The Definitive Guide to Commercial Griddle Options

The Workhorse of the Commercial Kitchen

Commercial griddles are the indispensable, versatile workhorses that power the engine of any successful food service operation. From busy urban diners and high-volume university cafeterias to quaint local cafes and mobile food trucks, these heavy-duty cooking surfaces are the cornerstone of culinary productivity. Their expansive, flat tops are designed for maximum efficiency, allowing chefs to brown, sear, toast, and cook an incredible variety of menu items across all dayparts. Imagine the morning rush: pancakes sizzling, eggs frying, and bacon crisping all on one surface. As the day progresses, that same griddle seamlessly transitions to searing burger patties for lunch and delicately cooking fish fillets for dinner service. This adaptability is what makes the commercial griddle a non-negotiable asset in any professional kitchen.

A Comprehensive Overview of Commercial Griddles

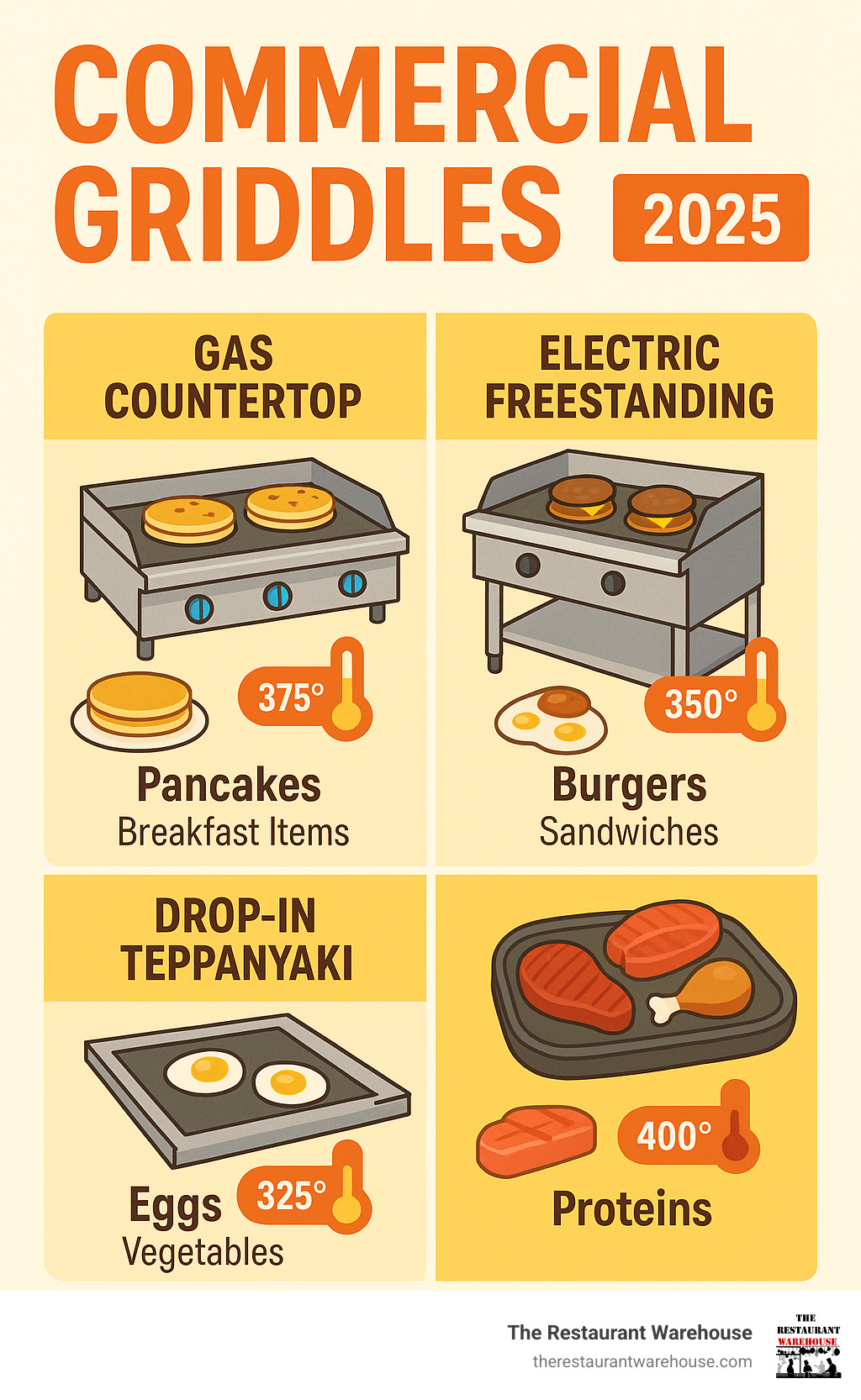

Navigating commercial griddles requires understanding their core attributes. They are primarily categorized by their power source, which can be gas or electric, and their physical form, including countertop, freestanding, and drop-in models. Sizes vary dramatically to fit any space and volume requirement, typically ranging from a compact 24 inches to an expansive 72 inches in width. The cooking surface itself, known as the griddle plate, is a critical component available in different materials like economical steel, non-stick chrome, or high-performance composite. Control systems also vary, from basic manual knobs to precise thermostatic dials and programmable digital interfaces. Essential features like individually controlled burner zones for temperature versatility, robust grease management systems for safety and cleanliness, and protective splash guards are standard in professional-grade units. These griddles are the go-to equipment for everything from breakfast staples and proteins to sandwiches and vegetables, making them perfect for any high-volume cooking scenario.

Choosing the right griddle is a strategic decision that directly impacts a kitchen's efficiency, food quality, and ultimately, its profitability. While gas griddles have traditionally dominated the market due to their lower operating costs and responsive heat control, modern electric models offer unparalleled temperature consistency and are often easier to install where gas lines are unavailable. The success of your operation hinges on a clear understanding of your specific needs. A high-traffic breakfast diner will prioritize a large, multi-zone griddle for handling diverse orders simultaneously, whereas a steakhouse will demand a thick plate capable of retaining intense heat for the perfect sear. Factors like plate thickness, control precision, and overall size are not just specifications—they are variables that directly influence cooking speed, consistency, and operational costs. From economical 1/2-inch steel plates ideal for smaller kitchens to heavy-duty 1-inch composite surfaces engineered for relentless, high-volume production, there is a griddle configuration perfectly suited for every culinary ambition and budget.

Understanding the Core Types of Commercial Griddles

Choosing the right commercial griddle is a foundational decision for any kitchen. The selection process begins with two fundamental classifications: how the unit is powered and how it will be physically integrated into your kitchen space. Getting these basics right is crucial, as it ensures your investment aligns perfectly with your menu's demands, your kitchen's workflow, spatial constraints, and your utility infrastructure.

Power Source: Gas vs. Electric Griddles

Your choice of power source is a long-term decision that significantly impacts daily operating costs, preheating speed, temperature recovery, and installation complexity. Each type offers distinct advantages custom to different operational needs.

Gas griddles are the long-standing industry standard, widely favored for their rapid heat-up times and lower ongoing utility costs in most regions. They provide chefs with instant, responsive control over the flame, allowing for quick adjustments. They are available in two fuel types:

- Natural Gas: These models connect directly to your building's existing gas line, providing a continuous and highly economical fuel supply. They are the preferred choice for permanent, high-volume kitchen installations.

- Liquid Propane (LP): Propane models offer best portability, using replaceable or refillable tanks. This makes them the ideal solution for food trucks, outdoor catering events, and kitchens located in buildings without access to a natural gas line.

The power of a gas griddle is measured in BTUs (British Thermal Units). A higher BTU rating indicates greater heating power, leading to faster preheating and quicker temperature recovery when cold food is placed on the surface. A typical 36-inch griddle might have a total output of 90,000 BTUs, with three 30,000 BTU burners.

Electric griddles are champions of consistency. They excel at providing incredibly even heat distribution across the entire cooking surface, thanks to heating elements embedded beneath the plate. This meticulous temperature control eliminates hot and cold spots, making them the superior choice for delicate items like pancakes, eggs, and crepes that require uniform browning. While they may have a higher initial purchase price and require specific electrical infrastructure (e.g., 208V or 240V, single-phase or three-phase power), their precision and consistency are invaluable for quality-focused menus. They are also an excellent option in locations with strict emissions regulations or where gas installation is impractical.

For a cutting-edge solution, infrared gas units bridge the gap between the two. These griddles use ceramic plates to generate intense infrared heat, which cooks food faster and more efficiently than standard gas burners. This technology offers superior heat transfer, leading to rapid recovery times and a significant reduction in gas consumption, often between 12% to 20%. This efficiency translates directly into lower utility bills and increased production capacity during peak hours.

For deeper insights into your power options, we've created comprehensive guides: our Commercial Gas Flat Top Grill Guide covers everything gas-powered, while our Best Electric Griddles 2024 explores the latest in electric technology.

Form Factor: Countertop, Freestanding, and Drop-In Models

How a griddle integrates into your kitchen's layout is just as important as how it's powered. The form factor dictates workflow, space utilization, and even the customer experience.

Countertop griddles are the epitome of versatility and space efficiency. These compact units are designed to sit securely on existing work tables or refrigerated chef bases. They are an excellent choice for smaller operations like cafes and concession stands, or as a way to add griddling capacity to a larger kitchen without a complete line overhaul. Their flexibility allows you to optimize your layout and expand your menu offerings with a minimal footprint. You can explore the full potential of these space-savers in our detailed Countertop Griddle guide.

Freestanding griddles are the heavy-duty anchors of high-volume kitchens. These robust units are built for continuous, demanding use and come with their own integrated support legs or a cabinet base. A cabinet base is a highly practical feature, offering valuable, easily accessible storage for pots, pans, and cooking utensils. Some models even feature refrigerated bases to keep ingredients like meat patties, cheese, and vegetables chilled and within arm's reach. These floor models are designed to be a central part of the main cooking line in busy restaurants, diners, and institutional settings.

Drop-in griddles offer a sleek, custom, and integrated appearance. These units are mounted flush into a countertop, creating a seamless surface that is perfect for display cooking or front-of-house applications. They are the star of hibachi and teppanyaki restaurants, where the chef's performance is part of the dining experience. Their design often concentrates intense heat in the center for active cooking, while the cooler outer edges serve as a convenient warming or staging area. This maximizes both performance and presentation, making them a powerful tool for engaging customers.

The Griddle Plate: Your Cooking Surface Showdown

The heart and soul of any commercial griddle is its cooking plate. This is the surface where the magic happens, and its material composition and thickness are the most critical factors influencing everything from heat distribution and recovery time to food quality, flavor transfer, and the daily cleanup routine. Selecting the right plate isn't just a preference; it's a strategic choice that must align with your menu, volume, and operational style.

Griddle Plate Materials: Steel, Chrome, and Composite

There are three primary materials used for griddle plates, each offering a unique combination of performance, maintenance requirements, and cost.

Steel griddle plates are the most common, economical, and traditional choice. They are incredibly durable, able to withstand the rigors of a demanding kitchen environment, and offer excellent heat retention. A properly maintained steel plate becomes a reliable workhorse for a vast range of menu items. The key to open uping a steel griddle's potential is seasoning. This process involves applying a thin layer of oil and heating it until it polymerizes, creating a natural, non-stick surface that improves with every use. This seasoned layer not only prevents food from sticking but also protects the steel from rust. Consistent seasoning and cleaning are essential for peak performance.

Chrome plates offer a premium, non-stick cooking experience from the very first use. The hard, mirror-like chrome finish is non-porous, which provides several distinct advantages. First, it significantly limits flavor transfer, allowing you to cook fish and then pancakes with minimal taste carryover. Second, it radiates far less heat into the kitchen, creating a cooler and more comfortable work environment for staff. Third, cleanup is remarkably easy, often requiring just a wipe-down with a damp cloth and non-abrasive cleaner. Chrome is ideal for display kitchens where appearance matters and for cooking delicate items like eggs and seafood. The primary consideration is that chrome surfaces are sensitive to metal utensils and abrasive scrubbers, which can scratch the finish.

Composite plates represent the pinnacle of griddle technology, engineered for maximum performance in the most demanding settings. These plates typically feature a steel core layered with highly conductive materials like aluminum. This construction provides superior heat transfer that can be up to five times more efficient than standard steel. The practical benefit is exceptionally fast preheating and near-instantaneous recovery times, even when the griddle is slammed with frozen burger patties. This means higher production capacity and consistent cooking temperatures during the busiest rushes. They also offer excellent non-stick properties and prevent flavor transfer, combining the best attributes of steel and chrome. While they carry a higher initial cost, their efficiency and productivity provide a significant return on investment for high-volume operations.

The Importance of Griddle Plate Thickness

Plate thickness, which typically ranges from 1/2-inch to 1-inch, is directly proportional to the griddle's ability to act as a thermal battery. A thicker plate absorbs and holds more heat, ensuring a stable surface temperature even when loaded with cold or frozen food. This thermal stability is crucial for consistent results.

- A 1/2-inch thick plate is considered light-duty. It heats up quickly but also loses heat faster when food is added. This makes it suitable for low-volume kitchens, cafes, or applications with intermittent use, such as warming tortillas or toasting buns.

- A 3/4-inch thick plate is the versatile all-rounder. It provides a good balance between a reasonably fast heat-up time and solid heat retention. This thickness is an excellent choice for most medium-volume, general-purpose kitchens that cook a varied menu throughout the day, from breakfast eggs to lunch sandwiches.

- A 1-inch thick plate is the heavy-duty champion, offering the best heat retention possible. While it takes the longest to preheat, it maintains an incredibly stable temperature under the most demanding, high-volume conditions. This makes it the undisputed choice for kitchens that continuously cook frozen products, like burger patties, ensuring every item gets a perfect, consistent sear without dropping the surface temperature.

This table summarizes the best use for each thickness:

| Plate Thickness | Recommended Volume | Heat Retention | Recovery Time | Best For |

|---|---|---|---|---|

| 1/2-inch | Low | Moderate | Fast | Light-duty, quick-serve, occasional use |

| 3/4-inch | Medium | Good | Moderate | General purpose, varied menu, consistent use |

| 1-inch | High | Excellent | Fast | High-volume, frozen foods, continuous use |

Mastering Griddle Performance: Controls and Technology

A commercial griddle is far more than a simple hot slab of metal; it's a precision instrument designed for consistency and control. The technology embedded within—from the control style to the burner design—is what empowers chefs to transform raw ingredients into perfectly cooked menu items, time after time. Understanding these features is the key to separating kitchen chaos from culinary excellence, whether you're navigating the morning breakfast rush or executing a flawless dinner service.

Choosing Your Control Style: Manual vs. Thermostatic vs. Digital

The level of precision your menu requires will dictate the best control style for your operation. Each type offers a different balance of simplicity, accuracy, and cost.

Manual controls are the most basic, durable, and budget-friendly option. They feature simple knobs (low, medium, high) that adjust the gas flow or power level without a specific temperature display. This straightforward design has fewer electronic components that can fail, making them exceptionally reliable. Manual controls are a great choice for kitchens with consistent, simple menus (like a burger joint) and experienced cooks who can skillfully gauge temperature by sight, sound, and feel, managing heat zones intuitively.

Thermostatic controls are the most popular choice in commercial kitchens, offering a significant step up in precision. These controls allow you to set a specific target temperature (e.g., 350°F). The griddle then automatically cycles its burners or elements on and off to maintain that heat. This ensures consistency for operations with varied menus and is easier for less experienced staff to use. There are two main types:

- Snap-action thermostats are electromechanical and regulate heat within a wider temperature range (e.g., +/- 20-30°F). They are reliable and cost-effective for general-purpose cooking.

- Solid-state electronic controls offer much tighter temperature regulation (e.g., +/- 5-10°F). This superior accuracy is ideal for delicate foods like eggs, crepes, or sauces where precise temperature is critical to quality.

Digital controls represent the apex of griddle technology, providing unparalleled precision and programmability. These systems feature a digital display and allow for exact temperature inputs. Many models offer advanced features like programmable timers, recipe storage for multi-stage cooking processes, and even diagnostic alerts for maintenance. They eliminate guesswork, ensure perfect replication of menu items across different shifts and staff members, and are a worthwhile investment for high-end restaurants, chains, and any operation focused on absolute consistency.

For deeper insights into how these control systems can transform your cooking operation, explore our comprehensive Guide to Griddle Controls.

Key Components and Technologies in Commercial Griddles

Beyond the controls, several critical components define a griddle's day-to-day performance, safety, and ease of use.

Burner Design and Zoning: In gas griddles, burner design is crucial for even heating. Most models use powerful U-shaped or H-shaped burners strategically spaced every 8 to 12 inches to distribute heat effectively across the plate and minimize cold spots. A key feature is having individual controls for each burner. This allows a chef to create multiple temperature zones on a single griddle surface—for example, setting one zone to high heat (400°F) for searing steaks, a middle zone to medium heat (350°F) for cooking hash browns, and a third zone to low heat (250°F) for holding cooked items.

Grease Management Systems: Effective grease management is non-negotiable for safety and sanitation. Every griddle features a grease trough or channel, typically at the front or back, that collects rendered fat and food debris. This runoff is funneled into removable drip pans or grease drawers. A well-designed system with a wide, sloped trough and a large-capacity pan prevents dangerous grease buildup and flare-ups. It is also a key component for adhering to food safety standards, such as those outlined by NSF International.

Splashguards: These are raised metal barriers, typically 3 inches high or more, running along the sides and back of the griddle plate. Their simple but vital job is to contain grease splatter, protecting staff from burns and keeping the surrounding walls and equipment cleaner and safer.

Advanced Performance Features: Modern griddles incorporate technology to boost output and efficiency. Rapid recovery technology, inherent in composite and thick steel plates, helps the griddle return to the set temperature almost instantly after cold food is added, which is essential for maintaining throughput during peak hours. High-efficiency burner systems, such as those using infrared technology, optimize heat transfer to the plate, cutting gas consumption by 12% to 20% and lowering utility bills over the life of the unit.

Selecting and Maintaining Your Commercial Griddle

Choosing a commercial griddle is a significant strategic investment that directly shapes your kitchen's daily workflow, menu capabilities, and overall output. After carefully selecting the model that aligns with your operational goals, implementing a rigorous maintenance routine is essential to protect that investment, ensure food safety, and guarantee reliable, peak performance for years to come.

Key Factors for Purchasing the Right Commercial Griddle

To cut through the vast number of options, focus on these key decision-making factors to find the perfect griddle for your kitchen.

Size and Capacity: Griddle width typically ranges from 24 to 72 inches. The most important consideration is your projected peak production volume, not just the physical space you have available. Think in terms of output: a 24-inch model might be perfect for a small cafe, while a 36-inch griddle can handle the lunch rush at a diner. A high-volume hotel or institution might require a 48-inch, 60-inch, or even a 72-inch unit to allow multiple cooks to work side-by-side without interruption. A good rule of thumb is to allow at least 12 inches of width per cook. Our Guide to 24-inch Models can help you assess if a compact unit is sufficient for your needs.

Foodservice Application: Your menu is the ultimate guide to the ideal griddle. Different culinary concepts have different needs:

- Breakfast Diners: Require maximum versatility. A large griddle with multiple thermostatic control zones is essential for simultaneously cooking pancakes, eggs, bacon, and home fries at their respective ideal temperatures.

- High-Volume Kitchens (e.g., Schools, Hospitals): Demand durability and heat retention. A freestanding model with a 1-inch thick plate is necessary to handle the constant load of cooking, especially with frozen products, without losing temperature.

- Steakhouses and Burger Joints: Need intense, sustained searing power. A thick steel or composite plate with high-BTU gas burners is crucial for achieving a perfect crust and consistent results.

- Space-Constrained Kitchens or Food Trucks: Benefit from compact, efficient solutions. A countertop or drop-in griddle maximizes cooking area without consuming valuable floor space.

Specialized Options: Don't overlook griddles designed for specific tasks that can dramatically boost efficiency. Clamshell griddles, which feature a hinged top plate, cook food from both sides simultaneously. This can cut cooking times for items like burgers, chicken breasts, and paninis by more than half, increasing throughput and reducing labor. Our guide, From Shawarma to Panini: Finding Your Perfect Commercial Griller, explores these powerful units. For front-of-house theater, Teppanyaki griddles are specifically built for display cooking, turning the meal preparation into an engaging customer experience.

Essential Maintenance for Longevity and Performance

A well-maintained griddle is safer, more energy-efficient, cooks better food, and will last significantly longer. A consistent care routine is a non-negotiable part of professional kitchen management.

Daily Cleaning: This is the foundation of griddle care and must be performed after every service. While the griddle is still warm (not hot), use a scraper to remove food debris and push it into the grease trough. Empty the grease trap completely—a full trap is a serious fire hazard. Wipe down the surface with a non-abrasive pad and a small amount of clean water or a vinegar solution, then dry thoroughly.

Deep Cleaning: Periodically, your griddle will require a deep clean to remove tough, carbonized grease buildup. This process is often called "bricking the griddle." With the surface at a low, warm temperature, use a griddle brick (a porous pumice stone) or a griddle screen with a pad holder to scrub the surface, working in the direction of the grain if visible. This scouring action lifts baked-on residue without damaging the plate. Afterward, rinse the surface, wipe clean, and thoroughly degrease the entire trough and drain system. Our Bricking the Griddle guide provides a detailed step-by-step tutorial.

Protecting the Plate: Proper plate care is vital. For steel griddles, seasoning after cleaning is crucial. Apply a very thin coat of cooking oil to the clean, warm surface and heat it until it begins to smoke slightly. This polymerizes the oil, creating a protective, non-stick layer. For chrome plates, never use abrasive bricks or metal scrapers. Use only soft cloths and manufacturer-approved, non-abrasive cleaners to protect the finish.

Regular Inspection and Calibration: On a weekly or monthly basis, perform quick inspections. For gas models, check connections for leaks using a soap solution. For all models, verify that the thermostats are calibrated correctly by using a surface or infrared thermometer to check the plate temperature against the dial setting. Inaccurate temperatures lead to inconsistent food quality and waste. A quick calibration can restore your griddle to its peak performance.

Conclusion: Investing in the Right Griddle for Your Success

After exploring the critical details of commercial griddles, it becomes abundantly clear that they are far more than just another piece of kitchen equipment—they are the very heart of a productive, profitable culinary operation. From the first pancake served at the breakfast rush to the last perfectly seared steak of the night, your choice of griddle profoundly impacts your kitchen's efficiency, your menu's quality, and your staff's workflow.

Making the right selection is a process of thoughtfully matching the unit's core features—its power source, plate material, physical size, and control technology—to the unique demands of your business. A cozy neighborhood cafe has fundamentally different needs than a high-volume institutional cafeteria, and the ideal griddle will reflect and serve those specific operational realities. Just as important as the initial purchase is the unwavering commitment to consistent, thorough maintenance. Daily cleaning, periodic deep cleaning, and proper seasoning are not mundane chores; they are essential investments in your equipment's longevity, its safety, and its ability to perform at the highest level day in and day out.

At The Restaurant Warehouse, we understand that every one of these details translates directly to your bottom line. We have built our entire business model around a single, powerful idea: to eliminate the exorbitant retail markups and unnecessary middleman costs that often put high-quality, professional-grade equipment out of reach for many business owners.

Our mission is straightforward and transparent: to supply you with the professional-grade commercial griddles you need at true wholesale pricing. Whether you are launching your first food truck, renovating an established restaurant, or outfitting a large-scale catering facility, we believe you should never have to compromise on the quality of your tools to stay within your budget.

The griddle you choose will be a trusted partner in your kitchen for many years. Make a smart, informed choice that fits your space, your menu, your budget, and your highest culinary ambitions.

Ready to find the perfect griddle to anchor your kitchen? Explore our complete guide to commercial griddles and find how the right equipment can lift your capabilities and drive your success.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment