Top Commercial Food Steamers to Level Up Your Restaurant Game

Why Commercial Food Steamers Are Essential for Modern Restaurants

A commercial food steamer is the workhorse that transforms how professional kitchens prepare fresh, nutritious meals while cutting costs and boosting efficiency. These versatile machines use pressurized steam to cook everything from vegetables to seafood, preserving nutrients and flavors that traditional cooking methods often destroy.

Quick Commercial Food Steamer Buying Guide:

- Capacity: 3-12 pan configurations (match to your peak service volume)

- Power Source: Electric (8.5-32 kW) or Gas (32,000-200,000 BTU)

- Type: Boilerless/connectionless for mobility, generator-based for high volume

- Size: Countertop units for small kitchens, floor models for large operations

- Key Features: Auto-fill, smart drain, safety locks, energy-efficient design

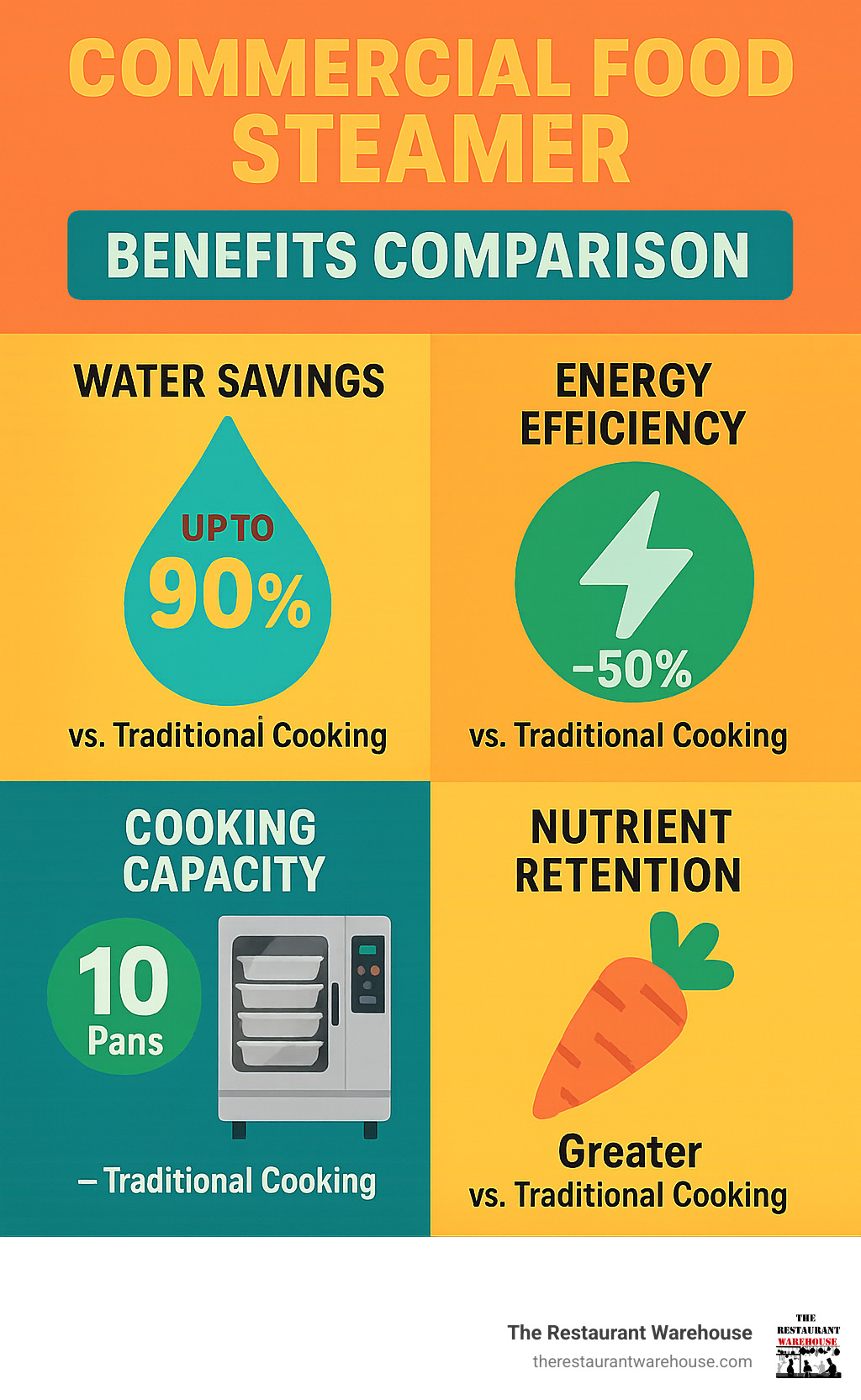

The numbers tell the story of why smart restaurant owners are investing in steam technology. Modern steamers can reduce water usage by up to 90% compared to traditional models, while some units accommodate up to 10 pans simultaneously for serious batch cooking power. Energy-efficient models cut operating costs by 50% through demand-based steam generation.

But here's what really matters for your bottom line: steamers deliver consistent results with minimal labor. Load your pans, set the timer, and move on to other tasks while the steam does the work. No stirring, no monitoring, no burned batches.

Whether you're running a startup restaurant on a tight budget or looking to upgrade your existing kitchen, the right commercial food steamer can transform your operation from reactive to proactive.

Quick look at commercial food steamer:

Why Choose a Commercial Food Steamer?

Picture this: It's 6 PM on a Friday night, your dining room is packed, and your kitchen is running like a well-oiled machine. While other restaurants struggle with overcooked vegetables and dried-out proteins, your team is plating perfectly steamed dishes that look as good as they taste. That's the power of a commercial food steamer.

The capacity and versatility of modern steamers will change how you think about food prep. We're talking about units that can handle up to 10 pans simultaneously - imagine steaming rice, vegetables, and seafood all at once while your staff focuses on other tasks.

Here's where it gets really interesting: rapid cook times that actually save you money. Those turbo jet burners generate steam in just 8 minutes, so you're not sitting around waiting for equipment to heat up during your busiest service periods.

But let's talk about the real game-changer - water savings. Traditional steamers gulp down about 55 gallons of water per hour. Modern Low Water Energy technology cuts that to just 4.29 gallons per hour. That's 90% less water usage, which means your utility bills will thank you month after month.

The flavor preservation aspect is where steam cooking really shines. Your vegetables keep their vibrant colors and crisp textures instead of turning into mushy disappointments. Proteins stay moist and tender without the guesswork that comes with grilling or sautéing.

Scientific research on nutrient retention backs up what many chefs already know - steam cooking maintains more vitamins and minerals compared to boiling or frying. In today's health-conscious market, that's not just a nice bonus; it's a competitive advantage you can actually market.

How Steam Cooking Works

Understanding the science behind steam cooking helps you get the most out of your equipment investment. The process is beautifully simple: moist heat generated by converting water into steam at around 212°F creates a cooking environment that's both gentle and incredibly effective.

Most commercial steamers operate at a standard input steam pressure of 0.02 MPa - that's just enough pressure to ensure safe, consistent operation without the complexity of high-pressure systems. This controlled environment eliminates hot spots and delivers even heat distribution throughout the cooking chamber.

Modern units often incorporate convection steam technology, using fans to circulate steam more efficiently. This combination increases steam velocity for faster, more uniform results while maintaining consistent temperatures throughout the cooking chamber.

Key Features & Buying Criteria

Selecting the perfect commercial food steamer for your restaurant doesn't have to be overwhelming. Think of it like choosing the right team member - you need someone who fits your space, handles your workload, and won't break your budget.

Pan capacity is where most restaurant owners start, and for good reason. A busy breakfast diner might thrive with a compact 3-pan countertop unit, while a catering operation needs the muscle of a 12-pan floor model. The sweet spot for most restaurants? A 6-pan unit handles moderate volume beautifully, while 10-12 pan models are perfect for banquet halls and high-volume kitchens.

The electric versus gas debate often comes down to what your kitchen can handle. Electric steamers offer incredible precision with their 8.5 kW to 32 kW range, and they're a lifesaver when gas lines aren't available. Gas models pack serious punch with 32,000 to 200,000 BTU output, heating faster and often costing less to operate where natural gas is plentiful.

Boilerless or connectionless steamers are changing the game entirely. These clever units don't need direct water line connections, giving you flexibility to move them around your kitchen. Even better, they eliminate the mineral buildup that plagues traditional boiler systems, meaning less headache and more cooking time.

Countertop versus floor models is really about maximizing your kitchen's potential. Tight on space? Countertop units are your friend. Need serious production capacity? Floor models deliver the volume you need without compromise.

Smart features like SmartDrain technology automatically flush the steam generator using sloped bottoms and positive water pressure. Auto-fill systems keep steam generation continuous during your busiest rushes, so you're never left waiting.

Don't overlook safety features in a commercial kitchen. Safety locks prevent doors from opening during operation, automatic shut-off protects against dry burning, and pressure relief systems prevent dangerous over-pressurization.

More info about financing options can help you get the right equipment without straining your cash flow.

Installation & Utility Requirements

Getting your commercial food steamer properly installed sets the foundation for years of reliable service. Electric steamers need specific voltage and phase configurations - single-phase works beautifully for smaller models, while three-phase power is essential for high-capacity units.

Gas steamers demand adequate BTU supply from your gas line. A 144,000 BTU unit needs substantial gas flow, so verify your existing service can handle the load before ordering.

Water quality makes or breaks your steamer's performance. Hard water accelerates mineral buildup, forcing you into frequent descaling cycles. Installing a water treatment system reduces maintenance headaches and extends your equipment's life significantly.

Ventilation needs vary by model and location. Steam generation increases kitchen humidity, so ensure your exhaust system can handle the extra moisture.

Maintenance & Troubleshooting Essentials

Keeping your commercial food steamer running smoothly doesn't require a maintenance degree - just consistent attention to a few key areas. Daily tasks include draining the water tank at least twice weekly to prevent scale buildup and wiping down gaskets to maintain proper sealing.

Descaling is your most important maintenance task. Use a 5% lemon solution or commercial descaling products in a boil-soak-boil process, then flush thoroughly. Hard water areas might need weekly descaling, while soft water areas can stretch intervals longer.

Auto-water replenishment systems prevent dry burning, which is a common cause of expensive heating element failure. These systems automatically add water when levels drop, protecting your investment from damage.

Dry-burn prevention systems monitor water levels and shut down heating elements when water runs low. This safety feature prevents costly repairs and potential hazards.

Modern low-water steamers have simplified filter maintenance dramatically. You'll only need to change filters once yearly compared to twice yearly for traditional models, reducing both maintenance costs and downtime.

Common troubleshooting issues include no steam production, uneven heating, leaks, and control malfunctions. Most problems stem from water quality issues, blocked vents, or worn gaskets.

Best Commercial Food Steamer Models by Category

Finding the right commercial food steamer for your restaurant doesn't have to be overwhelming. We've broken down the market into clear categories to help you identify which type matches your operation's needs and budget.

| Category | Capacity | Power Range | Price Range | Best For |

|---|---|---|---|---|

| Electric Countertop | 3-6 pans | 8.5-18 kW | $3,500-$8,500 | Small restaurants, cafes |

| Gas Floor Model | 10-12 pans | 144,000 BTU | $25,000-$40,000 | High-volume operations |

| Boilerless | 3-10 pans | 6-32 kW | $6,000-$15,000 | Flexible installations |

| Multi-Compartment | 10+ pans | 18-32 kW | $15,000-$35,000 | Banquet halls, institutions |

The beauty of today's steamer market is that there's truly something for every kitchen size and budget. Whether you're running a cozy neighborhood cafe or managing a busy banquet hall, the right steamer can transform how you prepare food.

Electric Commercial Food Steamer

Electric steamers are the workhorses of smaller kitchens, offering precision control and easy installation. The 8.5 kW countertop models fit perfectly in tight spaces, while the powerful 32 kW floor units can handle serious production without breaking a sweat.

Here's what makes electric steamers special: Low Water Energy technology cuts water consumption by up to 90% compared to older models. Your utility bills will thank you, and you'll spend less time on maintenance tasks like descaling and filter changes.

Electric units shine when it comes to consistent performance. Set your temperature and timer, and you'll get the same results every time. This reliability is perfect for kitchens where consistency matters more than raw speed.

Installation is typically straightforward - just electrical connections and you're ready to cook. No gas lines to worry about, no complex venting requirements. Many electric models qualify for ENERGY STAR rebates, which can offset your initial investment.

Popular models include 3-pan countertop units starting around $8,400 and 5-pan models reaching $9,100. These units typically run on 208V or 240V power, making them compatible with most commercial kitchen electrical systems.

Gas Commercial Food Steamer

When you need maximum power and lightning-fast startup, gas steamers deliver. With BTU ratings from 32,000 to 200,000, these units generate steam quickly and maintain consistent output during your busiest service periods.

Gas steamers are built for high-volume operations. The 10-pan floor models represent the sweet spot - enough capacity to handle continuous production without overwhelming your kitchen space. These units recover quickly between batches, so you're never waiting around for steam generation.

The cost advantage of gas becomes clear in areas with abundant natural gas supply. Operating costs are typically lower than electric, and the instant heat response gives experienced cooks excellent control over the steaming process.

Professional installation is non-negotiable with gas units. Your gas service needs to handle the BTU requirements - a 144,000 BTU unit demands substantial gas flow. Proper ventilation is also crucial for safe operation.

Quality 10-pan floor units typically run around $30,000. These workhorses feature heavy-duty 304 stainless steel construction and robust door mechanisms designed to withstand the demands of commercial kitchens.

Boilerless / Connectionless Units

Boilerless steamers are game-changers for kitchens that need flexibility and reduced maintenance. These clever units eliminate traditional water connections while delivering energy savings of up to 67% compared to conventional steamers.

The connectionless design prevents the mineral buildup that plagues traditional boiler systems. Less descaling, fewer service calls, and longer equipment life translate to real money saved over time. Your maintenance schedule becomes much more manageable.

Mobility is a huge advantage - you can relocate these units as your kitchen needs evolve. This flexibility is invaluable for seasonal businesses or restaurants that frequently reconfigure their layouts.

Don't worry about performance compromises. Modern boilerless units use advanced steam generation technology that matches or exceeds traditional steamers. You get the same great results with much less complexity.

Pricing ranges from $6,000 for smaller models to $15,000 for high-capacity units. The simplified design often means lower purchase prices and reduced installation costs, making them attractive for budget-conscious operations.

Multi-Compartment High-Volume Steamers

When you need to feed crowds efficiently, multi-compartment steamers with 10+ pan capacity become essential. These units enable serious batch cooking with independent compartments that can operate at different temperatures simultaneously.

The ability to steam different foods concurrently maximizes kitchen efficiency. Prepare vegetables, proteins, and starches all at once, streamlining your prep work and reducing labor costs during busy periods.

Premium models feature IoT connectivity for remote monitoring and energy optimization. Real-time status displays help kitchen managers track cooking progress and spot potential issues before they impact service.

Independent compartment control means you can run partial loads efficiently. Not every service requires full capacity, so operating selected compartments saves energy and water during slower periods.

These powerhouse units typically require three-phase electrical service and substantial installation planning. Professional installation ensures proper utility connections and compliance with local codes, protecting your investment and ensuring safe operation.

Boosting Kitchen Workflow With Steam

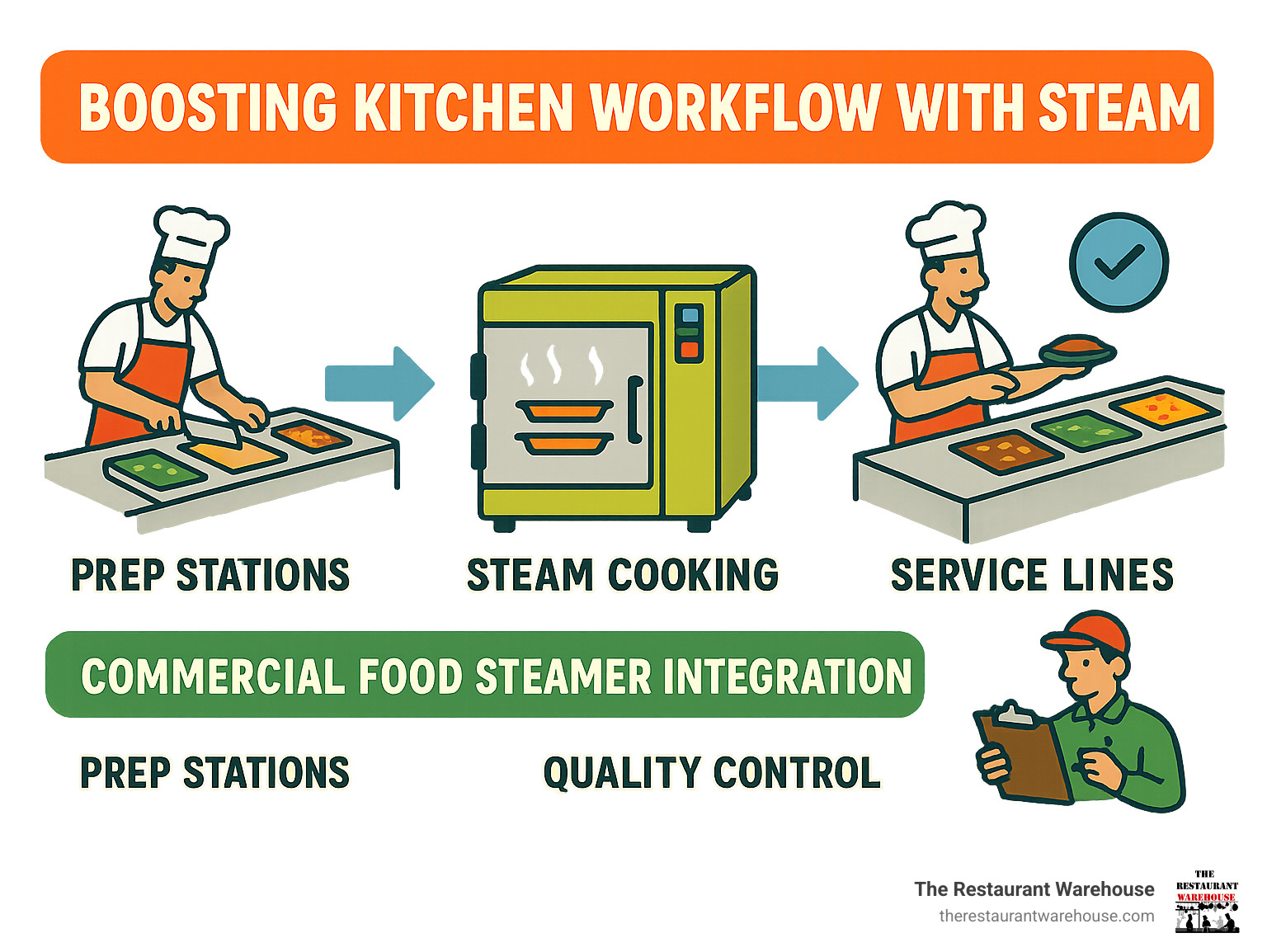

The magic happens when you see how a commercial food steamer transforms your entire kitchen operation. We've watched restaurant owners shake their heads in amazement as their prep times drop by 30% while their food quality actually improves.

Think about your busiest service periods. With traditional cooking methods, you're juggling multiple pans, watching timers, and praying nothing burns while you're plating another order. Steam cooking changes this completely. You can load up multiple pans with vegetables, rice, and proteins, set your timer, and walk away.

Batch cooking becomes your secret weapon. Instead of cooking items one at a time, you're preparing entire meal components in parallel. This isn't just about speed - it's about changing how your kitchen operates during those crazy rush periods.

For a la carte service, steam delivers something remarkable: consistency without compromise. Each portion cooks exactly the same way, every single time. Your customers get the same perfectly steamed vegetables whether they order at 6 PM or 9 PM.

HACCP safety compliance becomes much simpler with steam cooking. The controlled high-temperature environment naturally eliminates foodborne pathogens, and many modern steamers automatically log cooking temperatures for you.

IoT monitoring in advanced steamers gives you something restaurant owners have always wanted: real-time insight into your kitchen operations. You can track energy usage, monitor cooking cycles, and even predict when maintenance is needed - all from your phone.

Staff training becomes dramatically easier. Steam cooking's consistent, controlled environment means new employees can produce quality results much faster. Instead of spending weeks training someone on the nuances of sautéing or grilling, they can master steam cooking in days.

Menu expansion opportunities open up naturally. You can offer healthier options that appeal to health-conscious customers, explore ethnic cuisines that rely heavily on steaming, and serve fresh vegetables that actually retain their vibrant colors and nutritional value.

Environmental & Cost Advantages

ENERGY STAR certified steamers do more than just save money - they often qualify for utility rebates that can significantly reduce your initial investment. These units have proven their efficiency through rigorous testing.

The 50% energy reduction we see with modern steamer technology isn't just a marketing number - it shows up directly on your utility bills. Demand-based steam generation only uses energy when you're actually cooking, eliminating the waste of keeping traditional systems constantly heated.

Polyurethane foam insulation in quality steamers retains heat for over 4 hours after shutdown. This means during extended service periods, the unit maintains temperature with minimal energy input.

Maintenance costs drop noticeably with modern steamers. Filter changes go from twice yearly to once yearly with low-water units. This isn't just about saving money on filters - it's about reducing downtime and simplifying your maintenance schedule.

Water treatment system integration requires an upfront investment, but the reduced descaling frequency and extended equipment life make it worthwhile.

Commercial Kitchen Steam Cleaner technology extends beyond cooking into cleaning applications. Steam cleaning eliminates the need for harsh chemicals while providing superior sanitation results.

Waste reduction happens naturally with steam cooking. The precise control prevents overcooking and food waste. Better portion control and consistent results mean fewer remakes and happier customers.

Frequently Asked Questions About Commercial Food Steamers

What foods can I cook in a commercial food steamer?

You'll be amazed at what you can create with a commercial food steamer. Most people think vegetables first, and they're absolutely right - broccoli, carrots, leafy greens, and root vegetables all come out perfect. The colors stay vibrant, the nutrients stick around, and the textures are just right.

Seafood is where steamers really shine. Fish fillets cook beautifully in 5-10 minutes without that rubbery texture you get from overcooking. Shrimp turn out perfect in just 3-6 minutes, and mussels open up nicely in 8-10 minutes.

Rice becomes foolproof in a steamer. Depending on your model, you can prepare anywhere from 20 to 280 kg per hour - that's a game-changer for Asian restaurants or any place where rice is a staple.

Don't overlook proteins either. Chicken breasts steam perfectly in 15-20 minutes, boneless thighs in 10-15 minutes, and even beef cubes work well with 20-30 minutes of steam time. The moist environment keeps everything tender while cooking it through completely.

Dim sum items like bao, shumai, and dumplings are traditional steamer favorites. The gentle heat creates those perfect, pillowy textures that make dim sum so special.

How do I size a steamer for my restaurant?

Getting the right size commercial food steamer is crucial for smooth operations. Start by looking at your peak service volume and what you're actually planning to steam.

Pan count tells the whole story. A 3-pan unit handles small cafes serving 50-100 covers daily without breaking a sweat. Medium-volume restaurants pushing 200-300 covers typically need 5-6 pan capacity to keep up. High-volume operations and banquet facilities should look at 10-12 pan units.

Think about your menu mix too. If steamed items make up 30% of your menu, size accordingly. Restaurants featuring lots of vegetable sides, Asian cuisines, or health-focused options need more capacity than a typical burger joint.

Peak service periods are what really matter. Even if your daily volume seems manageable, you need enough capacity to handle the dinner rush without creating bottlenecks.

Your kitchen footprint plays a big role in your options. Countertop models save precious floor space but limit your capacity. Floor models give you maximum cooking power but need adequate space and proper clearances for safe operation.

What daily maintenance does a steamer need?

The beauty of modern steamers is that they don't demand much daily attention. A few simple tasks keep everything running smoothly and prevent expensive repairs down the road.

Drain the water tank at least twice weekly, or daily if you're dealing with hard water. This simple step prevents mineral buildup that can damage heating elements and kill efficiency.

Wipe down door gaskets every day to maintain proper sealing. Clean gaskets keep steam where it belongs and prevent energy waste. A damp cloth removes food residue - just check for wear or damage while you're at it.

Clean the cooking chamber after each use. Remove any food debris and wipe down surfaces with a damp cloth. This prevents funky odors and keeps things sanitary.

Check water levels in units without auto-fill systems. Never run a steamer dry - it can damage heating elements and create safety hazards.

Weekly descaling might be necessary in hard water areas. Use manufacturer-recommended solutions or a 5% lemon solution. Follow the boil-soak-boil process, then flush everything thoroughly.

Professional service once a year ensures optimal performance and catches potential issues before they become wallet-draining problems.

Conclusion

Choosing the right commercial food steamer isn't just about buying equipment - it's about changing how your kitchen operates. The numbers speak for themselves: 90% water savings with modern LWE technology, 67% energy reduction with connectionless designs, and cooking capacity that can handle everything from a small cafe's daily vegetables to a banquet hall's massive batch cooking needs.

We've walked through the entire landscape of steam cooking technology, from compact 3-pan countertop units perfect for growing cafes to powerhouse 12-pan floor models that handle serious production volumes. The beauty of steam cooking lies in its versatility - whether you're steaming delicate fish fillets, preparing perfect rice, or keeping vegetables vibrant and nutritious.

A quality steamer does exactly what busy restaurant owners need. Load your pans, set your timer, and move on to the hundred other tasks demanding your attention. No babysitting, no stirring, no burned batches during the dinner rush.

At The Restaurant Warehouse, we've built our reputation on making quality equipment accessible. Our wholesale pricing approach eliminates the high commissions and retail overhead that can make equipment investments feel overwhelming. We understand that every dollar counts when you're building or upgrading your kitchen.

The technology keeps getting better too. IoT connectivity lets you monitor your steamer remotely, improved energy efficiency cuts your utility bills, and simplified maintenance means less downtime and fewer service calls.

Think about your current kitchen challenges for a moment. Are you spending too much time on prep work that could be automated? Struggling with inconsistent food quality during busy periods? A well-chosen commercial food steamer addresses these pain points while opening up new menu possibilities.

The investment typically pays for itself within 18-24 months through reduced labor costs, lower utility bills, and improved food quality. More importantly, it gives you the operational flexibility to grow your business without being constrained by equipment limitations.

Your customers deserve fresh, nutritious food prepared with care and consistency. Your bottom line deserves the operational advantages that modern steam technology provides. The real question isn't whether you can afford a commercial food steamer - it's whether you can afford to keep operating without one.

Ready to explore how steam technology can work for your specific situation? Our team understands the unique challenges facing foodservice operators, and we're here to help you find the right solution for your needs and budget.

More info about Commercial Kitchen Equipment Guide provides additional insights into optimizing your entire kitchen operation.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment