions that make them struggle from day one.

Your shiny new machine might be sitting too close to the fryer, getting blasted with 90°F air all day. Ice machines need breathing room - at least 6 inches of clearance around air-cooled units. Without proper ventilation, even the best machine will wheeze along at half capacity.

Water pressure is another sneaky culprit. Many restaurants assume their water pressure is fine, but ice machines need 20-80 psi to work properly. Too little pressure means your commercial ice machine not making ice at full capacity, creating those disappointing hollow cubes that melt instantly.

Don't forget that manufacturer ratings assume perfect conditions - 70°F ambient temperature and 50°F incoming water. Real kitchens rarely hit these ideal numbers, so expect 15-25% less ice production than the spec sheet promises. That's normal, not a defect.

Can I use household cleaning chemicals inside the ice machine?

Never, ever use household cleaners inside your ice machine. We've seen this mistake cost restaurants thousands in repairs and health department violations.

Bleach, kitchen degreasers, and bathroom cleaners leave residues that contaminate ice and can poison customers. These chemicals also attack rubber seals, plastic components, and food-grade surfaces. What starts as a $3 bottle of cleaner becomes a $800 repair bill when gaskets fail and water starts leaking everywhere.

Ice machines need food-safe cleaners specifically designed for ice equipment. These specialized products rinse completely clean and won't damage sensitive components. Yes, they cost more than grocery store cleaners, but they're formulated to meet strict food safety standards.

Using the wrong chemicals also voids your warranty faster than you can say "lawsuit." Manufacturers can tell when unauthorized cleaners caused the damage, and they won't cover repairs.

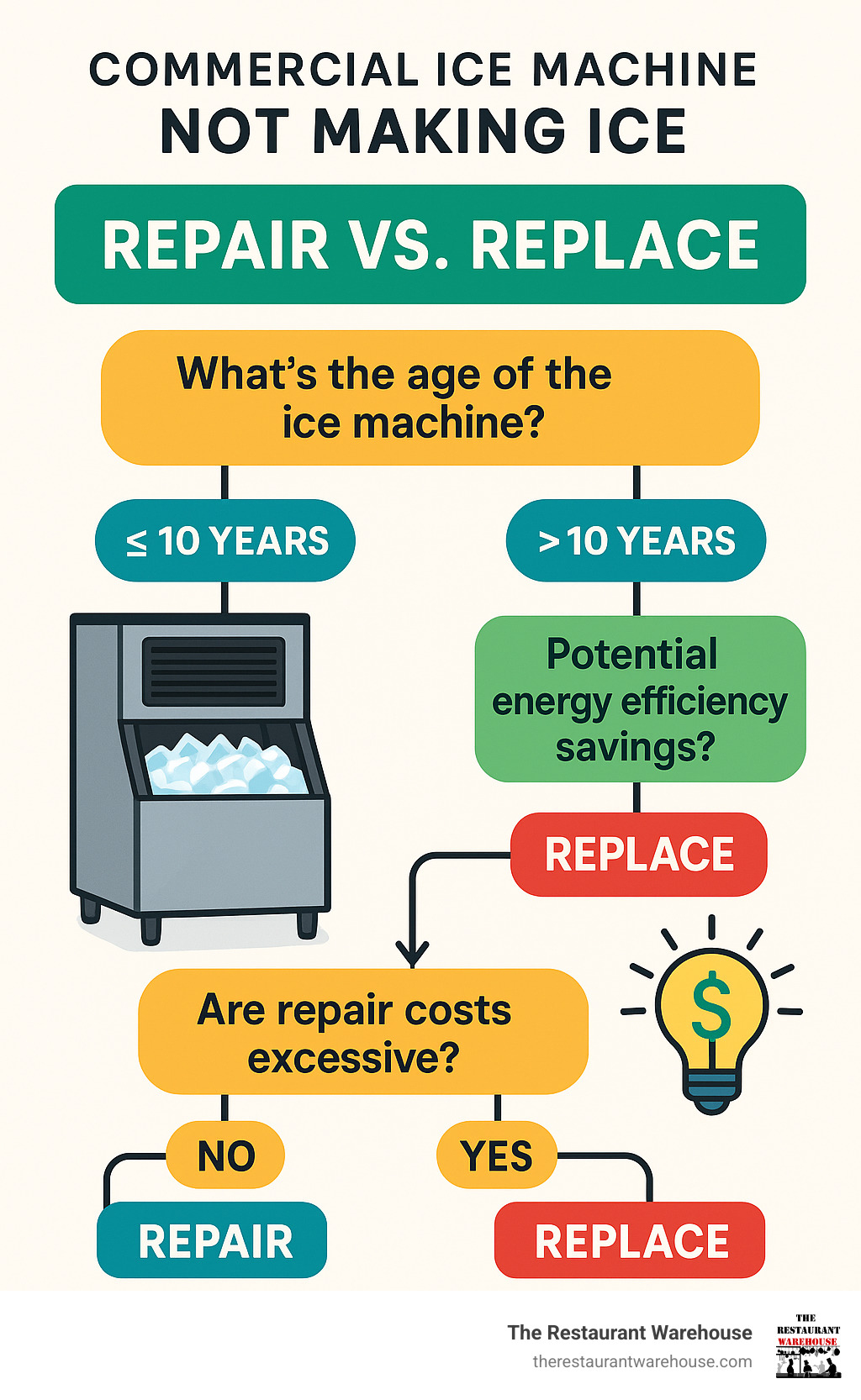

When should I replace versus repair major components?

This decision keeps restaurant owners awake at night, but the math is actually pretty straightforward.

Replace when repair costs hit 50% of a new machine's price, especially if your current machine is over 7 years old. A compressor replacement runs $800-1,200 plus labor. On an aging machine, you're often looking at other components failing soon after.

Age matters more than you might think. Machines over 10 years old with multiple problems become money pits. You fix the compressor, then the control board fails. Fix that, and the condenser starts leaking. It's like an old car that nickels and dimes you to death.

Energy efficiency adds another layer to consider. New Energy Star machines can save $200+ annually in electricity costs compared to older units. Those savings help justify replacement even when repairs are technically possible.

Consider replacement immediately when you're facing multiple expensive repairs within a short timeframe, or when parts become hard to find for discontinued models. Sometimes the smart financial move is cutting your losses and investing in reliable, efficient equipment.

Conclusion

When your commercial ice machine not making ice, most problems have simple solutions you can handle yourself. The systematic troubleshooting approach we've covered helps you identify and fix issues quickly - often saving hundreds in service calls.

Think of ice machine reliability as a direct investment in your profit margins. Every hour of downtime translates to frustrated customers, compromised food safety, and lost revenue. But here's the encouraging part: proactive care prevents 70% of service calls and can extend your equipment's life by years.

The maintenance routine doesn't have to be complicated. Regular filter changes every six months, monthly condenser cleaning, and keeping that simple maintenance logbook will catch most problems before they become emergencies. Stock a few spare filters and basic tools so you're ready when issues arise.

We've seen too many restaurants panic over ice machine failures that turned out to be clogged filters or tripped breakers. Start with the basics, work through our troubleshooting checklist systematically, and you'll be surprised how often you can get things running again without calling a technician.

At The Restaurant Warehouse, we know that equipment reliability directly impacts your success. That's why we focus on wholesale pricing for commercial ice machines and replacement parts. No high retail markups or commission-inflated prices - just professional-grade equipment at prices that make sense for your business.

Whether you need a replacement machine, maintenance supplies, or just want to keep spare parts on hand, our wholesale approach means you get the reliability you need without breaking your budget.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment