Prep Your Way to Perfection: A Guide to Commercial Kitchen Tables

Why Stainless Steel is the Gold Standard for Commercial Kitchens

When outfitting a foodservice operation, you'll find that the commercial kitchen prep table market is dominated by stainless steel, and for good reason. These tables are the foundation of food safety and efficiency in any professional kitchen. The superiority of stainless steel over materials like wood or plastic becomes clear when considering the rigorous demands of a busy kitchen.

Top Features to Look For:

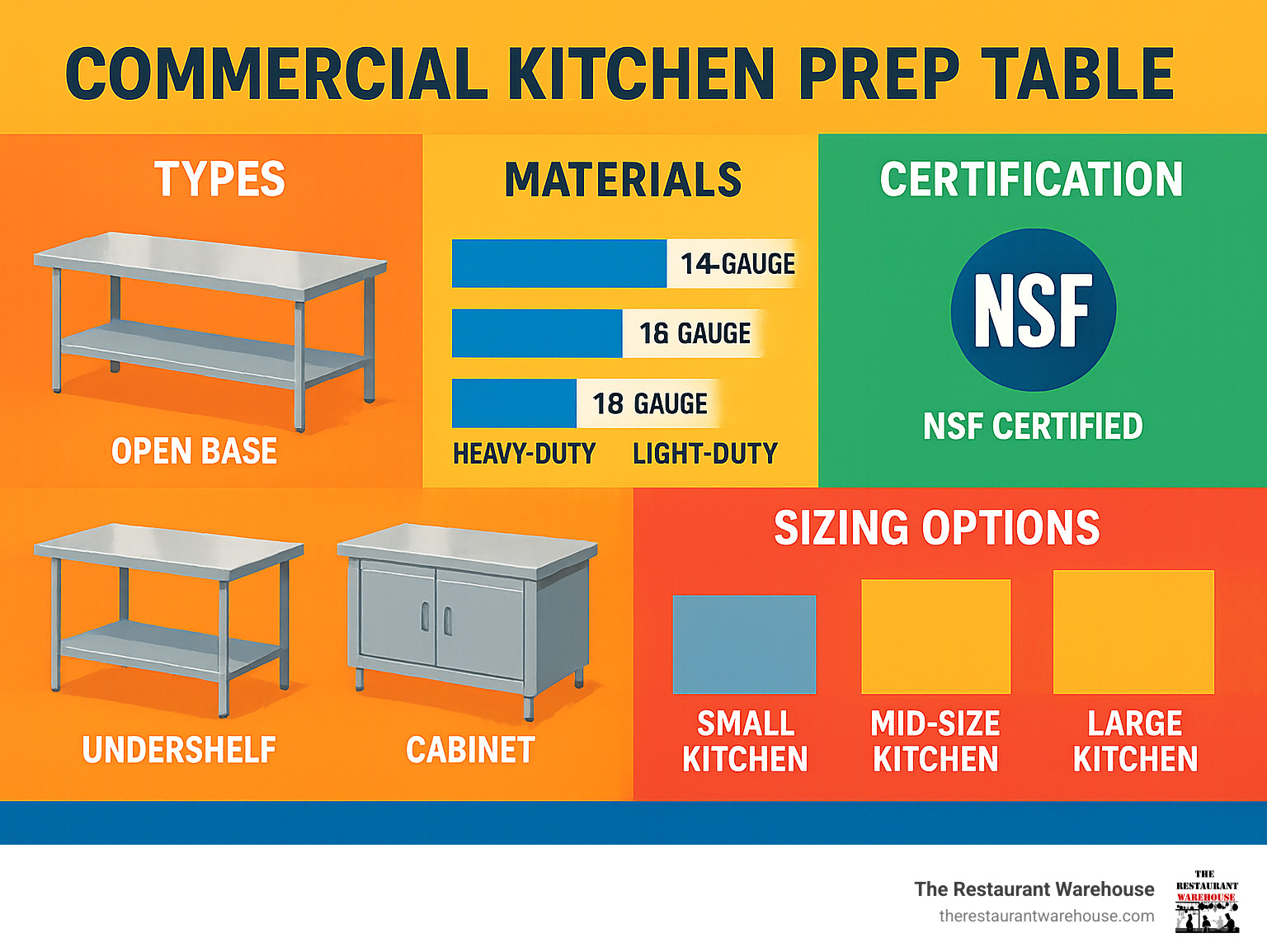

- Material: 14-18 gauge stainless steel (14-gauge is the thickest and most durable)

- Steel Type: 304 stainless steel for maximum corrosion resistance

- Certifications: NSF listed for health department compliance

- Base Options: Open base, undershelf, or cabinet storage

- Special Features: Backsplash, integrated sinks, or mobile casters

One of the most critical benefits of stainless steel is hygiene. Its non-porous surface prevents bacteria from accumulating in scratches or grooves, a common problem with wooden surfaces. This makes it easy to thoroughly clean and sanitize, ensuring you meet the strict standards required by health inspectors and maintain a safe environment for food preparation. According to the Centers for Disease Control and Prevention, proper food preparation surfaces are essential for preventing foodborne illness outbreaks in commercial establishments.

The science behind stainless steel's superior hygiene properties lies in its molecular structure. The chromium content in stainless steel forms a passive oxide layer on the surface that naturally resists bacterial adhesion. This means that even microscopic organisms struggle to establish colonies on properly maintained stainless steel surfaces. Unlike porous materials such as wood or certain plastics, stainless steel doesn't provide the tiny crevices where bacteria can hide and multiply.

Durability is another key factor that sets stainless steel apart from alternative materials. Stainless steel is engineered to resist corrosion, stains, and impact damage that would quickly compromise other surfaces. It can withstand constant exposure to moisture, cleaning chemicals, and temperature fluctuations that would rapidly degrade wooden or plastic alternatives. This resilience means a heavy-duty stainless steel work table will last significantly longer than other options, making it a smart long-term investment that protects your bottom line and reduces replacement costs over time.

The durability extends beyond just surface resistance. Quality stainless steel prep tables are constructed with reinforced frames and legs that can support substantial weight loads without wobbling or flexing. This structural integrity is crucial in busy kitchens where tables must support heavy equipment, large quantities of ingredients, and withstand the constant movement and activity of kitchen staff.

Beyond its strength and hygiene benefits, a well-chosen stainless steel prep table significantly improves kitchen workflow and organization. With ample, easy-to-clean surfaces and storage options like undershelves or cabinet bases, these tables create designated work zones that streamline prep tasks, reduce cross-contamination risks, and boost overall productivity. The reflective surface of stainless steel also helps improve lighting in work areas, making detailed prep work easier and safer for kitchen staff.

The organizational benefits of stainless steel prep tables extend to inventory management and kitchen efficiency. Many models feature integrated storage solutions that keep frequently used tools, ingredients, and supplies within arm's reach. This reduces the time staff spend walking back and forth across the kitchen, minimizing fatigue and maximizing productive work time. The clean, professional appearance of stainless steel also contributes to a more organized, efficient-feeling work environment that can boost staff morale and performance.

While a wooden top might be suitable for specific tasks like kneading dough, it lacks the all-around durability and hygiene required for general food prep. Wood requires special maintenance, can harbor bacteria in scratches and cuts, and may not meet health department standards in many jurisdictions. Plastic, though lightweight and initially affordable, cannot match the stability and longevity of steel. Plastic surfaces are prone to deep scratches that become bacterial breeding grounds, and they can warp or crack under heavy use or exposure to heat.

For a deeper dive into why stainless steel is our go-to recommendation and to explore the full range of options available, check out our comprehensive Stainless Steel Table Guide.

Decoding Prep Table Materials: Steel Gauge and Type Explained

When shopping for a commercial kitchen prep table, you'll find that not all stainless steel is the same. The key differences lie in two critical factors that determine a table's durability, performance, and lifespan: steel gauge and steel type. Understanding these specifications is essential for making an informed investment that will serve your kitchen's needs for years to come.

Steel gauge refers to the thickness of the steel used in the table's construction. It's a measurement system that can be counterintuitive: a lower gauge number actually means thicker, stronger steel. This thickness directly impacts how much weight the table can support, how well it resists denting and damage, and how long it will maintain its structural integrity under daily commercial use.

The gauge system originated in the wire industry, where thicker wires required more passes through progressively smaller dies. Each pass was numbered, so lower numbers indicated fewer passes and therefore thicker material. This numbering system carried over to sheet metal, including the stainless steel used in commercial kitchen equipment.

18-gauge steel represents the standard thickness for light-duty commercial applications. Measuring approximately 0.048 inches thick, it provides adequate strength for tasks like slicing vegetables, assembling sandwiches, or supporting lightweight equipment. This gauge is perfect for cafes, delis, bakeries, or as an auxiliary prep surface in larger kitchens. Its affordable price point makes it attractive for budget-conscious operators who still need professional-quality equipment that meets health department standards.

The cost-effectiveness of 18-gauge steel makes it an excellent choice for establishments with moderate prep volumes or those just starting out. While it may not withstand the punishment of a high-volume restaurant kitchen, it offers reliable performance for lighter applications. Many successful small foodservice operations have built their reputations using 18-gauge prep tables as their primary work surfaces.

16-gauge steel is the medium-duty workhorse of the commercial kitchen world, measuring approximately 0.060 inches thick. This gauge represents the most common choice for general restaurant use because it strikes an excellent balance between durability, functionality, and cost. It provides a sturdy, stable surface capable of handling a wide range of prep work, from chopping vegetables to kneading dough, without being prohibitively expensive.

The versatility of 16-gauge steel makes it suitable for most restaurant applications. It can support moderate equipment loads, resist daily wear and tear, and maintain its appearance over years of use. This gauge offers the reliability that busy kitchens demand while remaining accessible to operators working within typical equipment budgets.

14-gauge steel is the heavyweight champion of prep table construction, measuring approximately 0.075 inches thick. This is the thickest and most durable option commonly available, designed specifically for high-volume kitchens, butcher shops, or applications requiring support of heavy equipment. While it commands a higher upfront investment, its exceptional longevity and performance make it a wise choice for demanding commercial environments.

The superior strength of 14-gauge steel becomes apparent in heavy-duty applications. It can support substantial weight loads without flexing, resist impact damage from heavy tools or equipment, and maintain its structural integrity even under constant, intensive use. For operations that process large volumes of food or require maximum durability, the additional cost of 14-gauge steel pays dividends through reduced maintenance and replacement costs.

The durability versus cost equation is straightforward: thicker steel lasts longer but requires a higher initial investment. However, this investment often pays for itself through reduced replacement costs, lower maintenance requirements, and improved performance over the table's lifespan. When calculating the total cost of ownership, including factors like downtime for repairs or replacements, heavier gauge steel frequently proves more economical in the long run.

Beyond gauge, the stainless steel type significantly affects corrosion resistance, food safety, and overall performance. The two main types used in commercial kitchen applications are Type 304 and Type 430, each with distinct characteristics that make them suitable for different applications and budgets.

Type 304 stainless steel is widely considered the premium choice for most professional kitchen applications. Its composition includes 18% chromium and 8% nickel, giving it superior resistance to rust, corrosion, and staining. This improved corrosion resistance is especially important for tables exposed to moisture, acidic foods (such as tomatoes, citrus fruits, or vinegar-based preparations), and the harsh cleaning chemicals required for commercial sanitation.

The nickel content in Type 304 steel provides additional benefits beyond corrosion resistance. It improves the steel's formability, making it easier to create smooth, rounded edges and complex shapes. It also improves the material's ability to maintain its appearance over time, resisting the dulling and discoloration that can occur with lesser grades of stainless steel.

Type 430 stainless steel offers a more economical alternative while still providing good performance for many applications. It contains 17% chromium but no nickel, offering adequate corrosion resistance for general-purpose use in controlled environments. This makes it a suitable choice for drier kitchen areas or lighter-duty applications where cost savings are a priority without completely sacrificing quality or safety.

While Type 430 steel costs less than Type 304, it's important to understand its limitations. Without nickel, it's more susceptible to corrosion in humid environments or when exposed to acidic substances. It may also show wear and discoloration more readily over time. However, for many applications, particularly in dry storage areas or for tables used primarily for dry prep work, Type 430 can provide years of reliable service at a lower cost.

Both steel types are food-grade safe and approved for commercial kitchen use. However, for kitchens with high humidity, frequent exposure to acidic ingredients, or intensive cleaning regimens, Type 304's superior corrosion resistance makes it the smarter long-term investment. The additional cost is often justified by the extended lifespan and maintained appearance over years of use.

Many commercial prep tables also incorporate galvanized steel for legs, undershelves, and structural components to help control costs while maintaining functionality. Galvanized steel consists of carbon steel coated with a protective layer of zinc, which provides good corrosion resistance at a lower cost than stainless steel. While functional and economical, galvanized steel is less corrosion-resistant than stainless steel, particularly in wet conditions or high-humidity environments.

The choice between galvanized and stainless steel components often comes down to budget considerations and environmental factors. For dry storage areas or applications where the components won't be exposed to frequent moisture, galvanized steel can provide adequate performance at significant cost savings. However, for maximum durability and hygiene, all-stainless construction remains the gold standard.

| Material | Durability | Common Applications | Typical Cost |

|---|---|---|---|

| 14-gauge Steel | Maximum strength, resists heavy impact | Butchering, heavy equipment placement, high-volume processing | Highest investment |

| 16-gauge Steel | Excellent balance of strength and value | Standard restaurant prep, general kitchen use | Medium range |

| 18-gauge Steel | Good for everyday tasks | Light prep work, auxiliary surfaces, cafes | Most economical |

| Type 304 Steel | Superior corrosion resistance | High-humidity kitchens, acidic food prep | Premium pricing |

| Type 430 Steel | Good general corrosion resistance | Cost-effective general purpose use | Budget-friendly |

Understanding these material differences empowers you to choose a commercial kitchen prep table that perfectly matches your kitchen's specific demands, operational volume, and budget constraints. The right choice will provide years of reliable service while supporting your kitchen's efficiency and food safety goals.

Choosing the Right Duty Rating: A Deep Dive into Light-Duty vs. Heavy-Duty Tables

Matching your table's duty rating to your kitchen's operational demands is one of the most critical decisions you'll make. This choice goes far beyond the initial price tag; it directly impacts kitchen safety, workflow efficiency, and the long-term return on your investment. The primary distinction lies in the thickness of the steel (gauge) and the robustness of the underlying construction.

Light-Duty Tables: The Economical Choice for Lighter Tasks Light-duty tables, typically constructed from 18-gauge stainless steel, are the ideal solution for less intensive applications. They provide a reliable, NSF-certified work surface that is perfect for tasks that don't involve heavy impact or significant weight loads. These tables are an excellent fit for:

- Cafes and Coffee Shops: Assembling pastries, preparing coffee orders, and holding light equipment like blenders or small displays.

- Delis and Sandwich Shops: Slicing meats and cheeses, assembling sandwiches, and portioning salads.

- Bakeries: Decorating cakes, kneading small batches of dough, or as a cooling station.

- Concession Stands or Food Trucks: Where space is limited and tasks are generally lighter. While economical, it's crucial to understand their limitations. A light-duty model may have a weight capacity of around 300-450 pounds and is not designed to support heavy countertop equipment or withstand the rigors of constant, heavy chopping.

Heavy-Duty Tables: Built for the Demands of High-Volume Kitchens When your kitchen operates at a high tempo, a heavy-duty table is not a luxury—it's a necessity. Constructed from thicker 16-gauge or ultra-durable 14-gauge steel, these tables are engineered to endure the most punishing commercial environments. They are the workhorses needed for:

- High-Volume Restaurants: Handling relentless prep work, from vigorous chopping to supporting heavy stockpots.

- Butcher Shops: Withstanding the impact of cleavers, tenderizers, and processing large cuts of meat.

- Institutional Kitchens: In schools, hospitals, and hotels where equipment runs nonstop and durability is paramount.

- Supporting Heavy Equipment: Providing a stable, non-flexing platform for large mixers, heavy-duty slicers, or vacuum sealers.

The Structural Differences That Matter The distinction between light and heavy-duty goes deeper than just the tabletop's gauge. The real difference is in the frame and support system:

- Weight Capacity: Heavy-duty tables boast a significantly higher weight capacity, often rated to hold 600 to over 900 pounds, ensuring they won't buckle under the load of your most substantial equipment.

- Legs and Bracing: While a light-duty table may rely on a single undershelf for basic stability, heavy-duty models feature superior bracing. Look for H-bracing or cross-bracing—additional steel bars that connect the legs, preventing any side-to-side wobble or movement, even under heavy force.

- Gussets: A key indicator of heavy-duty construction is the presence of gussets. These are triangular pieces of steel welded at the connection point between the legs and the tabletop. They reinforce this critical joint, distributing stress and dramatically increasing the table's stability and longevity.

Investing in a heavy-duty table for a demanding application means investing in safety and efficiency. It eliminates the risk of a wobbly or unstable work surface, which can lead to accidents and product loss. While the upfront cost is higher, the superior lifespan and unwavering reliability make it a more cost-effective choice in the long run, preventing the need for frequent replacements.

Certifications and Safety Standards

For kitchen owners and managers, equipment certifications are critical for passing health inspections and ensuring safety. Your commercial kitchen prep table is a key component that must meet strict standards.

The Importance of NSF Certification

The gold standard for commercial kitchen equipment is NSF International certification. NSF is an independent organization that tests equipment to ensure it meets public health and safety standards. When a commercial kitchen prep table has the NSF mark, it signifies that it has been rigorously evaluated for material safety, design, construction, and performance.

Meeting Health Department Requirements

Most health departments across the country mandate that commercial kitchen equipment be NSF-listed. This is often not a suggestion but a requirement for regulatory compliance. Using NSF-certified equipment demonstrates your commitment to food safety and can help you avoid violations, fines, or closures during health inspections.

Ensuring Public Safety Through Smart Design

NSF standards ensure that every part of the table that touches food is safe and non-toxic. The non-porous surface of a certified stainless steel table prevents bacterial growth and allows for effective sanitization. The design must also be free of cracks, crevices, or hard-to-clean areas where pathogens could hide. Materials must be durable enough to withstand repeated cleaning with commercial-grade chemicals.

What NSF Listing Means for Durability

Beyond safety, NSF certification is also an indicator of durability. The testing process includes assessments that ensure the table can withstand the demands of a commercial kitchen, including heavy loads, temperature changes, and daily wear and tear. This means an NSF-listed commercial kitchen prep table is a protected investment, built to last.

To learn more about why this certification is crucial for all your equipment, check out our guide on NSF Rated Equipment.

Rounded Edges for Comfort and Safety

Thoughtful design details also contribute to a safer kitchen. Quality commercial kitchen prep table models often feature rounded edges, sometimes called bullnose edges. This seemingly small detail prevents painful bumps and scrapes as staff move quickly through a busy kitchen. It eliminates sharp corners that can catch clothing or cause injury, separating professional-grade equipment from lesser alternatives.

The bottom line is that certifications and safety standards are not just about bureaucracy; they are your assurance that your equipment will keep your customers safe, your business compliant, and your investment secure for years to come.

Frequently Asked Questions about Commercial Kitchen Prep Tables

Investing in the right commercial kitchen prep table is a significant decision, and it's natural to have questions. To help you make an informed choice, we've compiled answers to some of the most common inquiries we receive from foodservice professionals.

How do I properly clean and maintain my stainless steel prep table?

Keeping your stainless steel commercial kitchen prep table in pristine condition is straightforward with a consistent routine. The non-porous surface is designed for easy cleaning and sanitization, which is essential for food safety.

Daily Cleaning and Sanitizing:

- Wipe Down: Immediately wipe up spills and food debris with a soft cloth or squeegee to prevent them from drying and sticking.

- Wash: Use a mild soap or detergent with warm water. Apply with a soft cloth, microfiber towel, or sponge to scrub the entire surface, including the legs and undershelf.

- Rinse: Thoroughly rinse the surface with clean, cool water. This is a critical step, as soap residue can dull the finish and attract dirt if left behind.

- Sanitize: Apply a food-grade sanitizer according to the manufacturer's directions. Most require a specific contact time to be effective. Allow the surface to air dry completely or use a dedicated clean, single-use towel.

Tips for Long-Term Care:

- For Shine: To remove fingerprints and restore luster, occasionally use a specialized stainless steel polish. Always wipe in the direction of the metal's grain (the faint parallel lines in the steel) for a streak-free finish.

- What to Avoid: Never use abrasive materials like steel wool, scouring pads, or gritty cleaners. These will permanently scratch the protective passive layer of the steel, which can lead to rust and corrosion. Also, avoid harsh cleaners containing bleach, chlorine, ammonia, or chlorides, as they can damage the finish.

- Stain and Rust Removal: For stubborn spots or minor surface rust, create a paste of baking soda and water. Gently rub it onto the spot with a soft cloth, moving with the grain, then rinse and dry thoroughly.

For more detailed instructions, see our guide on how to Clean Stainless Steel Equipment.

Can I put hot pans directly on a stainless steel table?

While stainless steel is highly heat-resistant and won't burn or melt like other materials, we strongly advise against placing extremely hot pans, pots, or sheet trays directly on your commercial kitchen prep table for extended periods. Although a brief touch is unlikely to cause harm, prolonged, direct high heat can lead to several issues:

- Discoloration: Intense heat can cause the steel to take on a temporary or even permanent yellowish or brownish tint, known as "heat tint."

- Warping: In rare cases, particularly with thinner gauge steel (18-gauge), the rapid and uneven temperature change from a very hot pan can cause the metal to expand and contract unevenly, potentially leading to slight warping of the surface.

- Safety Hazard: The table will absorb and conduct the heat, making the surface dangerously hot to the touch for unsuspecting staff members.

The best practice is to always use trivets, heat mats, or even a spare cutting board as a protective barrier. For workstations designated for landing hot items from a range or fryer, consider a dedicated equipment stand or a poly-top work table, as its surface is designed to better withstand temperature fluctuations.

What's the difference between galvanized steel and stainless steel for legs and shelves?

When examining a commercial kitchen prep table, you'll notice that legs and undershelves are often made of either stainless or galvanized steel. Understanding the difference is key to choosing the right table for your specific environment and budget.

Stainless Steel is an iron alloy containing chromium (and often nickel in Type 304), which forms a passive, non-reactive layer on the surface. This layer is what gives stainless steel its signature resistance to rust and corrosion. It offers the best performance, durability, and hygiene, especially in wet or humid environments.

Galvanized Steel is standard carbon steel that has been coated with a protective layer of zinc. The zinc acts as a sacrificial barrier, corroding first to protect the steel underneath. It is a more affordable option that provides good durability in dry environments.

How to Choose:

- Choose all-stainless steel components for maximum longevity and corrosion resistance. This is the best choice for tables located near sinks, dishwashers, steam tables, or in humid climates. They are easier to keep sanitary and maintain a clean, professional appearance over the long term.

- Choose galvanized steel components for dry prep areas, storage rooms, or if you are working within a tighter budget. However, be aware that if the zinc coating is deeply scratched or worn away, the carbon steel underneath can be exposed to moisture and begin to rust.

While an all-stainless steel table is the premium standard, a model with galvanized components can be a very effective and cost-efficient solution for many applications. For more information, explore our Stainless Steel Kitchen Table guide.

What size prep table do I need?

Choosing the right size is crucial for maximizing your kitchen's efficiency. Start by measuring the physical space where the table will go, but don't forget to account for workflow.

- Measure Your Space: Use a tape measure to determine the maximum length and width you can accommodate. Remember to leave at least 36-48 inches of clearance for walkways to ensure staff can move safely and freely, even when opening cabinet doors or pulling out bins.

- Consider Standard Dimensions: Commercial prep tables typically come in standard depths of 24" or 30", and standard lengths like 36", 48", 60", 72", and 96". A 30" depth provides a more generous work area, while a 24" depth is ideal for narrower kitchens.

- Match Size to Task: Think about what the table will be used for. A small 36" table might be perfect for a simple beverage station, while a large 96" table is necessary for large-scale batch prep or as a central landing area for multiple cooks.

What is a backsplash and do I need one?

A backsplash is a raised edge along the back of the prep table. Its purpose is twofold: to prevent food, liquids, and utensils from falling behind the table, and to protect the wall from splashes and stains.

- When to Get a Backsplash: If your table will be placed against a wall, a backsplash is highly recommended. It makes cleanup significantly easier and helps maintain a more sanitary environment by preventing debris from accumulating in the hard-to-reach gap between the table and the wall.

- When to Avoid a Backsplash: If the table is intended for use as a central island workstation, a backsplash is unnecessary and would obstruct access. You would also want a flat-top table if you need to place equipment on it that is deeper than the table itself.

Should I get a mobile prep table with casters?

Casters are heavy-duty wheels that can be fitted to the legs of a prep table, changing it into a mobile unit. Whether you need them depends on your kitchen's need for flexibility.

- Benefits of Casters: A mobile table can be easily moved for floor cleaning, reconfigured to adapt to changing menu needs, or wheeled to different locations for prep or service. This is especially valuable for catering operations or kitchens with dynamic layouts.

- Look for Locking Casters: It is essential that at least two of the casters have reliable locking mechanisms. This ensures the table remains stationary and stable during use, preventing dangerous movement while chopping or using equipment.

What are the different base and storage options?

The base of your commercial kitchen prep table defines its storage capabilities. The three main types are open base, undershelf, and cabinet base.

- Open Base: This design features only legs with no shelf, offering maximum clearance underneath. It's ideal for storing large, mobile items like ingredient bins or bussing carts directly under the work surface.

- Undershelf: This is the most common and versatile option. An adjustable undershelf provides accessible storage for frequently used pots, pans, containers, and small equipment, keeping them off the floor but within easy reach.

- Cabinet Base: A cabinet base encloses the storage area, often with sliding or hinged doors. This is the best option for protecting stored items from dust, splashes, and pests, creating a very clean and organized look. It's an excellent choice for open kitchens or for storing sensitive dry goods.

Conclusion

Your commercial kitchen prep table is more than just a piece of furniture; it's the heart of your daily operations. It's the reliable foundation where your culinary creativity takes shape, supporting your team through every service.

As we've covered, stainless steel is the undisputed champion for commercial kitchens due to its best durability, superior hygiene, and ability to improve kitchen efficiency. Understanding the differences in steel gauge, steel type, and table configuration allows you to make a smart investment custom to your specific needswether it's a heavy-duty 14-gauge table for a butcher station or a mobile 18-gauge unit for flexible prep.

Choosing the right features, like a backsplash or integrated sink, and ensuring the table is NSF certified, are practical steps that improve workflow and ensure compliance. These details contribute to a smoother, safer, and more profitable operation.

At The Restaurant Warehouse, we believe that every restaurant deserves access to high-quality equipment without the inflated prices. We cut out the high retail overhead to bring you affordable, durable equipment. Investing in a quality commercial kitchen prep table is an investment in your kitchen's long-term success.

Ready to find the perfect prep table for your operation? We're here to help you build a kitchen that works as hard as you do.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment