Small Footprint, Big Flavor: Your Guide to Single Door Prep Tables

Why Single Door Prep Tables Are Essential for Small Kitchens

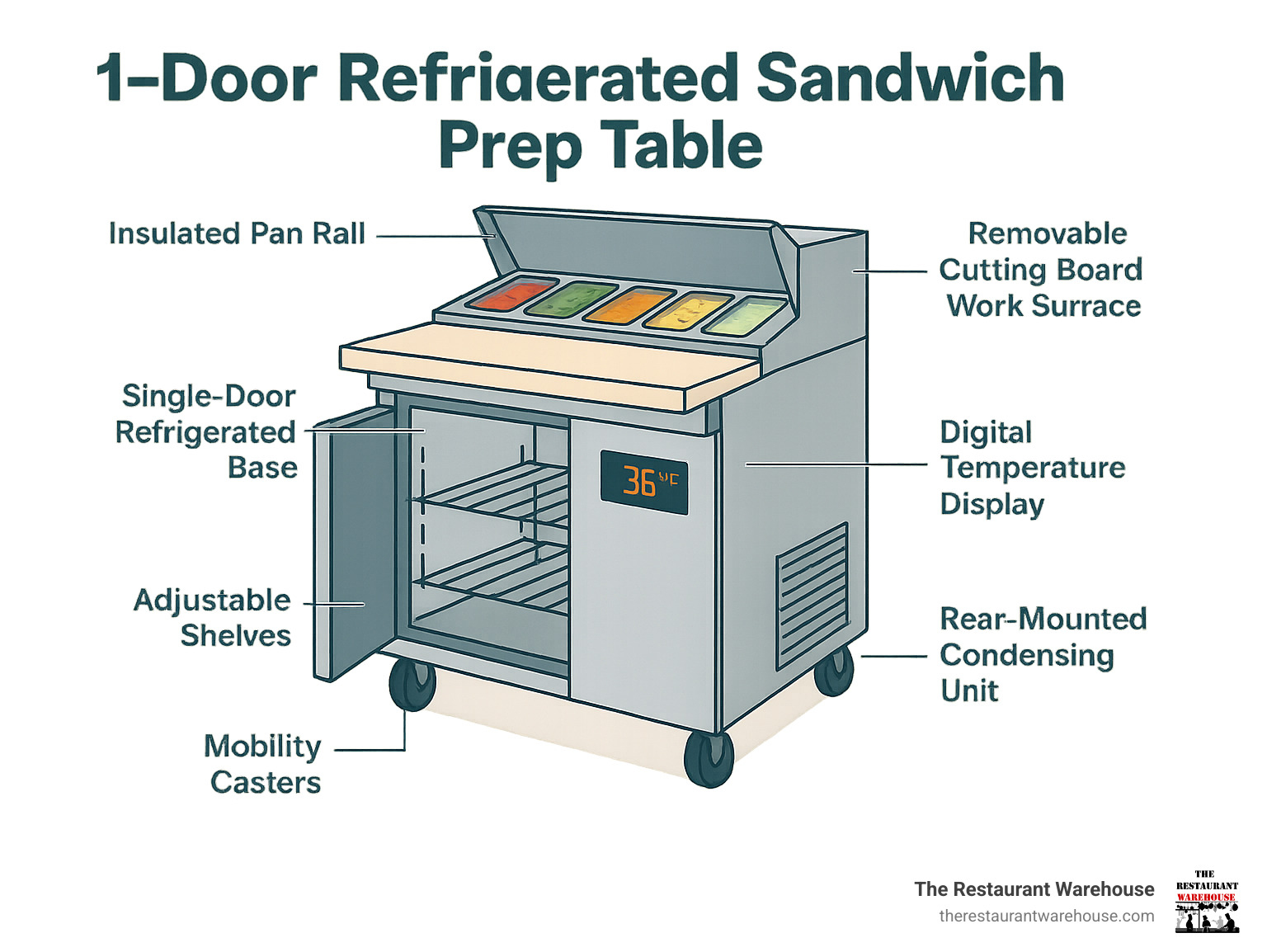

A 1 door refrigerated sandwich prep table is a multifunctional unit that combines refrigerated storage, ingredient organization, and a dedicated workspace. These tables feature a refrigerated base, a cutting board work surface, and an insulated top rail designed to hold multiple food pans at safe, cool temperatures.

Key features of 1-door refrigerated sandwich prep tables:

- Temperature range: 33°F to 41°F (0.5°C to 5°C) for food safety

- Typical dimensions: 27-29" wide, 30-32" deep, 42-45" high

- Storage capacity: 6-8 cubic feet in the base compartment

- Pan capacity: 6-12 food pans, depending on the model

- Construction: Durable stainless steel exterior and interior

- Refrigeration: Rear-mounted compressor with a forced-air cooling system

For many restaurant owners, a cramped kitchen, backed-up orders, and inefficient workflows are common struggles. This is where single door prep tables prove their worth. They are engineered to solve three critical problems simultaneously: limited space, inefficient processes, and food safety concerns.

Unlike larger multi-door units, a 1-door model fits easily into tight kitchen layouts while providing essential refrigerated storage and organized ingredient access. This design puts all your sandwich ingredients within arm's reach, helps maintain proper food temperatures, and frees up valuable counter space. Their simplicity means fewer mechanical parts, lower initial costs, and easier maintenance, all while delivering professional-grade refrigeration to keep ingredients fresh during busy service periods.

Why a 1-Door Refrigerated Sandwich Prep Table is a Kitchen Game-Changer

Imagine the lunch rush: orders are piling up, and your team is navigating a crowded space to grab ingredients from multiple locations. A 1-door refrigerated sandwich prep table can transform this chaotic scene into a streamlined operation.

These compact units don't just save space; they revolutionize your kitchen's workflow. With streamlined preparation, every sandwich, wrap, or salad is assembled faster and more efficiently because all ingredients are chilled, organized, and within arm's reach. The compact footprint allows you to install professional-grade prep capabilities in cozy cafes, busy delis, or food trucks where every inch matters.

Crucially, these tables provide consistent temperature control, keeping ingredients fresh and safe throughout the busiest service periods. This dedication to temperature management directly impacts food quality. Ingredients retain their vibrant flavors and crisp textures, a difference customers can taste. Furthermore, the organized pan layout naturally reduces cross-contamination risks by assigning a specific spot for each ingredient.

Their versatility extends far beyond sandwiches. They are perfect for assembling salads, wraps, poke bowls, and parfaits, making them ideal for cafes, delis, and food trucks that value menu diversity and speed.

Boosting Kitchen Efficiency

In a kitchen equipped with a 1-door refrigerated sandwich prep table, you'll notice significantly reduced staff movement. Cooks no longer need to walk to the main cooler for ingredients. Everything they need is integrated into their station: fresh produce in the top rail, backup supplies in the refrigerated base, and a clean cutting board ready for use. This "all ingredients within arm's reach" setup eliminates workflow interruptions.

The direct result is faster order fulfillment. When the team can assemble dishes without leaving their station, ticket times drop, which is a major advantage during peak hours. This optimized workflow creates a logical sequence for tasks, allowing staff to focus on food preparation rather than searching for supplies. This efficiency boost means your team can handle higher order volumes without feeling overwhelmed, leading to better food quality and a less stressful environment.

Maximizing Your Kitchen Space

Kitchen space is a premium asset. A 1-door refrigerated sandwich prep table offers a small footprint design that delivers maximum functionality in minimal square footage. These units are perfect for fitting in tight layouts, turning an awkward corner or a narrow galley into a fully productive prep station.

By combining refrigeration and a work surface, these tables free up counter space that would otherwise be cluttered with cutting boards and ingredient containers. This is especially valuable for ghost kitchens, where space is limited and efficiency is paramount. They also serve effectively as a secondary prep station in larger kitchens, allowing for dedicated zones for specific menu items like salads or breakfast sandwiches, improving overall organization and flow.

Upholding Food Safety Standards

Food safety is non-negotiable in any foodservice operation. A 1-door refrigerated sandwich prep table is a key tool for maintaining health standards by keeping foods within the safe temperature zone of 33°F to 41°F. This precise range prevents the growth of harmful bacteria.

The insulated lids protect ingredients in the top rail from ambient temperatures, which is crucial during busy periods with frequent access. This consistent cooling reduces the risk of spoilage, keeping vegetables crisp and proteins safe for longer, which in turn minimizes food waste. When selecting a unit, look for NSF certification. This indicates the equipment meets strict public health and safety standards, which is important for health inspections and demonstrates a commitment to safety. For more information on food safety, consult the USDA's safe temperature chart.

Decoding the Features: What to Look for in Your Prep Table

Choosing the right 1 door refrigerated sandwich prep table requires looking beyond aesthetics and focusing on the features that impact performance and durability. Understanding the key components—from material quality and refrigeration technology to capacity and construction—will help you invest in a solution that improves kitchen efficiency and food quality.

Sizing Up Your Needs: Dimensions and Capacity

Before purchasing, measure your available space. Single-door models are compact, with widths typically ranging from 27 to 29 inches, depths of 30 to 32 inches, and heights around 42 to 45 inches. Some units offer ADA-compliant working heights, often using casters to set the surface at a more accessible level, promoting an inclusive and efficient work environment.

Despite their small footprint, these tables provide 6 to 8 cubic feet of refrigerated storage. This space is customizable with adjustable shelving to accommodate various container sizes. Look for heavy-duty shelves, some of which are rated to handle up to 90 pounds, ensuring they can support the weight of bulk ingredients without issue.

The Heart of the Unit: Refrigeration and Energy Efficiency

The refrigeration system is the core of your prep table. Modern units use forced-air cooling to circulate cold air evenly, eliminating hot spots and ensuring consistent temperatures from the storage base to the top pans. Digital thermostats with clear LED displays allow for precise temperature control, making it easy to maintain the critical 33°F to 41°F range.

Many contemporary tables use eco-friendly R290 refrigerant, which has zero ozone depletion potential and a low global warming potential, making it a responsible choice. The common rear-mounted compressor design keeps the work area clear and simplifies maintenance. When paired with energy-efficient ECM fan motors and an automatic defrost cycle, the system runs efficiently, prevents ice buildup, and helps control electricity costs.

Built to Last: Construction and Materials

A prep table must withstand the rigors of a commercial kitchen, making its construction quality paramount. Look for units with a stainless steel exterior (often 430-grade) for corrosion resistance and a professional look, and a 304-grade stainless steel interior for superior durability in a humid, acidic environment.

High-quality insulation, such as foamed-in-place polyurethane, creates a dense thermal barrier that keeps cold air in, improving temperature consistency and energy efficiency. Important door features include a self-closing mechanism to prevent energy loss and a stay-open feature for easier stocking. Magnetic door gaskets create a tight seal, which is crucial for maintaining temperature and food safety. Finally, heavy-duty casters are essential for mobility, allowing you to easily move the unit for cleaning and maintenance.

Maximizing Functionality: The Workstation Breakdown

A 1 door refrigerated sandwich prep table is an integrated workstation where every component is designed for efficiency. From the cutting board to the pan configuration, each element works to make food prep faster, safer, and more organized.

The system's integration is its key strength. Ingredients remain chilled right where you need them, the workspace is always ready for action, and the workflow becomes smooth and manageable, even during the busiest periods.

The Cutting Board: Your Primary Workspace

The cutting board is the central hub of activity on a 1 door refrigerated sandwich prep table. Most quality units feature a durable polyethylene cutting board, a material that resists knife marks and is easy to clean and sanitize. A standard thickness of about 3/4 inches provides a solid, stable surface for all prep tasks.

A key feature is that the board is removable. This allows for thorough washing and sanitizing, which is essential for meeting health codes and preventing cross-contamination. The depth of the cutting board, typically around 10 1/2 inches, affects workflow efficiency. Some models offer deeper boards for those who need more space to handle larger ingredients or more complex orders. Having adequate space is crucial for working comfortably and quickly during a lunch rush.

Pan Capacity and Configuration: Standard vs. Mega Top

The food pan configuration is the organizational core of your 1 door refrigerated sandwich prep table. Most units are designed for standard 1/6-size pans, which are ideal for holding individual ingredients like sliced meats, cheeses, and vegetables.

The standard top configuration typically holds 6 to 8 pans in a single row. This setup is perfect for cafes, small delis, or businesses with a focused menu, providing easy access to essential ingredients without taking up excess space.

For operations with more complex menus or higher volume, a mega top design is a better fit. These models feature a deeper top section that can accommodate 12 or more pans, often in a double-row configuration. This allows for a greater variety of ingredients to be held at once, reducing the need for restocking during peak hours.

In either configuration, the insulated lid system is vital. These lids protect ingredients from temperature fluctuations, minimize condensation, and help maintain the crucial 33°F to 41°F temperature range, ensuring food stays fresh and appealing.

Choosing the Right 1-Door Refrigerated Sandwich Prep Table for Your Business

Selecting the perfect 1 door refrigerated sandwich prep table depends on your specific operational needs. Factors like menu complexity, daily customer volume, kitchen layout, and budget will guide you to the right unit.

Consider your busiest service period. Are you making simple sandwiches or elaborate custom orders with numerous toppings? The answer will help you decide between a standard top and a mega top configuration, each designed to match different workflows and space constraints.

The Compact Contender: Standard Top 1-Door Refrigerated Sandwich Prep Table

The standard top 1 door refrigerated sandwich prep table is an excellent choice for many small businesses. These units typically hold 6 to 8 food pans, providing organized access to core ingredients. They are ideal for coffee shops adding a lunch menu, small delis, or food trucks where space is at a premium.

The smaller overall profile makes them versatile for tight layouts. They can serve as a primary prep area or as a secondary station in a larger kitchen for specific items like salads. From a cost perspective, standard top units offer great value for startups, allowing them to invest in reliable performance without the higher price of larger models.

The High-Volume Hero: Mega Top 1-Door Refrigerated Sandwich Prep Table

For businesses that require maximum ingredient variety in a compact footprint, a mega top 1 door refrigerated sandwich prep table is a game-changer. These units can hold 12 or more food pans, making them indispensable for busy delis and high-volume sandwich shops.

The increased pan capacity reduces the need for restocking during peak hours and allows for a more diverse menu. The deeper top section of a mega top also provides a larger cutting board surface, which is invaluable when assembling multiple orders simultaneously. These units are designed to maximize ingredient variety and workflow efficiency, leading to faster service and greater customer satisfaction.

| Feature | Standard Top 1-Door Prep Table | Mega Top 1-Door Prep Table |

|---|---|---|

| Pan Capacity | 6-8 (1/6 size pans) | 12+ (1/6 size pans) |

| Best For | Coffee shops, small cafes, limited menus | Busy delis, sandwich shops, complex menus |

| Cutting Board Depth | Standard (8-10.5 inches) | Deeper (12+ inches) |

| Typical Footprint | Most compact for tight spaces | Slightly larger but maximizes ingredient density |

Ownership Essentials: Maintenance, Cleaning, and Warranty

Investing in a 1 door refrigerated sandwich prep table is the first step; proper care is what ensures its longevity and performance. Good maintenance protects your investment by ensuring consistent temperature control, energy efficiency, and food safety. A well-maintained unit keeps ingredients fresh, energy bills down, and health inspectors satisfied.

Understanding your warranty is also crucial, as it provides a safety net against unexpected issues and can save you significant costs on repairs.

Daily, Weekly, and Monthly Cleaning

Consistent cleaning is about performance and safety, not just appearance. A dirty unit works harder, consumes more energy, and can pose a health risk.

- Daily: Wipe down all stainless steel surfaces with a food-safe cleaner. Remove, wash, and sanitize the cutting board. Clean all ingredient pans and the pan rail area to prevent food particle buildup.

- Weekly: Perform a deeper clean. Wash the door gaskets with warm, soapy water to ensure a proper seal, which prevents the compressor from overworking. Empty and sanitize the refrigerated base and shelves.

- Monthly: Condenser coil cleaning is non-negotiable. In a typical kitchen, this should be done every 90 days, but in environments with high grease levels, monthly cleaning is recommended. Dust and grease buildup on the coils insulates them, forcing the compressor to work harder and increasing energy consumption. Use a stiff brush or a vacuum to clear away debris. This simple task can prevent costly equipment failure.

A clean unit runs more efficiently. A dirty condenser coil alone can significantly increase your energy costs.

Understanding Your Warranty

Your warranty is an insurance policy, but not all are created equal. Standard manufacturer warranties typically cover parts and labor for one to three years. This handles most issues that arise from normal use. Be aware that neglecting maintenance can void your coverage.

The most valuable part of a warranty is often the extended compressor coverage. The compressor is the heart of the unit and is expensive to replace. Many manufacturers offer five, seven, or even ten years of coverage on this component, which signals confidence in their product and provides you with long-term peace of mind.

When reviewing a warranty, check the specific coverage details, the process for filing a claim, and the availability of a local service network. Keep records of your maintenance schedule, as proof of proper care is often required for a warranty claim to be approved.

Frequently Asked Questions about Single Door Prep Tables

When considering a 1 door refrigerated sandwich prep table, business owners often have similar questions about temperature, versatility, and maintenance. Getting clear answers helps you make a confident and informed purchase.

What is the ideal temperature for a sandwich prep table?

The ideal and food-safe temperature range for a sandwich prep table is between 33°F and 41°F (0.5°C to 5°C). This range is critical because it keeps perishable ingredients out of the temperature "danger zone" (40°F to 140°F), where harmful bacteria can multiply rapidly. Modern prep tables use forced-air cooling systems to maintain this temperature consistently throughout the unit, from the refrigerated base to the top ingredient pans, ensuring both food safety and quality.

Can I use a sandwich prep table for other foods besides sandwiches?

Absolutely. These units are incredibly versatile. Their design—organized, refrigerated storage combined with a workspace—is perfect for any dish requiring quick assembly of cold ingredients. Common alternative uses include:

- Salad Stations: Pans can be filled with various greens, chopped vegetables, proteins, and dressings for an efficient salad bar.

- Wrap and Burrito Assembly: Keep tortillas, seasoned meats, beans, cheese, and salsas organized and chilled for a streamlined assembly line.

- Yogurt Parfait Stations: Ideal for breakfast service, with pans holding yogurt, granola, fresh berries, and other toppings.

- Poke Bowl Preparation: The setup is perfect for keeping raw fish, rice, and various toppings fresh and ready for assembly.

- Bar Prep: Use it to store and organize cocktail garnishes, cut fruits, and mixers, keeping them at a perfect serving temperature.

How often should I clean the condenser coil on my 1-door refrigerated sandwich prep table?

It is recommended to clean the condenser coil every 30 to 90 days. The exact frequency depends on your kitchen environment.

- Monthly cleaning is advised for high-volume kitchens or those with a lot of grease in the air, as airborne particles can quickly clog the coil.

- Every 90 days may be sufficient for cleaner, lower-volume environments like a small coffee shop.

Skipping this maintenance forces the unit to work harder, leading to higher energy bills and eventual compressor failure—an expensive repair. Signs that your coil needs immediate cleaning include the unit running constantly or failing to maintain its set temperature. Regular cleaning is simple preventive care that ensures your prep table runs efficiently for years.

Conclusion

The right 1 door refrigerated sandwich prep table can truly transform a kitchen, turning potential chaos into a streamlined and efficient operation. These compact units deliver on three essential benefits for any foodservice business: improved efficiency, smart space utilization, and uncompromising food safety.

With a well-chosen prep table, your staff can work more effectively, your prep areas remain organized, and you can be confident that your ingredients are held at safe temperatures. Whether you need a standard top model for a small cafe or a higher-capacity unit for a busy deli, there is a configuration that fits your needs. These tables are adaptable, excelling at everything from crafting sandwiches and salads to assembling poke bowls and parfaits.

Your 1 door refrigerated sandwich prep table is more than just equipment; it's an investment in your operational efficiency, food quality, and bottom line. By choosing the right unit for your menu, volume, and kitchen space, you are setting your business up for success.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment