The Anatomy of Awesome Pizza: Demystifying Prep Tables

Understanding What You Call a Pizza Prep Table

What do you call pizza prep table equipment in the , demanding world of the foodservice industry? The answer isn't as simple as one might assume. These highly specialized, multi-functional workstations are known by a variety of names, each shedding light on a different aspect of their indispensable role in a modern kitchen. While the names may vary, their purpose is singular: to empower chefs to create delicious, consistent pizzas with maximum efficiency and uncompromising food safety.

Common terminology you'll encounter includes:

- Pizza prep table - The most widely used and universally understood term.

- Pizza prep station - This name emphasizes its role as an all-in-one, centralized hub for the entire pizza-building process.

- Pizza preparation refrigerator - This technical term highlights the critical integrated cooling function that is the heart of the unit.

- Refrigerated pizza prep table - A more descriptive and technically accurate name often used in equipment catalogs and by suppliers.

- Pizza assembly table - This term focuses specifically on the hands-on process of constructing the pizza, from stretching the dough to arranging the toppings.

Behind every perfectly cooked, mouth-watering slice of pizza lies an unsung hero: the pizza prep table. While customers marvel at the final product, they rarely glimpse the sophisticated engineering that makes high-volume, high-quality pizza production not just possible, but profitable. In the chaotic symphony of a busy pizzeria, these stainless steel workstations are the conductors, orchestrating a seamless workflow that transforms raw ingredients into culinary art.

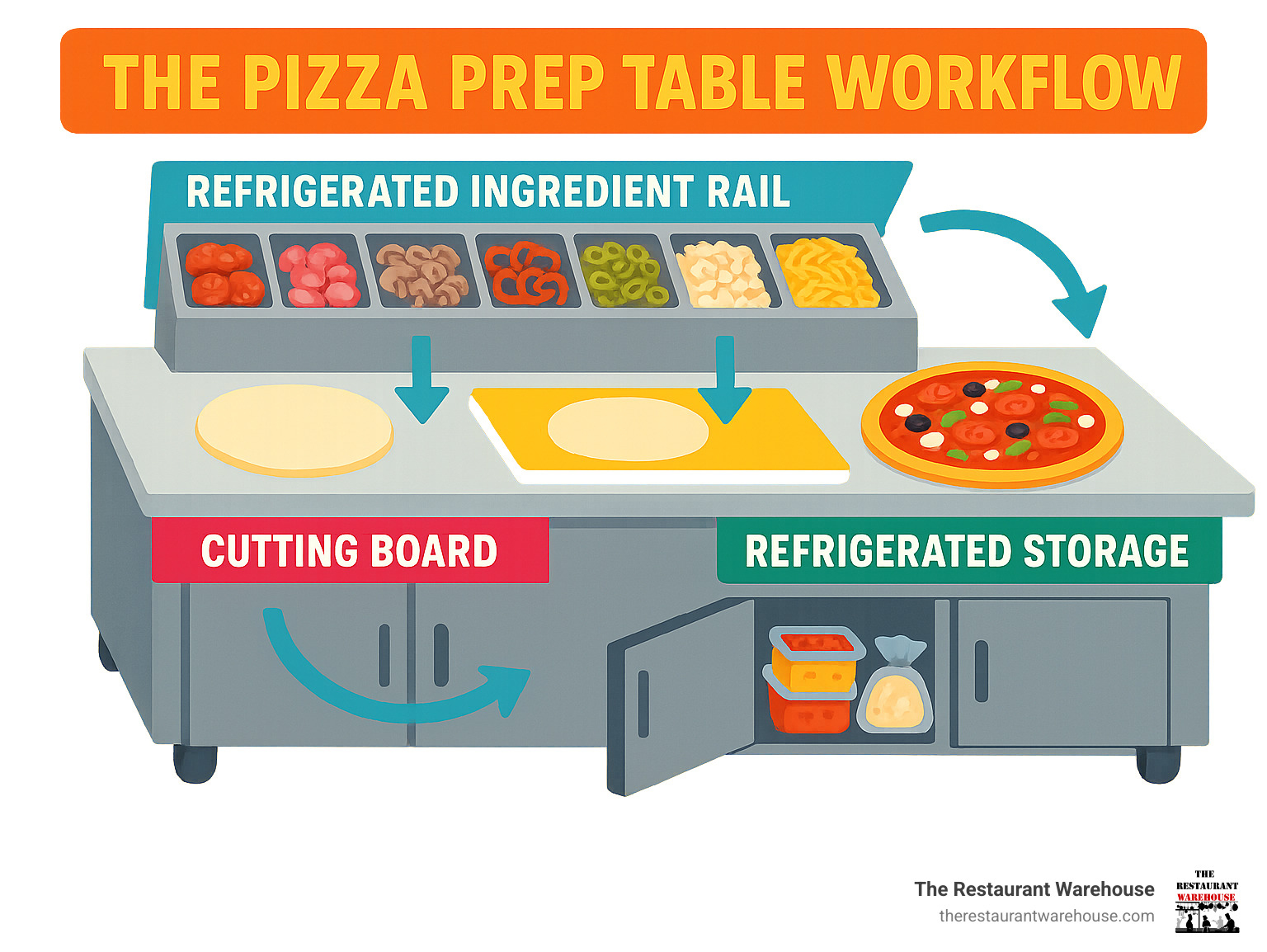

They are the nexus of kitchen efficiency, carefully designed to keep ingredients impeccably fresh, organize a vast array of toppings for lightning-fast assembly, and provide the ideal, ergonomic workspace for stretching dough and building pies. The magic unfolds across three distinct, yet perfectly integrated, zones: the refrigerated rail that holds toppings at precise, food-safe temperatures; the expansive cutting board engineered for the unique demands of dough preparation; and the refrigerated base that stores backup ingredients, ensuring they are always within arm's reach. This guide will serve as your comprehensive resource, breaking down everything you need to know about pizza prep tables, from their essential components and various types to the key considerations for choosing the perfect model to revolutionize your kitchen's unique workflow.

What Do You Call a Pizza Prep Table? Unpacking the Terminology

The lexicon of a professional kitchen is rich and surprisingly diverse. The question, what do you call pizza prep table equipment, might seem straightforward, but the answer reveals a fascinating array of terminology. Each name reflects a different priority, a different function, or even the perspective of the person using the term, from the head chef to the purchasing manager.

While pizza prep table is the most common and easily recognized name, you will frequently encounter alternatives. Calling it a pizza prep station shifts the focus from a mere piece of furniture to its true identity as a complete, self-contained workstation. The term pizza preparation refrigerator places the emphasis squarely on the unit's most critical technological feature: its ability to maintain food safety through consistent, reliable cooling. Understanding this varied terminology is the first step toward making an informed purchasing decision.

The Core Function of a Pizza Prep Table

To truly grasp what do you call pizza prep table equipment, you must first understand what it does. This is not just a table with a refrigerator underneath; it is a purpose-built, ergonomic solution engineered specifically for the high-stakes environment of volume pizza production. Its core functions are designed to solve the biggest challenges in any pizzeria: speed, consistency, and safety.

- Workflow Optimization: The fundamental design principle is to minimize movement and maximize output. Instead of chefs wasting precious seconds walking between separate refrigerators, storage racks, and prep surfaces, everything they need is consolidated within arm's reach. This centralized layout eliminates wasted steps, reduces physical strain on staff, and creates a smooth, logical, and repeatable process from a ball of dough to a fully topped pizza ready for the next stage.

- Ingredient Organization and Accessibility: A well-organized station is a fast station. Each topping, sauce, and cheese has its own designated pan within the refrigerated rail. This system ensures that all ingredients are not only visible and immediately accessible but also properly portioned and protected. This level of organization is crucial for maintaining recipe consistency and controlling food costs.

- Unyielding Food Safety: In the foodservice industry, food safety is non-negotiable. The integrated refrigeration system is the prep table's most vital feature, engineered to keep perishable ingredients at precise, safe temperatures (typically 33°F to 41°F). This constant chill prevents the growth of harmful bacteria and maintains the freshness, flavor, and texture of ingredients throughout long, demanding service periods.

- Improved Speed and Consistency: The combination of optimized workflow and perfect organization directly translates to increased speed and unwavering consistency. When ingredients are logically arranged and easily reachable, your team can assemble pizzas faster without sacrificing quality. This allows them to maintain the highest standards of excellence, even during the chaotic peak of a dinner rush. Every pizza receives the same meticulous attention and care, ensuring customer satisfaction every time.

Common Names and Why They Matter

The various names for pizza prep tables are more than just synonyms; they provide valuable clues into specific features, designs, and intended uses. This industry jargon, such as "refrigerated pizza table" or "condiment rail table," often signals particular design elements that can be crucial for your operation. For instance, a purchasing manager might search for a "commercial pizza preparation refrigerator" to ensure it meets specific health codes and durability standards, while a kitchen designer might refer to it as a "pizza assembly station" when planning the kitchen layout for optimal flow.

When you're researching equipment, leveraging these different search terms can be a powerful strategy. It can open up a wider range of options that you might otherwise miss. A search for a "pizza assembly table" might lead you to models with extra-wide cutting boards designed for large, artisanal pies. Meanwhile, searching for a "pizza preparation refrigerator" could highlight units with advanced, energy-efficient cooling systems. Understanding the specifications and features implied by these different names helps you make smarter, more targeted purchasing decisions and ensures you are accurately comparing the features and benefits of similar models.

The Core Components: What Makes a Pizza Prep Table Tick

When you analyze what you call a pizza prep table, you're looking at a sophisticated, integrated system where every component is engineered to work in perfect harmony. It's a testament to ergonomic design, carefully built to meet the unique and rigorous demands of professional pizza making. The unit is comprised of three perfectly coordinated sections: the refrigerated rail, the expansive workspace, and the refrigerated base, all designed to create a seamless and efficient production line.

The Refrigerated Rail: Keeping Toppings Cool and Accessible

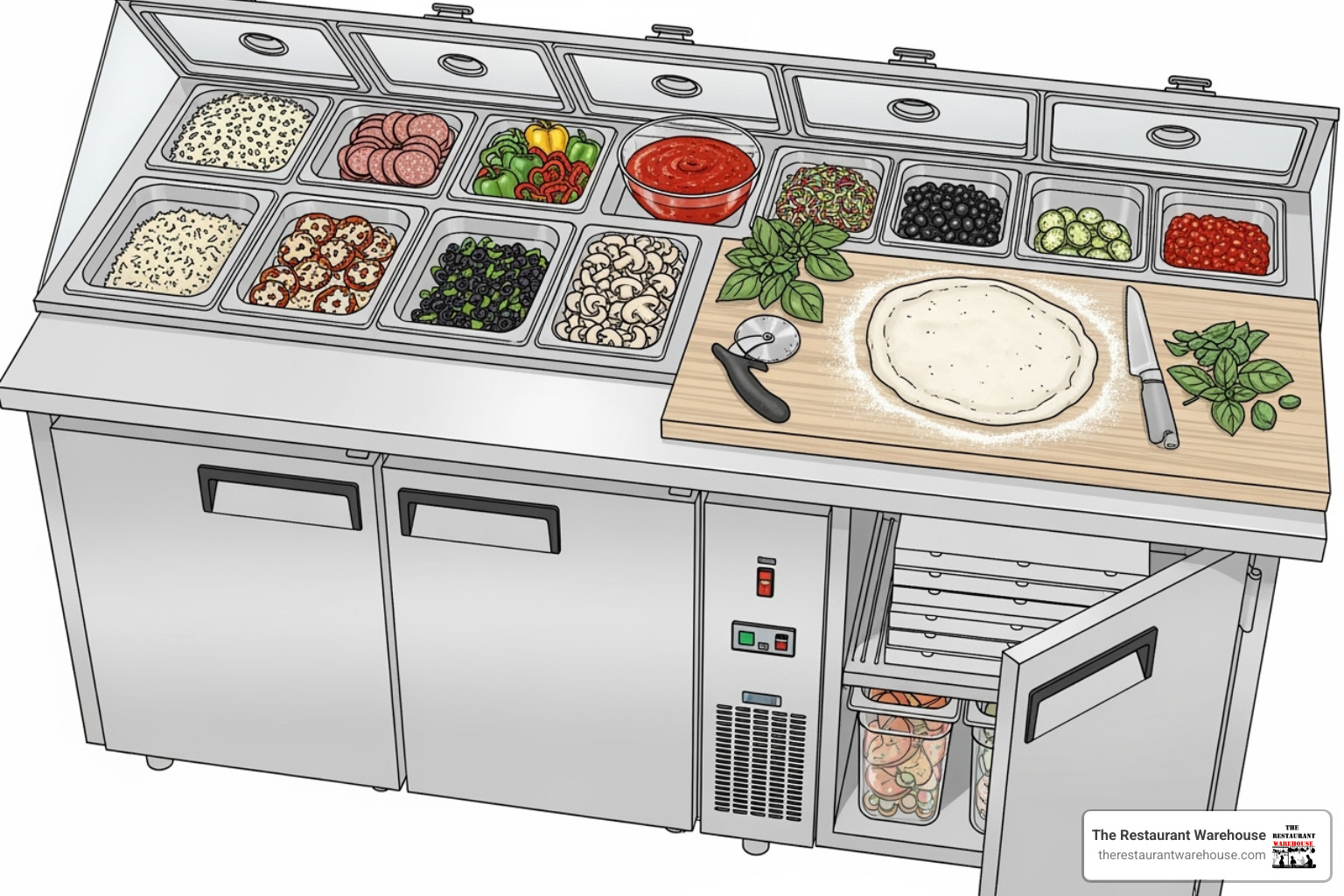

The uppermost section of any pizza prep table is the refrigerated rail, also known as the condiment rail. This is the command center for toppings. The system is designed to hold multiple ingredient pans, which are typically standard 1/3 size food pans, keeping every topping from pepperoni to pineapple perfectly organized, chilled, and within the chef's immediate reach.

The cooling technology is critical here. Most modern units use a forced-air cooling system, which employs fans to actively circulate cold air around and underneath every pan, ensuring even and consistent temperature distribution with no warm spots. Some models may feature a cold-wall design, where refrigerant lines are embedded in the walls of the rail. This creates a blanket of cold air and can offer greater energy efficiency, though it may sometimes result in less uniform cooling compared to forced-air systems. A crucial feature is the insulated lid or lids that cover the rail. These lids are essential for maintaining the cold air, protecting ingredients from ambient kitchen heat and contaminants, and significantly reducing energy consumption when the station is not in active use. The entire system is calibrated to maintain temperatures between 33°F to 41°F (0.5°C to 5°C), the federally mandated food-safe zone that is the sweet spot for preserving ingredient quality and preventing microbial growth.

The Workspace: The All-Important Cutting Board

Positioned directly in front of the refrigerated rail lies the heart of the operation: the cutting board workspace. This is far more than an ordinary prep surface; it is a purpose-built platform engineered for the specific art and science of pizza making.

The most defining feature is its exceptional cutting board depth, which typically ranges from a generous 14 inches to an expansive 19 inches. This ample space is your canvas for pizza dough stretching, saucing, and assembly. It allows a pizza maker to work on even the largest 18-inch pies without feeling cramped or making a mess. The cutting board itself is almost always crafted from a high-density, NSF-approved white polyethylene. This material is the industry standard for good reason: it is incredibly durable, resists deep knife cuts that can harbor bacteria, is non-porous, and is exceptionally easy to clean and sanitize, allowing it to meet the strictest foodservice health and safety requirements. Furthermore, these boards are typically removable, allowing for thorough cleaning and even replacement over the life of the unit.

Preparation Table Kitchen Guide

The Refrigerated Base: Bulk Storage Below Deck

Directly beneath the workspace lies the refrigerated base, a spacious under-counter storage area that functions as the pizzeria's immediate backup supply. This is where you store bulk quantities of extra cheese, backup sauces, and high-turnover toppings for quick and easy replenishment during a service rush. Its proximity means staff don't have to leave their station to restock.

The base is intelligently designed to hold industry-standard 18" x 26" full-size sheet pans and stackable dough trays, making it incredibly versatile. When choosing a unit, you'll find bases configured with either doors or drawers. Door configurations offer larger, more flexible open storage, ideal for bulky items like large containers of sauce or stacks of dough boxes. Drawer configurations, on the other hand, excel at rapid replenishment tasks. They are often designed to hold food pans directly, making it incredibly easy to swap an empty pan from the top rail with a full one from a drawer below in seconds. Inside, you'll find heavy-duty epoxy-coated shelves that are designed to resist corrosion from spills and moisture, ensuring a long-lasting, hygienic storage environment that is easy to clean.

Types of Pizza Prep Tables: Finding Your Perfect Match

Not every pizza kitchen operates on the same scale or with the same menu, and consequently, pizza prep tables are not a one-size-fits-all solution. Selecting the right match for your establishment is a critical decision that hinges on a careful analysis of your kitchen's specific needs, your average and peak operational volume, and the complexity of your menu.

Standard vs. Mega-Top Units: A Question of Topping Capacity

The most significant initial choice you'll face is between a standard and a mega-top configuration. This decision comes down almost entirely to your topping capacity requirements.

-

Standard Units: These models feature a single row of ingredient pans in the refrigerated rail. They are the perfect choice for pizzerias with a focused, traditional menu (e.g., cheese, pepperoni, sausage, mushrooms) or for moderate-volume operations. The primary advantage of a standard unit is that it offers a more generous cutting board area, typically the full 19-inch depth, giving pizza makers maximum room to stretch dough and work comfortably.

- Who should choose a Standard Unit? Pizzerias with a classic, streamlined menu; kitchens where ample dough prep space is the top priority; operations with moderate daily output.

-

Mega-Top Units: As the name implies, mega-top units are built for capacity. They feature extended rail systems that can accommodate significantly more pans, often arranged in two or even three rows. This design can increase pan capacity by 30-50% over a standard unit of the same width. These are the ideal solution for high-volume kitchens, "build-your-own" pizza concepts, or restaurants with extensive and complex topping menus. The trade-off for this increased capacity is a slightly smaller cutting board depth, as the board is narrowed to make room for the extra rows of pans.

- Who should choose a Mega-Top Unit? High-volume pizzerias; restaurants with a large, diverse topping selection; fast-casual concepts where customization is key.

48 Inch Mega Top Sandwich Prep Tables

Doors vs. Drawers: The Great Storage Debate

When it comes to the refrigerated base, you'll need to decide between doors, drawers, or a combination of both. This choice directly impacts your bulk storage capacity, ingredient accessibility, and daily workflow efficiency.

Door Configurations: Doors are the champions of bulk storage. They provide large, open, and flexible cabinet space that is perfect for storing irregularly shaped or oversized items. This includes large blocks of cheese, buckets of sauce, cases of beverages, and tall stacks of dough trays. The adjustable shelving inside allows for customization based on your specific storage needs.

Drawer Configurations: Drawers are all about speed, organization, and ergonomics. They are engineered to create a seamless pan rotation system that can be a game-changer for high-volume operations. Each drawer is typically sized to hold multiple food pans. When a topping pan in the rail runs empty, a staff member can simply pull out the drawer, grab a full replacement pan, and swap it in seconds, minimizing downtime and keeping the assembly line moving. This is far more efficient than opening a large door and searching for the right container.

How Do Pizza Prep Tables Differ from Sandwich Units?

While they may look like close relatives, pizza prep tables and sandwich/salad units are distinct pieces of equipment, each engineered for a different purpose. Mistaking one for the other can lead to significant frustration and inefficiency in your kitchen. Understanding these key differences ensures you invest in the right tool for the job.

| Feature | Pizza Prep Table | Sandwich/Salad Unit |

|---|---|---|

| Design Purpose | Specifically engineered for the complete pizza assembly process, from raw dough to a fully topped pie. | Designed for assembling smaller cold items like sandwiches, salads, wraps, and burritos. |

| Workspace Depth | Features a deep cutting board, typically 14 to 19 inches, to accommodate stretching large pizza doughs. | Features a much shallower cutting board, typically 8 to 10 inches, sufficient for bread slices or tortillas. |

| Pan Configuration | Primarily uses larger 1/3 size food pans in the rail to hold high-volume toppings like cheese and pepperoni. | Primarily uses smaller 1/6 size food pans in the rail for a wider variety of smaller-quantity ingredients. |

| Refrigeration Design | The refrigeration system is often more robust to handle the larger mass of ingredients and the frequent opening of the lid. | The system is balanced for smaller, lighter ingredients and may not recover temperature as quickly under heavy load. |

| Primary Use Case | Essential for pizza restaurants, pizzerias, and any establishment with a high-volume pizza operation. | The standard for deli operations, sandwich shops, salad bars, and cafes. |

The most critical and immediately obvious difference is the workspace depth. Attempting to stretch a 16-inch pizza dough on a narrow 8-inch sandwich unit cutting board is an exercise in futility and mess. Furthermore, the reliance on larger 1/3 size food pans in pizza tables reflects the need for large quantities of core ingredients, whereas the smaller 1/6 size pans in sandwich units allow for a greater variety of toppings in a smaller space. While you could technically use a sandwich unit for pizza in an emergency, you would be fighting against its design every step of the way, leading to slower service and a compromised product.

The Ultimate Guide to Buying a Pizza Prep Table

Key Features and Considerations for Your Kitchen

When you are ready to invest in what you call pizza prep table equipment, you are making a long-term strategic decision that will directly impact your kitchen's efficiency, your staff's morale, and your product's quality. To make the best choice, it's crucial to move beyond the basic specifications and dig into the key features that separate a truly great pizza prep table from a merely adequate one.

Construction and Durability: The Stainless Steel Advantage

Walk into any high-functioning professional kitchen, and you'll be surrounded by one dominant material: stainless steel. There's a very good reason for this. It is unequivocally the best material for the demanding, high-impact environment of foodservice. When it comes to your prep table, stainless steel construction is non-negotiable. It provides the rugged durability needed to handle the daily grind of a busy kitchen, resisting dents, dings, and scratches. Its hygiene benefits are equally critical; the non-porous surface is incredibly easy to clean and sanitize, and it won't absorb odors or harbor bacteria. Furthermore, its natural corrosion resistance is essential in a humid kitchen environment where spills and moisture are constant. For maximum longevity, look for models featuring high-quality 304-gauge stainless steel for the exterior and work surfaces, as it offers superior corrosion resistance compared to the more economical 430-gauge steel often used on sides and backs.

Stainless Steel Prep Table Guide

Refrigeration System: The Cool Science of What You Call a Pizza Prep Table

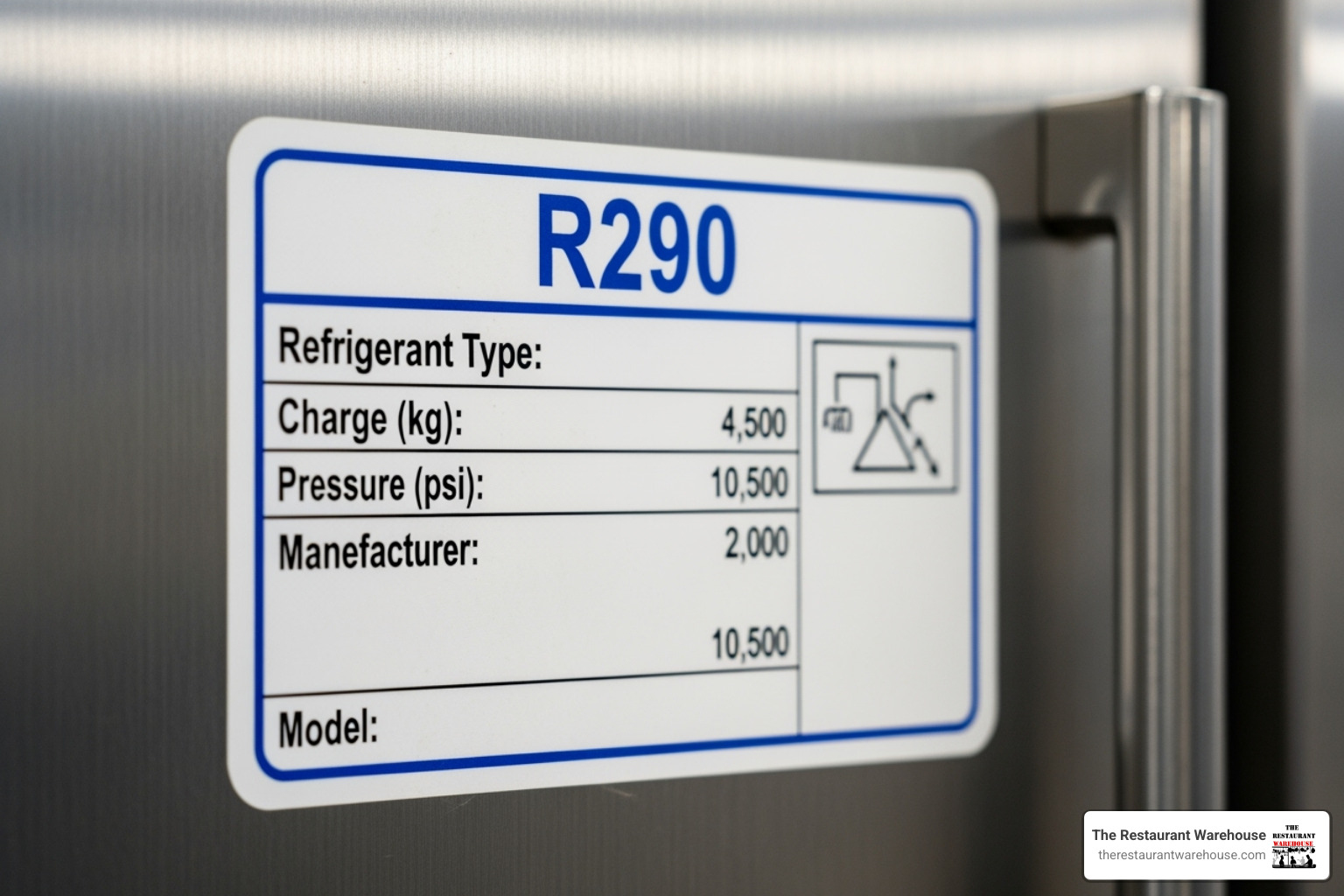

Behind every perfectly preserved topping is a sophisticated and powerful refrigeration system. Modern pizza prep tables feature high-capacity, front-breathing, forced-air refrigeration designed to maintain unwavering temperature consistency. Your prep table must be able to hold that critical 33°F to 41°F temperature range even when the lid is being opened constantly during a rush and the ambient temperature in the kitchen is high. Look for units with powerful compressors and efficient airflow design. A significant advancement in recent years is the widespread adoption of R290 hydrocarbon refrigerant. This is an eco-friendly, natural alternative to older synthetic refrigerants. It has zero ozone depletion potential (ODP) and a very low global warming potential (GWP). Beyond its environmental benefits, R290 is also a more efficient refrigerant, meaning it can cool the unit faster and use less energy, which translates directly to lower monthly operating costs for your business.

Size and Capacity: Matching the Unit to Your Volume

Getting the size right is one of the most critical decisions you'll make. It's essential to perform an honest assessment of your current and projected production volume as well as the physical constraints of your kitchen. Pizza prep tables come in a vast range of sizes, from compact 32-inch units perfect for a small cafe to massive 119-inch models that can anchor the production line of a major pizzeria chain. Carefully consider your kitchen layout and how staff will need to move around the unit. A table that is too large can create bottlenecks, while one that is too small will constantly hinder your production capacity. A high-volume operation will need more pan capacity in the rail, which is where mega-top units excel. The choice between doors and drawers will also significantly affect your storage capacity and workflow, so map out how you plan to store and access your backup ingredients.

Maintenance and Cleaning: Designing for Simplicity

A prep table that is difficult to clean is not just an inconvenience; it's a food safety liability. Smart design features that simplify cleaning and maintenance can save you countless hours of labor and help you avoid health code violations. Look for self-closing doors with a stay-open feature (usually at 90 degrees) for easy loading. The magnetic door gaskets should be easily removable without tools, allowing for thorough cleaning to prevent mold and mildew buildup. The interior of the refrigerated cabinet should have coved corners (rounded edges where the floor meets the walls), which eliminate sharp 90-degree angles where dirt and grime can accumulate. A consistent schedule of preventive maintenance, especially cleaning the condenser coil, combined with daily cleaning protocols, will be the determining factor in whether your prep table serves you reliably for five, ten, or even fifteen years.

Frequently Asked Questions about Pizza Prep Tables

As specialists in commercial kitchen equipment, we get tons of questions about these essential workhorses of the pizza kitchen! Let's explore some of the most common inquiries that arise when people are trying to fully understand what you call a pizza prep table and how to get the most out of it.

What is the ideal temperature range for a refrigerated pizza prep table?

When it comes to keeping your valuable ingredients fresh and your customers safe, temperature control is paramount. The universally accepted and health-code-mandated sweet spot for what you call a pizza prep table is a consistent temperature range of 33°F to 41°F (0.5°C to 5°C).

This range is not arbitrary. Food safety regulations, such as those outlined in the NSF/ANSI Standard 7 for commercial refrigerators, require that these units maintain product temperatures at or below 41°F. This is known as the food safety "danger zone" threshold, as temperatures above this allow for the rapid multiplication of harmful bacteria. Staying within this range not only ensures safety but also preserves the optimal quality, texture, and flavor of every ingredient, from delicate cheeses and fresh vegetables to cured meats.

Can I use a sandwich prep table for making pizzas?

While you technically could in the same way you could technically haul lumber in a sports car, it's a classic case of using the wrong tool for the job. It would be an exercise in frustration, inefficiency, and mess. The workflow differences and physical design limitations are significant.

The two biggest obstacles are the cutting board limitations (a standard sandwich unit's board is only 8-10 inches deep, making it impossible to properly stretch a large pizza) and the pan configuration (they are designed for smaller 1/6 size pans, not the 1/3 size pans needed for high-volume pizza toppings). Trying to stretch a 16-inch pizza dough on a narrow surface will inevitably lead to flour and toppings all over the floor. For any serious pizza operation, investing in a dedicated pizza prep table is not a luxury; it's a fundamental requirement for success.

Why is the cutting board on what you call a pizza prep table so deep?

That exceptionally deep cutting board—typically ranging from 14 to 19 inches—is a direct result of thoughtful, purpose-driven design that understands the specific needs of a pizza maker.

Dough preparation is the primary reason. Pizza dough, especially for large American-style or Neapolitan pies, requires significant real estate to be properly stretched, slapped, and shaped without being constrained. The generous workspace also acts as a containment area, helping to prevent messes by keeping flour, cornmeal, and stray toppings on the board instead of on the kitchen floor. Finally, the ergonomics are a crucial factor. The extended depth allows chefs to work with a more natural and comfortable posture, reducing back and shoulder strain during long, repetitive shifts.

What does NSF certification mean and why is it important?

When you see an NSF logo on a piece of equipment, it's a mark of quality and safety. NSF International (formerly the National Sanitation Foundation) is an independent organization that develops public health standards and certification programs. For a pizza prep table, NSF certification means the unit has been rigorously tested to meet strict standards for material safety (the materials won't leach harmful chemicals into food), design and construction (it's easy to clean and has no crevices where bacteria can hide), and product performance (it can reliably hold food at safe temperatures). Most local health departments require that all equipment in a commercial kitchen be NSF certified, so it's not just a nice-to-have, it's often a legal requirement.

What are the electrical and placement requirements for a pizza prep table?

Proper placement and electrical supply are crucial for performance and safety. Most pizza prep tables operate on a standard 115V electrical connection and come with a NEMA 5-15P plug, which is the common three-prong plug you see everywhere. However, it is highly recommended, and often required by code, that the unit be plugged into a dedicated circuit. This prevents the compressor from being starved for power or tripping a breaker when it cycles on, especially if other high-draw appliances are on the same circuit. For placement, ensure there is adequate clearance around the unit, especially around the compressor's air intake and exhaust vents (usually on the back, side, or front). Obstructing airflow will force the compressor to work harder, leading to higher energy bills and potential equipment failure.

Conclusion: The Right Prep Table for a Perfect Slice

After exploring every angle of what you call a pizza prep table—from its various names and core components to its different types and critical features—one truth becomes abundantly clear: this is not just another piece of stainless steel in your kitchen. It is the command center, the heart of your entire pizza operation. It is the carefully engineered workhorse that orchestrates the complex dance of turning simple, fresh ingredients into the culinary magic your customers crave.

The right prep table is a force multiplier. It directly boosts efficiency, allowing your team to produce more pizzas in less time. It underpins your commitment to food safety, protecting both your customers and your reputation. And it fosters organization, creating a calmer, more streamlined work environment. These benefits cascade into tangible business results: faster service, more consistent product quality, better food cost control, and ultimately, happier, more loyal customers.

Investing in the right pizza prep table is not an expense; it's a strategic investment in your kitchen's workflow, your team's success, and your brand's promise of quality. At The Restaurant Warehouse, we have seen how the right piece of equipment can fundamentally transform a foodservice operation. We are passionate about empowering businesses like yours to succeed by providing top-tier commercial restaurant equipment and food service supplies at lower prices, effectively cutting out the middleman costs that can make premium equipment feel out of reach.

Whether you call it a pizza prep table, a pizza prep station, or simply the key to your pizzeria's success, what matters most is finding the specific model that aligns perfectly with your unique operational needs. From the cooling power of the refrigerated rail to the expansive canvas of the cutting board, every component works in concert to help you and your team create those perfect slices, day in and day out.

Ready to lift your pizza game? We're here to help you steer the options and find the ideal Pizza Prep Table that will serve as the durable, reliable foundation for countless delicious pizzas for years to come.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment